ISO 8518:2022

(Main)Workplace air — Determination of particulate lead and lead compounds — Flame and electrothermal atomic absorption spectrometric methods

Workplace air — Determination of particulate lead and lead compounds — Flame and electrothermal atomic absorption spectrometric methods

This document specifies flame and electrothermal atomic absorption spectrometric methods for the determination of the time-weighted average mass concentration of particulate lead and lead compounds in workplace air. These methods are typically applicable to personal sampling of the inhalable fraction of airborne particles, as defined in ISO 7708, and to static (area) sampling. It can be applied to other health-related fractions as required. The sample dissolution procedure specifies hot plate or microwave assisted digestion, or ultrasonic extraction (see 11.2). The use of an alternative, more vigorous dissolution procedure is necessary when it is desired to extract lead from compounds present in the test atmosphere that are insoluble using the dissolution procedures described herein (see Clause 5). The flame atomic absorption method is applicable to the determination of masses of approximately 1 µg to 200 µg of lead per sample, without dilution[1]. The electrothermal atomic absorption method is applicable to the determination of masses of approximately 0,01 µg to 0,5 µg of lead per sample, without dilution[1]. The ultrasonic extraction procedure has been validated for the determination of masses of approximately 20 µg to 100 µg of lead per sample, for laboratory-generated lead fume air filter samples[2]. The concentration range for lead in air for which this procedure is applicable is determined in part by the sampling procedure selected by the user (see 10.1).

Air des lieux de travail — Dosage du plomb particulaire et des composés particulaires du plomb — Méthode par spectrométrie d'absorption atomique dans la flamme et méthode par spectrométrie d'absorption avec atomisation électrothermique

Zrak na delovnem mestu - Določevanje svinca in svinčevih spojin v delcih - Plamenska in elektrotermijska atomska absorpcijska spektrometrijska metoda

Ta dokument določa plamenske in elektrotermijske atomske absorpcijske spektrometrijske metode za določanje časovno obtežene povprečne masne koncentracije svinca in svinčevih spojin v delcih v zraku na delovnem mestu.

Te metode se običajno uporabljajo za osebno vzorčenje inhalabilne frakcije delcev v zraku, kot je opredeljeno v standardu ISO 7708, in za statično vzorčenje (območja). Uporabljati jih je mogoče tudi za druge frakcije, povezane z zdravjem.

Postopek raztapljanja vzorcev določa razkroj s pomočjo grelne plošče ali mikrovalovne pečice oziroma ultrazvočno ekstrakcijo (glej točko 11.2). Uporaba alternativnega, močnejšega postopka raztapljanja je potrebna, kadar želimo izločiti svinec iz spojin, ki so prisotne v preskusni atmosferi, a jih ni mogoče raztopiti s tu opisanimi postopki raztapljanja (glej odstavek 5).

Plamenska atomska absorpcijska metoda se uporablja za določanje mas, ki brez redčenja znašajo približno od 1 µg do 200 µg svinca na vzorec[1]. Elektrotermijska atomska absorpcijska metoda se uporablja za določanje mas, ki brez redčenja znašajo približno od 0,01 µg do 0,5 µg svinca na vzorec[1].

Postopek ultrazvočne ekstrakcije je potrjen za določanje mas, ki brez redčenja znašajo približno od 20 µg do 100 µg svinca na vzorec, za vzorce zračnih filtrov za svinčene hlape[2].

Razpon koncentracije svinca v zraku, pri katerem se uporablja ta postopek, je delno določen s postopkom vzorčenja, ki ga izbere uporabnik (glej točko 10.1).

General Information

Relations

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2023

Nadomešča:

SIST ISO 8518:2002

Zrak na delovnem mestu - Določevanje svinca in svinčevih spojin v delcih -

Plamenska in elektrotermijska atomska absorpcijska spektrometrijska metoda

Workplace air - Determination of particulate lead and lead compounds - Flame and

electrothermal atomic absorption spectrometric methods

Air des lieux de travail - Dosage du plomb particulaire et des composés particulaires du

plomb - Méthode par spectrométrie d'absorption atomique dans la flamme et méthode

par spectrométrie d'absorption avec atomisation électrothermique

Ta slovenski standard je istoveten z: ISO 8518:2022

ICS:

13.040.30 Kakovost zraka na delovnem Workplace atmospheres

mestu

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

INTERNATIONAL ISO

STANDARD 8518

Third edition

2022-10

Workplace air — Determination of

particulate lead and lead compounds

— Flame and electrothermal atomic

absorption spectrometric methods

Air des lieux de travail — Dosage du plomb particulaire et des

composés particulaires du plomb — Méthode par spectrométrie

d'absorption atomique dans la flamme et méthode par spectrométrie

d'absorption avec atomisation électrothermique

Reference number

© ISO 2022

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

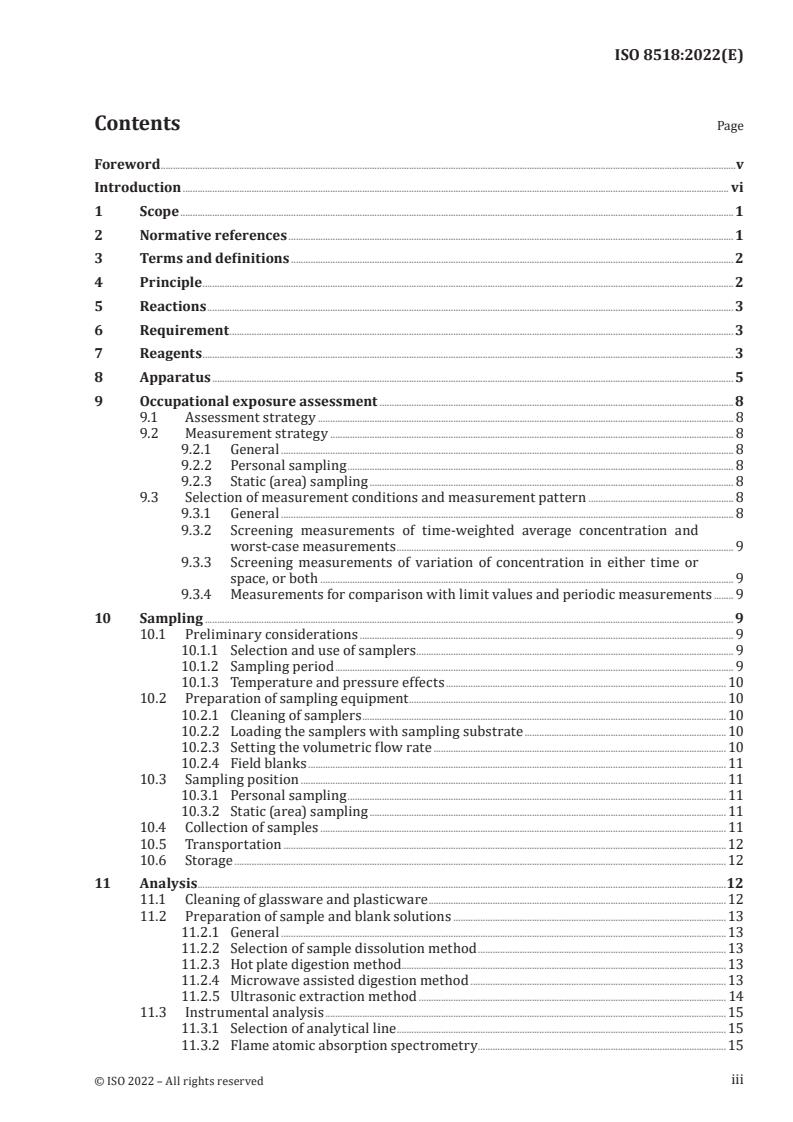

Contents Page

Foreword .v

Introduction . vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Principle . 2

