ASTM D4194-03(2008)

(Test Method)Standard Test Methods for Operating Characteristics of Reverse Osmosis and Nanofiltration Devices

Standard Test Methods for Operating Characteristics of Reverse Osmosis and Nanofiltration Devices

SIGNIFICANCE AND USE

Reverse osmosis and nanofiltration desalinating devices can be used to produce potable water from brackish supplies (10 000 mg/L) and seawater as well as to upgrade the quality of industrial water. These test methods permit the measurement of the performance of reverse osmosis devices using standard sets of conditions and are intended for short-term testing (24 h). These test methods can be used to determine changes that may have occurred in the operating characteristics of reverse osmosis and nanofiltration devices but are not intended to be used for plant design.

SCOPE

1.1 These test methods cover the determination of the operating characteristics of reverse osmosis devices using standard test conditions and are not necessarily applicable to natural waters. Three test methods are given, as follows:

Sections Test Method A—Brackish Water Reverse Osmosis Devices8-13 Test Method B—Nanofiltration Devices14-19 Test Method B—Seawater Reverse Osmosis Devices20-25

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4194 −03(Reapproved 2008)

Standard Test Methods for

Operating Characteristics of Reverse Osmosis and

Nanofiltration Devices

This standard is issued under the fixed designation D4194; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope nanofiltration devices. They are applicable to both new and

used reverse osmosis or nanofiltration devices.

1.1 These test methods cover the determination of the

operating characteristics of reverse osmosis devices using

5. Significance and Use

standard test conditions and are not necessarily applicable to

natural waters. Three test methods are given, as follows: 5.1 Reverse osmosis and nanofiltration desalinating devices

can be used to produce potable water from brackish supplies

Sections

(<10000 mg/L) and seawater as well as to upgrade the quality

Test Method A—Brackish Water Reverse Osmosis 8-13

ofindustrialwater.Thesetestmethodspermitthemeasurement

Devices

of the performance of reverse osmosis devices using standard

Test Method B—Nanofiltration Devices 14-19

Test Method B—Seawater Reverse Osmosis Devices 20-25

sets of conditions and are intended for short-term testing (<24

1.2 This standard does not purport to address all of the h). These test methods can be used to determine changes that

safety concerns, if any, associated with its use. It is the may have occurred in the operating characteristics of reverse

responsibility of the user of this standard to establish appro- osmosis and nanofiltration devices but are not intended to be

priate safety and health practices and determine the applica- used for plant design.

bility of regulatory limitations prior to use.

6. Reagents

2. Referenced Documents

6.1 Purity of Reagents—Reagent grade chemicals shall be

2.1 ASTM Standards:

used in all tests. Unless otherwise indicated, it is intended that

D512Test Methods for Chloride Ion In Water

all reagents shall conform to the specifications of the Commit-

D1125Test Methods for Electrical Conductivity and Resis-

tee onAnalytical Reagents of theAmerican Chemical Society,

tivity of Water

where such specifications are available. Other grades may be

D1129Terminology Relating to Water

used, provided it is first ascertained that the reagent is of

D1193Specification for Reagent Water

sufficiently high purity to permit its use without lessening the

D6161TerminologyUsedforMicrofiltration,Ultrafiltration,

accuracy of the determination.

Nanofiltration and Reverse Osmosis Membrane Processes

6.2 Purity of Water—Unless otherwise indicated, references

to water shall be understood to mean Type III reagent con-

3. Terminology

forming to Specification D1193.

3.1 Definitions—For definitions of terms used in these test

methods, refer to Terminology D1129 and D6161.

