SIST EN 14044:2005

(Main)High rise aerial appliances for fire service use - Turntable ladders with sequential movements - Safety and performance requirements and test methods

High rise aerial appliances for fire service use - Turntable ladders with sequential movements - Safety and performance requirements and test methods

1.1 This European Standard specifies the safety and performance requirements and test methods applicable to turntable ladders with sequential movements of classes 18, 24 and 30, as defined in 3.13, under the control of firefighters and intended for fire fighting and rescuing people.

NOTE This European Standard is intended to be used in conjunction with EN 1846-1, EN 1846-2 and EN 1846-3.

Turntable ladder vehicles comprise a chassis, bodywork and a powered extending structure unit in the form of a ladder with or without a cage.

Turntable ladder vehicles covered by this European Standard have a self-propelled chassis, the motor of which supplies the power required for the operation of the ladder. They do not permit operational movements to be made simultaneously.

1.2 This European Standard deals with the technical requirements to minimise the hazards listed in Clause 4 which can arise during the commissioning, the operational use and the routine checking and maintenance of turntable ladders when carried out in accordance with the specifications given by the manufacturer or the manufacturer authorised representative.

It also deals with performance requirements.

1.3 This European Standard deals with the use of turntable ladder vehicles within a temperature range from - 15 °C to + 35 °C and with a wind velocity on the ladder set £ 12,5 m/s. Additional measures can be necessary for use outside this range (to be negotiated between the manufacturer and the user).

NOTE Special designs for use under special climatic conditions should be by arrangement between the manufacturer and the purchaser.

1.4 This European Standard is not dealing with the hazards of the standard automotive chassis or due to use as a road vehicle.

1.5 This European Standard is not applicable to turntable ladders vehicles with sequential movements which are manufactured before the date of publication of this European Standard by CEN.

Hubrettungsfahrzeuge für die Feuerwehr - Drehleitern mit aufeinander folgenden (sequenziellen) Bewegungen (Halbautomatik-Drehleitern) - Sicherheits- und Leistungsanforderungen sowie Prüverfahren

1.1 Diese Europäische Norm legt die Sicherheits- und Leistungsanforderungen sowie die Prüfverfahren für Drehleitern mit aufeinander folgenden (sequenziellen) Bewegungen (Halbautomatik-Drehleitern) fest, eingeteilt in die Klassen 18, 24 oder 30 (siehe 3.13), die von Feuerwehrpersonal bedient werden und für die Rettung von Menschen sowie die Brandbekämpfung vorgesehen sind.

ANMERKUNG Diese Europäische Norm ist für die Anwendung in Zusammenhang mit EN 1846-1, EN 1846-2 und EN 1846-3 vorgesehen.

Drehleitern bestehen aus einem Fahrgestell, einem Aufbau und einem kraftbetrieben Ausleger in Form einer Leiter mit oder ohne Korb.

Die in dieser Europäischen Norm behandelten Drehleitern verfügen über ein selbstfahrendes Fahrgestell, dessen Motor die für den gesamten Betrieb der Drehleiter notwendige Energie liefert. Die Einsatzbewegungen können nicht gleichzeitig ausgeführt werden (Halbautomatik-Drehleiter).

1.2 Diese Europäische Norm behandelt die technischen Anforderungen zur Minimierung der in Abschnitt 4 aufgeführten Gefährdungen, die während Inbetriebnahme, Bedienung, regelmäßigen Überprüfungen und Wartung von Drehleitern auftreten können, wenn diese Tätigkeiten entsprechend den Festlegungen des Herstellers bzw. dessen bevollmächtigten Vertreters durchgeführt werden.

Leistungsanforderungen werden ebenfalls behandelt.

1.3 Diese Europäische Norm behandelt den Gebrauch von Drehleitern innerhalb eines Temperaturbereiches von -15 °C bis 35 °C und bei einer an der Leiter wirkenden Windgeschwindigkeit von £ 12,5 m/s. Für den Gebrauch außerhalb dieses Bereiches können zusätzliche Maßnahmen erforderlich sein (zu vereinbaren zwischen Hersteller und Kunden).

ANMERKUNG Spezielle Bauarten für den Gebrauch bei besonderen klimatischen Bedingungen sollten zwischen Hersteller und Kunde vereinbart werden.

1.4 Diese Europäische Norm gilt nicht für die Gefährdungen des Standard-Fahrzeuggestells oder durch den Gebrauch als Straßenfahrzeug.

Moyens élévateurs aériens pour la lutte contre l'incendie - Echelles pivotantes a mouvements séquentiels - Prescriptions de sécurité et de performances et méthodes d'essais

1.1 La présente Norme européenne spécifie les prescriptions de sécurité et de performances, et les méthodes d'essais applicables aux échelles pivotantes à mouvements séquentiels de classes 18, 24 et 30, telles que définies au 3.13, manœuvrées par les sapeurs-pompiers et prévues pour la lutte contre l'incendie et le sauvetage de personnes.

NOTE La présente Norme européenne est destinée à être utilisée en association avec les normes EN 1846-1, EN 1846-2 et EN 1846-3.

Les véhicules à échelle pivotante comprennent un châssis, une carrosserie et une structure extensible motorisée, sous la forme d'une échelle avec ou sans panier.

Les véhicules à échelle pivotante couverts par la présente Norme européenne ont un châssis automoteur, dont le moteur assure la puissance requise pour faire fonctionner l'échelle. Ils ne permettent pas de faire simultanément des mouvements opérationnels.

1.2 La présente Norme européenne traite des prescriptions techniques destinées à minimiser les phénomènes dangereux énumérés à l'Article 4, pouvant survenir pendant la mise en service, le fonctionnement, la vérification et la maintenance de routine des échelles pivotantes, effectués conformément aux spécifications données par le fabricant ou son représentant autorisé.

Il traite également des prescriptions de performances.

1.3 La présente Norme européenne traite de l'utilisation des véhicules à échelle pivotante dans une plage de température de – 15 °C à + 35 °C et avec une vitesse de vent sur la structure extensible £ 12,5 m/s. Des dispositions supplémentaires peuvent être nécessaires pour un usage en dehors de cette plage (à négocier entre le fabricant et l'utilisateur).