5 Reactions . 3

6 Requirement . 3

7 Reagents . 3

8 Apparatus . 5

9 Occupational exposure assessment .8

9.1 Assessment strategy . 8

9.2 Measurement strategy . 8

9.2.1 General . 8

9.2.2 Personal sampling . 8

9.2.3 Static (area) sampling . 8

9.3 Selection of measurement conditions and measurement pattern . 8

9.3.1 General . 8

9.3.2 Screening measurements of time-weighted average concentration and

worst-case measurements . 9

9.3.3 Screening measurements of variation of concentration in either time or

space, or both . 9

9.3.4 Measurements for comparison with limit values and periodic measurements . 9

10 Sampling . 9

10.1 Preliminary considerations . 9

10.1.1 Selection and use of samplers . 9

10.1.2 Sampling period . 9

10.1.3 Temperature and pressure effects . 10

10.2 Preparation of sampling equipment . 10

10.2.1 Cleaning of samplers . 10

10.2.2 Loading the samplers with sampling substrate . 10

10.2.3 Setting the volumetric flow rate . 10

10.2.4 Field blanks . 11

10.3 Sampling position . 11

10.3.1 Personal sampling . 11

10.3.2 Static (area) sampling . 11

10.4 Collection of samples . 11

10.5 Transportation .12

10.6 Storage . 12

11 Analysis .12

11.1 Cleaning of glassware and plasticware .12

11.2 Preparation of sample and blank solutions . 13

11.2.1 General .13

11.2.2 Selection of sample dissolution method . 13

11.2.3 Hot plate digestion method . . 13

11.2.4 Microwave assisted digestion method . 13

11.2.5 Ultrasonic extraction method . 14

11.3 Instrumental analysis . 15

11.3.1 Selection of analytical line . 15

11.3.2 Flame atomic absorption spectrometry . 15

iii

11.3.3 Electrothermal atomic absorption spectrometry . 16

11.4 Estimation of the instrumental detection limit . 18

11.5 Estimation of the method detection limit and method quantification limit . 18

11.6 Quality control . 18

11.6.1 General . 18

11.6.2 Reagent blanks and media blanks . 19

11.6.3 Spiked samples and spiked duplicate samples . 19

11.6.4 Certified reference materials . 19

11.6.5 External quality assessment . 19

12 Expression of results .19

12.1 Calculation . 19

12.2 Method performance . 20

12.2.1 Sample collection .20

12.2.2 Hot plate digestion and flame atomic absorption spectrometry .20

12.2.3 Microwave assisted digestion and flame atomic absorption spectrometry .20

12.2.4 Ultrasonic extraction and flame atomic absorption spectrometry .20

12.2.5 Hot plate digestion and electrothermal atomic absorption spectrometry .20

12.2.6 Microwave assisted digestion and electrothermal atomic absorption

spectrometry . 20

12.2.7 Ultrasonic extraction and electrothermal atomic absorption spectrometry . 21

13 Special cases .21

14 Test report .21

Annex A (informative) Guidance on filter selection .23

Annex B (informative) Sampler wall deposits .26

Annex C (normative) Temperature and pressure correction .28

Bibliography .30

iv

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 146, Air quality, Subcommittee SC 2,

Workplace atmospheres.

This third edition cancels and replaces the second edition (ISO 8518:2001), which has been technically

revised.

The main changes are as follows:

— a new Annex B (informative) has been added concerning sampler wall deposits;

— references and definitions have been updated;

— additional editorial changes have been made.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

v

Introduction

The health of workers in many industries, for example, mining, metal refining, battery manufacture,

construction, is at risk through exposure by inhalation of particulate lead and lead compounds.

Industrial hygienists and other public health professionals need to determine the effectiveness of

measures taken to control workers' exposure, and this is generally achieved by making workplace air

measurements. This document provides a method for making valid exposure measurements for lead. It

will be of benefit to:

— agencies concerned with health and safety at work;

— industrial hygienists and other public health professionals;

— analytical laboratories;

— industrial users and workers of metals and metalloids, etc.

During the development of this document, it has been assumed that the execution of its provisions

and the interpretation of the results obtained is entrusted to appropriately qualified and experienced

people.

vi

INTERNATIONAL STANDARD ISO 8518:2022(E)

Workplace air — Determination of particulate lead and

lead compounds — Flame and electrothermal atomic

absorption spectrometric methods

1 Scope

This document specifies flame and electrothermal atomic absorption spectrometric methods for the

determination of the time-weighted average mass concentration of particulate lead and lead compounds

in workplace air.

These methods are typically applicable to personal sampling of the inhalable fraction of airborne

particles, as defined in ISO 7708, and to static (area) sampling. It can be applied to other health-related

fractions as required.

The sample dissolution procedure specifies hot plate or microwave assisted digestion, or ultrasonic

extraction (see 11.2). The use of an alternative, more vigorous dissolution procedure is necessary when

it is desired to extract lead from compounds present in the test atmosphere that are insoluble using the

dissolution procedures described herein (see Clause 5).

The flame atomic absorption method is applicable to the determination of masses of approximately

[1]

1 µg to 200 µg of lead per sample, without dilution . The electrothermal atomic absorption method is

applicable to the determination of masses of approximately 0,01 µg to 0,5 µg of lead per sample, without

[1]

dilution .

The ultrasonic extraction procedure has been validated for the determination of masses of approximately

[2]

20 µg to 100 µg of lead per sample, for laboratory-generated lead fume air filter samples .

The concentration range for lead in air for which this procedure is applicable is determined in part by

the sampling procedure selected by the user (see 10.1).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3585, Borosilicate glass 3.3 — Properties

ISO 3696:1987, Water for analytical laboratory use — Specification and test methods

ISO 7708:1995, Air quality — Particle size fraction definitions for health-related sampling

ISO 8655-1, Piston-operated volumetric apparatus — Part 1: Terminology, general requirements and user

recommendations

ISO 8655-2, Piston-operated volumetric apparatus — Part 2: Pipettes

ISO 8655-5, Piston-operated volumetric apparatus — Part 5: Dispensers

ISO 8655-6, Piston-operated volumetric apparatus — Part 6: Gravimetric reference measurement

procedure for the determination of volume

ISO 13137, Workplace atmospheres — Pumps for personal sampling of chemical agents — Requirements

and test methods

ISO 15202-2, Workplace air — Determination of metals and metalloids in airborne particulate matter by

inductively coupled plasma atomic emission spectrometry — Part 2: Sample preparation

ISO/IEC 17025, General requirements for the competence of testing and calibration laboratories

ISO 17034, General requirements for the competence of reference material producers

ISO 18158, Workplace air — Terminology

ISO 20581, Workplace air — General requirements for the performance of procedures for the measurement

of chemical agents

EN 13205, Workplace atmospheres — Assessment of performance of instruments for measurement of

airborne particle concentrations

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 18158 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

sample dissolution

process of obtaining a solution containing all analytes of interest from a sample, which might or might

not involve complete dissolution of the sample

[SOURCE: ISO 15202-2:2020, 3.1]

3.2

sample solution

solution prepared from a sample by the process of sample dissolution (3.1)

Note 1 to entry: A sample solution might need to be subjected to further operations, e.g. dilution, or addition, or

both, of an internal standard(s), in order to produce a test solution (3.3).