7. Apparatus

4. Summary of Test Methods

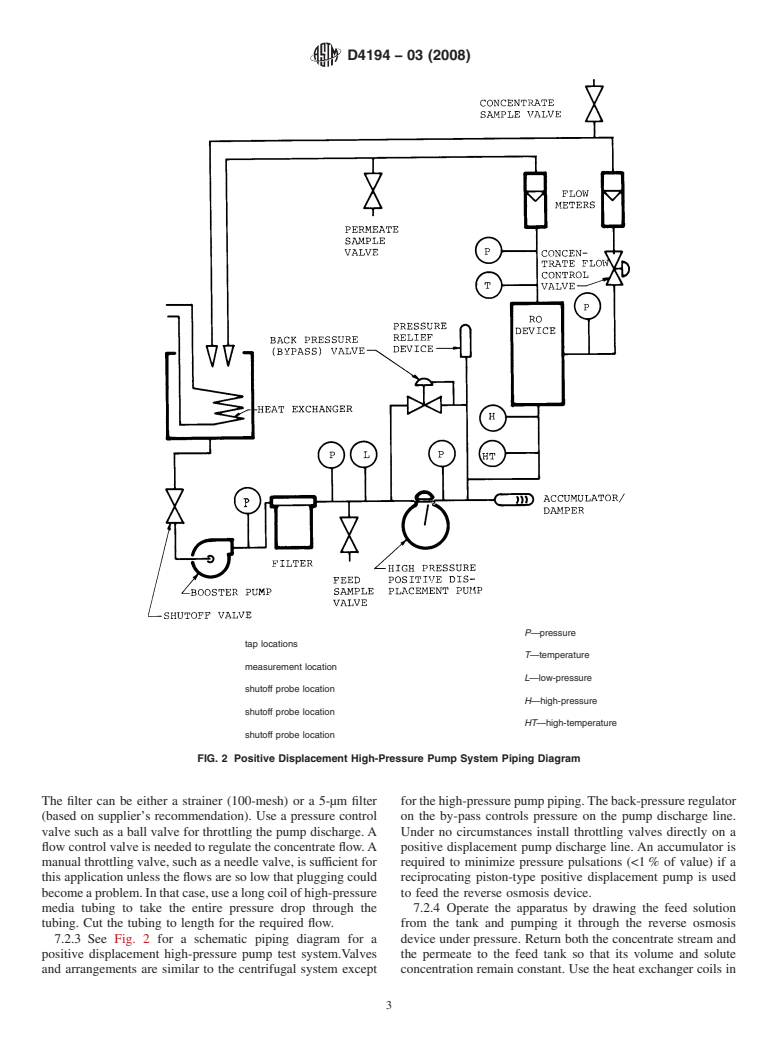

7.1 The apparatus for both methods is schematically de-

scribed in Fig. 1 and Fig. 2.Aconductivity meter can be used

4.1 Thesetestmethodsconsistofdeterminingthedesalinat-

to determine the salt concentration in accordance with Test

ing ability and permeate flow rate of reverse osmosis and

Methods D1125.

7.2 Installation:

These test methods are under the jurisdiction of ASTM Committee D19 on

Water and are the direct responsibilities of Subcommittee D19.08 on Membranes

and Ion Exchange Materials.

Current edition approved May 1, 2008. Published May 2008. Originally

approved in 1982. Last previous edition approved in 2003 as D4194–03. DOI: Reagent Chemicals, American Chemical Society Specifications, American

10.1520/D4194-03R08. Chemical Society, Washington, DC. For suggestions on the testing of reagents not

For referenced ASTM standards, visit the ASTM website, www.astm.org, or listed by the American Chemical Society, see Analar Standards for Laboratory

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Standards volume information, refer to the standard’s Document Summary page on and National Formulary,U.S.PharmaceuticalConvention,Inc.(USPC),Rockville,

the ASTM website. MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4194−03 (2008)

P—pressure

tap locations

T—temperature

measurement location

L—low-pressure

shutoff probe location

H—high-pressure

shutoff probe location

HT—high-temperature

shutoff probe location

FIG. 1 Centrifugal High-Pressure Pump System Piping Diagram

7.2.1 Materials of construction shall be of high-quality the manufacturer’s working pressure rating. Review manufac-

stainless steel (Type 316) or plastic for all wetted parts to turer’s rating for compliance with standard engineering prac-

prevent contamination of the feed solution by corrosion prod- tice.

