ASTM A48/A48M-03(2008)

(Specification)Standard Specification for Gray Iron Castings

Standard Specification for Gray Iron Castings

ABSTRACT

This specification covers gray iron castings intended for general engineering use where tensile strength is a major consideration. Castings are classified on the basis of the tensile strength of the iron in separately cast test bars. The surface of the casting shall be free of adhering sand, scale, cracks, and hot tears, as determined by visual examination. The test bars are designated into S, A, B, and C categories, according to the thickness of its controlling wall section. The casting shall be subjected to a tension test to determine its tensile strength.

SCOPE

1.1 This specification covers gray iron castings intended for general engineering use where tensile strength is a major consideration. Castings are classified on the basis of the tensile strength of the iron in separately cast test bars.

1.1.1 This specification subordinates chemical composition to tensile strength.

1.2 Castings produced to this specification are graded on the basis of minimum tensile strength obtained in special test coupons designed to standardize cooling rate. The tensile strength developed in certain casting sections may vary from test coupon values (see X1.2).

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A48/A48M −03(Reapproved 2008)

Standard Specification for

Gray Iron Castings

This standard is issued under the fixed designation A48/A48M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

This specification replaces Federal Specification QQ-I-652.

1. Scope 3.1.1 Definitions for many terms common to gray iron

castings are found in Terminology A644.

1.1 This specification covers gray iron castings intended for

general engineering use where tensile strength is a major

4. Classification

consideration. Castings are classified on the basis of the tensile

4.1 Castings ordered and produced in accordance with this

strength of the iron in separately cast test bars.

specificationareclassifiedintoanumberofgradesbasedonthe

1.1.1 This specification subordinates chemical composition

properties of separately cast test bars (Table 1, Table 2). Each

to tensile strength.

class is designated by a number followed by a letter. The

1.2 Castings produced to this specification are graded on the

number indicates the minimum tensile strength of the sepa-

basis of minimum tensile strength obtained in special test

rately cast test bar, and the letter indicates the size of the test

coupons designed to standardize cooling rate. The tensile

bar. Examples of proper designations are as follows:

strength developed in certain casting sections may vary from

Gray Iron Castings, ASTM Specification A48, Class 30B.

test coupon values (see X1.2).

Gray Iron Castings, ASTM Specification A48, Class 40C.

1.3 The values stated in either SI units or inch-pound units

5. Ordering Information

are to be regarded separately as standard. The values stated in

5.1 Orders for material to this specification shall include the

each system may not be exact equivalents; therefore, each

following information:

system shall be used independently of the other. Combining

5.1.1 ASTM designation number and year of issue,

values from the two systems may result in non-conformance

5.1.2 Class of iron required (see 4.1, Table 1, and Table 2),

with the standard.

5.1.3 The size of the separately cast test bar (letter

classification—A, B, C, or S) that best represents the thickness

2. Referenced Documents

of the controlling section of the casting (see Table 3),

2.1 ASTM Standards:

5.1.4 The tension test specimen (B or C) to be machined

A644 Terminology Relating to Iron Castings

from test bar C (see 13.3, Table 4, and Fig. 1),

E8 Test Methods for Tension Testing of Metallic Materials

5.1.5 The tension test specimen to be machined from test

2.2 Military Standard:

bar S (see 13.4, Table 4, and Fig. 1),

MIL-STD-129 Marking for Shipment and Storage

5.1.6 Lot size (see Section 10),

5.1.7 Special requirements (see Section 6),

2.3 Federal Standard:

5.1.8 Saving tested specimens or unbroken test bars (see

Federal Standard No. 123 Marking for Shipment (Civil

15.1), and

Agencies)

5.1.9 Special preparation for delivery (see Section 19).

3. Terminology

6. Special Requirements

3.1 Definitions:

6.1 When agreed upon in writing between the manufacturer

and the purchaser, it may be necessary for the castings to meet

special requirements as to hardness, chemical composition,

This specification is under the jurisdiction of ASTM Committee A04 on Iron

microstructure, pressure tightness, radiographic soundness,

CastingsandisthedirectresponsibilityofSubcommitteeA04.01onGreyandWhite

dimensions, surface finish, and so forth.

Iron Castings.

Current edition approved Oct. 1, 2008. Published November 2008. Originally

7. Tensile Requirements

approved in 1905. Last previous edition approved in 2003 as A48/A48M – 03. DOI:

10.1520/A0048_A0048M-03R08.