[SOURCE: ISO 15202-2:2020, 3.2]

3.3

test solution

blank solution or sample solution (3.2) that has been subjected to all operations required to bring it into

a state in which it is ready for analysis

[SOURCE: ISO 15202-2:2020, 3.3, modified — Note 1 to entry has been deleted.]

4 Principle

4.1 A known volume of air is drawn through a sampling substrate to collect particulate lead and lead

compounds. For personal sampling, a sampler designed to collect the inhalable fraction of airborne

particles is typically used.

4.2 The sampling substrate and collected sample are subjected to a dissolution procedure in order

to extract lead. The sample dissolution procedure can use one of three techniques: hot plate digestion,

microwave assisted digestion or ultrasonic extraction.

4.3 Sample solutions are analysed for lead content by aspirating into the oxidizing air-acetylene

flame of an atomic absorption spectrometer equipped with a lead hollow-cathode lamp or electrodeless

discharge lamp. Absorbance measurements are made at 283,3 nm with background correction (e.

g. Zeeman mode or deuterium background correction), and analytical results are obtained by the

analytical curve technique. Potential interference by anions that form precipitates with lead is overcome

by the addition of the disodium salt of ethylenediamine tetraacetic acid (EDTA) when necessary.

4.4 For accurate lead determination when the concentration of lead in the solution is low, the analysis

can be repeated using electrothermal atomic absorption spectrometry. Aliquots of the test solution are

injected into a graphite furnace, and after drying and sample ashing stages, the sample is atomized

electrothermally. Absorbance measurements are made at 283,3 nm with background correction and

results are obtained by the analytical curve technique.

4.5 The results can be used for the assessment of workplace exposures to airborne particulate lead

[3]

(see ISO 21832 ).

5 Reactions

In general, the overwhelming majority of particulate lead compounds that are commonly found in

2+

samples of workplace air are converted to water-soluble lead ions (Pb ) by the sample dissolution

procedures described in 11.2. However, certain lead compounds, for example, lead-containing silicates,

can possibly not be dissolved. If necessary, a dissolution procedure employing hydrofluoric acid should

be used to dissolve silicate lead. If there is any doubt about the effectiveness of these procedures for the

dissolution of particulate lead compounds that can be present in the test atmosphere, then this shall be

investigated before proceeding with the analytical method described in Clause 11.

6 Requirement

The measuring procedure shall comply with applicable requirements of ISO 20581 and with any

relevant national standard that specifies performance requirements for procedures for measuring

chemical agents in workplace air.

7 Reagents

During the analysis, use only reagents of recognized analytical grade, and only water as specified in 7.1.

7.1 Water, conforming with the requirements for ISO 3696:1987, grade 2 water (electrical

conductivity less than 0,1 mS/m and resistivity greater than 0,01 MΩ·m at 25 °C).

The concentration of lead in the water shall be less than 0,01 µg/ml.

It is recommended that the water used be obtained from a water purification system that delivers

ultrapure water having a resistivity greater than 0,18 MΩ·m (usually expressed by manufacturers of

water purification systems as 18 MΩ·cm).

7.2 Nitric acid (HNO ), concentrated, ρ ≈ 1,42 g/ml (about 70 % mass fraction).

The concentration of lead shall be less than 0,01 µg/ml.

WARNING — Concentrated nitric acid is corrosive and oxidizing, and nitric acid fumes are

irritant. Avoid exposure by contact with the skin or eyes, or by inhalation of fumes. Use suitable

personal protective equipment (including suitable gloves, face shield or safety glasses, etc.)

when working with the concentrated or dilute nitric acid, and carry out sample dissolution with

concentrated nitric acid in open vessels in a fume hood.

7.3 Nitric acid, diluted 1 + 1.

Carefully add 500 ml of concentrated nitric acid (7.2) to 450 ml of water (7.1) in a 2-litre beaker. Swirl

to mix, allow to cool and transfer to a 1-litre one-mark volumetric flask. Dilute to the mark with water,

stopper and mix thoroughly.

7.4 Nitric acid, diluted 1 + 9.

Place approximately 800 ml of water (7.1) in a 1-litre one-mark volumetric flask. Carefully add 100 ml

of concentrated nitric acid (7.2) to the flask and swirl to mix. Allow to cool, dilute to 1 litre with water

and mix thoroughly.

7.5 Hydrofluoric acid (HF), concentrated, with the density, ρ, almost equal to 1,14 g/ml (about 38 %

mass fraction), if required, for digestion of samples containing lead silicates.

The concentration of lead in the HF shall be less than 0,1 µg/ml.

WARNING — Concentrated hydrofluoric acid and hydrogen fluoride vapour are extremely

toxic and intensely corrosive, and diluted hydrofluoric acid can also cause serious and painful

burns that can possibly not be felt until up to 24 h after contact. Avoid exposure by contact with

the skin or the eyes, or by inhalation of the vapour. Use of personal protection (for example,

impermeable gloves, face shield or safety glasses) is essential when working with concentrated

or diluted hydrofluoric acid, and concentrated hydrofluoric acid should be used in a fume

hood. It is essential that hydrofluoric acid antidote gel containing calcium gluconate is readily

available to workers, both during and for 24 h after use of hydrofluoric acid.

7.6 Matrix modifier, NH H PO , Mg(NO ) or Pd(NO ) , or a combination of these, if required, for

4 2 4 3 2 3 2

analysis by electrothermal atomic absorption spectrometry.

7.7 Stock lead standard solution, 1 000 mg/l of lead.

Use a commercial standard solution with a certified lead concentration traceable to national standards.

Observe the manufacturer's expiration date or recommended shelf life.

Alternatively, prepare a lead standard solution by one of the following procedures.

a) Dissolve 1,598 g ± 0,001 g of lead(II) nitrate [Pb(NO ) ], previously dried to constant mass at

3 2

110 °C and cooled in a desiccator, in 200 ml of 1 + 1 nitric acid (7.3). Quantitatively transfer the

solution to a 1 000 ml one-mark volumetric flask. Dilute to the mark with water (7.1), stopper and

mix thoroughly. Store in a suitable container, for example, a polypropylene bottle (8.6.2.2), for a

maximum period of one year.

b) Dissolve 1,000 g ± 0,001 g of lead wire (99,9 % mass fraction Pb) in 200 ml of 1 + 1 nitric acid

(7.3). Quantitatively transfer the solution into a 1 000 ml one-mark volumetric flask, dilute to the

mark with water (7.1), stopper and mix thoroughly. Store in a suitable container, for example, a

polypropylene bottle (8.6.2.2), for a maximum period of one year.

7.8 Working lead standard solution, 1 mg/l of lead, if required, for analysis by electrothermal

atomic absorption spectrometry.

Accurately pipette 100 µl of stock lead standard solution (7.7) into a 100 ml one-mark volumetric flask

(8.6.1.4). Add 1 ml of concentrated nitric acid (7.2), dilute to the mark with water (7.1), stopper and mix

thoroughly. Store in a suitable container, for example, a polypropylene bottle (8.6.2.2), for a maximum

period of one month.

7.9 Hydrogen peroxide (H O ), approximately 30 % mass fraction solution, if required, for use in

2 2

the hot-plate sample digestion method.

The concentration of lead in the hydrogen peroxide solution shall be less than 0,01 µg/ml.

7.10 Acetylene, if required, for use in analysis by flame atomic absorption spectrometry.

7.11 Air, compressed and filtered, if required, for use in analysis by flame atomic absorption

spectrometry.

