ASTM E1032-95

(Test Method)Standard Test Method for Radiographic Examination of Weldments

Standard Test Method for Radiographic Examination of Weldments

SCOPE

1.1 This test method provides a uniform procedure for radiographic examination of weldments using industrial radiographic film. Requirements expressed in this method are intended to control the quality of the radiographic images and are not intended for controlling acceptability or quality of welds.

1.2 The radiographic extent, the quality level, and the acceptance criteria to be applied shall be specified in the contract, purchase order, product specification, or drawings.

1.3 The radiographic test method is highly sensitive to detection of volumetric discontinuities. The radiographic techniques stated herein provide adequate assurance for defect detectability; however, it is recognized that, for special applications, specific techniques using more stringent requirements may be required to provide additional detection capability. The use of specific radiographic techniques shall be agreed upon between purchaser and supplier.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (For more specific safety precautionary information, see Section 7.)

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1032 – 95 An American National Standard

Standard Test Method for

Radiographic Examination of Weldments

This standard is issued under the fixed designation E 1032; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope diographic Film Processing

E 1025 Practice for Design, Manufacture, and Material

1.1 This test method provides a uniform procedure for

Grouping Classification of Hole-Type Image Quality Indi-

radiographic examination of weldments using industrial radio-

cators (IQI) Used for Radiology

graphic film. Requirements expressed in this method are

E 1316 Terminology for Nondestructive Examinations

intended to control the quality of the radiographic images and

2.2 ASNT Standards:

are not intended for controlling acceptability or quality of

Recommended Practice No. SNT-TC-1A Personnel Quali-

welds.

fication and Certification in Nondestructive Testing

1.2 The radiographic extent, the quality level, and the

ANSI/ASNT-CP-189 Standard for Qualification and Certi-

acceptance criteria to be applied shall be specified in the

fication of Nondestructive Testing Personnel

contract, purchase order, product specification, or drawings.

2.3 Military Standard:

1.3 The radiographic test method is highly sensitive to

MIL-STD-410 Nondestructive Testing Personnel Qualifica-

detection of volumetric discontinuities. The radiographic tech-

tion and Certification

niques stated herein provide adequate assurance for defect

detectability; however, it is recognized that, for special appli-

3. Terminology

cations, specific techniques using more stringent requirements

3.1 Definitions—For definitions of terms used in this test

may be required to provide additional detection capability. The

method, see Terminology E 1316.

use of specific radiographic techniques shall be agreed upon

between purchaser and supplier.

4. Basis of Application

1.4 This standard does not purport to address all of the

4.1 Personnel Qualification—Nondestructive testing (NDT)

safety concerns, if any, associated with its use. It is the

personnel shall be qualified in accordance with a nationally

responsibility of the user of this standard to establish appro-

recognized NDT personnel qualification practice or standard

priate safety and health practices and determine the applica-

such as ANSI/ASNT-CP-189, SNT-TC-1A, MIL STD-410, or a

bility of regulatory limitations prior to use. (For more specific

similiar document. The practice or standard used and its

safety precautionary information, see Section 7.)

applicable revision shall be specified in the contractual agree-

ment between the using parties.

2. Referenced Documents

4.2 Qualification of Nondestructive Agencies—If specified

2.1 ASTM Standards:

2 in the contractual agreement, NDT agencies shall be qualified

E 94 Guide for Radiographic Testing

and evaluated in accordance with Practice E 543. The appli-

E 242 Reference Radiographs for Appearances of Radio-

2 cable edition of Practice E 543 shall be specified in the

graphic Images as Certain Parameters are Changed

2 contractual agreement.

E 390 Reference Radiographs for Steel Fusion Welds

4.3 Time of Examination—The time of examination shall be

E 543 Practice for Evaluating Agencies that Perform Non-

2 in accordance with 8.1 unless otherwise specified.

destructive Testing

4.4 Procedures—The procedures to be utilized shall be as

E 746 Test Method for Determining Relative Image Quality

2 described in 7.1.

Response of Industrial Radiographic Film

4.5 Extent of Examination—The extent of the examination

E 747 Practice for Design, Manufacture and Material

shall be in accordance with 7.2.

Grouping Classification of Wire Image Quality Indicators

2 4.6 Reporting Criteria/Acceptance Criteria—Reporting cri-

(IQI) Used for Radiology

teria of the examination results shall be in accordance with

E 999 Guide for Controlling the Quality of Industrial Ra-

Section 11.

4.7 Reexamination of Repaired or Reworked Items—

This test method is under the jurisdiction of ASTM Committee E-7 on

Nondestructive Testing and is the direct responsibility of Subcommittee E07.01 on

Radiographic Practice and Penetrameters. Available from American Society for Nondestructive Testing (ANST), 1711

Current edition approved Dec. 10, 1995. Published February 1996. Originally Arlingate Lane, P.O. Box 28518, Columbus, OH 43228-0518.

published as E 1032 – 85. Last previous edition E 1032 – 92. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Annual Book of ASTM Standards, Vol 03.03. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 1032

Reexamination of repaired or reworked items is not addressed 5.6 IQI’s (Penetrameters)—Unless otherwise specified by

in this test method and if required shall be specified in the the applicable job order or contract, only those IQI’s that

contractual agreement. comply with the design and identification requirements speci-