7.1 Test bars representing castings conforming to this speci-

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

fication shall meet the requirements for tensile strength as

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

www.dodssp.daps.mil. described in Table 1 and Table 2.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

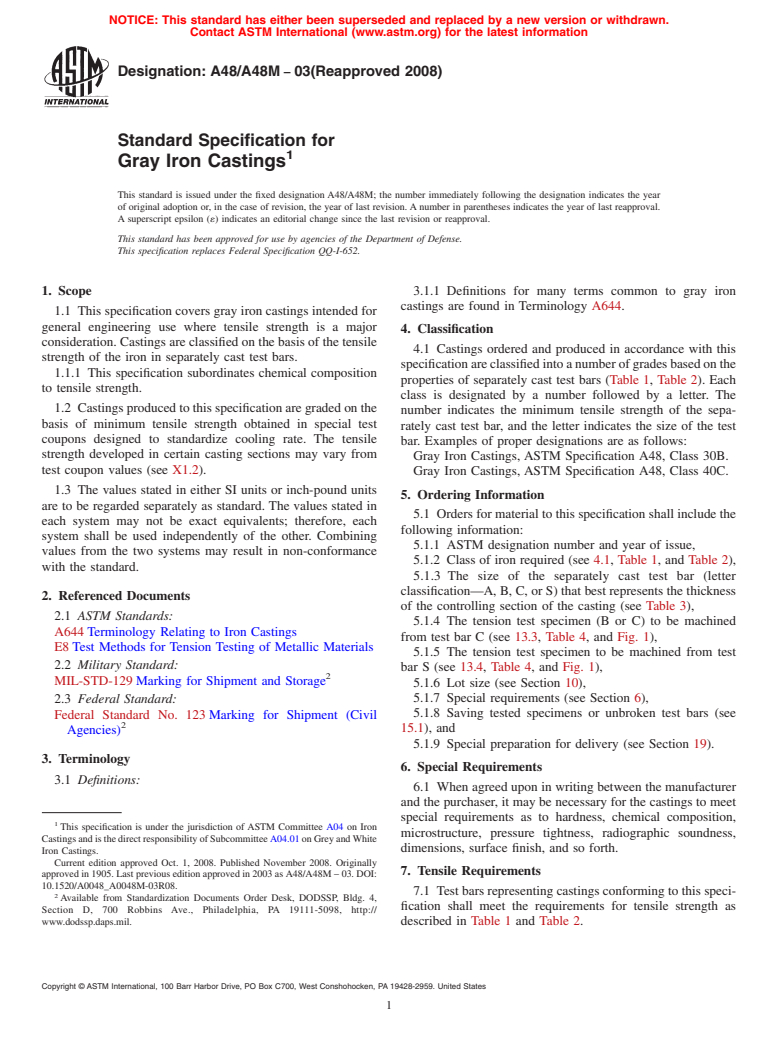

A48/A48M−03 (2008)

TABLE 1 Requirements for Tensile Strength of Gray Cast Irons in TABLE 2 Requirements for Tensile Strength of Gray Cast Irons in

Separately Cast Test Bars (Inch-Pound) Separately Cast Test Bars (Metric)

Tensile Strength, Nominal Test Bar Tensile Strength, Nominal Test Bar

Class Class

min, ksi Diameter, in. min, ksi [MPa] Diameter, in. [mm]

