oSIST prEN 15012:2014

(Main)Plastics piping systems - Buried and above ground piping components for non pressure soil and waste discharge within the building structure - Requirements and test/assessment methods for pipes and fittings

Plastics piping systems - Buried and above ground piping components for non pressure soil and waste discharge within the building structure - Requirements and test/assessment methods for pipes and fittings

This European Standard specifies product characteristics for plastics pipes and fittings for non-pressure soil and waste applications.

Pipes and fittings covered by this standard are intended to be used in soil and waste discharge applications without pressure:

- inside the building (application area code "B"),

- buried in ground within the building structure (application area code "D") and with a diameter greater than or equal to 75 mm.

This standard gives the associated test/assessment methods.

This standard does not cover adhesives, joint sealings and gaskets.

Kunststoff-Rohrleitungssysteme - Erdverlegte und nicht erdverlegte drucklose Rohrleitungsteile zum Ableiten von Abwasser innerhalb der Gebäudestruktur - Anforderungen und Prüf-/Bewertungsverfahren für Rohre und Formstücke

Diese Europäische Norm legt Produkteigenschaften für Rohre und Formstücke aus Kunststoff für drucklose Anwendungen zum Ableiten von Abwasser fest.

Die in dieser Europäischen Norm behandelten Rohre und Formstücke sind vorgesehen für den Einsatz in drucklosen Anwendungen zum Ableiten von Abwasser:

- innerhalb von Gebäuden (Anwendungskennzeichen „B“);

- erdverlegt innerhalb der Gebäudestruktur (Anwendungskennzeichen „D“) mit einem Durchmesser 75 mm.

Diese Norm enthält die zugehörigen Prüf /Bewertungsverfahren.

Diese Norm gilt nicht für Klebstoffe, Abdichtungen von Rohrverbindungen und Dichtungen.

Systèmes de canalisations en plastique - Composants de canalisations enterrées et aériennes pour l’évacuation des eaux-vannes et des eaux usées sans pression à l’intérieur de la structure des bâtiments - Exigences et méthodes d’essais/d’évaluation pour tubes et raccords

La présente Norme européenne spécifie les caractéristiques de produit relatives aux tubes et raccords en plastique destinés aux applications pour eaux-vannes et eaux usées sans pression.

Les tubes et raccords traités dans la présente norme sont destinés à être utilisés dans les applications d’évacuation des eaux-vannes et des eaux usées sans pression :

- à l’intérieur du bâtiment (code de zone d’application « B ») ;

- enterrées à l'intérieur de la structure du bâtiment (code de zone d’application « D ») et de diamètre égal ou supérieur à 75 mm.

La présente norme indique les méthodes d’essais/d’évaluation associées.

La présente norme ne couvre pas les adhésifs, les joints d’étanchéité et les garnitures de joints.

Cevni sistemi iz polimernih materialov - Podzemne in nadzemne cevne komponente brez tlaka za odvodne sisteme v zgradbah - Zahteve in preskusi/metode ocenjevanja za cevi in fitinge

General Information

- Status

- Not Published

- Public Enquiry End Date

- 30-Jul-2014

- Technical Committee

- PCV - Plastic pipes, fittings and valves

- Current Stage

- 98 - Abandoned project (Adopted Project)

- Start Date

- 22-Jul-2016

- Due Date

- 27-Jul-2016

- Completion Date

- 22-Jul-2016

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 01-Jul-2014

Overview

The oSIST prEN 15012:2014:2014 standard, developed by the European Committee for Standardization (CEN), specifies essential requirements and test methods for plastics piping systems used in non-pressure soil and waste discharge applications within building structures. This standard covers both buried and above ground piping components, focusing on pipes and fittings designed for soil and waste discharge without pressure. The pipes and fittings targeted by this standard are intended for:

- Installation inside buildings (application code "B")

- Buried within ground inside the building structure (application code "D")

- Pipes with diameters ≥ 75 mm

Importantly, this standard excludes adhesives, joint sealings, and gaskets, concentrating solely on the physical and mechanical product characteristics and testing of pipes and fittings.

Key Topics

Scope and Application

- Specifies product characteristics for non-pressure soil and waste piping systems.

- Applicable to plastic pipes and fittings used indoors and underground inside building structures.

- Provides test and assessment methods crucial for certifying product compliance.

Product Characteristics Covered

- Reaction to fire: Resistance and behavior under fire conditions to ensure safety.

- Maximum load for admissible deformation: For buried pipes, limits on deformation under load are defined.

- Dimensional tolerances: Ensures uniformity in manufacturing for reliable installations.

- Tightness (gas and liquid): Tests to guarantee leak-free joints and components.

- Release of dangerous substances: Limits hazardous emissions from materials used.

- Durability: Longevity assessment under operational thermal and mechanical conditions.

Testing and Assessment Methods

- Standardized procedures for evaluating fire reaction, mechanical strength, tightly sealed joints, and chemical stability.

- Includes factory production controls (FPC) and type testing for quality assurance.

- Harmonized with EU Construction Products Regulation requirements for market compliance.

Terms and Definitions

- Clarifies technical terms such as nominal size (DN), nominal ring stiffness (SN), and connection.

- Defines abbreviations including PVC, PE, PP, ABS, ensuring consistent industry terminology.

Applications

This standard is invaluable for manufacturers, installers, and inspectors involved in plumbing and wastewater management systems within building infrastructures. Typical applications include:

- Drainage systems for soil and waste discharge in residential, commercial, and industrial buildings.

- Installation of buried piping systems for effective wastewater transport inside the building footprint.

- Ensuring sustainability and safety in building plumbing by adhering to stringent fire safety and chemical resistance criteria.