NOTE Il convient de définir les conceptions particulières relatives à un usage dans des conditions climatiques spéciales entre le fabricant et l'acheteur.

Visoke nadzemne naprave za gasilske enote – Polavtomatske vrtljive gasilske avtolestve – Zahteve za varnost in obnašanje v uporabi in preskusne metode

General Information

- Status

- Withdrawn

- Publication Date

- 30-Nov-2005

- Withdrawal Date

- 27-Apr-2009

- Technical Committee

- POZ - Požarna varnost

- Current Stage

- 9900 - Withdrawal (Adopted Project)

- Start Date

- 24-Apr-2009

- Due Date

- 17-May-2009

- Completion Date

- 28-Apr-2009

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 01-Jun-2009

- Effective Date

- 01-Sep-2008

- Effective Date

- 01-Sep-2007

Frequently Asked Questions

SIST EN 14044:2005 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "High rise aerial appliances for fire service use - Turntable ladders with sequential movements - Safety and performance requirements and test methods". This standard covers: 1.1 This European Standard specifies the safety and performance requirements and test methods applicable to turntable ladders with sequential movements of classes 18, 24 and 30, as defined in 3.13, under the control of firefighters and intended for fire fighting and rescuing people. NOTE This European Standard is intended to be used in conjunction with EN 1846-1, EN 1846-2 and EN 1846-3. Turntable ladder vehicles comprise a chassis, bodywork and a powered extending structure unit in the form of a ladder with or without a cage. Turntable ladder vehicles covered by this European Standard have a self-propelled chassis, the motor of which supplies the power required for the operation of the ladder. They do not permit operational movements to be made simultaneously. 1.2 This European Standard deals with the technical requirements to minimise the hazards listed in Clause 4 which can arise during the commissioning, the operational use and the routine checking and maintenance of turntable ladders when carried out in accordance with the specifications given by the manufacturer or the manufacturer authorised representative. It also deals with performance requirements. 1.3 This European Standard deals with the use of turntable ladder vehicles within a temperature range from - 15 °C to + 35 °C and with a wind velocity on the ladder set £ 12,5 m/s. Additional measures can be necessary for use outside this range (to be negotiated between the manufacturer and the user). NOTE Special designs for use under special climatic conditions should be by arrangement between the manufacturer and the purchaser. 1.4 This European Standard is not dealing with the hazards of the standard automotive chassis or due to use as a road vehicle. 1.5 This European Standard is not applicable to turntable ladders vehicles with sequential movements which are manufactured before the date of publication of this European Standard by CEN.

1.1 This European Standard specifies the safety and performance requirements and test methods applicable to turntable ladders with sequential movements of classes 18, 24 and 30, as defined in 3.13, under the control of firefighters and intended for fire fighting and rescuing people. NOTE This European Standard is intended to be used in conjunction with EN 1846-1, EN 1846-2 and EN 1846-3. Turntable ladder vehicles comprise a chassis, bodywork and a powered extending structure unit in the form of a ladder with or without a cage. Turntable ladder vehicles covered by this European Standard have a self-propelled chassis, the motor of which supplies the power required for the operation of the ladder. They do not permit operational movements to be made simultaneously. 1.2 This European Standard deals with the technical requirements to minimise the hazards listed in Clause 4 which can arise during the commissioning, the operational use and the routine checking and maintenance of turntable ladders when carried out in accordance with the specifications given by the manufacturer or the manufacturer authorised representative. It also deals with performance requirements. 1.3 This European Standard deals with the use of turntable ladder vehicles within a temperature range from - 15 °C to + 35 °C and with a wind velocity on the ladder set £ 12,5 m/s. Additional measures can be necessary for use outside this range (to be negotiated between the manufacturer and the user). NOTE Special designs for use under special climatic conditions should be by arrangement between the manufacturer and the purchaser. 1.4 This European Standard is not dealing with the hazards of the standard automotive chassis or due to use as a road vehicle. 1.5 This European Standard is not applicable to turntable ladders vehicles with sequential movements which are manufactured before the date of publication of this European Standard by CEN.

SIST EN 14044:2005 is classified under the following ICS (International Classification for Standards) categories: 13.220.10 - Fire-fighting; 97.145 - Ladders. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14044:2005 has the following relationships with other standards: It is inter standard links to SIST EN 14044:2005+A1:2009, SIST EN 14044:2005/oprA1:2008, SIST EN 14044:2005/AC:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14044:2005 is associated with the following European legislation: EU Directives/Regulations: 98/37/EC; Standardization Mandates: M/079. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase SIST EN 14044:2005 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Visoke nadzemne naprave za gasilske enote – Polavtomatske vrtljive gasilske avtolestve – Zahteve za varnost in obnašanje v uporabi in preskusne metodeHubrettungsfahrzeuge für die Feuerwehr - Drehleitern mit aufeinander folgenden (sequenziellen) Bewegungen (Halbautomatik-Drehleitern) - Sicherheits- und Leistungsanforderungen sowie PrüverfahrenMoyens élévateurs aériens pour la lutte contre l'incendie - Echelles pivotantes a mouvements séquentiels - Prescriptions de sécurité et de performances et méthodes d'essaisHigh rise aerial appliances for fire service use - Turntable ladders with sequential movements - Safety and performance requirements and test methods97.145LestveLadders13.220.10Gašenje požaraFire-fightingICS:Ta slovenski standard je istoveten z:EN 14044:2005SIST EN 14044:2005en01-december-2005SIST EN 14044:2005SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14044October 2005ICS 13.220.10 English VersionHigh rise aerial appliances for fire service use - Turntableladders with sequential movements - Safety and performancerequirements and test methodsMoyens élévateurs aériens pour la lutte contre l'incendie -Echelles pivotantes à mouvements séquentiels -Prescriptions de sécurité et de performances et méthodesd'essaisHubrettungsfahrzeuge für die Feuerwehr - Drehleitern mitaufeinander folgenden (sequenziellen) Bewegungen(Halbautomatik-Drehleitern) - Sicherheits- undLeistungsanforderungen sowie PrüverfahrenThis European Standard was approved by CEN on 29 August 2005.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2005 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14044:2005: ESIST EN 14044:2005