No. 20 A 20 0.8 No. 150A 150 20 to 22

No. 20 B 1.2 No. 150B 30

No. 20 C 2.0 No. 150C 50

A A

No. 20 S Bars S No. 150S Bars S

No. 25 A 25 0.88 No. 175A 175 20 to 22

No. 25 B 1.2 No. 175B 30

No. 25 C 2.0 No. 175C 50

A A

No. 25 S Bars S No. 175S Bars S

No. 30 A 30 0.88 No. 200A 200 20 to 22

No. 30 B 1.2 No. 200B 30

No. 30 C 2.0 No. 200C 50

A A

No. 30 S Bars S No. 200S Bars S

No. 35 A 35 0.88 No. 225A 225 20 to 22

No. 35 B 1.2 No. 225B 30

No. 35 C 2.0 No. 225C 50

A A

No. 35 S Bars S No. 225S Bars S

No. 40 A 40 0.88 No. 250A 250 20 to 22

No. 40 B 1.2 No. 250B 30

No. 40 C 2.0 No. 250C 50

A A

No. 40 S Bars S No. 250S Bars S

No. 45 A 45 0.88 No. 275A 275 20 to 22

No. 45 B 1.2 No. 275B 30

No. 45 C 2.0 No. 275C 50

A A

No. 45 S Bars S No. 275S Bars S

No. 50 A 50 0.88 No. 300A 300 20 to 22

No. 50 B 1.2 No. 300B 30

No. 50 C 2.0 No. 300C 50

A A

No. 50 S Bars S No. 300S Bars S

No. 55 A 55 0.88 No. 325A 325 20 to 22

No. 55 B 1.2 No. 325B 30

No. 55 C 2.0 No. 325C 50

A A

No. 55 S Bars S No. 325S Bars S

No. 60 A 60 0.88 No. 350A 350 20 to 22

No. 60 B 1.2 No. 350B 30

No. 60 C 2.0 No. 350C 50

A A

No. 60 S Bars S No. 350S Bars S

A

AlldimensionsoftestbarSshallbeasagreeduponbetweenthemanufacturer

No. 375A 375 20 to 22

and the purchaser.

No. 375B 30

No. 375C 50

A

No. 375S Bars S

No. 400A 400 20 to 22

8. Dimensional Requirements No. 400B 30

No. 400C 50

A

8.1 The castings shall conform to the dimensions or draw-

No. 400S Bars S

ings furnished by the purchaser, or, if there are no drawings, to A

AlldimensionsoftestbarSshallbeasagreeduponbetweenthemanufacturer

and the purchaser.

the dimensions predicted by the pattern equipment supplied by

the purchaser.

10.1.1 All the metal poured from a single heating in a batch

9. Workmanship and Finish

type melting furnace.

9.1 The surface of the casting shall be free of adhering sand,

10.1.2 All the metal from two or more batch type melting

scale, cracks, and hot tears, as determined by visual examina-

furnaces poured into a single ladle or a single casting.

tion.

10.1.3 All the metal poured from a continuous melting

9.2 No repairing by plugging or welding of any kind shall

furnace for a given period of time between changes in charge,

be permitted unless written permission is granted by the

processing conditions, or aim-for chemistry or 4 h, whichever

purchaser.

is the shorter period.

10.1.3.1 The purchaser may agree to extend the 4-h time

10. Sampling

period to8hifthe manufacturer can demonstrate sufficient

10.1 A lot shall consist of one of the following: process control to warrant such an extension.

A48/A48M−03 (2008)

TABLE 3 Separately Cast Test Bars for Use When a Specific

12.3 If the results of a valid test fail to conform to the

Correlation Has Not Been Established Between the Test Bar and

requirements of this specification, two retests shall be made. If

the Casting

either retest fails to meet the specification requirements, the

Thickness of the Wall of the Controlling

Test Bar castings represented by these test specimens shall be rejected.

Section of the Casting, in. [mm]

A valid test is one wherein the specimen has been properly

Under 0.25 [under 5] S

prepared and appears to be sound and on which the approved

0.25 to 0.50 [5 to 14] A

0.51 to 1.00 [15 to 25] B

test procedure has been followed.

1.01 to 2 [26 to 50] C

Over 2 [over 50] S 12.4 Ifsufficientseparatelycasttestpiecesarenotavailable,

the manufacturer shall have the option of removing a test

specimen from a location of representative casting, as agreed

upon between the manufacturer and purchaser.

12.5 If the first test results indicate that a heat treatment is

11. Cast Test Bars

needed to meet the test requirements, the entire lot of castings

11.1 Test bars shall be separate castings poured from the

and the representative test specimens shall be heat treated

same lot as the castings they represent and shall have dimen-

together. Testing shall proceed in accordance with 12.1-12.3.

sions as shown in Table 4. Allowance may be made for

12.6 If, after testing, a test specimen shows evidence of a

reasonablepatterndraftwithinthetolerancesshowninTable4.

defect, the results of the test may be invalidated and another

Test bars A, B, and C are all standard test bars in the form of

made on a specimen from the same lot.

simple cylinders. Test bar S is special and is intended for use

where the standard bars are not satisfactory.