8 Apparatus

8.1 Inhalable samplers, designed to collect the inhalable fraction of airborne particles, complying

with the provisions of EN 13205, for use when the exposure limits of interest apply to the inhalable

fraction of airborne particles.

NOTE 1 In general, personal samplers for collection of the inhalable fraction of airborne particles do not

exhibit the same size selective characteristics if used for static (area) sampling.

NOTE 2 Some inhalable samplers are designed to collect the fraction of airborne particles on a sampling

substrate, and any particulate matter deposited on the internal surfaces of the sampler is not of interest. Other

inhalable samplers are designed such that airborne particles that pass through the entry orifice(s) match the

inhalable convention, in which case particulate matter deposited on the internal surfaces of the sampler does

form part of the sample. (Samplers of this second type generally incorporate an internal filter cassette or

cartridge that can be removed from the sampler to enable this material to be easily recovered.) The operating

instructions supplied by the manufacturer should be consulted to find out whether particulate matter deposited

on the internal surfaces of the sampler forms part of the sample. Annex B provides additional guidance on

sampler wall deposits.

NOTE 3 Samplers to collect other fractions defined in ISO 7708 can be used when necessary (for example,

when there are occupational exposure limit values associated with those fractions.)

8.2 Sampling substrate, (for example, a filter) of a diameter suitable for use with the samplers (see

8.1), with a collection efficiency of not less than 99,5 % for particles with a 0,3 µm diffusion diameter in

accordance with 2.2 of ISO 7708:1995, with a maximum lead content (typically less than 0,1 µg Pb), and

compatible with the selected sample preparation method.

NOTE 1 Guidance on filter selection is provided in Annex A.

NOTE 2 Digestible cellulosic capsules (consisting of cellulose acetate housing attached to cellulosic filter) that

are placed within certain types of samplers are now available for use, thereby accounting for potential internal

[4],[5]

aerosol wall losses .

8.3 Sampling pumps, meeting the specifications of ISO 13137.

8.4 Flowmeter, portable, with an accuracy that is sufficient to enable the volumetric flow rate (see

10.1.1.2) to be measured to within ±5 %.

The calibration of the flowmeter shall be checked against a primary standard, i.e. a flowmeter whose

accuracy is traceable to national standards. If appropriate (see 10.1.3.1), record the atmospheric

temperature and pressure at which the calibration of the flowmeter was checked.

8.5 Ancillary equipment

8.5.1 Flexible tubing, of a diameter suitable for making a leak-proof connection from the samplers to

the sampling pumps.

8.5.2 Belts or harnesses, to which the sampling pumps can conveniently be fixed for personal

sampling (except where the sampling pumps are small enough to fit inside worker's pockets).

8.5.3 Flat-tipped forceps, for loading and unloading sampling substrates into samplers.

8.5.4 Transport cassettes, or similar, if required to transport samples for laboratory analysis.

8.5.5 Barometer, (readable to 0,1 kPa), suitable for measurement of atmospheric pressure, if required

(see 10.1.3).

8.5.6 Thermometer, (readable to 1 °C), minimum temperature range of 0 °C to 50 °C, with graduated

divisions of 1 °C or less, for measurement of atmospheric temperature.

For applications at temperatures below freezing, the range of the thermometer shall extend to the

appropriate desired range.

8.6 Analytical or laboratory apparatus

Ordinary laboratory apparatus, and the following.

8.6.1 Glassware, made of borosilicate glass 3.3 and conforming with the requirements of ISO 3585.

It is preferable to reserve a set of glassware for analysis of lead by this method, in order to ensure that

problems do not arise from incomplete removal of lead contamination by cleaning.

8.6.2 Plastic labware, including the following:

8.6.2.1 Heatable beakers, beaker covers, etc., if required, made of a material that is resistant to

corrosion by hydrofluoric acid, for example, a fluorocarbon polymer such as polytetrafluoroethylene

(PTFE), and suitable for performing dissolutions using hydrofluoric acid.

8.6.2.2 Polypropylene bottles, of capacities from 100 ml to 1 000 ml.

8.6.3 Piston-operated volumetric instruments, complying with the requirements of ISO 8655-1

and tested in accordance with ISO 8655-6:

8.6.3.1 Pipetters, complying with the requirements of ISO 8655-2, as an alternative to one-mark

pipettes, for the preparation of standard solutions, calibration solutions and dilution of samples.

8.6.3.2 Dispensers, complying with the requirements of ISO 8655-5, for dispensing acids.

8.6.4 Hot plate, thermostatically controlled, capable of maintaining a surface temperature of

approximately 150 °C, for hot-plate procedures.

8.6.5 Microwave digestion apparatus

8.6.5.1 General

Ensure that manufacturer's safety recommendations are followed.

NOTE 1 The specified method is for closed vessel microwave digestion systems with a temperature control

system. Microwave digestion systems that are equipped only with either a pressure control system or lower

pressure vessels, or both, can be used provided that a suitable sample dissolution procedure is developed, and a

prior assessment of dissolution efficiency is carried out.

NOTE 2 Open-vessel microwave digestion systems can give results equivalent to closed-vessel microwave

digestion systems. They can therefore be used provided that a suitable sample dissolution procedure is

developed, and a prior assessment of dissolution efficiency is carried out.

8.6.5.2 Microwave digestion system, designed for closed-vessel sample digestion in the laboratory,

with power output regulation, fitted with a temperature control system capable of minimum sensing

the temperature to within ±2 °C and automatically adjusting the microwave power output within

minimum 2 s.

The microwave cavity shall be corrosion-resistant and well ventilated, with all electronics protected

against corrosion to ensure safe operation.

CAUTION — Do not use domestic (kitchen) microwave ovens, since there are very significant

hazards associated with their use for the procedure described in this document. Acid vapours

released into the cavity can corrode safety devices that prevent the magnetron from shutting

off when the door is opened, potentially exposing the operator to microwave energy. Also, the

fumes generated can be extremely hazardous.

NOTE A pressure control system is also very useful, since it provides a safeguard against the possibility of

sample loss due to excessive pressure build-up and partial venting of the sample vessels.

8.6.5.3 Vessels, designed for carrying out microwave assisted digestions, capable of withstanding a

temperature of 180 °C, and with an internal volume of at least 50 ml.

The vessels shall be transparent to microwave energy, and shall be capable of withstanding internal

pressures up to at least 3 000 kPa or greater, and temperatures up to at least 180 °C or greater.

Closed vessels shall also be equipped with a safety relief valve or disc that will prevent vessel

rupture or ejection of the vessel cap. Such vessels consist of an inner liner and cover made of a

microwave-transparent and chemically resistant material [usually a fluorocarbon polymer such

as tetrafluoromethoxyl polymer (TFM)], which contains and isolates the sample solution from a

high-strength, outer pressure vessel structure. Other types of sample vessel designed to operate at

equivalent or higher temperatures or pressures, or both, can be used. If hydrofluoric acid (HF) is to be

used, the vessels shall be compatible with HF.

CAUTION — For closed-vessel designs, the material from which the outer vessels are made

is usually not as chemically resistant as the liner material. Since the outer vessels provide

the strength required to withstand the high pressures within the inner liners, they shall be

inspected regularly to check for any chemical or physical degradation.

NOTE Alternatively, a one reaction chamber microwave assisted pressure digestion system can be used.

8.6.6 Ultrasonic bath (sonicator), for performing ultrasonic extractions, capable of delivering

sufficient power to effect the quantitative dissolution of particulate lead under the conditions described

in 11.2.5 (typically 1 W/cm power density or greater).