- Product conformity assurance for pipe and fitting manufacturers aiming to meet European market requirements.

Related Standards

oSIST prEN 15012:2014 works alongside various harmonized and normative references that further define plastics piping systems and materials for soil and waste applications:

- EN 1329-1 and EN 1329-2: Specifications and conformity of PVC-U pipes and fittings.

- EN 1451-1 and EN 1451-2: Polypropylene piping systems specifications and conformity.

- EN 1277: Leaktightness testing of elastomeric sealing ring type joints.

- EN ISO 1167-2: Determination of resistance to internal pressure of thermoplastics.

- EN 13501-1: Fire classification standards for construction products.

- Various other CEN technical specifications and test methods addressing performance, durability, and installation characteristics of plastics piping systems.

These standards collectively ensure a comprehensive framework for addressing the performance, safety, and quality of non-pressure plastics piping used in soil and waste discharge within buildings.

Keywords: oSIST prEN 15012:2014, plastics piping systems, non-pressure soil discharge, waste discharge piping, buried pipes, above ground piping, building plumbing standards, test methods, pipe fittings, CEN, reaction to fire, dimensional tolerances, tightness test, factory production control, European standard for plastics pipes, plumbing system durability.

Frequently Asked Questions

oSIST prEN 15012:2014 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Plastics piping systems - Buried and above ground piping components for non pressure soil and waste discharge within the building structure - Requirements and test/assessment methods for pipes and fittings". This standard covers: This European Standard specifies product characteristics for plastics pipes and fittings for non-pressure soil and waste applications. Pipes and fittings covered by this standard are intended to be used in soil and waste discharge applications without pressure: - inside the building (application area code "B"), - buried in ground within the building structure (application area code "D") and with a diameter greater than or equal to 75 mm. This standard gives the associated test/assessment methods. This standard does not cover adhesives, joint sealings and gaskets.

This European Standard specifies product characteristics for plastics pipes and fittings for non-pressure soil and waste applications. Pipes and fittings covered by this standard are intended to be used in soil and waste discharge applications without pressure: - inside the building (application area code "B"), - buried in ground within the building structure (application area code "D") and with a diameter greater than or equal to 75 mm. This standard gives the associated test/assessment methods. This standard does not cover adhesives, joint sealings and gaskets.

oSIST prEN 15012:2014 is classified under the following ICS (International Classification for Standards) categories: 23.040.20 - Plastics pipes; 23.040.45 - Plastics fittings; 91.140.80 - Drainage systems. The ICS classification helps identify the subject area and facilitates finding related standards.

oSIST prEN 15012:2014 has the following relationships with other standards: It is inter standard links to SIST EN 15012:2008, SIST EN 15012:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

oSIST prEN 15012:2014 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/131. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase oSIST prEN 15012:2014 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2014

Cevni sistemi iz polimernih materialov - Podzemne in nadzemne cevne

komponente brez tlaka za odvodne sisteme v zgradbah - Zahteve in

preskusi/metode ocenjevanja za cevi in fitinge

Plastics piping systems - Buried and above ground piping components for non pressure

soil and waste discharge within the building structure - Requirements and

test/assessment methods for pipes and fittings

Kunststoff-Rohrleitungssysteme - Erdverlegte und nicht erdverlegte drucklose

Rohrleitungsteile zum Ableiten von Abwasser innerhalb der Gebäudestruktur -

Anforderungen und Prüf-/Bewertungsverfahren für Rohre und Formstücke

Systèmes de canalisations en plastique - Composants de canalisations enterrées et

aériennes pour l’évacuation des eaux-vannes et des eaux usées sans pression à

l’intérieur de la structure des bâtiments - Exigences et méthodes d’essais/d’évaluation

pour tubes et raccords

Ta slovenski standard je istoveten z: prEN 15012

ICS:

23.040.20 Cevi iz polimernih materialov Plastics pipes

23.040.45 Fitingi iz polimernih Plastics fittings

materialov

91.140.80 Drenažni sistemi Drainage systems

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

DRAFT

NORME EUROPÉENNE

EUROPÄISCHE NORM

April 2014

ICS 23.040.01; 91.140.80 Will supersede EN 15012:2007

English Version

Plastics piping systems - Buried and above ground piping

components for non pressure soil and waste discharge within the

building structure - Requirements and test/assessment methods

for pipes and fittings

Systèmes de canalisations en plastique - Composants de Kunststoff-Rohrleitungssysteme - Erdverlegte und nicht

canalisations enterrées et aériennes pour l'évacuation des erdverlegte drucklose Rohrleitungsteile zum Ableiten von

eaux-vannes et des eaux usées sans pression à l'intérieur Abwasser innerhalb der Gebäudestruktur - Anforderungen

de la structure des bâtiments - Exigences et méthodes und Prüf-/Bewertungsverfahren für Rohre und Formstücke

d'essais/d'évaluation pour tubes et raccords

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee CEN/TC 155.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations which

stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other language

made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United

Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are aware and to

provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without notice and

shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2014 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 15012:2014 E

worldwide for CEN national Members.