13. Tension Test Specimens

11.2 The test bars shall be cast in dried, baked, or chemi-

13.1 For test Bar A, the tension-test specimen A, as shown

cally bonded molds made mainly of an aggregate of siliceous

in Fig. 1, shall be machined concentric with the axis of the test

sand with appropriate binders. The average grain size of the

bar.

sand shall approximate that of the sand in which the castings

are poured. Molds for the test bars shall be approximately at

13.2 For test Bar B, the tension test specimen B, as shown

room temperature when poured. More than one test bar may be

in Fig. 1, shall be machined concentric with the axis of the test

cast in a single mold, but each bar in the mold shall be

bar.

surrounded by a thickness of sand which is not less than the

13.3 For test Bar C, tension test specimens B or C, as shown

diameter of the bar. A suitable design for a mold is shown in

in Fig. 1, shall be machined concentric with the axis of the test

Fig. 2.

bar.Unlessthesizeofthetensiontestspecimentobemachined

NOTE 1—The intent of these provisions is as follows: to prohibit the

from test bar C is specified in writing by the purchaser, the

casting of test bars in molds of metal, graphite, zircon, light-weigh

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A48/A48M–00 Designation: A 48/A 48M – 03 (Reapproved 2008)

Standard Specification for

Gray Iron Castings

This standard is issued under the fixed designation A 48/A 48M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense. This specification replaces Federal Specification

QQ-I-652.

1. Scope

1.1 This specification covers gray iron castings intended for general engineering use where tensile strength is a major

consideration. Castings are classified on the basis of the tensile strength of the iron in separately cast test bars.

1.1.1 This specification subordinates chemical composition to tensile strength.

1.2 Castings produced to this specification are graded on the basis of minimum tensile strength obtained in special test coupons

designed to standardize cooling rate. The tensile strength developed in certain casting sections may vary from test coupon values

(see X1.2).

1.3 The values stated in either inch-poundSI units or SIinch-pound units are to be regarded separately as standard. Within the

text, the SI units are shown in brackets. The values stated in each system aremay not be exact equivalents; therefore, each system

shall be used independently of the other. Combining values from the two systems may result in non-conformance with the

specification. standard.

2. Referenced Documents

2.1 ASTM Standards:

A 644 Terminology Relating to Iron Castings

E 8 Test Methods for Tension Testing of Metallic Materials

2.2 Military Standard:

MIL-STD-129 Marking for Shipment and Storage

2.3 Federal Standard:

Federal Standard No. 123 Marking for Shipment (Civil Agencies)

3. Terminology

3.1 Definitions:

3.1.1 Definitions for many terms common to gray iron castings are found in Terminology A 644.

4. Classification

4.1 Castings ordered and produced in accordance with this specification are classified into a number of grades based on the

properties of separately cast test bars (Table 1, Table 2). Each class is designated by a number followed by a letter. The number

indicates the minimum tensile strength of the separately cast test bar, and the letter indicates the size of the test bar. Examples of

proper designations are as follows:

Gray Iron Castings, ASTM Specification A 48, Class 30B.

Gray Iron Castings, ASTM Specification A 48, Class 40C.

5. Ordering Information

5.1 Orders for material to this specification shall include the following information:

5.1.1 ASTM designation number and year of issue,

5.1.2 Class of iron required (see 4.1and , Table 1, and Table 2),

This specification is under the jurisdiction of ASTM Committee A04 on Iron Castings and is the direct responsibility of Subcommittee A04.01 on Gray Iron Castings.

Current edition approved May 10, 2000. Published June 2000. Originally published as A48–05. Last previous edition A48–94a.

This specification is under the jurisdiction of ASTM Committee A04 on Iron Castings and is the direct responsibility of Subcommittee A04.01 on Grey and White Iron

Castings.

Current edition approved Oct. 1, 2008. Published November 2008. Originally approved in 1905. Last previous edition approved in 2003 as A 48/A 48M – 03.

Annual Book of ASTM Standards, Vol 01.02.

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://www.dodssp.daps.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 48/A 48M – 03 (2008)

TABLE 1 Requirements for Tensile Strength of Gray Cast Irons

in Separately Cast Test Bars (Inch-Pound)

Tensile Strength, Nominal Test Bar

Class

min, ksi [MPa] Diameter, in. [mm]

No. 20 A 20 (138) 0.88 (22.4)

No. 20 A 20 0.8

No. 20 B 1.2 (30.5)

No. 20 B 1.2

No. 20 C 2.0 (50.8)

No. 20 C 2.0

A

No. 20 S Bars S

No. 25 A 25 (172) 0.88 (22.4)

No. 25 A 25 0.88

No. 25 B 1.2 (30.5)

No. 25 B 1.2

No. 25 C 2.0 (50.8)

No. 25 C 2.0

A

No. 25 S Bars S

No. 30 A 30 (207) 0.88 (22.4)

