ISO/PRF TS 21397

(Main)FTIR analysis of fire effluents in cone calorimeter tests

FTIR analysis of fire effluents in cone calorimeter tests

Analyse par FTIR des effluents du feu dans les essais au calorimètre à cône

General Information

Standards Content (sample)

TECHNICAL ISO/TS

SPECIFICATION 21397

First edition

FTIR analysis of fire effluents in cone

calorimeter tests

Analyse par FTIR des effluents du feu dans les essais au calorimètre à

cône

PROOF/ÉPREUVE

Reference number

ISO/TS 21397:2021(E)

ISO 2021

---------------------- Page: 1 ----------------------

ISO/TS 21397:2021(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/TS 21397:2021(E)

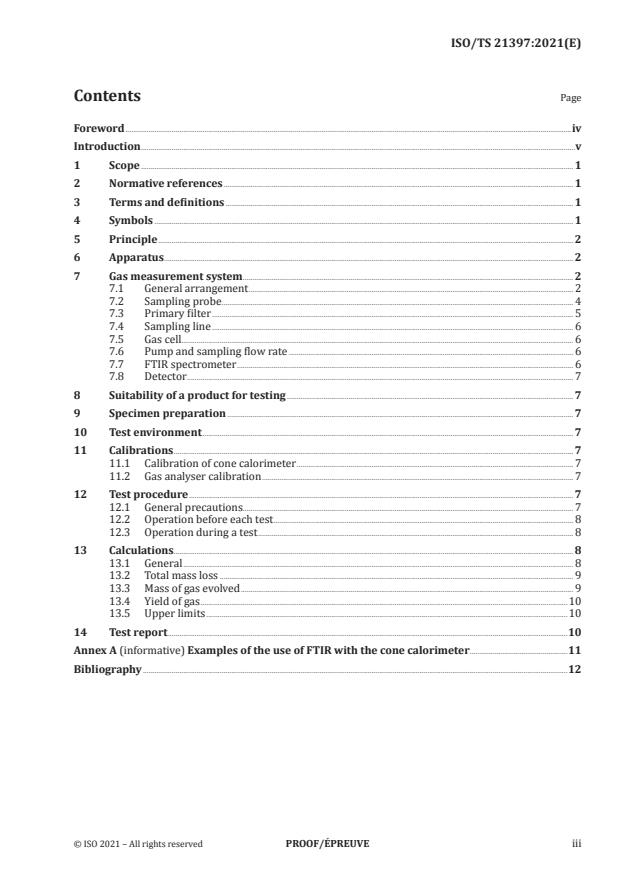

Contents Page

Foreword ........................................................................................................................................................................................................................................iv

Introduction ..................................................................................................................................................................................................................................v

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms and definitions ..................................................................................................................................................................................... 1

4 Symbols .......................................................................................................................................................................................................................... 1

5 Principle ........................................................................................................................................................................................................................ 2

6 Apparatus ..................................................................................................................................................................................................................... 2

7 Gas measurement system ............................................................................................................................................................................ 2

7.1 General arrangement ......................................................................................................................................................................... 2

7.2 Sampling probe ....................................................................................................................................................................................... 4

7.3 Primary filter ............................................................................................................................................................................................ 5

7.4 Sampling line ............................................................................................................................................................................................ 6

7.5 Gas cell............................................................................................................................................................................................................ 6

7.6 Pump and sampling flow rate .................................................................................................................................................... 6

7.7 FTIR spectrometer ............................................................................................................................................................................... 6

7.8 Detector ......................................................................................................................................................................................................... 7

8 Suitability of a product for testing ..................................................................................................................................................... 7

9 Specimen preparation .................................................................................................................................................................................... 7

10 Test environment ................................................................................................................................................................................................. 7

11 Calibrations ................................................................................................................................................................................................................ 7

11.1 Calibration of cone calorimeter ................................................................................................................................................ 7

11.2 Gas analyser calibration .................................................................................................................................................................. 7

12 Test procedure ........................................................................................................................................................................................................ 7

12.1 General precautions ......... ................................................................................................................................................................... 7