ucts. Do not use reactive piping material such as plain carbon 7.2.2 The reverse osmosis testing apparatus, represented

steel,galvanizedorcadmium-platedcarbonsteel,andcastiron schematically in Fig. 1 using a centrifugal pump, consists of a

forpiping.Takecaretoensurethatnocontaminationwilloccur feed holding tank equipped with a thermostated heat ex-

from oil films on new metal piping, release agents on raw changer system to maintain the feed solution at the desired

plastic components, or from feed solutions previously used in temperature, a booster pump, a high-pressure centrifugal

the system. If materials are suspect, thoroughly clean or pump, and a reverse osmosis device. Use a valve with a

degrease or both, before use. All pressurized components minimum flow restriction (for example, ball valve or plug

whether stainless steel or plastic should be designed based on valve)fortheshut-offvalvetopreventexcessivepressuredrop.

D4194−03 (2008)

P—pressure

tap locations

T—temperature

measurement location

L—low-pressure

shutoff probe location

H—high-pressure

shutoff probe location

HT—high-temperature

shutoff probe location

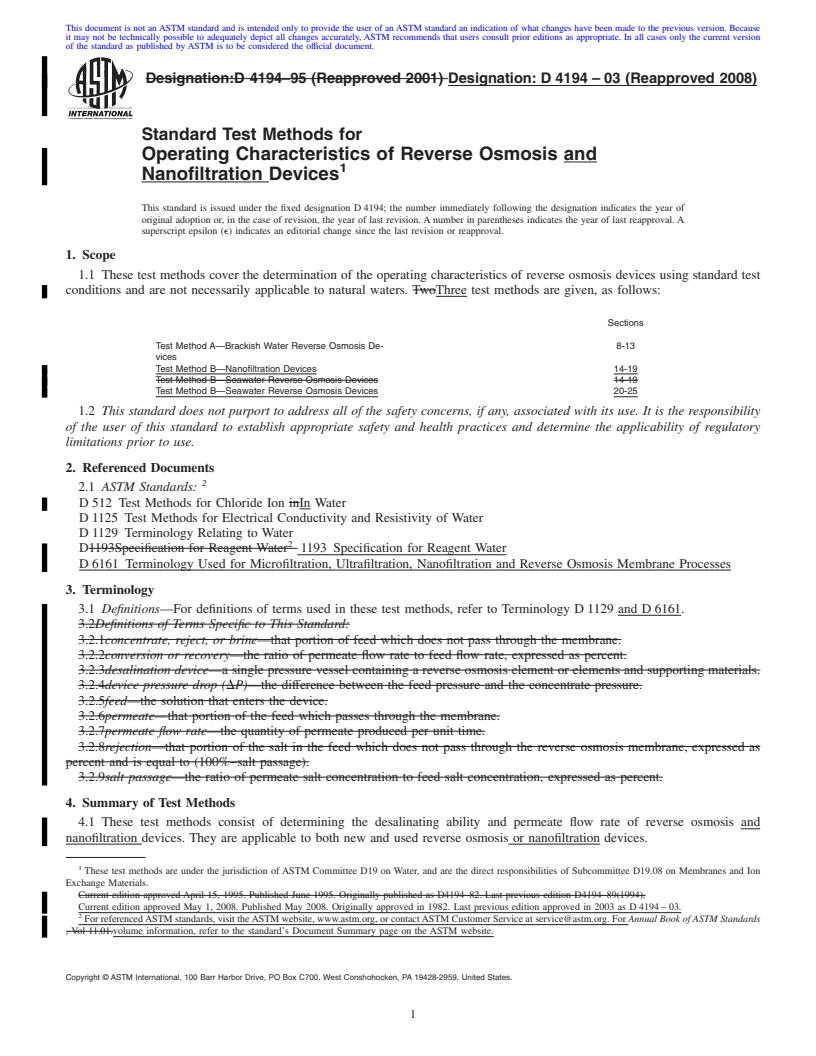

FIG. 2 Positive Displacement High-Pressure Pump System Piping Diagram

The filter can be either a strainer (100-mesh) or a 5-µm filter forthehigh-pressurepumppiping.Theback-pressureregulator

(based on supplier’s recommendation). Use a pressure control on the by-pass controls pressure on the pump discharge line.