No. 30 A 30 0.88

No. 30 B 1.2 (30.5)

No. 30 B 1.2

No. 30 C 2.0 (50.8)

No. 30 C 2.0

A

No. 30 S Bars S

No. 35 A 35 (241) 0.88 (22.4)

No. 35 A 35 0.88

No. 35 B 1.2 (30.5)

No. 35 B 1.2

No. 35 C 2.0 (50.8)

No. 35 C 2.0

A

No. 35 S Bars S

No. 40 A 40 (276) 0.88 (22.4)

No. 40 A 40 0.88

No. 40 B 1.2 (30.5)

No. 40 B 1.2

No. 40 C 2.0 (50.8)

No. 40 C 2.0

A

No. 40 S Bars S

No. 45 A 45 (310) 0.88 (22.4)

No. 45 A 45 0.88

No. 45 B 1.2 (30.5)

No. 45 B 1.2

No. 45 C 2.0 (50.8)

No. 45 C 2.0

A

No. 45 S Bars S

No. 50 A 50 (345) 0.88 (22.4)

No. 50 A 50 0.88

No. 50 B 1.2 (30.5)

No. 50 B 1.2

No. 50 C 2.0 (50.8)

No. 50 C 2.0

A

No. 50 S Bars S

No. 55 A 55 (379) 0.88 (22.4)

No. 55 A 55 0.88

No. 55 B 1.2 (30.5)

No. 55 B 1.2

No. 55 C 2.0 (50.8)

No. 55 C 2.0

A

No. 55 S Bars S

No. 60 A 60 (414) 0.88 (22.4)

No. 60 A 60 0.88

No. 60 B 1.2 (30.5)

No. 60 B 1.2

No. 60 C 2.0 (50.8)

No. 60 C 2.0

A

No. 60 S Bars S

A

AlldimensionsoftestbarSshallbeasagreeduponbetweenthemanufacturer

and the purchaser.

A 48/A 48M – 03 (2008)

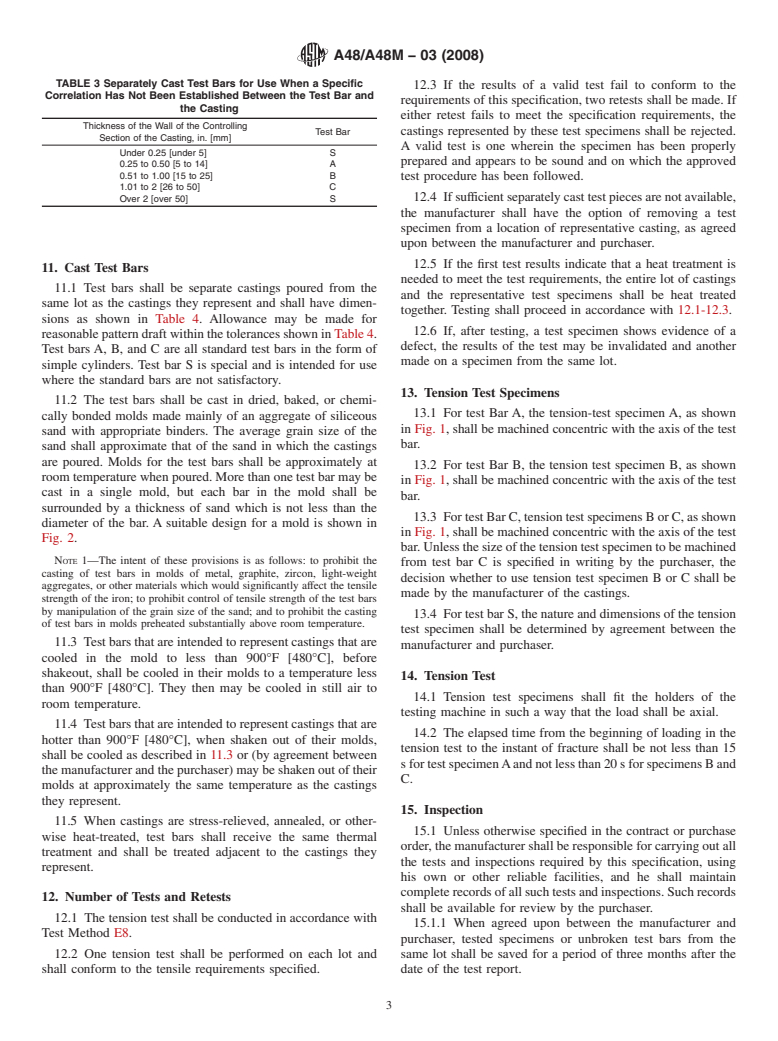

TABLE 2 Requirements for Tensile Strength of Gray Cast Irons

in Separately Cast Test Bars (Metric)