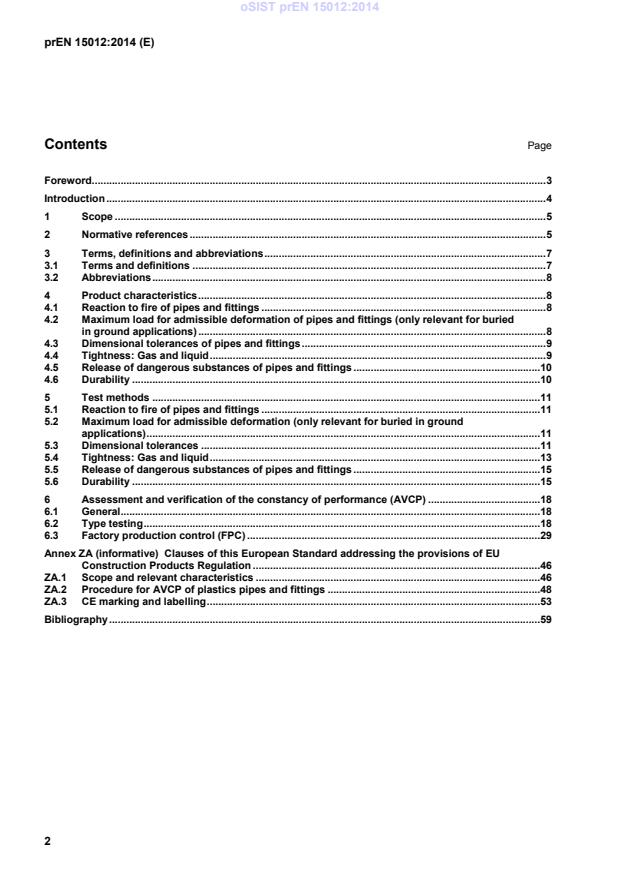

Contents Page

Foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms, definitions and abbreviations . 7

3.1 Terms and definitions . 7

3.2 Abbreviations . 8

4 Product characteristics . 8

4.1 Reaction to fire of pipes and fittings . 8

4.2 Maximum load for admissible deformation of pipes and fittings (only relevant for buried

in ground applications) . 8

4.3 Dimensional tolerances of pipes and fittings . 9

4.4 Tightness: Gas and liquid . 9

4.5 Release of dangerous substances of pipes and fittings . 10

4.6 Durability . 10

5 Test methods . 11

5.1 Reaction to fire of pipes and fittings . 11

5.2 Maximum load for admissible deformation (only relevant for buried in ground

applications) . 11

5.3 Dimensional tolerances . 11

5.4 Tightness: Gas and liquid . 13

5.5 Release of dangerous substances of pipes and fittings . 15

5.6 Durability . 15

6 Assessment and verification of the constancy of performance (AVCP) . 18

6.1 General . 18

6.2 Type testing . 18

6.3 Factory production control (FPC) . 29

Annex ZA (informative) Clauses of this European Standard addressing the provisions of EU

Construction Products Regulation . 46

ZA.1 Scope and relevant characteristics . 46

ZA.2 Procedure for AVCP of plastics pipes and fittings . 48

ZA.3 CE marking and labelling . 53

Bibliography . 59

Foreword

This document (prEN 15012:2014) has been prepared by Technical Committee CEN/TC 155 “Plastics piping

systems and ducting systems”, the secretariat of which is held by NEN.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 15012:2007.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this document.

Introduction

This European Standard specifies only those characteristics of pipes and fittings for soil and waste

applications inside buildings or buried in ground within the building structure, that need to be known to

determine if the works in which these are to be installed can satisfy the essential requirements of the EU

Directive(s). Additional characteristics are specified in the documents listed in clause 2 or in other appropriate

product specifications.

This harmonised European Standard covers plastics pipes and fittings for non pressure soil and waste

applications. Other components such as floor gullies and non return valves are covered by CEN/TC 165.

1 Scope

This European Standard specifies product characteristics for plastics pipes and fittings for non-pressure soil

and waste applications.

Pipes and fittings covered by this standard are intended to be used in soil and waste discharge applications

without pressure:

inside the building (application area code "B"),

buried in ground within the building structure (application area code "D") and with a diameter greater than

or equal to 75 mm.

This standard gives the associated test/assessment methods.

This standard does not cover adhesives, joint sealings and gaskets.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

EN 681-1, Elastomeric seals — Materials requirements for pipe joint seals used in water and drainage

applications — Part 1: Vulcanised rubber

EN 681-2, Elastomeric seals — Materials requirements for pipe joint seals used in water and drainage

applications — Part 2: Thermoplastic elastomers

EN 681-3, Elastomeric seals — Materials requirements for pipe joint seals used in water and drainage

applications — Part 3: Cellular materials of vulcanised rubber

EN 681-4, Elastomeric seals — Materials requirements for pipe joint seals used in water and drainage

applications — Part 4: Cast polyurethane sealing elements

EN 727:1994, Plastics piping and ducting systems — Thermoplastics pipes and fittings — Determination of

vicat softening temperature (VST)

EN 728:1997, Plastics piping and ducting systems — Polyolefin pipes and fittings — Determination of

oxidation induction time

EN 1053:1995, Plastics piping systems — Thermoplastics piping systems for non-pressure applications —

Test method for watertightness

EN 1054:1995, Plastics piping systems — Thermoplastics piping systems for soil and waste discharge — Test

method for airtightness of joints

EN 1055:1996, Plastics piping systems — Thermoplastics piping systems for soil and waste discharge inside

buildings — Test method for resistance to elevated temperature cycling

EN 1277:2003, Plastics piping systems — Thermoplastics piping systems for buried non-pressure

applications — Test methods for leaktightness of elastomeric sealing ring type joints

prEN 1329-1:2013, Plastics piping systems for soil and waste discharge (low and high temperature) within the

building structure — Unplasticized poly(vinyl chloride) (PVC-U) — Part 1: Specifications for pipes, fittings and

the system

CEN/TS 1329-2:2012, Plastics piping systems for soil and waste discharge (low and high temperature) within

the building structure - Unplasticized poly(vinyl chloride) (PVC-U) - Part 2: Guidance for the assessment of

conformity

EN 1451-1:1998, Plastics piping systems for soil and waste discharge (low and high temperature) within the

building structure — Polypropylene (PP) — Part 1: Specifications for pipes, fittings and the system