8.6.7 Plastic centrifuge tubes, 50 ml, with screw caps (for ultrasonic procedure).

8.6.8 Atomic absorption spectrometer, fitted with an air-acetylene burner supplied with

compressed air and acetylene, and equipped with either a lead hollow cathode lamp or electrodeless

[6],[7]

discharge lamp . If sample dissolution is carried out with the aid of hydrofluoric acid (see

11.2.3.3 and 11.2.4.2), the atomic absorption spectrometer shall be hydrofluoric acid-compatible. If

electrothermal atomic absorption is to be carried out, the atomic absorption spectrometer shall be

capable of carrying out simultaneous background correction at 283,3 nm, either by using a continuum

source such as a deuterium lamp to measure non-specific attenuation, or by using Zeeman or Smith-

[8]

Hieftje background correction systems .

8.6.9 Electrothermal atomiser, fitted with a solid, pyrolytic graphite platform mounted in a

pyrolytically-coated graphite tube, supplied with argon purge gas, and equipped with an autosampler

capable of injecting microlitre volumes onto the platform.

NOTE Some manufacturers of atomic absorption spectrometers use an alternative design of electrothermal

atomiser to achieve a constant temperature environment during atomisation, and some use aerosol deposition

as a means of sample introduction. The use of such accessories is acceptable, provided satisfactory method

performance is verified. Likewise, atomisers made from heat-resistant metal, such as tungsten, can also be

suitable.

8.6.10 Analytical balance, capable of weighing to ±0,1 mg, if required, for use in preparation of stock

standard lead solution.

8.6.11 Disposable gloves, for prevention of sample contamination.

9 Occupational exposure assessment

9.1 Assessment strategy

[9] [10]

Refer to relevant International or national Standards (for example, EN 689 and ASTM E1370 ) for

guidance on how to develop an appropriate assessment strategy.

9.2 Measurement strategy

9.2.1 General

[9] [10]

Refer to relevant International or national Standards (for example, EN 689 and ASTM E1370 ) for

general guidance on measurement strategy.

9.2.2 Personal sampling

Exposure of workers to lead shall normally be determined by personal sampling, since the concentration

of lead and lead compounds in the breathing zone is usually higher than their background levels in the

workplace.

9.2.3 Static (area) sampling

Static (area) sampling can be carried out, if appropriate, to assess the exposure of workers in a situation

where personal sampling is not possible; to characterise the background level of lead in the workplace

to give an indication of the efficiency of ventilation or other engineering controls; or to provide

information on the location and intensity of an emission source.

9.3 Selection of measurement conditions and measurement pattern

9.3.1 General

9.3.1.1 The sampling procedure shall be devised to provide samples that are representative of normal

working conditions and that are compatible with the analytical method while causing the least possible

interference with the worker and the normal performance of the job.

9.3.1.2 The pattern of sampling shall take into consideration practical issues, such as the nature of

the measurement task and the frequency and duration of particular work activities.

NOTE Additional information concerning purposes of measurement and performance requirements can be

found in ISO 20581.

9.3.2 Screening measurements of time-weighted average concentration and worst-case

measurements

Screening measurements of time-weighted average con

...

INTERNATIONAL ISO

STANDARD 8518

Third edition

2022-10

Workplace air — Determination of

particulate lead and lead compounds

— Flame and electrothermal atomic

absorption spectrometric methods

Air des lieux de travail — Dosage du plomb particulaire et des

composés particulaires du plomb — Méthode par spectrométrie

d'absorption atomique dans la flamme et méthode par spectrométrie

d'absorption avec atomisation électrothermique

Reference number

© ISO 2022

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

Contents Page

Foreword .v

Introduction . vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Principle . 2

5 Reactions . 3

6 Requirement . 3

7 Reagents . 3

8 Apparatus . 5

9 Occupational exposure assessment .8

9.1 Assessment strategy . 8

9.2 Measurement strategy . 8

9.2.1 General . 8

9.2.2 Personal sampling . 8

9.2.3 Static (area) sampling . 8

9.3 Selection of measurement conditions and measurement pattern . 8

9.3.1 General . 8

9.3.2 Screening measurements of time-weighted average concentration and

worst-case measurements . 9

9.3.3 Screening measurements of variation of concentration in either time or

space, or both . 9

9.3.4 Measurements for comparison with limit values and periodic measurements . 9

10 Sampling . 9

10.1 Preliminary considerations . 9

10.1.1 Selection and use of samplers . 9

10.1.2 Sampling period . 9

10.1.3 Temperature and pressure effects . 10

10.2 Preparation of sampling equipment . 10

10.2.1 Cleaning of samplers . 10

10.2.2 Loading the samplers with sampling substrate . 10

10.2.3 Setting the volumetric flow rate . 10

10.2.4 Field blanks . 11

10.3 Sampling position . 11

10.3.1 Personal sampling . 11

10.3.2 Static (area) sampling . 11

10.4 Collection of samples . 11

10.5 Transportation .12

10.6 Storage . 12

11 Analysis .12

11.1 Cleaning of glassware and plasticware .12

11.2 Preparation of sample and blank solutions . 13

11.2.1 General .13

11.2.2 Selection of sample dissolution method . 13

11.2.3 Hot plate digestion method . . 13

11.2.4 Microwave assisted digestion method . 13

11.2.5 Ultrasonic extraction method . 14

11.3 Instrumental analysis . 15

11.3.1 Selection of analytical line . 15

11.3.2 Flame atomic absorption spectrometry . 15

iii

11.3.3 Electrothermal atomic absorption spectrometry . 16

11.4 Estimation of the instrumental detection limit . 18

11.5 Estimation of the method detection limit and method quantification limit . 18

11.6 Quality control . 18

11.6.1 General . 18

11.6.2 Reagent blanks and media blanks . 19

11.6.3 Spiked samples and spiked duplicate samples . 19

11.6.4 Certified reference materials . 19

11.6.5 External quality assessment . 19

12 Expression of results .19

12.1 Calculation . 19

12.2 Method performance . 20

12.2.1 Sample collection .20

12.2.2 Hot plate digestion and flame atomic absorption spectrometry .20

12.2.3 Microwave assisted digestion and flame atomic absorption spectrometry .20

12.2.4 Ultrasonic extraction and flame atomic absorption spectrometry .20

12.2.5 Hot plate digestion and electrothermal atomic absorption spectrometry .20

12.2.6 Microwave assisted digestion and electrothermal atomic absorption

spectrometry . 20

12.2.7 Ultrasonic extraction and electrothermal atomic absorption spectrometry . 21

13 Special cases .21

14 Test report .21

Annex A (informative) Guidance on filter selection .23

Annex B (informative) Sampler wall deposits .26

Annex C (normative) Temperature and pressure correction .28

Bibliography .30

iv

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 146, Air quality, Subcommittee SC 2,

Workplace atmospheres.

This third edition cancels and replaces the second edition (ISO 8518:2001), which has been technically

revised.

The main changes are as follows:

— a new Annex B (informative) has been added concerning sampler wall deposits;

— references and definitions have been updated;

— additional editorial changes have been made.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

v

Introduction

The health of workers in many industries, for example, mining, metal refining, battery manufacture,

construction, is at risk through exposure by inhalation of particulate lead and lead compounds.

Industrial hygienists and other public health professionals need to determine the effectiveness of

measures taken to control workers' exposure, and this is generally achieved by making workplace air

measurements. This document provides a method for making valid exposure measurements for lead. It

will be of benefit to:

— agencies concerned with health and safety at work;

— industrial hygienists and other public health professionals;

— analytical laboratories;

— industrial users and workers of metals and metalloids, etc.