Tensile Strength, Nominal Test Bar

Class

min, ksi [MPa] Diameter, in. [mm]

No. 150A 150 20 to 22

No. 150B 30

No. 150C 50

A

No. 150S Bars S

No. 175A 175 20 to 22

No. 175B 30

No. 175C 50

A

No. 175S Bars S

No. 200A 200 20 to 22

No. 200B 30

No. 200C 50

A

No. 200S Bars S

No. 225A 225 20 to 22

No. 225B 30

No. 225C 50

A

No. 225S Bars S

No. 250A 250 20 to 22

No. 250B 30

No. 250C 50

A

No. 250S Bars S

No. 275A 275 20 to 22

No. 275B 30

No. 275C 50

A

No. 275S Bars S

No. 300A 300 20 to 22

No. 300B 30

No. 300C 50

A

No. 300S Bars S

No. 325A 325 20 to 22

No. 325B 30

No. 325C 50

A

No. 325S Bars S

No. 350A 350 20 to 22

No. 350B 30

No. 350C 50

A

No. 350S Bars S

No. 375A 375 20 to 22

No. 375B 30

No. 375C 50

A

No. 375S Bars S

No. 400A 400 20 to 22

No. 400B 30

No. 400C 50

A

No. 400S Bars S

A

AlldimensionsoftestbarSshallbeasagreeduponbetweenthemanufacturer

and the purchaser.

5.1.3 The size of the separately cast test bar (letter classification—A, B, C, or S) that best represents the thickness of the

controlling section of the casting (see Table 2Table 3),

5.1.4 The tension test specimen (B or C) to be machined from test bar C (see 13.3, Table 3Table 4, and Fig. 1),

5.1.5 The tension test specimen to be machined from test bar S (see 13.4, Table 3Table 4, and Fig. 1),

5.1.6 Lot size (see Section 10),

5.1.7 Special requirements (see Section 6),

5.1.8 Saving tested specimens or unbroken test bars (see 15.1), and

5.1.9 Special preparation for delivery (see Section 19).

6. Special Requirements

6.1 When agreed upon in writing between the manufacturer and the purchaser, it may be necessary for the castings to meet

A 48/A 48M – 03 (2008)