CEN/TS 1451-2:2012, Plastic piping systems for soil and waste discharge (low and high temperature) within

the building structure - Polypropylene (PP) - Part 2: Guidance for the assessment of conformity

EN 1453-1:2000, Plastics piping systems with structured wall-pipes for soil and waste discharge (low and high

temperature) inside buildings — Unplasticized poly(vinyl chloride) (PVC-U) — Part 1: Specifications for pipes

and the system

ENV 1453-2:2000, Plastics piping systems with structured wall pipes for soil and waste discharge (low and

high temperature) inside buildings - Unplasticized poly(vinyl chloride) (PVC-U) - Part 2: Guidance for the

assessment of conformity

EN 1455-1:1999, Plastics piping systems for soil and waste discharge (low and high temperature) within the

building structure — Acrylonitrile-butadiene-styrene (ABS) — Part 1: Requirements for pipes, fittings and the

system

CEN/TS 1455-2:2012, Plastics piping systems for soil and waste discharge (low and high temperature) within

the building structure - Acrylonitrile-butadiene-styrene (ABS) - Part 2: Guidance for the assessment of

conformity

EN 1519-1:1999, Plastics piping systems for soil and waste discharge (low and high temperature) within the

building structure — Polyethylene (PE) — Part 1: Specifications for pipes, fittings and the system

CEN/TS 1519-2:2012, Plastic piping systems for soil and waste discharge (low and high temperature) within

the building structure - Polyethylen (PE) - Part 2: Guidance for the assessment of conformity

EN 1565-1:1998, Plastics piping systems for soil and waste discharge (low and high temperature) within the

building structure — Styrene copolymer blends (SAN+PVC) — Part 1: Specifications for pipes, fittings and the

system

CEN/TS 1565-2:2012, Plastics piping systems for soil and waste discharge (low and high temperature) within

the building structure - Styrene-copolymer blends (SAN+PVC) - Part 2: Guidance for the assessment of

conformity

EN 1566-1:1998, Plastics piping systems for soil and waste discharge (low and high temperature) within the

building structure — Chlorinated poly(vinyl chloride) (PVC-C) — Part 1: Specifications for pipes, fittings and

the system

CEN/TS 1566-2:2012, Plastics piping systems for soil and waste discharge (low and high temperature) within

the building structure - Chlorinated poly(vinyl chloride) (PVC-C) - Part 2: Guidance for assessment of

conformity

EN 13501-1, Fire classification of construction products and building elements — Part 1: Classification using

test data from reaction to fire tests

EN 13823, Reaction to fire tests for building products — Building products excluding floorings exposed to the

thermal attack by a single burning item

EN 16000, Plastics piping systems — Systems within the building structure — Mounting and fixing of

components in the test apparatus to thermal attack by a single burning item

EN ISO 1167-2:2006, Thermoplastics pipes, fittings and assemblies for the conveyance of fluids —

Determination of the resistance to internal pressure — Part 2: Preparation of pipe test pieces

(ISO 1167-2:2006)

EN ISO 3126, Plastics piping systems — Plastics components — Determination of dimensions

(ISO 3126:2005)

EN ISO 9969, Thermoplastics pipes — Determination of ring stiffness (ISO 9969:2007)

EN ISO 13967, Thermoplastics fittings — Determination of ring stiffness (ISO 13967:2009)

ISO 1133:2011, Plastics — Determination of the melt mass-flow rate (MFR) and the melt volume-flow rate

(MVR) of thermoplastics

ISO 2507-2:1995, Thermoplastics pipes and fittings -- Vicat softening temperature -- Part 2: Test conditions

for unplasticized poly(vinyl chloride) (PVC-U) or chlorinated poly(vinyl chloride) (PVC-C) pipes and fittings and

for high impact resistance poly (vinyl chloride) (PVC-HI) pipes

ISO 13254:2010, Thermoplastics piping systems for non-pressure applications -- Test method for

watertightness

ISO 13255:2010, Thermoplastics piping systems for soil and waste discharge inside buildings -- Test method

for airtightness of joints

ISO 13257:2010, Thermoplastics piping systems for non-pressure applications -- Test method for resistance

to elevated temperature cycling

ISO 13966, Thermoplastics pipes and fittings — Nominal ring stiffnesses

3 Terms, definitions and abbreviations

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1.1

nominal size

DN

numerical designation of the size of a component, other than a component designated by thread size, which is

a convenient round number approximately equal to the manufacturing dimension

Note 1 to entry: This can apply to either the internal diameter (DN/ID) or external diameter (DN/OD)

Note 2 to entry: The nominal size is expressed in millimetres (mm).

3.1.2

nominal outside diameter

d

n

specified outside diameter, in millimetres, assigned to a nominal size

3.1.3

nominal ring stiffness

SN

numerical designation of the ring stiffness of a pipe or fitting, which is a convenient round number indicating

the minimum required ring stiffness of the pipe or fitting

Note 1 to entry : It is designated by the letters "SN" followed by the appropriate number.

3.1.4

connection

assembly of pipe(s) and fitting(s)

Note 1 to entry: For this standard, the term fitting includes the term joint.

3.2 Abbreviations

For the purposes of this document, the following abbreviations apply.

ABS: acrylonitrile-butadiène-styrène

DN: nominal size

PE: polyethylene

PP: polypropylene

PVC: poly(vinyl chloride)

PVC-C: chlorinated poly(vinyl chloride)

PVC-U: unplasticized poly(vinyl chloride)

SAN + PVC: styrene-acrylonitrile plastic + poly(vinyl chloride)

SN: nominal ring stiffness

CWFT: classified without further testing

FPC: factory production control

4 Product characteristics

4.1 Reaction to fire of pipes and fittings

The contribution to fire development of products falling under the scope of this European standard is verified

according to the provisions of clause 5.1.