During the development of this document, it has been assumed that the execution of its provisions

and the interpretation of the results obtained is entrusted to appropriately qualified and experienced

people.

vi

INTERNATIONAL STANDARD ISO 8518:2022(E)

Workplace air — Determination of particulate lead and

lead compounds — Flame and electrothermal atomic

absorption spectrometric methods

1 Scope

This document specifies flame and electrothermal atomic absorption spectrometric methods for the

determination of the time-weighted average mass concentration of particulate lead and lead compounds

in workplace air.

These methods are typically applicable to personal sampling of the inhalable fraction of airborne

particles, as defined in ISO 7708, and to static (area) sampling. It can be applied to other health-related

fractions as required.

The sample dissolution procedure specifies hot plate or microwave assisted digestion, or ultrasonic

extraction (see 11.2). The use of an alternative, more vigorous dissolution procedure is necessary when

it is desired to extract lead from compounds present in the test atmosphere that are insoluble using the

dissolution procedures described herein (see Clause 5).

The flame atomic absorption method is applicable to the determination of masses of approximately

[1]

1 µg to 200 µg of lead per sample, without dilution . The electrothermal atomic absorption method is

applicable to the determination of masses of approximately 0,01 µg to 0,5 µg of lead per sample, without

[1]

dilution .

The ultrasonic extraction procedure has been validated for the determination of masses of approximately

[2]

20 µg to 100 µg of lead per sample, for laboratory-generated lead fume air filter samples .

The concentration range for lead in air for which this procedure is applicable is determined in part by

the sampling procedure selected by the user (see 10.1).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3585, Borosilicate glass 3.3 — Properties

ISO 3696:1987, Water for analytical laboratory use — Specification and test methods

ISO 7708:1995, Air quality — Particle size fraction definitions for health-related sampling

ISO 8655-1, Piston-operated volumetric apparatus — Part 1: Terminology, general requirements and user

recommendations

ISO 8655-2, Piston-operated volumetric apparatus — Part 2: Pipettes

ISO 8655-5, Piston-operated volumetric apparatus — Part 5: Dispensers

ISO 8655-6, Piston-operated volumetric apparatus — Part 6: Gravimetric reference measurement

procedure for the determination of volume

ISO 13137, Workplace atmospheres — Pumps for personal sampling of chemical agents — Requirements

and test methods

ISO 15202-2, Workplace air — Determination of metals and metalloids in airborne particulate matter by

inductively coupled plasma atomic emission spectrometry — Part 2: Sample preparation

ISO/IEC 17025, General requirements for the competence of testing and calibration laboratories

ISO 17034, General requirements for the competence of reference material producers

ISO 18158, Workplace air — Terminology

ISO 20581, Workplace air — General requirements for the performance of procedures for the measurement

of chemical agents

EN 13205, Workplace atmospheres — Assessment of performance of instruments for measurement of

airborne particle concentrations

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 18158 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

sample dissolution

process of obtaining a solution containing all analytes of interest from a sample, which might or might

not involve complete dissolution of the sample

[SOURCE: ISO 15202-2:2020, 3.1]

3.2

sample solution

solution prepared from a sample by the process of sample dissolution (3.1)

Note 1 to entry: A sample solution might need to be subjected to further operations, e.g. dilution, or addition, or

both, of an internal standard(s), in order to produce a test solution (3.3).

[SOURCE: ISO 15202-2:2020, 3.2]

3.3

test solution

blank solution or sample solution (3.2) that has been subjected to all operations required to bring it into

a state in which it is ready for analysis

[SOURCE: ISO 15202-2:2020, 3.3, modified — Note 1 to entry has been deleted.]

4 Principle

4.1 A known volume of air is drawn through a sampling substrate to collect particulate lead and lead

compounds. For personal sampling, a sampler designed to collect the inhalable fraction of airborne

particles is typically used.

4.2 The sampling substrate and collected sample are subjected to a dissolution procedure in order

to extract lead. The sample dissolution procedure can use one of three techniques: hot plate digestion,

microwave assisted digestion or ultrasonic extraction.

4.3 Sample solutions are analysed for lead content by aspirating into the oxidizing air-acetylene

flame of an atomic absorption spectrometer equipped with a lead hollow-cathode lamp or electrodeless

discharge lamp. Absorbance measurements are made at 283,3 nm with background correction (e.

g. Zeeman mode or deuterium background correction), and analytical results are obtained by the

analytical curve technique. Potential interference by anions that form precipitates with lead is overcome

by the addition of the disodium salt of ethylenediamine tetraacetic acid (EDTA) when necessary.

4.4 For accurate lead determination when the concentration of lead in the solution is low, the analysis

can be repeated using electrothermal atomic absorption spectrometry. Aliquots of the test solution are

injected into a graphite furnace, and after drying and sample ashing stages, the sample is atomized

electrothermally. Absorbance measurements are made at 283,3 nm with background correction and

results are obtained by the analytical curve technique.

4.5 The results can be used for the assessment of workplace exposures to airborne particulate lead

[3]

(see ISO 21832 ).

5 Reactions

In general, the overwhelming majority of particulate lead compounds that are commonly found in

2+

samples of workplace air are converted to water-soluble lead ions (Pb ) by the sample dissolution

procedures described in 11.2. However, certain lead compounds, for example, lead-containing silicates,

can possibly not be dissolved. If necessary, a dissolution procedure employing hydrofluoric acid should

be used to dissolve silicate lead. If there is any doubt about the effectiveness of these procedures for the

dissolution of particulate lead compounds that can be present in the test atmosphere, then this shall be

investigated before proceeding with the analytical method described in Clause 11.

6 Requirement

The measuring procedure shall comply with applicable requirements of ISO 20581 and with any

relevant national standard that specifies performance requirements for procedures for measuring

chemical agents in workplace air.

7 Reagents

During the analysis, use only reagents of recognized analytical grade, and only water as specified in 7.1.

7.1 Water, conforming with the requirements for ISO 3696:1987, grade 2 water (electrical

conductivity less than 0,1 mS/m and resistivity greater than 0,01 MΩ·m at 25 °C).

The concentration of lead in the water shall be less than 0,01 µg/ml.

It is recommended that the water used be obtained from a water purification system that delivers

ultrapure water having a resistivity greater than 0,18 MΩ·m (usually expressed by manufacturers of

water purification systems as 18 MΩ·cm).

7.2 Nitric acid (HNO ), concentrated, ρ ≈ 1,42 g/ml (about 70 % mass fraction).

The concentration of lead shall be less than 0,01 µg/ml.

WARNING — Concentrated nitric acid is corrosive and oxidizing, and nitric acid fumes are

irritant. Avoid exposure by contact with the skin or eyes, or by inhalation of fumes. Use suitable

personal protective equipment (including suitable gloves, face shield or safety glasses, etc.)

when working with the concentrated or dilute nitric acid, and carry out sample dissolution with

concentrated nitric acid in open vessels in a fume hood.

7.3 Nitric acid, diluted 1 + 1.

Carefully add 500 ml of concentrated nitric acid (7.2) to 450 ml of water (7.1) in a 2-litre beaker. Swirl

to mix, allow to cool and transfer to a 1-litre one-mark volumetric flask. Dilute to the mark with water,

stopper and mix thoroughly.