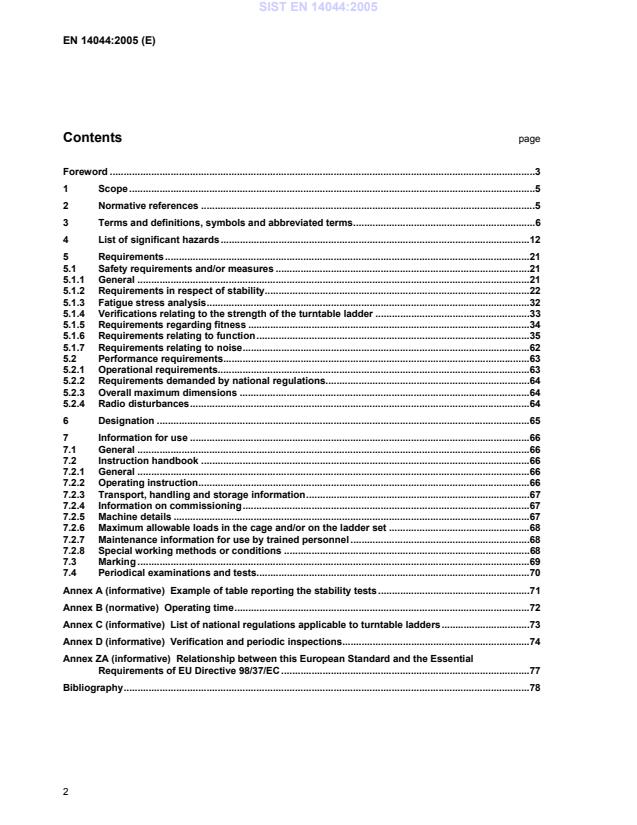

Example of table reporting the stability tests.71 Annex B (normative)

Operating time.72 Annex C (informative)

List of national regulations applicable to turntable ladders.73 Annex D (informative)

Verification and periodic inspections.74 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC.77 Bibliography.78

This European Standard has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association and supports essential requirements of EU Directive(s). For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this European Standard. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom. SIST EN 14044:2005

L distance, expressed in metres, between the extreme points of the extended ladder 3.5 rescue cage fixed or removable complementary device principally used for firefighting, rescuing people and other operational services 3.6 angle of elevation

αααα angle, expressed in degrees, between the longitudinal axis of the last (downmost) ladder section and the horizontal 3.7 camber angle

ββββ angle, expressed in degrees, in the transverse direction to the longitudinal axis of the vehicle between the horizontal and the ground surface SIST EN 14044:2005

γγγγ angle, expressed in degrees, in the longitudinal axis of the vehicle between the horizontal and the ground surface 3.9 training angle

θθθθ angle, expressed in degrees, determined cIockwise between the longitudinal axis of the vehicle and the longitudinal axis of the last ladder section projection NOTE The zero degrees position corresponds to the longitudinal axis of the vehicle facing towards the driver's cab. 3.10 rescue height

h vertical height, expressed in metres, from the horizontal ground surface to the base of the rescue cage without loading. The height of the topmost ladder round is taken as the rescue height in the case of turntable ladders without cage 3.11 nominal rescue height

hN specified height, expressed in metres, at nominal reach 3.12 maximum rescue height

hm height, expressed in metres, at the maximum angle of elevation and the maximum extension distance 3.13 ladder's class identification of a turntable ladder as class which corresponds to the value equal or immediately less than the maximum rescue height, expressed in metres 3.14 horizontal projection

l distance, expressed in metres, from the outer edge of the vehicle to the perpendicular dropped from the outer edge of the base of the rescue cage or the working platform or the projection from the outer edge of the vehicle to perpendicular from the topmost round NOTE 1 The measurement is taken at right angles to the longitudinal axis of the vehicle on horizontal terrain without loading. NOTE 2 If the jacks extend beyond the maximum width of the vehicle, the distance is measured from the outer edge of the most extended jack. 3.15 nominal rescue projection

lN specified horizontal projection at nominal rescue height; measured in accordance with 3.11, expressed in metres 3.16 nominal reach h-l coordinates derived from rescue height and horizontal projection NOTE Values for the nominal reaches may be specified in the regulations in force in each country (see 5.2.2). SIST EN 14044:2005

PN specified load, expressed in newtons, with which a rescue cage or the tip of the turntable ladder may be loaded vertically within the corresponding range of free-standing use NOTE 1 Permanently fixed equipment is not included in the nominal load. NOTE This nominal load may be exceeded to a certain extent (see 3.19 and 3.20). 3.18 test loads

PP specified loads applied in tests for stability, overload, and proper functioning etc. of the turntable ladder 3.19 supplementary load

PZ load permitted by the manufacturer in addition to the nominal load, e.g. loose equipment 3. 20 maximum working load

PL greatest load with which the turntable ladder may be loaded NOTE PL = PN + PZ 3.21 residual force

FR force (at any ladder position and loading within the range of use) which is transferred to the bearing surface on the unloaded side of the vehicle during operation of the turntable ladder (see Figure 4) NOTE For stability calculation front axle(s) is (are) not considered to be a bearing surface(s) in this instance. 3.22 range of use space within which the turntable ladder may be operated without endangering stability 3.22.1 range of free-standing use space in which the movement at the maximum working load PL permitted for this range does not endanger the stability of the turntable ladder, the head of the ladder set being unsupported 3.22.2 range of supported use space of use in which the movement without loading does not endanger stability of the turntable ladder. Within this space, the head of the turntable ladder set is supported, at the objective, before applying the load 3.23 boundary (see Figure 1) 3.23.1 free standing boundary boundary in the range of free-standing use within which movement is permitted with the load PL permitted for this range 3.23.2 supported boundary boundary in the range of supported use within which movement in this area is permitted SIST EN 14044:2005

Key 1 Free standing boundary (3.23.1) 2 Special boundary of use, load = 0 + turntable ladder equipment (3.23.3) 3 Supported boundary of use, load + cage = 0 (3.23.2) x = horizontal projection y = rescue height