Test results shall be expressed by the classification.

4.2 Maximum load for admissible deformation of pipes and fittings (only relevant for buried

in ground applications)

4.2.1 General

This clause is only applicable for components intended to be used buried in ground within the building

structure and with a nominal outside diameter greater than or equal to 75 mm.

NOTE The maximum load for admissible deformation is addressed as ring stiffness.

4.2.2 Ring stiffness of pipes

The ring stiffness of a thermoplastics pipe shall be determined in accordance with 5.2.1 and shall be

expressed either:

as SN 2, SN 4, SN 8 or SN 16 in accordance with ISO 13966, or,

as the declared minimum value based on the test, expressed in kN/m .

4.2.3 Ring stiffness of fittings

The ring stiffness of the body of thermoplastics fittings shall be expressed either:

as SN 2, SN 4, SN 8 or SN 16 in accordance with ISO 13966, as applicable, or

as the actual value obtained, expressed in kN/m .

The ring stiffness of a fitting made from the same material and having the same wall thickness and design as

the corresponding pipe may, because of the geometry, be considered to have the same stiffness as that of the

associated pipe.

For thermoplastics fittings with structured wall, the ring stiffness of bends and branches with the largest side

branch shall be determined in accordance with 5.2.2. Based on the obtained lowest value of the result other

fittings of the same design family shall be classified with the same stiffness class.

4.3 Dimensional tolerances of pipes and fittings

Dimensional tolerances are assuring the proper functioning of the connections when installing the pipes and

fittings.

Dimensions shall be measured according to 5.3. Results shall be within the declared tolerances given in the

following standard, and expressed as a DN:

Where the pipes and fittings are not complying with the above criteria, the manufacturer shall declare its own

values and associated connecting method, either by:

reference to a specific publicly available product specification, or

reference to an International Standard, or

by stating the values of his own specification and associated connecting method.

4.4 Tightness: Gas and liquid

4.4.1 General

Pipes and fittings and connections between pipes and/or fittings intended for application inside buildings

(application area code"B") shall comply with the requirements of 4.4.2.

Pipes and fittings and connections between pipes and/or fittings intended for application buried in ground

within the building structure (application area code"D") shall comply with the requirements of 4.4.3.

4.4.2 Tightness of pipes and fittings intended for application inside buildings

Connections between pipes and/or fittings intended for application inside buildings shall be assembled

according to the manufacturer’s instructions and shall be tested against water and air leakage in accordance

with 5.4.2.

No water leakage and no air leakage shall occur during the test. The result shall be expressed as : “no water

leakage” and/or “no air leakage” accordingly.

4.4.3 Tightness of pipes and fittings intended for application buried in ground within the building

structure

Sealing ring connections between pipes and/or fittings intended for application buried in ground within the

building structure shall be assembled according to the manufacturer's instructions and shall be tested against

water tightness under deformation and under angular deflection, in accordance with 5.4.3.

In order to enable the declaration of leak-tightness of sealing ring connections, the following applies:

no water leakage may occur;

the loss of partial vacuum shall not exceed 3 kPa (10 %).

The result shall be expressed as: “no leakage under deflection”.

NOTE Connection systems using adhesive bonding or fusion techniques are considered to be leak-tight when

assembled in accordance with the manufacturer's instructions.

4.5 Release of dangerous substances of pipes and fittings

National regulations on dangerous substances may require verification and declaration on release, and

sometimes content, when construction products covered by this standard are placed on those markets. In the

absence of European harmonized test methods, verification and declaration on release/content should be

done taking into account national provisions in the place of use.

NOTE An informative database covering European and national provisions on dangerous substances is available at

the Construction web site on EUROPA accessed through: http://ec.europa.eu/enterprise/construction/cpd-ds/.

4.6 Durability

4.6.1 General

The durability of tightness of pipes and fittings and connections between pipes and/or fittings intended for

application inside buildings (application area code "B") shall comply with the requirements of 4.6.2.

The durability of tightness of pipes and fittings and connections between pipes and/or fittings intended for

application buried in ground within the building structure (application area code "D") shall comply with the

requirements of 4.6.3.

4.6.2 Durability of tightness of pipes and fittings intended for application inside buildings

The durability of tightness of pipes and fittings intended for application inside buildings shall be assessed in

accordance with 5.6.2 by testing the relevant material characteristic, using the test conditions and

requirements given in table 5 and by testing the resistance of connections between pipes and/or fittings to

temperature cycling using the test conditions and requirements given in table 6.

The durability of tightness shall be expressed as the application area code "B".

4.6.3 Durability of tightness of pipes and fittings intended for application buried in ground within the

building structure

The durability of tightness of pipes and fittings intended for buried in ground within the building structure shall

be assessed in accordance with 5.6.3 by testing the pressure resistance of material using the test conditions

and requirements given in table 7 and by testing the resistance of connections between pipes and/or fittings to

temperature cycling, using the test conditions and requirements given in table 8.

The durability of tightness shall be expressed as the application area code "D".

5 Test methods

5.1 Reaction to fire of pipes and fittings

The reaction to fire is tested according to the test methods relevant for the claimed class.

When tested in accordance with EN 13823 (SBI test), the mounting and fixing conditions of the samples to be

tested shall be in accordance with EN 16000.

Test results shall be classified according to EN 13501-1.

5.2 Maximum load for admissible deformation (only relevant for buried in ground

applications)

5.2.1 Ring stiffness of thermoplastics pipes

For thermoplastics pipes the ring stiffness shall be determined in accordance with EN ISO 9969.