7.4 Nitric acid, diluted 1 + 9.

Place approximately 800 ml of water (7.1) in a 1-litre one-mark volumetric flask. Carefully add 100 ml

of concentrated nitric acid (7.2) to the flask and swirl to mix. Allow to cool, dilute to 1 litre with water

and mix thoroughly.

7.5 Hydrofluoric acid (HF), concentrated, with the density, ρ, almost equal to 1,14 g/ml (about 38 %

mass fraction), if required, for digestion of samples containing lead silicates.

The concentration of lead in the HF shall be less than 0,1 µg/ml.

WARNING — Concentrated hydrofluoric acid and hydrogen fluoride vapour are extremely

toxic and intensely corrosive, and diluted hydrofluoric acid can also cause serious and painful

burns that can possibly not be felt until up to 24 h after contact. Avoid exposure by contact with

the skin or the eyes, or by inhalation of the vapour. Use of personal protection (for example,

impermeable gloves, face shield or safety glasses) is essential when working with concentrated

or diluted hydrofluoric acid, and concentrated hydrofluoric acid should be used in a fume

hood. It is essential that hydrofluoric acid antidote gel containing calcium gluconate is readily

available to workers, both during and for 24 h after use of hydrofluoric acid.

7.6 Matrix modifier, NH H PO , Mg(NO ) or Pd(NO ) , or a combination of these, if required, for

4 2 4 3 2 3 2

analysis by electrothermal atomic absorption spectrometry.

7.7 Stock lead standard solution, 1 000 mg/l of lead.

Use a commercial standard solution with a certified lead concentration traceable to national standards.

Observe the manufacturer's expiration date or recommended shelf life.

Alternatively, prepare a lead standard solution by one of the following procedures.

a) Dissolve 1,598 g ± 0,001 g of lead(II) nitrate [Pb(NO ) ], previously dried to constant mass at

3 2

110 °C and cooled in a desiccator, in 200 ml of 1 + 1 nitric acid (7.3). Quantitatively transfer the

solution to a 1 000 ml one-mark volumetric flask. Dilute to the mark with water (7.1), stopper and

mix thoroughly. Store in a suitable container, for example, a polypropylene bottle (8.6.2.2), for a

maximum period of one year.

b) Dissolve 1,000 g ± 0,001 g of lead wire (99,9 % mass fraction Pb) in 200 ml of 1 + 1 nitric acid

(7.3). Quantitatively transfer the solution into a 1 000 ml one-mark volumetric flask, dilute to the

mark with water (7.1), stopper and mix thoroughly. Store in a suitable container, for example, a

polypropylene bottle (8.6.2.2), for a maximum period of one year.

7.8 Working lead standard solution, 1 mg/l of lead, if required, for analysis by electrothermal

atomic absorption spectrometry.

Accurately pipette 100 µl of stock lead standard solution (7.7) into a 100 ml one-mark volumetric flask

(8.6.1.4). Add 1 ml of concentrated nitric acid (7.2), dilute to the mark with water (7.1), stopper and mix

thoroughly. Store in a suitable container, for example, a polypropylene bottle (8.6.2.2), for a maximum

period of one month.

7.9 Hydrogen peroxide (H O ), approximately 30 % mass fraction solution, if required, for use in

2 2

the hot-plate sample digestion method.

The concentration of lead in the hydrogen peroxide solution shall be less than 0,01 µg/ml.

7.10 Acetylene, if required, for use in analysis by flame atomic absorption spectrometry.

7.11 Air, compressed and filtered, if required, for use in analysis by flame atomic absorption

spectrometry.

8 Apparatus

8.1 Inhalable samplers, designed to collect the inhalable fraction of airborne particles, complying

with the provisions of EN 13205, for use when the exposure limits of interest apply to the inhalable

fraction of airborne particles.

NOTE 1 In general, personal samplers for collection of the inhalable fraction of airborne particles do not

exhibit the same size selective characteristics if used for static (area) sampling.

NOTE 2 Some inhalable samplers are designed to collect the fraction of airborne particles on a sampling

substrate, and any particulate matter deposited on the internal surfaces of the sampler is not of interest. Other

inhalable samplers are designed such that airborne particles that pass through the entry orifice(s) match the

inhalable convention, in which case particulate matter deposited on the internal surfaces of the sampler does

form part of the sample. (Samplers of this second type generally incorporate an internal filter cassette or

cartridge that can be removed from the sampler to enable this material to be easily recovered.) The operating

instructions supplied by the manufacturer should be consulted to find out whether particulate matter deposited

on the internal surfaces of the sampler forms part of the sample. Annex B provides additional guidance on

sampler wall deposits.

NOTE 3 Samplers to collect other fractions defined in ISO 7708 can be used when necessary (for example,

when there are occupational exposure limit values associated with those fractions.)

8.2 Sampling substrate, (for example, a filter) of a diameter suitable for use with the samplers (see

8.1), with a collection efficiency of not less than 99,5 % for particles with a 0,3 µm diffusion diameter in

accordance with 2.2 of ISO 7708:1995, with a maximum lead content (typically less than 0,1 µg Pb), and

compatible with the selected sample preparation method.

NOTE 1 Guidance on filter selection is provided in Annex A.

NOTE 2 Digestible cellulosic capsules (consisting of cellulose acetate housing attached to cellulosic filter) that

are placed within certain types of samplers are now available for use, thereby accounting for potential internal

[4],[5]

aerosol wall losses .

8.3 Sampling pumps, meeting the specifications of ISO 13137.

8.4 Flowmeter, portable, with an accuracy that is sufficient to enable the volumetric flow rate (see

10.1.1.2) to be measured to within ±5 %.

The calibration of the flowmeter shall be checked against a primary standard, i.e. a flowmeter whose

accuracy is traceable to national standards. If appropriate (see 10.1.3.1), record the atmospheric

temperature and pressure at which the calibration of the flowmeter was checked.

8.5 Ancillary equipment

8.5.1 Flexible tubing, of a diameter suitable for making a leak-proof connection from the samplers to

the sampling pumps.

8.5.2 Belts or harnesses, to which the sampling pumps can conveniently be fixed for personal

sampling (except where the sampling pumps are small enough to fit inside worker's pockets).

8.5.3 Flat-tipped forceps, for loading and unloading sampling substrates into samplers.

8.5.4 Transport cassettes, or similar, if required to transport samples for laboratory analysis.

8.5.5 Barometer, (readable to 0,1 kPa), suitable for measurement of atmospheric pressure, if required

(see 10.1.3).

8.5.6 Thermometer, (readable to 1 °C), minimum temperature range of 0 °C to 50 °C, with graduated

divisions of 1 °C or less, for measurement of atmospheric temperature.

For applications at temperatures below freezing, the range of the thermometer shall extend to the

appropriate desired range.

8.6 Analytical or laboratory apparatus

Ordinary laboratory apparatus, and the following.

8.6.1 Glassware, made of borosilicate glass 3.3 and conforming with the requirements of ISO 3585.

It is preferable to reserve a set of glassware for analysis of lead by this method, in order to ensure that

problems do not arise from incomplete removal of lead contamination by cleaning.

8.6.2 Plastic labware, including the following:

8.6.2.1 Heatable beakers, beaker covers, etc., if required, made of a material that is resistant to

corrosion by hydrofluoric acid, for example, a fluorocarbon polymer such as polytetrafluoroethylene

(PTFE), and suitable for performing dissolutions using hydrofluoric acid.