valve such as a ball valve for throttling the pump discharge.A Under no circumstances install throttling valves directly on a

flowcontrolvalveisneededtoregulatetheconcentrateflow.A positive displacement pump discharge line.An accumulator is

manualthrottlingvalve,suchasaneedlevalve,issufficientfor required to minimize pressure pulsations (<1% of value) if a

thisapplicationunlesstheflowsaresolowthatpluggingcould reciprocating piston-type positive displacement pump is used

becomeaproblem.Inthatcase,usealongcoilofhigh-pressure to feed the reverse osmosis device.

media tubing to take the entire pressure drop through the 7.2.4 Operate the apparatus by drawing the feed solution

tubing. Cut the tubing to length for the required flow. from the tank and pumping it through the reverse osmosis

7.2.3 See Fig. 2 for a schematic piping diagram for a device under pressure. Return both the concentrate stream and

positive displacement high-pressure pump test system.Valves the permeate to the feed tank so that its volume and solute

and arrangements are similar to the centrifugal system except concentration remain constant. Use the heat exchanger coils in

D4194−03 (2008)

the feed tank to adjust the feed to specified operating tempera- using standard test conditions and can be used for all types of

ture and thereafter use to remove the energy load generated by devices (tubular, spiral wound, and hollow fiber).

the pump. Monitor the permeate temperature very near the

reverse osmosis device (within 500 mm). Pressure gages 9. Summary of Test Method

before and after the reverse osmosis device give the feed

9.1 The test method provides for at least three different

pressure and the pressure drop across the device (∆P; feed

concentrations of sodium chloride feed solution.

pressure−concentrate pressure). Locate these gages as close

as possible to the reverse osmosis device. Measure the con-

10. Reagents and Materials

centrate and permeate flow rates with calibrated flowmeters

10.1 Sodium Chloride Feed Solution (5.0 g/L)—Dissolve

from which the feed rate to the device may be determined.

enough sodium chloride (NaCl) in water to make a solution

Removesamplesofthesetwostreamsthroughsamplingvalves

containing in each litre 5.0 g of NaCl.

for conductivity/concentration measurements. Sample the feed

usingthefeedsamplevalve.Directthereturnflowsinthefeed

10.2 Sodium Chloride Feed Solution (1.5 g/L)—Dissolve

tank to provide adequate mixing.

enough sodium chloride (NaCl) in water to make a solution

containing in each litre 1.5 g of NaCl.

7.3 Systems—To protect the reverse osmosis device and the

high-pressure pump from abnormal operating conditions, in-

10.3 Sodium Chloride Feed Solution (0.5 g/L)—Dissolve

stall limit controls in the system. An electric limit control is

enough sodium chloride (NaCl) in water to make a solution

used to shut down the high-pressure feed pump. The limit

containing in each litre 0.5 g of NaCl.

control circuit should have a manual reset relay in it so that

10.4 Sodium Chloride Feed Solutions, Optional—Other

when it shuts down it will not automatically restart. See Fig. 1

concentrations of NaCl solutions (<10 g/L) can be used.

andFig.2forthelimitcontrollocations.Theirfunctionsareas

follows:

11. Procedure

7.3.1 High-Pressure Shut-Off—Set the cutoff point in accor-

dance with the supplier’s recommendations (protects the re-

11.1 Start-Up and Operating Procedure:

verse osmosis device against excessive pressure).

11.1.1 If the reverse osmosis device contains sanitizing or

7.3.2 Low-Pressure Shut-Off—Set the cutoff point at a gage

winterizingagents,orboth,flushthedeviceinaccordancewith

pressure of 103 kPa (15 psi) (shuts the system down when the

the supplier’s recommendations.

pump water supply is interrupted and thus protects the reverse

11.1.2 Makepreliminarycheckstomakesureallfittingsare

osmosis pump).

tight,allcomponentsareoperational,andthefeedsolutionisat

7.3.3 High-Temperature Shut-Off—Set the maximum tem-

the proper concentration and temperature. Before energizing

perature at 30°C (protects the reverse osmosis device against

the high-pressure pump, the low-pressure switch must be off

excessive temperature).

forstart-uptocompletethecircuitpastthelow-pressurecutout.