5.2.2 Ring stiffness of thermoplastics fittings

For thermoplastics structured-wall fabricated fittings, the ring stiffness of bends and branches shall be

measured in accordance with EN ISO 13967.

5.3 Dimensional tolerances

The dimensional tolerances of pipes and fittings shall be determined in accordance with Table 1 or Table 2.

Table 1 — Dimensional tolerances of pipes

Material Test parameters Compliance Test method

criteria

ABS EN 1455-1:1999 Clause 4.3 EN ISO 3126

- metric series clause 6.2.1 Table 1

- inch series clause 6.2.1 Table 2

PE EN 1519-1:1999, Clause 4.3 EN ISO 3126

- metric serie clause 6.2.1 Table 1

- inch series clause 6.2.1 Table 2

PP

EN 1451-1:1998, Clause 4.3 EN ISO 3126

- metric serie clause 6.2.1 Table 1

- inch series clause 6.2.1 Table 2

PVC-C EN 1566-1:1998, Clause 4.3 EN ISO 3126

- metric series clause 6.2.1 Table 1

- inch series clause 6.2.1 Table 2

PVC-U Compact prEN 1329-1:2013, Clause 4.3 EN ISO 3126

- metric series clause 6.2.1 Table 3

- inch series clause 6.2.1 Table 4

PVC-U Structured Wall EN 1453-1:2000, Clause 4.3 EN ISO 3126

- metric series clause 6.2.1 Table 1

SAN+PVC EN 1565-1:1998, Clause 4.3 EN ISO 3126

- metric series clause 6.2.1 Table 1

- inch series clause 6.2.1 Table 2

Table 2 — Dimensional tolerances of fittings

Material Test parameters Compliance Test method

criteria

ABS EN 1455-1:1999, Clause 4.3 EN ISO 3126

- metric series

- Adhesive fittings clause 6.4.3 Table 11

- Ring seal fittings clause 6.4.2.1 Table 5 or 6 or 8

- inch series

- Adhesive fittings clause 6.4.3 Table 12

- Ring seal fittings clause 6.4.2.1 Table 7

PE EN 1519-1:1999, Clause 4.3 EN ISO 3126

- metric series

- Ring seal fittings clause 6.4.1.1 Table 5

- Electrofusion fittings clause 6.4.2. Table 9

- inch series

- Ring seal fittings clause 6.4.1.1 Table 6

PP EN 1451-1:1998, Clause 4.3 EN ISO 3126

- metric series

- Ring seal fittings clause 6.4.1.1 Table 5

- Butt welded fittings clause 6.4.2.

- inch series

- Ring seal fittings clause 6.4.1.1 Table 6

PVC-C

EN 1566-1:1998, Clause 4.3 EN ISO 3126

- metric series

- Ring seal fittings clause 6.4.2.1 Table 5 or 6 or 8

- Adhesive fittings clause 6.4.2.2 Table 11

- inch series

- Ring seal fittings clause 6.4.2.1 Table 7

PVC-U Compact prEN 1329-1:2013, Clause 4.3 EN ISO 3126

- metric series

- Adhesive fittings clause 6.4.1 Table 11

- Ring seal fittings clause 6.4.2 Table 13 or 14 or 15 or

clause 6.4.3 Table 17

- inch series

- Adhesive fittings clause 6.4.1 Table 12

- Ring seal fittings clause 6.4.3 Table 16

SAN+PVC

EN 1565-1:1998, Clause 4.3 EN ISO 3126

- metric series

- Ring seal fittings clause 6.4.2.1 Table 5 or 7

- Adhesive fittings clause 6.4.3.1 Table 10

- inch series

- Ring seal fittings clause 6.4.2.1 Table 6

- Adhesive fittings clause 6.4.3 Table 11

5.4 Tightness: Gas and liquid

5.4.1 General

Test methods for the assessment of tightness of pipes, fittings and connections between pipes and/or fittings

are defined in clause 5.4.2 and 5.4.3, in relation to the intended use.

5.4.2 Tightness of pipes and fittings intended for application inside buildings

Connections between pipes and/or fittings shall be tested in accordance with table 3. Unless otherwise

specified in the applicable standard listed in table 3, the sampling procedure is free and the number of test

pieces is one (see clause 6.2).

Table 3 — Tightness of pipes, fittings and connections for application inside buildings

Test method

Compliance

Material Test parameters

criteria

Watertightness Airtightness

EN 1455-1:1999,

ABS EN 1053:1995 EN 1054:1995 Clause 4.4.2

clause 9, table 20

EN 1519-1:1999,

PE EN 1053:1995 EN 1054:1995 Clause 4.4.2

clause 8, table 13

EN 1451-1:1998,

PP EN 1053:1995 EN 1054:1995 Clause 4.4.2

clause 9, table 16

EN 1566-1:1998,

PVC-C EN 1053:1995 EN 1054:1995 Clause 4.4.2

clause 9, table 20

PVC-U prEN 1329-1:2013,

ISO 13254:2010 ISO 13255:2010 Clause 4.4.2

Compact clause 9, table 24

PVC-U EN 1453-1:2000,

EN 1053:1995 EN 1054:1995 Clause 4.4.2

Structured Wall clause 9, table 12

EN 1565-1:1998,

SAN+PVC EN 1053:1995 EN 1054:1995 Clause 4.4.2

clause 9, table 19

5.4.3 Tightness of pipes and fittings intended for application buried in ground within the building

structure

Sealing ring connections between pipes and/or fittings shall be tested in accordance with table 4, whereby the

sampling procedure is free and the number of test pieces is one (see clause 6.2).

