ASTM F1145-05(2022)

(Specification)Standard Specification for Turnbuckles, Swaged, Welded, Forged

Standard Specification for Turnbuckles, Swaged, Welded, Forged

ABSTRACT

This specification covers swaged welded, cast, or forged turnbuckles with and without jam nuts. A turnbuckle is an internally threaded loop or sleeve intended for assembly with a threaded stud, eye, hook, or jaw at each end, used for applying tension to rods, wire rope, and so forth. Turnbuckles shall be of the following types and grades: Type I (forged, spread, resistance welded and arc or gas welded); Type II; and Type III. Turnbuckles shall be of the following classes; Class A; Class B; Class C; Class D; Class E; Class F; Class G; and Class H. The following tests shall be performed: proof test; breaking strength test; bending test; and galvanizing test.

SCOPE

1.1 This specification covers swaged welded, cast, or forged turnbuckles with and without jam nuts.

1.2 A turnbuckle is an internally threaded loop or sleeve intended for assembly with a threaded stud, eye, hook, or jaw at each end, used for applying tension to rods, wire rope, and so forth.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F1145 −05 (Reapproved 2022) An American National Standard

Standard Specification for

1

Turnbuckles, Swaged, Welded, Forged

This standard is issued under the fixed designation F1145; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

3

1. Scope 2.2 AWS Standards:

AWS A5.1 Covered Carbon Steel Arc Welding Electrodes

1.1 This specification covers swaged welded, cast, or forged

AWS A5.2 Iron and Steel Oxyfuel Gas Welding Rods

turnbuckles with and without jam nuts.

AWS A5.5 Low Alloy Steel Covered Arc Welding Elec-

1.2 A turnbuckle is an internally threaded loop or sleeve

trodes

4

intended for assembly with a threaded stud, eye, hook, or jaw

2.3 ASME Standards:

at each end, used for applying tension to rods, wire rope, and

ASME B1.1 Unified Inch Screw Threads (UN, UNR, and

so forth.

UNJ Thread Forms)

1.3 The values stated in inch-pound units are to be regarded ASME B18.2.2 Nuts for General Applications: Machine

Screw Nuts, Hex, Square, Hex Flange, and Coupling Nuts

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only (Inch Series)

5

2.4 Military Standards:

and are not considered standard.

MIL-STD-1186 Cushioning, Anchoring, Bracing, Blocking,

1.4 This standard does not purport to address all of the

and Waterproofing; with Appropriate Test Methods

safety concerns, if any, associated with its use. It is the

MIL-STD-2073-1 DoD Material Procedures for Develop-

responsibility of the user of this standard to establish appro-

ment and Application of Packaging Requirements

priate safety, health, and environmental practices and deter-

5

2.5 Military Specification:

mine the applicability of regulatory limitations prior to use.

MIL-L-19140 Lumber and Plywood, Fire-Retardant Treated

1.5 This international standard was developed in accor-

MIL-P-116 Preservation, Methods of

dance with internationally recognized principles on standard-

4

2.6 Federal Specifications:

ization established in the Decision on Principles for the

PPP-B-636 Boxes, Shipping, Fiberboard

Development of International Standards, Guides and Recom-

PPP-F-320 Fiberboard: Corrugated and Solid Sheet Stock

mendations issued by the World Trade Organization Technical

(Container Grade) and Cut Shapes

Barriers to Trade (TBT) Committee.

5

2.7 Federal Standard:

FED-STD-123 Marking for Shipment (Civil Agencies)

2. Referenced Documents

2

2.1 ASTM Standards:

3. Classification

A29/A29M SpecificationforGeneralRequirementsforSteel

3.1 Turnbuckles covered under this specification shall be of

Bars, Carbon and Alloy, Hot-Wrought

the following types and grades, as specified (see 4.1.3 and

A153/A153M Specification for Zinc Coating (Hot-Dip) on

4.1.7):

Iron and Steel Hardware

3.1.1 Type I—Open turnbuckle bodies (see 5.2.4 – 5.2.7):

B633 Specification for Electrodeposited Coatings of Zinc on

3.1.1.1 Grade:

Iron and Steel

(1) Forged

D3951 Practice for Commercial Packaging

(2) Spread

(3) Resistance welded

1

This specification is under the jurisdiction of ASTM Committee F25 on Ships (4) Arc or gas welded

and Marine Technology and is the direct responsibility of Subcommittee F25.07 on

General Requirements.

3

Current edition approved Feb. 1, 2022. Published February 2022. Originally Available from American Welding Society (AWS), 8669 NW 36 St., #130,

approved in 1988. Last previous edition approved in 2017 as F1145 – 05 (2017). Miami, FL 33166-6672, http://www.aws.org.

4

DOI: 10.1520/F1145-05R22. Available from American Society of Mechanical Engineers (ASME), ASME

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.asme.org.