12.2 Operation before each test ............................................................................................................................................................ 8

12.3 Operation during a test .................................................................................................................................................................... 8

13 Calculations................................................................................................................................................................................................................ 8

13.1 General ........................................................................................................................................................................................................... 8

13.2 Total mass loss ........................................................................................................................................................................................ 9

13.3 Mass of gas evolved ............................................................................................................................................................................. 9

13.4 Yield of gas ...............................................................................................................................................................................................10

13.5 Upper limits ............................................................................................................................................................................................10

14 Test report ................................................................................................................................................................................................................10

Annex A (informative) Examples of the use of FTIR with the cone calorimeter ...................................................11

Bibliography .............................................................................................................................................................................................................................12

© ISO 2021 – All rights reserved PROOF/ÉPREUVE iii---------------------- Page: 3 ----------------------

ISO/TS 21397:2021(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.This document was prepared by Technical Committee ISO/TC 92, Fire safety, Subcommittee SC 1, Fire

initiation and growth.Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.iv PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/TS 21397:2021(E)

Introduction

The composition of the effluent from an enclosure fire is determined by the combustible items in the

enclosure, such as interior furnishings and wall linings, and the fire conditions within the enclosure. To

represent any product involved in any fire scenario, the ideal fire test specimen is the complete item,

and the ideal test is one conducted in an enclosure of appropriate size. Unfortunately, real-scale testing

of commercial products is not generally economically feasible. This document describes an indicative

approach for obtaining gas yields under specific fire conditions. It involves the use of a small-scale

combustor in which a small test specimen is exposed to a pre-defined radiative heat flux. The test

specimen should be representative of the finished productThis document provides a method for continuous quantification of gases (i.e. time-resolved gas

analysis) emitted from a test specimen exposed to irradiance in a cone calorimeter, after extraction of

effluent gas to a FTIR gas analyser. It produces data as the gas volume fraction (µL/L) or gas yield (mg/

kg) during the test period. Data generated allow a better understanding of gas emissions during cone

calorimeter tests, which can be useful for Fire Safety Engineering and for material development. The

repeatability/reproducibility results from an interlaboratory trial on the method are found in Annex A.

Some examples of FTIR analysers used with cone calorimeters are presented in Table A.1.

The cone calorimeter uses a well-ventilated physical fire model, so results are only relevant for

this scenario. Toxicity assessment for materials or products are not covered in this document and

interpretation of data is covered separately in ISO 13571 or ISO 13344.© ISO 2021 – All rights reserved PROOF/ÉPREUVE v

---------------------- Page: 5 ----------------------

TECHNICAL SPECIFICATION ISO/TS 21397:2021(E)

FTIR analysis of fire effluents in cone calorimeter tests

1 Scope

This document specifies a method for determining the kinetics and yields of gaseous emissions from a

specimen exposed to radiant heat in a cone calorimeter. Gas yields are determined by exposing small

representative specimens to an external heat flux with or without spark ignition. The concentrations

of specific gases in the effluent (smoke) are measured. In combination with calculated masses of gases,

their yields from the specimen mass, mass loss or mass loss rate can be determined. This document

uses Fourier-Transform Infrared (FTIR) spectroscopy as described in ISO 19702, with additional

information on the test apparatus and gas analyser suitable for this specific application.

2 Normative referencesThe following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 13943, Fire safety — VocabularyISO 5660-1:2015, Reaction-to-fire tests — Heat release, smoke production and mass loss rate — Part 1:

Heat release rate (cone calorimeter method) and smoke production rate (dynamic measurement)

ISO 19702, Guidance for sampling and analysis of toxic gases and vapours in fire effluents using Fourier

Transform Infrared (FTIR) spectroscopyISO 12828-1, Validation method for fire gas analysis — Part 1: Limits of detection and quantification

ISO 12828-2, Validation method for fire gas analysis — Part 2: Intralaboratory validation of

quantification methods3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 13943, ISO 5660-1, ISO 19702,

ISO 12828-1 and ISO 12828-2 apply.ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp— IEC Electropedia: available at http:// www .electropedia .org/

