ASTM D4194-03

(Test Method)Standard Test Methods for Operating Characteristics of Reverse Osmosis and Nanofiltration Devices

Standard Test Methods for Operating Characteristics of Reverse Osmosis and Nanofiltration Devices

SIGNIFICANCE AND USE

Reverse osmosis and nanofiltration desalinating devices can be used to produce potable water from brackish supplies (10 000 mg/L) and seawater as well as to upgrade the quality of industrial water. These test methods permit the measurement of the performance of reverse osmosis devices using standard sets of conditions and are intended for short-term testing (24 h). These test methods can be used to determine changes that may have occurred in the operating characteristics of reverse osmosis and nanofiltration devices but are not intended to be used for plant design.

SCOPE

1.1 These test methods cover the determination of the operating characteristics of reverse osmosis devices using standard test conditions and are not necessarily applicable to natural waters. Three test methods are given, as follows:SectionsTest Method A—Brackish Water Reverse Osmosis Devices8-13Test Method B—Nanofiltration Devices14-19Test Method C—Seawater Reverse Osmosis Devices20-25

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4194 – 03

Standard Test Methods for

Operating Characteristics of Reverse Osmosis and

1

Nanofiltration Devices

This standard is issued under the fixed designation D 4194; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Methods

1.1 These test methods cover the determination of the 4.1 Thesetestmethodsconsistofdeterminingthedesalinat-

operating characteristics of reverse osmosis devices using ing ability and permeate flow rate of reverse osmosis and

standard test conditions and are not necessarily applicable to nanofiltration devices. They are applicable to both new and

natural waters. Three test methods are given, as follows: used reverse osmosis or nanofiltration devices.

5. Significance and Use

Sections

5.1 Reverse osmosis and nanofiltration desalinating devices

Test Method A—Brackish Water Reverse Osmosis De- 8-13

can be used to produce potable water from brackish supplies

vices

(<10000 mg/L) and seawater as well as to upgrade the quality

Test Method B—Nanofiltration Devices 14-19

Test Method B—Seawater Reverse Osmosis Devices 20-25

ofindustrialwater.Thesetestmethodspermitthemeasurement

of the performance of reverse osmosis devices using standard

1.2 This standard does not purport to address all of the

sets of conditions and are intended for short-term testing (<24

safety concerns, if any, associated with its use. It is the

h). These test methods can be used to determine changes that

responsibility of the user of this standard to establish appro-

may have occurred in the operating characteristics of reverse

priate safety and health practices and determine the applica-

osmosis and nanofiltration devices but are not intended to be

bility of regulatory limitations prior to use.

used for plant design.

2. Referenced Documents

6. Reagents

2.1 ASTM Standards:

2

6.1 Purity of Reagents—Reagent grade chemicals shall be

D 512 Test Methods for Chloride Ion in Water

used in all tests. Unless otherwise indicated, it is intended that

D 1125 Test Methods for Electrical Conductivity and Re-

2

all reagents shall conform to the specifications of the Commit-

sistivity of Water

2

tee onAnalytical Reagents of theAmerican Chemical Society,

D 1129 Terminology Relating to Water

4

2

where such specifications are available. Other grades may be

D 1193 Specification for Reagent Water

used, provided it is first ascertained that the reagent is of

D 6161 Terminology Used for Crossflow Microfiltration,

sufficiently high purity to permit its use without lessening the

Ultrafiltration, Nanofiltration, and Reverse Osmosis Mem-

3

accuracy of the determination.

brane Processes

6.2 Purity of Water—Unlessotherwiseindicated,references

3. Terminology

to water shall be understood to mean Type III reagent con-

forming to Specification D1193.

3.1 Definitions—For definitions of terms used in these test

methods, refer to Terminology D1129 and D6161.