5

Standards volume information, refer to the standard’s Document Summary page on Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

the ASTM website. Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1145−05 (2022)

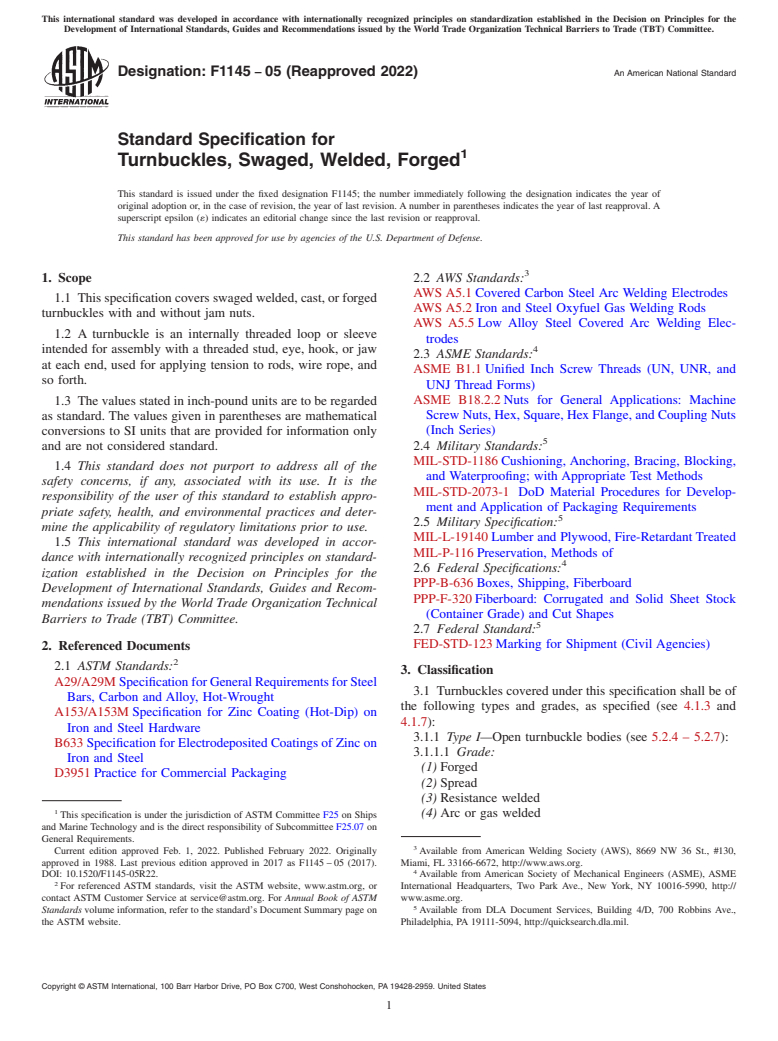

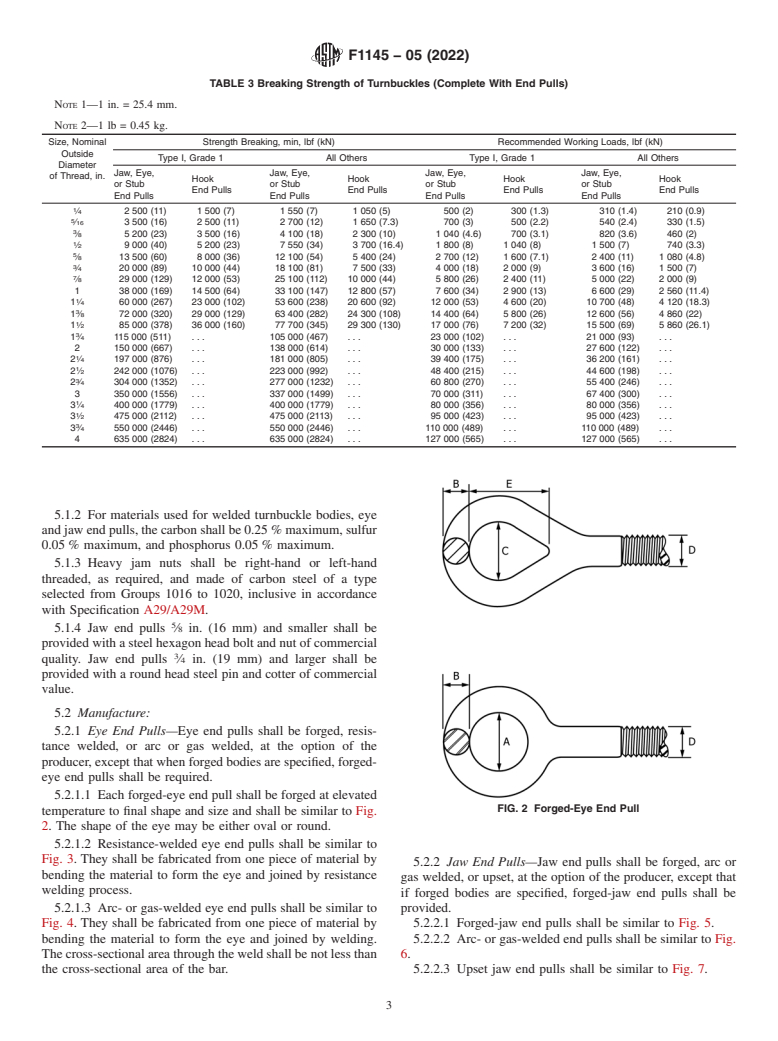

TABLE 1 Turnbuckle Bodies, Classes A and B, and Turnbuckles,

3.1.2 Type II—Pipe turnbuckle bodies (see 5.2.8).

Class C

3.1.3 Type III—Rigging turnbuckle bodies (see 5

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.