Energize the high-pressure pump momentarily to check proper

7.4 Instrumentation:

rotation.

7.4.1 Pressure—See Fig. 1 and Fig. 2 for pressure tap

11.1.3 Open the feed supply valve, the concentrate flow

locations. Use a single gage equipped with a high-pressure

control valve, the pump by-pass on the positive displacement

“quick-connect” or Taylor plug gage fitting for measuring

feed pump, or the centrifugal pump throttling valve. Start the

individual pressures and device pressure drop (∆P). Individual

booster pump and then the high-pressure pump.

gages are also satisfactory but not as reliable as a “quick-

11.1.4 Bring the feed pressure to a gage pressure that is in

connect”testgageoraspecial∆Pgage.Usepressuresnubbers

accordance with the specifications of membrane manufacturer

topreventpulsationdamagetogages,andcalibrateallpressure

for a given element model. It is possible that the by-pass valve

gages.

or the throttling valve (depending on pump system) and the

7.4.2 Temperature—See Fig. 1 and Fig. 2 for temperature-

concentrate flow control valve may need to be adjusted

measurement locations. Calibrated dial thermometers with the

simultaneously. If necessary, another pressure agreed upon

probeimmersedintheflowingwatershouldprovidegooddata.

between the user and the supplier may be used.

7.4.3 Permeate Back-Pressure Considerations—It is per-

11.1.5 Set concentrate flow in accordance with the suppli-

missible to operate reverse osmosis devices with a back-

er’s recommendation by adjusting the concentrate flow control

pressure on the permeate. The maximum recommended back-

valve. But maintain conversion within 62% of the supplier’s

pressure for these methods is 35 kPa (5 psi). This pressure is

recommendation.

more than adequate for transferring the permeate back to the

11.1.6 Recheck and adjust if necessary both the concentrate

feed tank.

flow and feed pressure to give the selected values for flow and

pressure.

TEST METHOD A—BRACKISH WATER REVERSE

OSMOSIS DEVICES 11.1.7 Check and adjust the cooling system in the feed

solution to give a permeate temperature of 25 6 1°C.

8. Scope 11.1.8 Once sustained operation is attained, energize the

low-pressure shut-off switch.

8.1 This test method covers the determination of the oper-

ating characteristics of brackish water reverse osmosis devices 11.2 Data Recording:

D4194−03 (2008)

NOTE1—Theuseofconductivityratiosforcalculatingsaltpassagewill

11.2.1 Onehourafterstart-up,measureandrecordonadata

giveslightlydifferentresultsascomparedtousingratiosfromchlorideion

sheet the inlet and outlet pressures of the filter and the feed,

analyses.However,fortheconcentrationrangesinvolvedforthismethod,

concentrate, and permeate pressures.

the slight error resulting from using conductivity ratios is not considered

11.2.2 At the same time measure and record the permeate

significant.

and concentrate flows using the calibrated flowmeters or a

12.4 Calculate the rejection as follows:

calibrated volume container and stopwatch.

Rejection, % 5 ~1 2 ~K /K ! 3100!

p f

11.2.3 Also at the same time measure and record the

permeate temperature and the conductivity of the feed, perme-

13. Precision and Bias

ate, and concentrate, using a conductivity meter, or determine

the chloride content of the three streams in accordance with 13.1 Theprecisionofthetestmethodforpermeateflowrate

of reverse osmosis devices is as follows:

Test Methods D512.

11.2.4 Repeattheabovemeasurements2to3hafterstart-up

S 50.016X 24.542

o

andhourlythereafteruntilthreesuccessivepermeateflowrates

S 50.058X 217.411

t

(corrected to 25°C) and salt passages agree within 5% (rela-

tive). Industry manufacturers generally report performance where:

specifications based on a 20 to 30 min test.

S = single-operator precision, mL/min,

o

11.2.5 All data shall be obtained using the specified condi- S = overall precision, mL/min, and

t

X = determined permeate flow rate of reverse osmosis

tions of temperature, pressure, and conversion.