Figure 1 — Example of boundary

3.24 jacking width b distance at right angles between two imaginary parallel lines to be drawn on either side of the central axis of the vehicle at the outer edges of the furthest extended and lowered jacks (see Figure 2)

NOTE It is assumed, for this measurement, that the vehicle is standing on a horizontal surface. SIST EN 14044:2005

Figure 2 — Jacking width 3.25 operating time

tR time required in order to reach, from the travel position, the maximum rescue height (at 90° to the longitudinal axis of the chassis) NOTE If appropriate the operating time (tR) includes the time for attaching the cage and making it ready for use with the ladder stabilized at maximum jacking width by the vehicle. 3.26 stability test – static verification test of a turntable ladder’s ability to resist tipping or rolling over with the ladder set not being moved under a load 3.27 stability test – dynamic verification test of a turntable ladder’s ability to resist tipping or rolling over with the ladder set being permitted to move under a load 3.28 static overload test static test of the turntable ladder for permanent deformation NOTE The static overload test is not a stability test. 3.29 test of fitness for purpose test to confirm the correct functioning of all the functions of a turntable ladder and its special equipment 3.30 forces and loads for calculations NOTE 1 Forces are expressed in newtons and are measured in the direction in which they act. NOTE 2 Loads are forces resulting from the mass of the components and are expressed in newtons. Their direction is the direction of the gravity. 3.30.1 static loads forces resulting from the masses, expressed in kilograms, which are not moved during operation of the turntable ladder SIST EN 14044:2005

A area of the floor minus the area occupied by fixed equipment located completely or partially within the rescue cage or its perpendicular projection with the exception of the handrail and dead man's pedal if this is located on the floor 3.32 plumbing (rounds) movement which allows the ladder rounds to be maintained horizontally 3.33 levelling (cage floor) movement which allows the cage floor to be maintained at right angles to the direction of gravity whatever may be its position on the ladder set 3.34 transport position (ladder with cage) position in which the jacks are housed, the ladder set being fully housed and resting on its gantry and the power supply to the ladder set being isolated and the rescue cage unfolded NOTE This position allows the vehicle to be moved a short distance. 3.35 travel position same conditions as the transport position and the following additional condition: the rescue cage is housed or stowed SIST EN 14044:2005

Key A First section B Intermediate sections C Last section Figure 3 — Designation of ladder set sections 4 List of significant hazards This clause contains all the significant hazards, hazardous situations and events, as far as they are dealt with in this European Standard, identified by risk assessment as significant for this type of machinery and which require action to eliminate or reduce the risk (see Table 1). Table 1 — List of significant hazards Clause/ subclause reference in EN 1050:1996 Hazard Assembly Process/Function/cause Clause/subclause in this European Standard or in others 1 Mechanical hazards 1.1 Crushing hazard Jacks Moving the jacks • 5.1.6.2.11 • 5.1.6.2.15 • 5.1.6.5.2 • 7

Pressure of the jacks on the ground • 5.1.6.5.2 • 5.1.6.2.12 • 5.1.6.2.13 • 5.1.6.2.14 • 7

Uncontrolled movement (lifting on • 5.1.6.2.14 SIST EN 14044:2005

Suspensions locking device Re-establishing ground contact with the tyres during return to travel position • 5.1.6.2.15

Defect in the suspension locking device on activation • 5.1.6.2.1 • 7

Cradle/turret Crushing by the training drive mechanism • 5.1.6.7.1

Crushing by the turntable in motion • 5.1.6.7.1 • 5.1.6.7.2

Crushing by the cradle in motion • 5.1.6.7.1

Ladder set Crushing between the rounds during extending and housing • 5.1.6.5.3 • 5.1.6.8.1 • 7

Rescue cage Crushing by mobile parts during levelling correction • 5.1.6.4.8

Impact against an obstacle • 5.1.6.4.3 • 5.1.6.4.12 • 5.1.6.4.14 • 5.1.6.5.3 • 5.1.6.5.5 • 5.1.6.8.5 • 7

Fitting/removal of the rescue cage • 5.1.6.4.6

Movement in the rescue cage • 5.1.6.4.13

Crushing a person outside the cage • 5.1.6.4.12 • 5.1.6.5.3 • 5.1.6.5.4 • 5.1.6.8.1 • 7 1.2 Shearing hazard Cradle/turret Crushing by the cradle in motion • 5.1.6.7.1 SIST EN 14044:2005

Ladder set Crushing between the rounds during extending and housing • 5.1.6.5.3 • 5.1.6.8.1

Rescue cage Crushing by mobile parts during levelling correction • 5.1.6.4.8

Impact against an obstacle • 5.1.6.4.12 • 5.1.6.5.3 • 5.1.6.5.5 1.3 Cutting or severing hazard General

• EN 1846-2

Ladder set Damaged wire ropes • 5.1.6.8.2 1.4 Entanglement hazard General All moving parts • 5.1.6.7.1 • 5.1.6.8.2 • 7

Jacks Movement of the jacks • 5.1.6.2.11 • 5.1.6.2.14 • 5.1.6.2.15 • 5.1.6.5.2 • 7

Cradle/turret Entanglement by pinion/crown • 5.1.6.7.2

Entanglement by the moving turret • 5.1.6.5.3 • 5.1.6.7.1 • 5.1.6.7.2

Rescue cage Cage deployment control • 5.1.6.5.4

Ladder set Entanglement by pulley and chains and entanglement by the winding drum• 5.1.6.8.2 1.5 Drawing-in or trapping hazard General Presence of a person in the working area

• 5.1.6.5.6 1.6 Impact hazard Jacks Movement of the jacks • 5.1.6.5.2 • 5.1.6.2.14 • 7 SIST EN 14044:2005

Put pressure on the ground • 5.1.6.5.2 • 5.1.6.2.14 • 7

Neutralisation suspension Re-establishing ground contact with the tyres during return to travel position • 5.1.6.2.15

Cradle/turret Crushing by the turret in motion • 5.1.6.5.3 • 5.1.6.7.1 • 5.1.6.7.2 • 7