1

These test methods are under the jurisdiction of ASTM Committee D19 on

4

Water, and are the direct responsibilities of Subcommittee D19.08 on Membranes Reagent Chemicals, American Chemical Society Specifications, American

and Ion Exchange Materials. Chemical Society, Washington, DC. For suggestions on the testing of reagents not

Current edition approved June 10, 2003. Published July 2003. Originally listed by the American Chemical Society, see Analar Standards for Laboratory

approved in 1982. Last previous edition approved in 2001 as D4194–95(2001). Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

2

Annual Book of ASTM Standards, Vol 11.01. and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

3

Annual Book of ASTM Standards, Vol 11.02. MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 4194 – 03

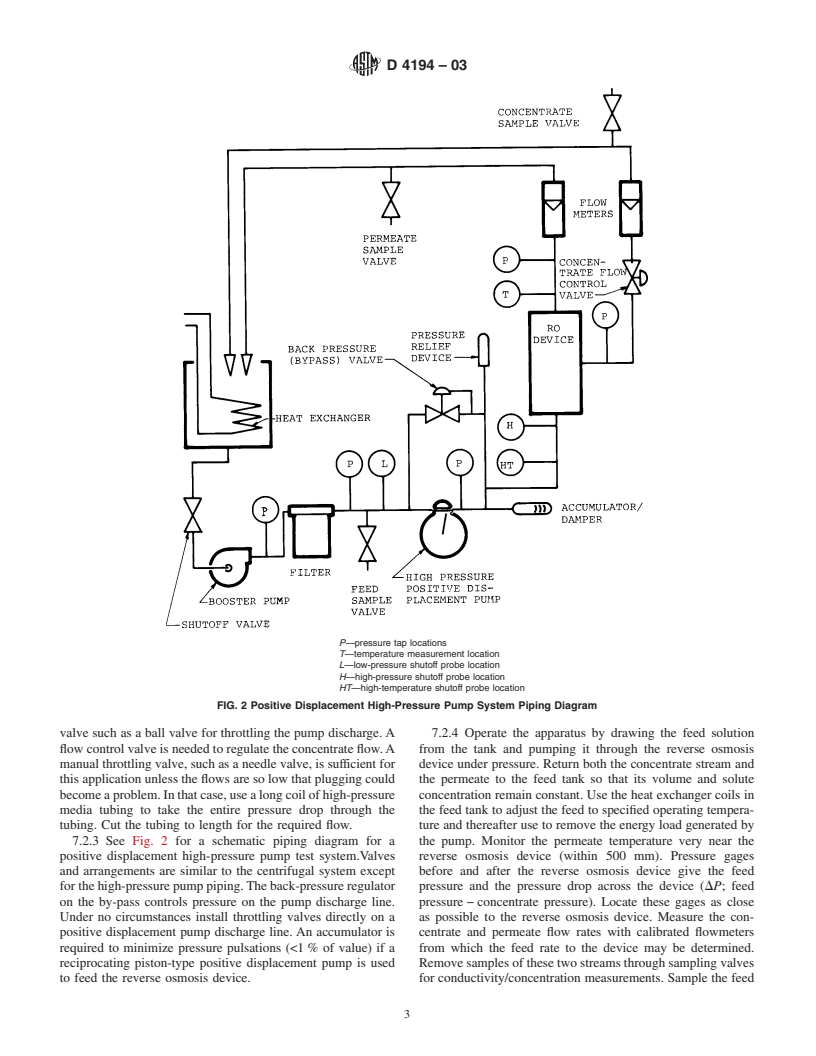

7. Apparatus degrease or both, before use. All pressurized components

whether stainless steel or plastic should be designed based on

7.1 The apparatus for both methods is schematically de-

the manufacturer’s working pressure rating. Review manufac-

scribed in Fig. 1 and Fig. 2.Aconductivity meter can be used

turer’s rating for compliance with standard engineering prac-

to determine the salt concentration in accordance with Test

tice.

Methods D1125.

7.2.2 The reverse osmosis testing apparatus, represented

7.2 Installation:

7.2.1 Materials of construction shall be of high-quality schematically in Fig. 1 using a centrifugal pump, consists of a

feed holding tank equipped with a thermostated heat ex-

stainle

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.