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D 4194–95 (Reapproved 2001) Designation: D 4194 – 03 (Reapproved 2008)

Standard Test Methods for

Operating Characteristics of Reverse Osmosis and

Nanofiltration Devices

This standard is issued under the fixed designation D4194; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods cover the determination of the operating characteristics of reverse osmosis devices using standard test

conditions and are not necessarily applicable to natural waters. TwoThree test methods are given, as follows:

Sections

Test Method A—Brackish Water Reverse Osmosis De- 8-13

vices

Test Method B—Nanofiltration Devices 14-19

Test Method B—Seawater Reverse Osmosis Devices 14-19

Test Method B—Seawater Reverse Osmosis Devices 20-25

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D512 Test Methods for Chloride Ion inIn Water

D1125 Test Methods for Electrical Conductivity and Resistivity of Water

D1129 Terminology Relating to Water

D1193Specification for Reagent Water 1193 Specification for Reagent Water

D6161 Terminology Used for Microfiltration, Ultrafiltration, Nanofiltration and Reverse Osmosis Membrane Processes

3. Terminology

3.1 Definitions—For definitions of terms used in these test methods, refer to Terminology D1129 and D6161.

3.2Definitions of Terms Specific to This Standard:

3.2.1concentrate, reject, or brine—that portion of feed which does not pass through the membrane.

3.2.2conversion or recovery—the ratio of permeate flow rate to feed flow rate, expressed as percent.

3.2.3desalination device—a single pressure vessel containing a reverse osmosis element or elements and supporting materials.

3.2.4device pressure drop (DP)—the difference between the feed pressure and the concentrate pressure.

3.2.5feed—the solution that enters the device.

3.2.6permeate—that portion of the feed which passes through the membrane.

3.2.7permeate flow rate—the quantity of permeate produced per unit time.

3.2.8rejection—that portion of the salt in the feed which does not pass through the reverse osmosis membrane, expressed as

percent and is equal to (100%−salt passage).

3.2.9salt passage—the ratio of permeate salt concentration to feed salt concentration, expressed as percent.

4. Summary of Test Methods

4.1 These test methods consist of determining the desalinating ability and permeate flow rate of reverse osmosis and

nanofiltration devices. They are applicable to both new and used reverse osmosis or nanofiltration devices.

These test methods are under the jurisdiction of ASTM Committee D19 on Water, and are the direct responsibilities of Subcommittee D19.08 on Membranes and Ion

Exchange Materials.

Current edition approved April 15, 1995. Published June 1995. Originally published as D4194–82. Last previous edition D4194–89(1994).

Current edition approved May 1, 2008. Published May 2008. Originally approved in 1982. Last previous edition approved in 2003 as D4194–03.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 11.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4194 – 03 (2008)

5. Significance and Use

5.1 Reverse osmosis and nanofiltration desalinating devices can be used to produce potable water from brackish supplies

(<10000 mg/L) and seawater as well as to upgrade the quality of industrial water.These test methods permit the measurement of

theperformanceofreverseosmosisdevicesusingstandardsetsofconditionsandareintendedforshort-termtesting(<24h).These

test methods can be used to determine changes that may have occurred in the operating characteristics of reverse osmosis and

nanofiltration devices but are not intended to be used for plant design.

6. Reagents

6.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of the determination.

6.2 Purity of Water— Unless otherwise indicated, references to water shall be understood to meanType III reagent conforming

to Specification D1193.

7. Apparatus

7.1 The apparatus for both methods is schematically described in Fig. 1 and Fig. 2. A conductivity meter can be used to

determine the salt concentration in accordance with Test Methods D1125.

7.2 Installation:

7.2.1 Materials of construction shall be of high-quality stainless steel (Type 316) or plastic for all wetted parts to prevent

contaminationofthefeedsolutionbycorrosionproducts.Donotusereactivepipingmaterialsuchasplaincarbonsteel,galvanized

or cadmium-plated carbon steel, and cast iron for piping. Take care to ensure that no contamination will occur from oil films on

new metal piping, release agents on raw plastic components, or from feed solutions previously used in the system. If materials are

suspect, thoroughly clean or degrease or both, before use.All pressurized components whether stainless steel or plastic should be

designed based on the manufacturer’s working pressure rating. Review manufacturer’s rating for compliance with standard

engineering practice.