Rescue cage Impact against an obstacle • 5.1.6.4.3 • 5.1.6.4.12 • 5.1.6.4.14 • 5.1.6.5.3 • 5.1.6.5.5 • 5.1.6.8.5 • 7 1.8 Friction or abrasion hazard General Moving parts • 5.1.6.7.3

Coupling, etc. • 5.1.6.9

• Wire ropes • Linkages • All hydraulic components • 7 1.9 High pressure fluid injection or ejection hazard Hydraulic drive systems Injury and/or contamination by leak or rupture • 5.1.6.9 • 7 2 Electrical hazards 2.1

Contact of persons with live parts (direct contact) Overall design General measures • EN 60204-1 2.2 Contact of persons with parts which have become live under faulty conditions (indirect contact) Overall design General measures • EN 60204-1 SIST EN 14044:2005

• 5.1.6.2.10 4 Hazard generated by noise 4.2 Interference with speech communication, acoustic signals, etc. Communication

• 5.1.6.8.6

Ladder Normal operation • 5.1.6.8.6 • 5.1.7 • EN 1846-2:2001, Annexes C

and F 6 Hazards generated by radiation 6.1 Low frequency, radio frequency radiation, micro waves General Normal operation • 5.1.6.16 8 Hazards generated by neglecting ergonomic principles in turntable ladder with sequential movement design 8.1 Unhealthy postures or excessive effort Ladder set Rescue • access

rescue cage/ladder • access ladder/chassis deck • access ladder/ground level • Emergency operating system

• 5.1.6.8.4

• 5.1.6.8.3

• 5.1.6.11.2

• 5.1.2.3.6

Rescue cage Fitting/removal • 5.1.6.4.6 8.2 Inadequate consideration of hand-arm or foot-leg anatomy Jack control consoleJack control • 5.1.6.5.1 • 5.1.6.5.2

Cradle/turret control console Cradle/turret movement control • 5.1.6.5.1 • 5.1.6.5.3 SIST EN 14044:2005

Ladder set control console Ladder set movement control • 5.1.6.5.1 • 5.1.6.5.3

Ladder set Access • 5.1.6.11.2 • 5.1.6.11.5

Rescue cage control console Ladder/cradle/turret movement • 5.1.6.5.1 • 5.1.6.5.5

Good visibility of the movement • 5.1.6.5.5

Main control console Access • 5.1.6.5.3 8.3 Neglected use of personal protection equipment General

• 7 8.4 Inadequate local lighting Control consoles Use of consoles • 5.1.6.5.1

Access to the main control console Use of consoles • 5.1.6.5.3 8.5 Mental overload and underload, stress All movements Use of controls without error • 5.1.6.5.1 • 5.1.6.5.2 • 5.1.6.5.3 • 5.1.6.5.5 8.6 Human error, human behaviour Control consoles

Operating controls/reading of information • 5.1.6.5 • 7 10 Unexpected start-up, unexpected overrun/overspeed (or any similar malfunction)

The whole ladder General operating • 5.1.6

Intentional stop or failure of the main power supply • 5.1.2.3.6 • 5.1.2.3.7 10.3 External influences on electrical equipment Electrical circuit and components General measures • 5.1.6.10 10.5 Errors in the software Software

• 5.1.6.12 13 Failure of the power supply

The whole ladder General operating • 5.1.2.3.6

Intentional stop or failure of the main power supply • 5.1.2.3.6 SIST EN 14044:2005

Jacks Rupture of the power supply of the components • 5.1.6.2.5

Suspension locking Rupture of the power supply of the components • 5.1.6.2.5

Cradle/turret Failure of the power supply of the components • 5.1.6.13.1

Ladder set Rupture of the power supply of the components • 5.1.6.13.1

Rescue cage Rupture of the power supply of the components • 5.1.6.13.1

Software Insufficient supply • 5.1.6.12.3 • 5.1.6.12.7 14 Failure of the control circuit

Jacks Failure in the control software • 5.1.6.12

Restarting • 5.1.6.5.1

Suspension locking Failure in the control software • 5.1.6.12

Restarting • 5.1.6.5.1

Cradle/turret Failure in the control software • 5.1.6.12

Restarting • 5.1.6.5.1

Failure of a drive or load retaining element • 5.1.6.13.1 • 5.1.6.13.2 • 5.1.6.13.3

Ladder set Failure in the control software • 5.1.6.12

Restarting • 5.1.6.5.1

Failure of a drive or load retaining element • 5.1.2 • 5.1.6.13.1 • 5.1.6.13.2 • 5.1.6.13.3

Rescue cage Failure in the control software • 5.1.6.12

Restarting • 5.1.6.5.1 SIST EN 14044:2005

Failure of a drive or load retaining element • 5.1.6.4.2 • 5.1.6.4.7 • 5.1.6.5.1

Analogue detectors Normal operation • 5.1.6.12.5 • 5.1.6.12.6

Logical detectors Normal operation • 5.1.6.12.2 • 5.1.6.12.4 • 5.1.6.12.6 • 7

Management of the stability Normal operation • 5.1.2.3.9

Operation without safety measures • 5.1.2.3.5 • 5.1.2.3.7 15 Errors of fitting

Rescue cage Fitting of the rescue cage to the tip of the ladder set • 5.1.6.4.6 • 5.1.6.4.7 17 Falling or ejected objects or fluids

General

• 5.1.6.9 • 7

Drive hydraulic systems Injury and/or contamination by leak or rupture • 5.1.6.9 • 7

Rescue cage Elements falling from the rescue cage • 5.1.6.4.3 • 5.1.6.4.5 • 5.1.6.4.11 18 Loss of stability/overturning of machinery

General All movements • 5.1.1 • 5.1.2

Jacks Unsuitable ground • 5.1.6.2.12 • 7

Movement of the vehicle • 5.1.6.1

Variation of stabilisation width • 5.1.6.2

Unevenness of the ground • 5.1.6.2.6 • 5.1.6.2.7 • 5.1.6.2.8 SIST EN 14044:2005

Stabilisation Ground pressure failure • 5.1.6.2.2 • 5.1.6.5.3 • 7

Technical defect • 5.1.1

Inadvertent operation • 5.1.6.2.4

Damage to the jacks due to external action • 5.1.6.2.11

Suspension locking Normal operation • 5.1.6.2.16

Cradle/turret Technical defect • 5.1.1

Exterior impact • 5.1.6.7.2

Ladder set Exceeding the stability limits • 5.1.2 • 5.1.6.3.3 • 5.1.6.3.4

Overload • 5.1.4

External influence by win load • 5.1.6.6 • 7

Exceeding the limits of free standing use in order to attain the limits of supported use • 5.1.2.3.2 • 7