Table 4 — Tightness of pipes and fittings intended

for application buried in ground within the building structure

Test method

Compliance

Material Test parameters

Tightness under Tightness under

criteria

deformation angular deflection

EN 1455-1:1999, EN 1277:2003, EN 1277:2003,

ABS Clause 4.4.3

clause 9, table 20 method 4, cond B method 4, cond C

EN 1519-1:1999, EN 1277:2003, EN 1277:2003,

PE Clause 4.4.3

clause 8, table 13 method 4, cond B method 4, cond C

EN 1451-1:1998, EN 1277:2003, EN 1277:2003,

PP Clause 4.4.3

clause 9, table 16 method 4, cond B method 4, cond C

EN 1566-1:1998, EN 1277:2003, EN 1277:2003,

PVC-C Clause 4.4.3

clause 9, table 20 method 4, cond B method 4, cond C

PVC-U prEN 1329-1:2013, ISO 13259:2010 ISO 13259:2010

Clause 4.4.3

Compact clause 9, table 24 condition B condition C

EN 1565-1:1998, EN 1277:2003, EN 1277:2003,

SAN+PVC Clause 4.4.3

clause 9, table 19 method 4, cond B method 4, cond C

5.5 Release of dangerous substances of pipes and fittings

The release of dangerous substances shall comply with the existing national regulation.

5.6 Durability

5.6.1 General

The durability of the tightness of pipes, fittings and connections between pipes and/or fittings is assessed

through the testing of the material properties and the resistance of the system to thermocycling test, according

to the test methods given in clause 5.6.2 and 5.6.3, in relation to the intended use.

For thermocycling testing, connections between pipes and/or fittings shall be assembled according to the

manufacturer’s instructions.

5.6.2 Durability of tightness of pipes and fittings intended for application inside buildings

5.6.2.1 Material properties for applications inside buildings

5.6.2.1.1 The durability of tightness of elastomeric sealing connections between pipes and/or fittings is

deemed to be durable if the sealing element conforms to EN 681-1, EN 681-2, EN 681-3 or EN 681-4, as

applicable

5.6.2.1.2 For applications inside buildings, depending on the material from which the products are made,

material characteristic shall be assessed in accordance with the provisions given in table 5.

Table 5 — Material properties for applications inside buildings

Material Test parameters and Test method

Compliance criteria

ABS Pipes EN 1455-1:1999

- Softening temperature (VST) clause 8.1 table 17

- Softening temperature after

conditioning (VST ) clause 8.1 table 17

cond

EN 727:1994

ABS Fittings

- Softening temperature (VST) clause 8.2 table 18

- Softening temperature after clause 8.2 table 18

conditioning (VST )

cond

PE EN 1519-1:1999,

- Melt flow rate (MFR) clause 4.3 ISO 1133-1:2011

- Thermal stability clause 4.5 EN 728:1997

PP

EN 1451-1:1998,

- Melt flow rate (MFR) clause 4.3 ISO 1133-1:2011

- Thermal stability clause 4.4 EN 728:1997

PVC-C Pipes EN 1566-1:1998,

- Softening temperature (VST) clause 8.1 table 17

EN 727:1994

PVC-C Fittings

- Softening temperature (VST) clause 8.2 table 18

PVC-U Compact Pipes

prEN 1329-1:2013,

- Softening temperature (VST) clause 8.1 table 21

ISO 2507-2:1995

PVC-U Compact Fittings

- Softening temperature (VST) clause 8.2 table 22

PVC-U Structured Wall Pipes EN 1453-1:2000,

EN 727:1994

- Softening temperature (VST) clause 8, table 11

SAN + PVC Pipes EN 1565-1:1998,

- Softening temperature (VST) clause 8.1 Table 16

- Softening temperature after

conditioning (VST ) clause 8.1 Table 16

cond

EN 727:1994

ABS Fittings

- Softening temperature (VST) clause 8.2 Table 17

- Softening temperature after clause 8.2 Table 17

conditioning (VST )

cond

5.6.2.2 Resistance to temperature cycling test of pipes and fittings

For applications inside buildings, depending on the material from which the pipes and fittings are made,

thermocycling testing shall be assessed in accordance with the provisions given in table 5.

Table 6 — Temperature cycling test for applications inside building

Test parameters and

Material Test method

Compliance criteria

EN 1455-1:1999, clause 9, table

ABS EN 1055:1996

EN 1519-1:1999, clause 8, table

PE EN 1055:1996

EN 1451-1:1998, clause 9, table

PP EN 1055:1996

EN 1566-1:1998, clause 9, table

PVC-C EN 1055:1996

PVC-U prEN 1329-1:2013, clause 9,

ISO 13257:2010

Compact table 24

PVC-U EN 1453-1:2000, clause 9, table

EN 1055:1996

Structured Wall 12

EN 1565-1:1998, clause 9, table

SAN+PVC EN 1055:1996

5.6.3 Durability of tightness of pipes and fittings intended for application buried in ground within the

building structure

5.6.3.1 Material properties for application buried in ground within the building structure

For applications buried in ground within the building structure, depending on the material from which the

products are made, material characteristic shall be assessed in accordance with the provisions given in

Table 7.

Table 7 — Material properties for applications buried in ground within the building structure

Test parameters and

Material Test method

Compliance criteria

EN 1455-1:1999, clause 10.2,

ABS EN ISO 1167-2:2006

table 21

EN 1519-1:1999, clause 9.2,

PE EN ISO 1167-2:2006

table 14

EN 1451-1:1998, clause 10.2,

PP EN ISO 1167-2:2006

table 17

EN 1566-1:1998, clause 10.2,

PVC-C EN ISO 1167-2:2006

table 21

PVC-U Compact prEN 1329-1:2013,

- Pipes Clause 4.2, table 1 EN ISO 1167-2:2006

- Fittings Clause 4.3, table 2

EN 1565-1:1998, clause 10.2,

SAN+PVC EN ISO 1167-2:2006

table 20

5.6.3.2 Resistance to temperature cycling test of pipes and fittings

For applications buried in ground within the building structure, depending on the material from which the pipes

and fittings are made, thermocycling testing shall be assessed in accordance with the provisions given in table

8.