7.2.2 The reverse osmosis testing apparatus, represented schematically in Fig. 1 using a centrifugal pump, consists of a feed

holding tank equipped with a thermostated heat ex-changer system to maintain the feed solution at the desired temperature, a

booster pump, a high-pressure centrifugal pump, and a reverse osmosis device. Use a valve with a minimum flow restriction (for

example, ball valve or plug valve) for the shut-off valve to prevent excessive pressure drop. The filter can be either a strainer

(100-mesh) or a 5-µm filter (based on supplier’s recommendation). Use a pressure control valve such as a ball valve for throttling

the pump discharge.Aflow control valve is needed to regulate the concentrate flow.Amanual throttling valve, such as a needle

valve, is sufficient for this application unless the flows are so low that plugging could become a problem. In that case, use a long

coil of high-pressure media tubing to take the entire pressure drop through the tubing. Cut the tubing to length for the required

flow.

7.2.3 See Fig. 2 for a schematic piping diagram for a positive displacement high-pressure pump test system.Valves and

arrangements are similar to the centrifugal system except for the high-pressure pump piping. The back-pressure regulator on the

by-pass controls pressure on the pump discharge line. Under no circumstances install throttling valves directly on a positive

displacement pump discharge line.An accumulator is required to minimize pressure pulsations (<1% of value) if a reciprocating

piston-type positive displacement pump is used to feed the reverse osmosis device.

7.2.4 Operatetheapparatusbydrawingthefeedsolutionfromthetankandpumpingitthroughthereverseosmosisdeviceunder

pressure. Return both the concentrate stream and the permeate to the feed tank so that its volume and solute concentration remain

constant. Use the heat exchanger coils in the feed tank to adjust the feed to specified operating temperature and thereafter use to

remove the energy load generated by the pump. Monitor the permeate temperature very near the reverse osmosis device (within

500mm).Pressuregagesbeforeandafterthereverseosmosisdevicegivethefeedpressureandthepressuredropacrossthedevice

(D P; feed pressure−concentrate pressure). Locate these gages as close as possible to the reverse osmosis device. Measure the

concentrateandpermeateflowrateswithcalibratedflowmetersfromwhichthefeedratetothedevicemaybedetermined.Remove

samples of these two streams through sampling valves for conductivity/concentration measurements. Sample the feed using the

feed sample valve. Direct the return flows in the feed tank to provide adequate mixing.

7.3 Systems—To protect the reverse osmosis device and the high-pressure pump from abnormal operating conditions, install

limit controls in the system.An electric limit control is used to shut down the high-pressure feed pump. The limit control circuit

should have a manual reset relay in it so that when it shuts down it will not automatically restart. See Fig. 1 and Fig. 2 for the

limit control locations. Their functions are as follows:

7.3.1 High-Pressure Shut-Off—Set the cutoff point in accordance with the supplier’s recommendations (protects the reverse

osmosis device against excessive pressure).

Reagent Chemicals, American Chemical Society Specifications ,American Chemical Society, Washington, DC. For suggestions on the testing of reagents not listed by

the American Chemical Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville, MD.

D 4194 – 03 (2008)

P—pressure tap locations

T—temperature measurement location

L—low-pressure shutoff probe location

H—high-pressure shutoff probe location

HT—high-temperature shutoff probe location

FIG. 1 Centrifugal High-Pressure Pump System Piping Diagram

7.3.2 Low-Pressure Shut-Off—Setthecutoffpointatagagepressureof103kPa(15psi)(shutsthesystemdownwhenthepump

water supply is interrupted and thus protects the reverse osmosis pump).

7.3.3 High-Temperature Shut-Off—Set the maximum temperature at 30°C (protects the reverse osmosis device against

excessive temperature).