Rescue cage Overload in the rescue cage • 5.1.6.4.13 • 7 19 Slip, trip and fall of persons (related to machinery)

Vehicle deck Standing or moving

• 5.1.6.11.1 • 5.1.6.11.3

Ladder set Rounds • 5.1.6.3.1 • 5.1.6.8.7 • 5.1.6.11.4

Rescue cage Defective horizontal alignment of the cage floor • 5.1.6.4.1 • 7

Access rescue cage/ladder • 5.1.6.4.9 SIST EN 14044:2005

Standing or moving on the platform surface • 5.1.6.11.1 • 5.1.6.11.3

Cradle/turret Access to main control console as required • 5.1.6.5.3

Ladder set Access • 5.1.6.8.3 • 5.1.6.8.4 • 7

Rescue cage Access rescue cage/ladder • 5.1.6.4.9 21.8 Noise at the work position Ladder Normal operation • 5.1.6.5.3 • EN 1846-2 35 Falling of person from person carrier

Rescue cage Falling from the rescue cage • 5.1.6.4.3 • 5.1.6.4.4 • 7 37 Human error, human behaviour

Control consoles Operating controls • 5.1.6.3 • 5.1.6.5 • 7

Reading of information • 5.1.6.5 • 7 5 Requirements 5.1 Safety requirements and/or measures 5.1.1 General Turntable ladders for fire service use shall comply with the safety requirements and/or protective measures of this subclause. In addition, they shall be designed according to the principles of EN ISO 12100 for hazards relevant but not significant, which are not dealt with by this European Standard (e.g. sharp edges). NOTE For hazards which are to be reduced by the application of a B-level such as EN 418, EN 457, EN 954-1, EN 982, EN 60204-1 and EN ISO 12100, the manufacturer should carry out a risk assessment to establish the requirements of the B-standard which are to be applied. This specific risk assessment should be part of the general risk assessment of the turntable ladder. SIST EN 14044:2005

All loads and forces which may act simultaneously shall be considered in their least favourable combination (see example in Figure 4). The following shall be taken into consideration in the calculation: a) Pitching inaccuracies as specified in Table 2; b) Variations resulting from manufacturing inaccuracies in the components; c) Tolerances for the mechanical linkages in the ladder set; d) Elastic deformation resulting from applied forces. NOTE b), c) and d) may be determined by experiment. SIST EN 14044:2005

Key 1 Force resulting from wind load, Fw 2 Force resulting from dead weight load, FG and FE 3 Force resulting from inertial forces, FN 4 Force resulting from the working load, FL 5 Force resulting from diverse forces (e.g. jet reaction), Fs 6 Force resulting from residual forces, FR 7 Angle being the combination of camber angle and gradient angle Figure 4 — Example of forces acting on turntable ladder 5.1.2.1.2 Calculation of the working load (see Figure 5) The working load shall be assumed to be a point concentrated on the base of the rescue cage acting at the centre of area of the base. The area of the cage base is the area within the upper handrail and not the area determined in accordance with 5.1.6.4.13. For ladders without rescue cage, the mass shall be applied at the end of the ladder set, in the centre of the last round. The mass corresponding to the supplementary load to be taken into account shall be at least 25 kg. SIST EN 14044:2005

Key P point of application of the working load Figure 5 — Resulting force of the working load 5.1.2.1.3 Calculation of wind loads 5.1.2.1.3.1 All turntable ladder vehicles used in the open air shall be considered as being subjected to wind with a static pressure of 100 N/m2 which corresponds to a wind velocity of 12,5 m/s (6 on the Beaufort scale). Wind forces shall be calculated by assuming that the wind is horizontal and acts on the surfaces of components exposed to the wind and to be dynamic forces acting at their centres of areas. 5.1.2.1.3.2 For the calculation of forces resulting from wind, ISO 4302 shall apply in particular for covered surfaces of components (see 5.1.2.1.3.3 for partially shielded persons). NOTE Wind forces can be calculated using the following formula:

Fw = q.Aproj., where q is the impact pressure of 100 N/mm² and Aproj. the outside surface of the ladder 5.1.2.1.3.3 The area of an occupied cage exposed directly to the wind is calculated by multiplying the width of the side of the working cage exposed to the wind, rounded up to the nearest 0,5 m, by the overall height of the cage plus 0,4 m (see Figure 6). Example: if the width of the cage exposed to the wind is 1,25 m and the overall height of the cage is 1,15 m, the area exposed to the wind is 1,5 m × (1,15 m + 0,4 m) = 2,325 m2. SIST EN 14044:2005

Key 1

Overall height of cage 2

Width exposed to the wind Figure 6 — Surface exposed to the wind 5.1.2.1.3.4 The wind force acting on the equipment in the rescue cage is calculated as a force equal to 3 % of dead weight (see Table 1) of the equipment acting at a point 0,5 m above the base of the rescue cage. 5.1.2.1.4 Calculation of manual force The minimum value for the manual force is assumed to be 200 N for turntable ladder vehicles. The manual force acts at a height of 1,1 m over the base of the rescue cage. Any greater permissible force shall be specified by the manufacturer. 5.1.2.1.5 Safety factors for turntable ladders 5.1.2.1.5.1 Table 2 and Figures 4 and 5 shall be used for the load calculations. SIST EN 14044:2005

Symbol Unit Direction of action Factors for use in calculations Speed of movement V m/s - ≤ 0,7 > 0,7 Forces engendered by gravity (dead weight) FG N vertical 1,0 × FG Force engendered by working load (applied load) FL N vertical 1,25 × FL Inertial forces FN N

tangential to direction of movement 0,1 × FE

+ 0,1 × FL 0,2 × FE

+ 0,2 × FL Wind forces FW N horizontal 1,1 × FW Diverse forces FS N Selected angle1,1 × FS Key

FL = PL × g (N) FE is the force engendered by the unloaded ladder set (N) = mE × g mE is the mass of the ladder set (kg) FG = mG × g (N) g = 9,81 (m/s2) mG is the mass (kg) NOTE Pitching inaccuracies (sloping ground) : 0,5 (see 5.1.2.1.5.8).