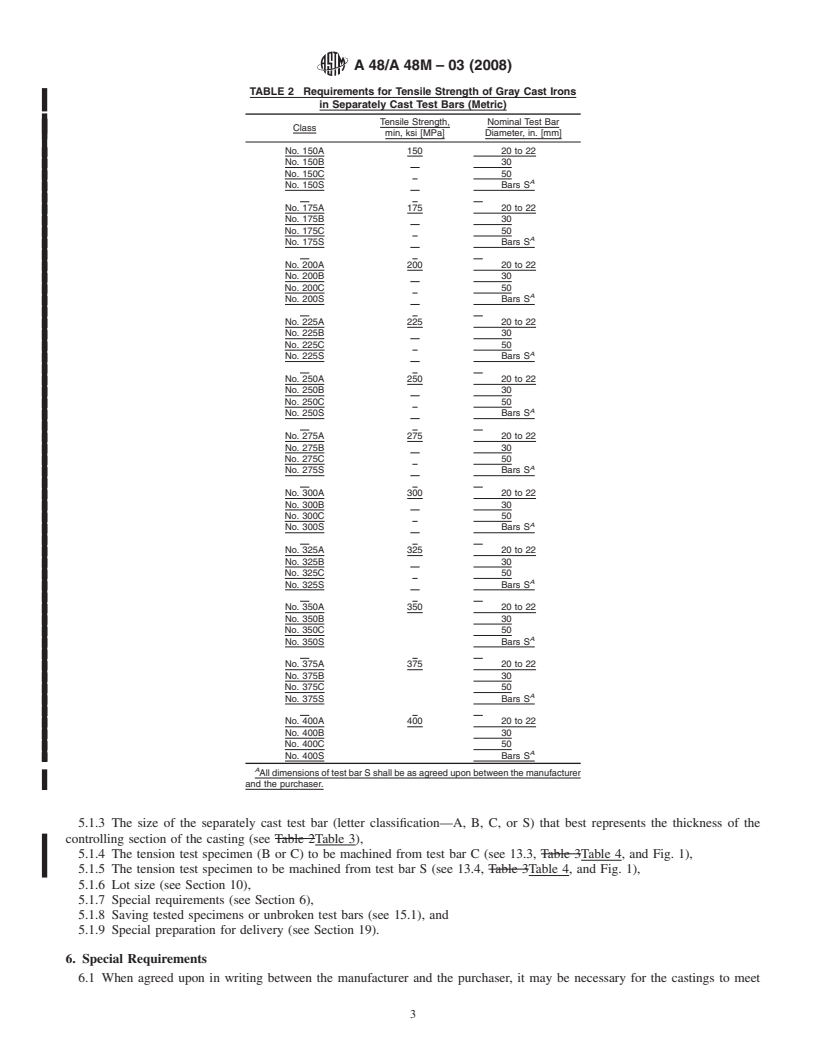

TABLE 2 3 Separately Cast Test Bars for Use When a Specific

Correlation Has Not Been Established Between the Test Bar and

the Casting

Thickness of the Wall of the Controlling

Test Bar

Section of the Casting, in. [mm]

Under 0.25 [under 6] S

Under 0.25 [under 5] S

0.25 to 0.50 [6 to 13] A

0.25 to 0.50 [5 to 14] A

0.51 to 1.00 [13 to 25] B

0.51 to 1.00 [15 to 25] B

1.01 to 2 [26 to 51] C

1.01 to 2 [26 to 50] C

Over 2 [over 51] S

Over 2 [over 50] S

TABLE 3 4 Diameters and Lengths of Cast Test Bars

As-Cast Diameter, in. [mm] Length, in. [mm]

Test Bar

Nominal Minimum Maximum

Minimum (Bottom) Maximum (Top)

(Mid-Length) (Specified) (Recommended)

A 0.88 [22.5] 0.85 [21.5] 0.96 [24.5] 5.0 [125] 6.0 [150]

A 0.88 [22.4] 0.85 [21.6] 0.96 [24.4] 5.0 [125] 6.0 [150]

B 1.20 [30.5] 1.14 [29.0] 1.32 [33.5] 6.0 [150] 9.0 [230]

C 2.00 [50.8] 1.90 [48.3] 2.10 [53.3] 7.0 [175] 10.0 [255]

A

S . . . . .

A

All dimensions of test bar S shall be as agreed upon by the manufacturer and the purchaser.

Tension Test Tension Test Tension Test

Dimensions, in. [mm]

Specimen A Specimen B Specimen C

G—Length of parallel, min 0.50 [13] 0.75 [19] 1.25 [32]

D—Diameter 0.500 6 0.010 0.750 6 0.015 1.25 6 0.025

[12.7 6 0.25] [19.0 6 0.38] [30 6 0.65]

[13 6 0.25] [20 6 0.4] [30 6 0.6]

R—Radius of fillet, min 1 [25] 1 [25] 2 [50]

1 1 1

A—Length of reduced section, min 1 ⁄4 [32] 1 ⁄2 [38] 2 ⁄4 [57]

3 3

L—Over-all length, min 3 ⁄4 [95] 4 [100] 6 ⁄8 [160]

7 1 7

C—Diameter of end section, approx ⁄8 [22] 1 ⁄4 [32] 1 ⁄8 [48]

7 1 7

C—Diameter of end section, approx ⁄8 [20] 1 ⁄4 [20] 1 ⁄8 [47]

1 1 5

E—Length of shoulder, min ⁄4 [6] ⁄4 [6] ⁄16 [8]

5 1 15 1 7 1

F—Diameter of shoulder ⁄8 6 ⁄64 ⁄16 6 ⁄64 1 ⁄16 6 ⁄64

[16 6 0.4] [25 6 0.4] [36 6 0.4]

[16 6 0.4] [24 6 0.4] [36 6 0.4]

AA A

B—Length of end section

A

Optional to fit holders on testing machine. If threaded, root diameter shall not be less than dimension F.

FIG. 1 Tension-Test Specimens

special requirements as to hardness, chemical composition, microstructure, pressure tightness, radiographic soundness, dimen-

sions, surface finish, etc. and so forth.

A 48/A 48M – 03 (2008)

7. Tensile Requirements

7.1 Test bars representing castings conforming to this specification shall meet the requirements for tensile strength as described

in Table 1 and Table 2.