7.4 Instrumentation :

7.4.1 Pressure—See Fig. 1 and Fig. 2 for pressure tap locations. Use a single gage equipped with a high-pressure

“quick-connect” or Taylor plug gage fitting for measuring individual pressures and device pressure drop (DP). Individual gages

are also satisfactory but not as reliable as a “quick-connect” test gage or a special D P gage. Use pressure snubbers to prevent

pulsation damage to gages, and calibrate all pressure gages.

7.4.2 Temperature—SeeFig.1andFig.2fortemperature-measurementlocations.Calibrateddialthermometerswiththeprobe

immersed in the flowing water should provide good data.

7.4.3 Permeate Back-Pressure Considerations —It is permissible to operate reverse osmosis devices with a back-pressure on

thepermeate.Themaximumrecommendedback-pressureforthesemethodsis35kPa(5psi).Thispressureismorethanadequate

for transferring the permeate back to the feed tank.

D 4194 – 03 (2008)

P—pressure tap locations

T—temperature measurement location

L—low-pressure shutoff probe location

H—high-pressure shutoff probe location

HT—high-temperature shutoff probe location

FIG. 2 Positive Displacement High-Pressure Pump System Piping Diagram

TEST METHOD A—BRACKISH WATER REVERSE OSMOSIS DEVICES

8. Scope

8.1 This test method covers the determination of the operating characteristics of brackish water reverse osmosis devices using

standard test conditions and can be used for all types of devices (tubular, spiral wound, and hollow fiber).

9. Summary of Test Method

9.1 The test method provides for at least three different concentrations of sodium chloride feed solution.

10. Reagents and Materials

10.1 SodiumChlorideFeedSolution(5.0g/L)—Dissolveenoughsodiumchloride(NaCl)inwatertomakeasolutioncontaining

in each litre 5.0 g of NaCl.

10.2 SodiumChlorideFeedSolution(1.5g/L)—Dissolveenoughsodiumchloride(NaCl)inwatertomakeasolutioncontaining

in each litre 1.5 g of NaCl.

10.3 SodiumChlorideFeedSolution(0.5g/L)—Dissolveenoughsodiumchloride(NaCl)inwatertomakeasolutioncontaining

in each litre 0.5 g of NaCl.

D 4194 – 03 (2008)

10.4 Sodium Chloride Feed Solutions, Optional—Other concentrations of NaCl solutions (<10 g/L) can be used.

11. Procedure

11.1 Start-Up and Operating Procedure :

11.1.1 If the reverse osmosis device contains sanitizing or winterizing agents, or both, flush the device in accordance with the

supplier’s recommendations.

11.1.2 Make preliminary checks to make sure all fittings are tight, all components are operational, and the feed solution is at

the proper concentration and temperature. Before energizing the high-pressure pump, the low-pressure switch must be off for

start-up to complete the circuit past the low-pressure cutout. Energize the high-pressure pump momentarily to check proper

rotation.

11.1.3 Open the feed supply valve, the concentrate flow control valve, the pump by-pass on the positive displacement feed

pump, or the centrifugal pump throttling valve. Start the booster pump and then the high-pressure pump.

11.1.4 Bringthefeedpressuretoagagepressureof2.75 60.07MPa(400 610psi).Toreach2.75MPa,itthatisinaccordance

with the specifications of membrane manufacturer for a given element model. It is possible that the by-pass valve or the throttling

valve (depending on pump system) and the concentrate flow control valve may need to be adjusted simultaneously. If necessary,

another pressure agreed upon between the user and the supplier may be used.

11.1.5 Set concentrate flow in accordance with the supplier’s recommendation by adjusting the concentrate flow control valve.

But maintain conversion within 62% of the supplier’s recommendation.

11.1.6 Recheck and adjust if necessary both the concentrate flow and feed pressure to give the selected values for flow and

pressure.

11.1.7 Check and adjust the cooling system in the feed solution to give a permeate temperature of 25 6 1°C.

11.1.8 Once sustained operation is attained, energize the low-pressure shut-off switch.

11.2 Data Recording:

11.2.1 One hour after start-up, measure and record on a data sheet the inlet and outlet pressures of the filter and the feed,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.