5.1.2.1.5.2 Forces engendered by gravity (FG and FE) which generate a tilting moment and/or righting moment, are multiplied by the factor of 1,0. They are assumed to be acting vertically downwards. 5.1.2.1.5.3 Forces engendered by the gravity of the maximum working load (FL), which create a tilting moment and/or righting moment are multiplied by the factor of 1,25. They are assumed to be acting vertically downwards. 5.1.2.1.5.4 Inertial forces engendered by masses in motion (mass forces FN) are multiplied by a factor of 0,1 for V ≤ 0,7 m/s and by the factor of 0,2 for V> 0,7 m/s. They are assumed to act tangentially to the direction of movement which generates the maximum tilting moment and applied to the centre of gravity of the structure in motion. 5.1.2.1.5.5 Diverse forces (FS) (e.g. manual forces, reaction to a water jet .) are multiplied by the factor of 1,1 and assumed to act in the direction of movement which generates the maximum tilting moment. 5.1.2.1.5.6 Wind forces (FW) having an influence on stability are multiplied by the factor of 1,1. They are assumed to act horizontally. 5.1.2.1.5.7 The absolute velocity at the head of the extended ladder set under normal working conditions shall be taken as the speed of movement V. 5.1.2.1.5.8 Forces resulting from 0,5° pitching inaccuracies in turntable ladders shall also be taken into consideration (see Table 2 and 5.1.2.1.1). 5.1.2.2 Practical requirements

5.1.2.2.1 Static stability

The minimum residual force FRmin shall be greater than or equal to 6 % of the corresponding mass of the total vehicle, minus the driver's and equipment's masses, in all permissible ladder positions and in the least favourable SIST EN 14044:2005

The test load shall be as specified above. The test load shall be applied once the boundary of use is reached. PZ = 0 kg for vehicles without a cage and if no load is applied. The point of application of the test load shall be: in the case of turntable ladders without cage: the last round of the ladder (see Figure 7); in the case of turntable ladders with cage: at the centre of gravity of the cage base (see Figure 8). The minimum load value FE shall comply with the requirements of 5.1.2.1 in each test. The ladder shall be elevated to as small an angle (α) as possible whilst permitting training (θ) of the turntable ladder from 0° to 180°. The ladder shall be trained at right angles to the long axis of the vehicle, taking care that the ladder is extended to its maximum limit. An example of table to report the stability test is given in Annex A (see Table A.1). 5.1.2.2.2 Dynamic stability

The minimum residual force FRmin shall be greater than 0 in the least favourable position of the turntable ladder. For the dynamic test, stability shall be demonstrated using

...

Die Norm SIST EN 14044:2005 legt umfassende Sicherheits- und Leistungsanforderungen sowie Prüfmethoden für Drehleiterfahrzeuge mit sequentiellen Bewegungen fest. Diese Norm ist von entscheidender Bedeutung für die Effektivität und Sicherheit von Drehleitern der Klassen 18, 24 und 30, die von Feuerwehrleuten zur Brandbekämpfung und Menschenrettung eingesetzt werden. Ein wesentlicher Schwerpunkt dieser Norm liegt auf den technischen Anforderungen, die darauf abzielen, potenzielle Gefahren während der Inbetriebnahme, des Betriebs sowie der regelmäßigen Kontrolle und Wartung der Drehleitern zu minimieren. Durch eine präzise Spezifikation der Sicherheitsanforderungen wird gewährleistet, dass die Fahrzeuge den strengen Vorgaben des Herstellers entsprechen, was für die Betriebssicherheit von zentraler Bedeutung ist. Ein weiterer Vorteil dieser Norm ist die Berücksichtigung von Leistungsanforderungen, die sicherstellt, dass die Drehleiterfahrzeuge auch unter extremen Bedingungen, wie einem Temperaturbereich von -15 °C bis +35 °C und einer maximalen Windgeschwindigkeit von 12,5 m/s, effizient betrieben werden können. Dies erhöht nicht nur die Zuverlässigkeit der Ausrüstung, sondern auch die Sicherheit der Einsatzkräfte. Darüber hinaus stellt die Norm klar, dass spezielle Designs für besondere klimatische Bedingungen zwischen Hersteller und Nutzer vereinbart werden müssen, wodurch der Raum für maßgeschneiderte Lösungen erweitert wird. Dies unterstreicht die Flexibilität und Anpassungsfähigkeit der Norm an unterschiedliche Einsatzszenarien. Die SIST EN 14044:2005 ist ein unverzichtbares Dokument für die Hersteller von Drehleitern und für die Feuerwehrleute, die diese Geräte bedienen. Die Standardisierung in diesem Bereich trägt nicht nur zur Verbesserung der Sicherheit bei, sondern auch zur Harmonisierung der Verfahren und Ausstattungen innerhalb der EU, was die Einsatzbereitschaft der Feuerwehr im gesamten europäischen Raum stärkt.