Table 8 — Temperature cycling test for applications buried in ground within the building structure

Test parameters and

Material Test method

Compliance criteria

EN 1455-1:1999

ABS EN 1055:1996

clause 9, table 20

EN 1519-1:1999

PE EN 1055:1996

clause 8, table 13

EN 1451-1:1998

PP EN 1055:1996

clause 9, table 16

EN 1566-1:1998

PVC-C EN 1055:1996

clause 9, table 20

prEN 1329-1:2013

PVC-U Compact ISO 13257:2010

clause 9, table 24

EN 1565-1:1998

SAN+PVC EN 1055:1996

clause 9, table 19

6 Assessment and verification of the constancy of performance (AVCP)

6.1 General

The compliance of pipes and fittings with the requirements of this standard and with the performances

declared by the manufacturer in the DoP shall be demonstrated by:

determination of the product type;

factory production control by the manufacturer, including product assessment.

The manufacturer shall always retain the overall control and shall have the necessary means to take

responsibility for the conformity of the product with.

6.2 Type testing

6.2.1 General

All performances related to characteristics included in this standard shall be determined when the

manufacturer intends to declare the respective performances unless the standard gives provisions for

declaring them without performing tests. (e.g. use of previously existing data, CWFT and conventionally

accepted performance).

Assessment previously performed in accordance with the provisions of this standard, respectively standards

as referenced in clause 2, may be taken into account provided that they were made to the same or a more

rigorous test method, under the same AVCP system on the same product or products of similar design,

construction and functionality, such that the results are applicable to the product in question.

NOTE 1 Same AVCP system means testing by an independent third party (only for reaction to fire and products

covered by AVCP system 1 and 3), under the responsibility of a notified product certification body (only for products

covered by AVCP system 1).

For the purposes of assessment, the manufacturer's products may be grouped into families, where it is

considered that the results for one or more characteristics from any one product within the family are

representative for that same characteristics for all products within that same family.

NOTE 2 Products may be in different families for different characteristics.

NOTE 3 Reference to the assessment method standards should be made to allow the selection of a suitable

representative sample.

For type testing the following family groups apply:

a) Size groups for pipes and fittings as given in Table 9.

Table 9 — Size groups

Size group Range of nominal diameters, d

n

1 32 ≤ d < 75

n

75 ≤ d < 200

n

d ≥ 200

n

b) Product groups for thermoplastics piping components as given in Table 10.

Table 10 — Product groups

Type group Thermoplastics piping components

1 Pipes

2 Bends and elbows

3 Branches

4 Other fittings

In addition, the determination of the product type shall be performed for all characteristics included in the

standard for which the manufacturer declares performances:

at the beginning of the production of a new pipe or fitting design, (unless a member of the same product

range), or

at the beginning of a new or modified method of production (where this may affect the stated properties);

or

they shall be repeated for the appropriate characteristic(s), whenever a change occurs in the pipe and fitting

design, in the raw material or in the supplier of the components, or in the method of production (subject to the

definition of a family), which would affect significantly one or more of the characteristics.

This is not applicable for routine in-process adjustment and extension of the product range.

A change of supplier of a material or stabiliser does not lead to a change in performance if the chemical

composition remains the same.

Material modifications within the limits as given in the standards referenced in clause 2 are not considered as

a change of material.

Where components are used whose characteristics have already been determined, by the component

manufacturer, on the basis of assessment methods of other product standards, these characteristics need not

be re-assessed. The specifications of these components shall be documented.

Products bearing regulatory marking in accordance with appropriate harmonized European specifications may

be presumed to have the performances declared in the DoP, although this does not replace the responsibility

on the plastic pipe and fitting manufacturer to ensure that the plastic pipe or fitting as a whole is correctly

manufactured and its components have the declared performance values.

6.2.2 Test samples, testing and compliance criteria

The number of samples of plastics pipes or fittings to be tested/assessed shall be in accordance with Table 11

to Table 23.

Where the type testing is performed according to the relevant clauses of the applicable technical

specifications given in clause 2, the provisions of 6.2 are met.

Table 11 — Number of samples and compliance criteria for type testing of ABS pipes

Assessment

Characteristics Requirement No. of samples Compliance criteria

method

Reaction to fire (only for Once sample / See classification in

4.1 5.1

above ground use) formulation EN 13501-1

Ring stiffness of pipes

CEN/TS 1455-

Expressed as SN value, or

(only for buried in ground 4.2.2 5.2.1

2:2012

declared minimum value

use)

Clause 6.3 Table 3

CEN/TS 1455-

Dimensional tolerances 4.3 5.3 table1 Expressed as DN

2:2012

Clause 6.3 Table 3

Tightness

- for applications inside

CEN/TS 1455-

buildings 4.4.2 5.4.2 No leakage air/water

2:2012

- for applications buried in

Clause 6.3 Table 5

ground within building

structure 4.4.3 5.4.3 No leakage under deflection

Release of dangerous

4.5 5.5 Shall comply with existing national regulation

substances

Durability of tightness

Expressed as area code:

- for applications inside

CEN/TS 1455-

buildings 4.6.2 5.6.2 "B"

2:2012

- for applications buried in

Clause 6.3 Table 3

ground within building

and Table 5

structure 4.6.3 5.6.3 "D"

-------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...