4 Symbols

Symbol Designations Unit

total mass loss of the test specimen g

-1

mass flow rate of sampled gas species of interest g s

total mass produced of sampled gas species of interest g

mass at test end g

molecular weight of gas of interest g mol

t is the time from ignition(t ) to extinction(t ) s

i e

© ISO 2021 – All rights reserved PROOF/ÉPREUVE 1

---------------------- Page: 6 ----------------------

ISO/TS 21397:2021(E)

Symbol Designations Unit

time to ignition (onset of sustained flaming) s

t time of extinction s

3 -1

V volume flow rate in exhaust duct at 0,1 MPa and 25 °C m s

298

3 -1

volume flow rate of sampled gas species at 0,1 MPa and 25 °C m s

total volume of sampled gas species at 0,1 MPa and 25 °C m

species yield of gas g g

volume fraction of gas dimensionless

gas density kg m

5 Principle

This document specifies a method for measurement of gas yields from small test specimens by

exposing them to an incident heat flux in a cone calorimeter. The concentrations (µL/L) of specific gases

presented in the effluents are determined via FTIR gas analysis, and their yields are determined in

combination with the specimen mass loss.6 Apparatus

The test apparatus is specified in ISO 5660-1 and the gas measurement system described in Clause 7

shall be used.7 Gas measurement system

7.1 General arrangement

The gas sampling system shall consist of a sampling probe, a heated primary filter, a heated gas sampling

line, a heated gas cell fitted with a gas pressure transducer, a pump and flow meter. An optional heated

secondary filter and an optional gas cooler may also be fitted. The sampling system shall be heated

to an even temperature which shall not be greater than the gas cell temperature in order to avoid

condensation in the cell. Other conditions not described in this document shall be in accordance with

ISO 19702. Examples of alternative sampling system schematics are provided in Figure 1 and Figure 2

respectively.A procedure to determine the response time for the complete FTIR gas measurement system is given in

ISO 19702:2015, Annex D.2 PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/TS 21397:2021(E)

Key

1 ISO 5660-1 gas sampling ring probe

2 heated primary filter

3 heated line for gas sample transport

4 heated secondary filter

5 heated FTIR gas cell

6 pressure transducer

7 optional gas cooler

8 sampling pump (here located downstream of the gas cell; upstream location is also allowed but requires a

heated pump head)9 flow meter

Direction of Combustion gas flow.

To O , CO and CO analyser.

2 2

To exhaust.

Figure 1 — Example schematic diagram of sampling system when using the ISO 5660-1 ring

probe fitted with a T-connection for sampling to FTIR analysis© ISO 2021 – All rights reserved PROOF/ÉPREUVE 3

---------------------- Page: 8 ----------------------

ISO/TS 21397:2021(E)

Key

1 linear multi-hole sampling probe fitted in the cone calorimeter exhaust duct

2 heated primary filter

3 heated line for gas sample transport

4 heated secondary filter

5 heated FTIR gas cell

6 pressure transducer

7 optional gas cooler

8 sampling pump (here located downstream of the gas cell; upstream location is also allowed but requires a

heated pump head)9 flow meter

Direction of Combustion gas flow.

To O , CO and CO analyser.

2 2

To exhaust.

Figure 2 — Example of schematic diagram of sampling system when using a linear multi-hole

probe for sampling to FTIR7.2 Sampling probe

The ISO 5660-1 gas sampling ring probe can be used. A heated tee-connection/heated gas line is

required to sample from the main gas sampling line from the ring probe (connecting the sampling ring

to the cone calorimeter oxygen analyser) for transfer to the FTIR analyser. The tee-connection shall be

located as close as possible to the sampling ring and shall as a minimum be efficiently insulated in order

not to cool the sampled gases.NOTE When using the ring probe for sampling to the FTIR it can be necessary to adjust the sampling flow

rate to the oxygen analyser.Alternatively, a separate linear multi-hole probe may be used for gas sampling. This is positioned

[3][4]vertically in the duct either 100 m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.