La norme SIST EN 14044:2005 définit de manière précise les exigences de sécurité et les performances ainsi que les méthodes d'essai applicables aux échelles à plate-forme rotative à mouvements séquentiels, de classes 18, 24 et 30, utilisées par les services d'incendie pour la lutte contre les incendies et le sauvetage de personnes. L'un des points forts de cette norme réside dans sa portée, car elle couvre non seulement les aspects techniques minimisant les risques liés à l'utilisation des échelles, mais également les exigences de performance essentielles pour garantir leur efficacité lors des opérations de secours. En encadrant les conditions d'utilisation dans une plage de température spécifique et en tenant compte de la vitesse du vent, cette norme garantit des opérations sûres et fiables, ce qui est crucial pour la sécurité des pompiers et des victimes potentielles. De plus, la norme SIST EN 14044:2005 souligne l'importance de la conformité aux spécifications du fabricant ou de son représentant autorisé, ce qui renforce la protection contre les dangers identifiés dans le Clause 4. Cela montre une approche systématique qui favorise la maintenance régulière et la vérification des échelles à plate-forme, minimisant ainsi les risques lors de leur emploi opérationnel. En permettant un usage adapté et sûr des véhicules équipés d'échelles à plate-forme, et en laissant place à des discussions entre le fabricant et l'utilisateur pour des conditions climatiques particulières, cette norme se révèle non seulement pertinente, mais également flexible. Cela est d'une importance capitale dans le domaine des services d'incendie, où les conditions opérationnelles peuvent varier considérablement. En résumé, la norme SIST EN 14044:2005 se distingue par ses exigences rigoureuses en matière de sécurité, son application dans des conditions pragmatiques et son renforcement de la performance des échelles à plate-forme rotative, rendant ainsi ce document essentiel pour les professionnels de la lutte contre les incendies.

The SIST EN 14044:2005 standard provides essential guidelines for the safety and performance requirements applicable to high rise aerial appliances, specifically focusing on turntable ladders with sequential movements. The standard clearly delineates its scope, which includes classes 18, 24, and 30 of turntable ladder vehicles intended for firefighting and rescues conducted by firefighters. This structured approach ensures that all vehicles meet stringent requirements, thereby enhancing safety for both users and individuals being rescued. One of the significant strengths of this standard is its comprehensive specifications regarding testing methods, which allows for consistent evaluation across different manufacturers. It emphasizes the importance of following the manufacturer’s specifications during commissioning, operational use, and routine maintenance checks, thereby minimizing potential hazards identified in Clause 4. The performance requirements outlined in this standard further underpin its relevance, ensuring that turntable ladder vehicles operate effectively within defined conditions, such as a temperature range from -15 °C to +35 °C and with limited wind velocities. The provision for negotiating additional measures for operation outside these conditions demonstrates the standard's flexibility while maintaining a focus on safety. Additionally, the exclusion of hazards related to standard automotive chassis and non-applicable vehicles manufactured before the publication date enhances the clarity of the standard, ensuring that users and manufacturers are aware of its limits and applications. Overall, the SIST EN 14044:2005 standard is a vital document that not only protects firefighters but also reinforces the efficiency and reliability of turntable ladders in high-stakes situations. Its clear guidelines and performance parameters are instrumental in driving improvements in fire service aerial technology.

SIST EN 14044:2005 は、消防用の自動車式旋回はしご(ターンテーブルラダー)に関連する安全性と性能要件を定めた重要な欧州規格です。本規格は、階級18、24、30の旋回はしごに適用され、消防士によって操作されることを想定しています。この標準化文書は、消防活動や人命救助における安全を確保するための基盤を提供しており、その関連性は非常に高いと言えます。 本規格の強みの一つは、旋回はしごの動作における安全基準を厳格に定め、具体的には、委託や日常の点検・保守を行う際に発生しうる危険を最小限に抑える技術的要件を網羅している点です。また、-15℃から+35℃の温度範囲および風速12.5m/sまでの条件下での使用を考慮しており、特定の気象条件下で特別な設計が必要となる場合についても言及されています。 さらに、本規格は旋回はしごの動作が同時に行われないことを明確にし、事故防止に向けた効果的な運用が求められています。加えて、EN 1846-1、EN 1846-2、EN 1846-3 と併せて利用することが想定されており、他の関連規格と整合性を持たせています。これにより、既存の標準と連携しながら、包括的な安全保障を実現しています。 総じて、SIST EN 14044:2005 は、消防用のターンテーブルラダーの安全性、性能、試験方法に関する標準として、その適用範囲が広く、消防士の安全を守るための不可欠なガイドラインを提供しています。その内容は、現場での実用性が高く、消防業務に従事する全ての関係者にとって非常に重要な参考資料となっています。

SIST EN 14044:2005는 소방 서비스 사용을 위한 고층 공중 장비에 대한 표준으로, 순차적으로 움직이는 회전식 사다리에 대한 안전 및 성능 요구사항과 테스트 방법을 규정하고 있습니다. 이 표준은 18, 24, 30 클래스의 회전식 사다리에 적용되며, 소방관의 통제 하에 화재 진압 및 구조 작업을 위한 목적으로 설계되었습니다. 이 표준의 주요 강점 중 하나는 고온 및 저온 환경에서의 작동을 보장하는 기술 요구사항을 포괄하고 있다는 점입니다. SIST EN 14044:2005는 -15도에서 +35도 사이의 온도 범위와 바람 속도 12.5m/s 이하에서의 사용을 다루고 있어, 다양한 기후 조건에서도 소방 작업의 안전성을 확보할 수 있습니다. 또한, 고객과 제조사 간의 협의를 통해 특별한 기후 조건에 따르는 설계에 대해서도 다룰 수 있는 유연성을 제공합니다. 또한, 이 표준은 제조업체가 제공한 사양에 따라 회전식 사다리를 운영하거나 정기적으로 점검 및 유지보수할 때 발생할 수 있는 위험 요소를 최소화하기 위한 기술적 요구 사항을 포함하고 있습니다. 따라서, 해당 모델의 안전성과 성능에 대한 신뢰성을 높일 수 있는 중요한 문서라 할 수 있습니다. SIST EN 14044:2005는 EN 1846-1, EN 1846-2, EN 1846-3과 함께 사용되도록 설계되어 있어, 다른 관련 표준들과의 연계성을 통해 통합적인 안전 기준을 제공함으로써 전반적인 소방 장비의 성능을 향상시키는 데 기여합니다. 이번 표준은 회전식 사다리 차량에 대해 자주 발생할 수 있는 문제를 사전에 예방할 수 있는 키 요소들을 정의하여, 실제 운영 상황에서도 안전하게 사용할 수 있도록 하고 있습니다. 이러한 점에서 SIST EN 14044:2005는 소방 서비스에 필수적인 기술적 기준을 제시하며, 관련 산업 및 사용자에게 높은 수준의 안전과 성능을 보장하는 중요한 역할을 합니다.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...