8.6.2.2 Polypropylene bottles, of capacities from 100 ml to 1 000 ml.

8.6.3 Piston-operated volumetric instruments, complying with the requirements of ISO 8655-1

and tested in accordance with ISO 8655-6:

8.6.3.1 Pipetters, complying with the requirements of ISO 8655-2, as an alternative to one-mark

pipettes, for the preparation of standard solutions, calibration solutions and dilution of samples.

8.6.3.2 Dispensers, complying with the requirements of ISO 8655-5, for dispensing acids.

8.6.4 Hot plate, thermostatically controlled, capable of maintaining a surface temperature of

approximately 150 °C, for hot-plate procedures.

8.6.5 Microwave digestion apparatus

8.6.5.1 General

Ensure that manufacturer's safety recommendations are followed.

NOTE 1 The specified method is for closed vessel microwave digestion systems with a temperature control

system. Microwave digestion systems that are equipped only with either a pressure control system or lower

pressure vessels, or both, can be used provided that a suitable sample dissolution procedure is developed, and a

prior assessment of dissolution efficiency is carried out.

NOTE 2 Open-vessel microwave digestion systems can give results equivalent to closed-vessel microwave

digestion systems. They can therefore be used provided that a suitable sample dissolution procedure is

developed, and a prior assessment of dissolution efficiency is carried out.

8.6.5.2 Microwave digestion system, designed for closed-vessel sample digestion in the laboratory,

with power output regulation, fitted with a temperature control system capable of minimum sensing

the temperature to within ±2 °C and automatically adjusting the microwave power output within

minimum 2 s.

The microwave cavity shall be corrosion-resistant and well ventilated, with all electronics protected

against corrosion to ensure safe operation.

CAUTION — Do not use domestic (kitchen) microwave ovens, since there are very significant

hazards associated with their use for the procedure described in this document. Acid vapours

released into the cavity can corrode safety devices that prevent the magnetron from shutting

off when the door is opened, potentially exposing the operator to microwave energy. Also, the

fumes generated can be extremely hazardous.

NOTE A pressure control system is also very useful, since it provides a safeguard against the possibility of

sample loss due to excessive pressure build-up and partial venting of the sample vessels.

8.6.5.3 Vessels, designed for carrying out microwave assisted digestions, capable of withstanding a

temperature of 180 °C, and with an internal volume of at least 50 ml.

The vessels shall be transparent to microwave energy, and shall be capable of withstanding internal

pressures up to at least 3 000 kPa or greater, and temperatures up to at least 180 °C or greater.

Closed vessels shall also be equipped with a safety relief valve or disc that will prevent vessel

rupture or ejection of the vessel cap. Such vessels consist of an inner liner and cover made of a

microwave-transparent and chemically resistant material [usually a fluorocarbon polymer such

as tetrafluoromethoxyl polymer (TFM)], which contains and isolates the sample solution from a

high-strength, outer pressure vessel structure. Other types of sample vessel designed to operate at

equivalent or higher temperatures or pressures, or both, can be used. If hydrofluoric acid (HF) is to be

used, the vessels shall be compatible with HF.

CAUTION — For closed-vessel designs, the material from which the outer vessels are made

is usually not as chemically resistant as the liner material. Since the outer vessels provide

the strength required to withstand the high pressures within the inner liners, they shall be

inspected regularly to check for any chemical or physical degradation.

NOTE Alternatively, a one reaction chamber microwave assisted pressure digestion system can be used.

8.6.6 Ultrasonic bath (sonicator), for performing ultrasonic extractions, capable of delivering

sufficient power to effect the quantitative dissolution of particulate lead under the conditions described

in 11.2.5 (typically 1 W/cm power density or greater).

8.6.7 Plastic centrifuge tubes, 50 ml, with screw caps (for ultrasonic procedure).

8.6.8 Atomic absorption spectrometer, fitted with an air-acetylene burner supplied with

compressed air and acetylene, and equipped with either a lead hollow cathode lamp or electrodeless

[6],[7]

discharge lamp . If sample dissolution is carried out with the aid of hydrofluoric acid (see

11.2.3.3 and 11.2.4.2), the atomic absorption spectrometer shall be hydrofluoric acid-compatible. If

electrothermal atomic absorption is to be carried out, the atomic absorption spectrometer shall be

capable of carrying out simultaneous background correction at 283,3 nm, either by using a continuum

source such as a deuterium lamp to measure non-specific attenuation, or by using Zeeman or Smith-

[8]

Hieftje background correction systems .

8.6.9 Electrothermal atomiser, fitted with a solid, pyrolytic graphite platform mounted in a

pyrolytically-coated graphite tube, supplied with argon purge gas, and equipped with an autosampler

capable of injecting microlitre volumes onto the platform.

NOTE Some manufacturers of atomic absorption spectrometers use an alternative design of electrothermal

atomiser to achieve a constant temperature environment during atomisation, and some use aerosol deposition

as a means of sample introduction. The use of such accessories is acceptable, provided satisfactory method

performance is verified. Likewise, atomisers made from heat-resistant metal, such as tungsten, can also be

suitable.

8.6.10 Analytical balance, capable of weighing to ±0,1 mg, if required, for use in preparation of stock

standard lead solution.

8.6.11 Disposable gloves, for prevention of sample contamination.

9 Occupational exposure assessment

9.1 Assessment strategy

[9] [10]

Refer to relevant International or national Standards (for example, EN 689 and ASTM E1370 ) for

guidance on how to develop an appropriate assessment strategy.

9.2 Measurement strategy

9.2.1 General

[9] [10]

Refer to relevant International or national Standards (for example, EN 689 and ASTM E1370 ) for

general guidance on measurement strategy.

9.2.2 Personal sampling

Exposure of workers to lead shall normally be determined by personal sampling, since the concentration

of lead and lead compounds in the breathing zone is usually higher than their background levels in the

workplace.

9.2.3 Static (area) sampling

Static (area) sampling can be carried out, if appropriate, to assess the exposure of workers in a situation

where personal sampling is not possible; to characterise the background level of lead in the workplace

to give an indication of the efficiency of ventilation or other engineering controls; or to provide

information on the location and intensity of an emission source.

9.3 Selection of measurement conditions and measurement pattern

9.3.1 General

9.3.1.1 The sampling procedure shall be devised to provide samples that are representative of normal

working conditions and that are compatible with the analytical method while causing the least possible

interference with the worker and the normal performance of the job.

9.3.1.2 The pattern of sampling shall take into consideration practical issues, such as the nature of

the measurement task and the frequency and duration of particular work activities.

NOTE Additional information concerning purposes of measurement and performance requirements can be

found in ISO 20581.

9.3.2 Screening measurements of time-weighted average concentration and worst-case

measurements

Screening measurements of time-weighted average concentration can be carried out in the initial

stages of a survey to assess the effectiveness of control measures. This can involve sampling during

representative work episodes to obtain clear information about the level and pattern of exposure, or

worst-case measurements can be made.

9.3.3 Screening measurements of variation of concentration in either time or space, or both

Screening measurements of variation of concentration in either time or space, or both, can be carried

out in the initial stages of a survey to identify locations and periods of elevated exposure, and to set the

duration and frequency of sampling for measurements for comparison with limit values.

NOTE For making screening measurements of variation of concentration in either time or space, or both, the

sampling time used is normally between 5 min and 30 min.

9.3.4 Measurements for comparison with limit values and periodic measurements

For making long-term measurements, samples shall be collected for the entire working period or during

[11]

a number of representative work episodes .

NOTE The best estimate of long-term exposure is obtained by taking samples for the entire working period,

but this is often not practicable or not desirable (for example, because of the possibility of overloading the

sa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...