8. Dimensional Requirements

8.1 The castings shall conform to the dimensions or drawings furnished by the purchaser, or, if there are no drawings, to the

dimensions predicted by the pattern equipment supplied by the purchaser.

9. Workmanship and Finish

9.1 The surface of the casting shall be free of adhering sand, scale, cracks, and hot tears, as determined by visual examination.

9.2 No repairing by plugging or welding of any kind shall be permitted unless written permission is granted by the purchaser.

10. Sampling

10.1 A lot shall consist of one of the following:

10.1.1 All the metal poured from a single heating in a batch type melting furnace.

10.1.2 All the metal from two or more batch type melting furnaces poured into a single ladle or a single casting.

10.1.3 All the metal poured from a continuous melting furnace for a given period of time between changes in charge, processing

conditions, or aim-for chemistry or 4 h, whichever is the shorter period.

10.1.3.1 The purchaser may agree to extend the 4-h time period to8hifthe manufacturer can demonstrate sufficient process

control to warrant such an extension.

11. Cast Test Bars

11.1 Test bars shall be separate castings poured from the same lot as the castings they represent and shall have dimensions as

shown in Table 3Table 4.Allowance may be made for reasonable pattern draft within the tolerances shown in Table 3Table 4. Test

bars A, B, and C are all standard test bars in the form of simple cylinders. Test bar S is special and is intended for use where the

standard bars are not satisfactory.

11.2 The test bars shall be cast in dried, baked, or chemically bonded molds made mainly of an aggregate of siliceous sand with

appropriate binders. The average grain size of the sand shall approximate that of the sand in which the castings are poured. Molds

for the test bars shall be approximately at room temperature when poured. More than one test bar may be cast in a single mold,

but each bar in the mold shall be surrounded by a thickness of sand which is not less than the diameter of the bar.Asuitable design

for a mold is shown in Fig. 2.

NOTE 1—The intent of these provisions is as follows: to prohibit the casting of test bars in molds of metal, graphite, zircon, light-weight aggregates,

or other materials which would significantly affect the tensile strength of the iron; to prohibit control of tensile strength of the test bars by manipulation

of the grain size of the sand; and to prohibit the casting of test bars in molds preheated substantially above room temperature.

Required Features: Optional Features:

1. Material—Aggregate of dry siliceous sand. 1. Number of test bars in a single mold—Two suggested.

2. Position—Bars vertical. 2. Design of pouring cup.

3. L—See Table 3. 3. P—2 in. [50 mm], suggested.

3. L—See Table 4. 3. P—2 in. [50 mm], suggested.

4. D—See Table 3. 4. N— ⁄16 in. [8 mm] in diameter, suggested.

4. D—See Table 4. 4. N— ⁄16 in. [8 mm] in diameter, suggested.

5. W—Not less than diameter D.f5. M=1.5 N, suggested.

FIG. 2 Suitable Design and Dimensions for Mold for Separately Cast Cylindrical Test Bars for Gray Iron

A 48/A 48M – 03 (2008)

11.3 Test bars that are intended to represent castings that are cooled in the mold to less than 900°F [480°C], before shakeout,

shall be cooled in their molds to a temperature less than 900°F [480°C]. They then may be cooled in still air to room temperature.

11.4 Test bars that are intended to represent castings that are hotter than 900°F [480°C], when shaken out of their molds, shall

be cooled as described in 11.3 or (by agreement between the manufacturer and the purchaser) may be shaken out of their molds

at approximately the same temperature as the castings they represent.

11.5 When castings are stress-relieved, annealed, or otherwise heat-treated, test bars shall receive the same thermal treatment

and shall be treated adjacent to the castings they represent.

12. Number of Tests and Retests

12.1 The tension test shall be conducted in accordance with Test Method E 8.

12.2 One tension test shall be performed on each lot and shall conform to the tensile requirements specified.

12.3 If the results of a valid test fail to conform to the requirements of this specification, two retests shall be made. If either

retest fails to meet the specification requirements, the castings represented by these test specimens shall be rejected. A valid test

is one wherein the specimen has been properly prepared and appears to be sound and on which the approved test procedure has

been followed.

12.4 If sufficient separately cast test pieces are not available, the manufacturer shall have the option of removing a test specimen

from a location of representative casting, as agreed upon between the manufacturer and purchaser.

12.5 If the first test results indicate that a heat treatment is needed to meet the test requirements, the entire lot of castings and

the representative test specimens shall be heat treated together. Testi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.