4.8 Radiographic Quality Level—The radiographic quality fied in Practice E 1025 or Practice E 747 shall be used.

level shall be in accordance with 5.6. 5.7 Shims, Separate Blocks, or Like Sections—Shims, sepa-

rate blocks, or like sections made of the same or radiographi-

5. Apparatus

cally similar materials (as defined in Practice E 1025) may be

5.1 Radiation Source (X-Ray or Gamma-Ray)—Selection of

used to facilitate IQI positioning. There is no restriction on

the appropriate source is dependent upon variables regarding

shim or separate block maximum thickness, provided the IQI

the weld being examined (material composition and thickness).

and area-of-interest density variation requirements of 8.8.2 are

The suitability of the source shall be demonstrated by attain-

met. The like section should be geometrically similar to the

ment of the required IQI sensitivity and compliance with all

object being radiographed.

other requirements stipulated herein (film density and area of

5.8 Radiographic Location and Identification Markers—

interest density tolerances, etc.).

Lead numbers and letters are used to designate the part number

5.2 Film Holders and Cassettes—Film holders and cassettes

and location number. The size and thickness of the markers

shall be light tight and shall be handled properly to reduce the

shall depend on the ability of the radiographic technique to

likelihood that they may be damaged. They may be flexible

discern the markers on the radiograph. As a general rule,

vinyl, plastic, or other durable material, or they may be made

markers ⁄16 in. thick will suffice for most low energy (less than

from metallic materials. In the event that light leaks into the

1 MeV) X ray and Iridium 192 radiography; for higher energy

film holder and produces images on the radiograph, the

radiography it may be necessary to use markers that are thicker

radiograph need not be rejected unless the images encroach on

( ⁄8 in. thick or more).

the radiographic area of interest. If the film holder exhibits

5.9 Radiographic Density Measurement Apparatus—Either

light leaks, it shall be repaired before reuse or discarded. Film

a transmission densitometer or a step-wedge comparison film

holders and cassettes should be routinely examined to mini-

shall be used for judging film-density requirements. Step-

mize the likelihood of light leaks.

wedge comparison films or densitometers calibration, or both,

5.3 Intensifying Screens:

shall be verified by comparison with a calibrated step-wedge

5.3.1 Metallic Screens:

film traceable to the National Institute of Standards and

5.3.1.1 Intensifying screens of the lead-foil type are gener-

Technology. Where applicable, a film digitization and analysis

ally used for production radiography. Screens shall be of the

system may be substituted for a transmission densitometer

same approximate dimensions as the film being used and shall

provided the film digitization and analysis system has been

be in direct intimate contact with the film during exposure.

calibrated and verified by comparison with a calibrated step-

5.3.1.2 For X-ray voltages between 200 kV and 1 MeV,

wedge film traceable to the National Institute of Standards and

front- and rear-screen thicknesses should be a minimum of

Technology.

0.005 in. thick. Below 200 kV, screen thicknesses up to 0.005

6. Materials

in. should be used if they improve radiographic quality. For

6.1 Films—Selections of film type should be determined by

isotope and high-voltage X radiography (greater than 1 MeV)

such factors as the required radiographic quality level, equip-

increased thicknesses may be appropriate for improvements in

ment capability, materials, etc. The films selected must be

radiographic quality and should be used accordingly. When

capable of demonstrating the required image quality indicator

double-load exposures are made, intermediate screens (be-

(IQI) sensitivity.

tween film) may be used if desired.

5.3.2 Fluorescent or Fluorometallic Screens—Such screens

NOTE 1—Test Method E 746 provides a system for determining the

may be used; however, they must be capable of demonstrating

relative image quality response of industrial radiographic film using an

the required IQI sensitivity.

IQI.

5.3.3 Screen Care:

7. Requirements

5.3.3.1 All screens should be handled carefully to avoid

dents, scratches, grease, or dirt on active surfaces. Screens that 7.1 Procedure Requirement—Unless otherwise specified by

render nonrelevant indications on radiographs shall be visually the applicable job order or contract, radiographic examination

examined and discarded if physical damage is observed. shall be performed in accordance with a written procedure.

5.3.3.2 Screens, with or without backing, shall be free of Specific requirements regarding the preparation and approval

dust, dirt, oxidation, or any other foreign material that render of the written procedures shall be dictated by purchaser and

undesirable nonrelevant images on the film. supplier agreement. The production procedure shall address all

5.4 Filters—Filters shall be used whenever the contrast applicable portions of this document and shall be available for

reductions caused by low energy, scattered radiation, or the review during interpretation of the radiographs.

extent of undercut (edge burn-off) occurring on production 7.2 Radiographic Coverage—Unless otherwise specified by

radiographs is of significant magnitude to cause difficulty in purchaser and supplier agreement, the extent of radiographic

meeting the quality level or radiographic coverage require- coverage shall include 100 % of the volume of the weld.

ments stipulated by the job order or contract (see Guide E 94). 7.3 Radiographic Film Quality—All radiographs shall be

5.5 Masking—Masking material may improve radiographic free of mechanical, chemical, handling-related, or other blem-

quality (see Guide E 94). ishes which could mask or be confused with the image of any

E 1032

discontinuity in the area of interest on the radiograph. If any

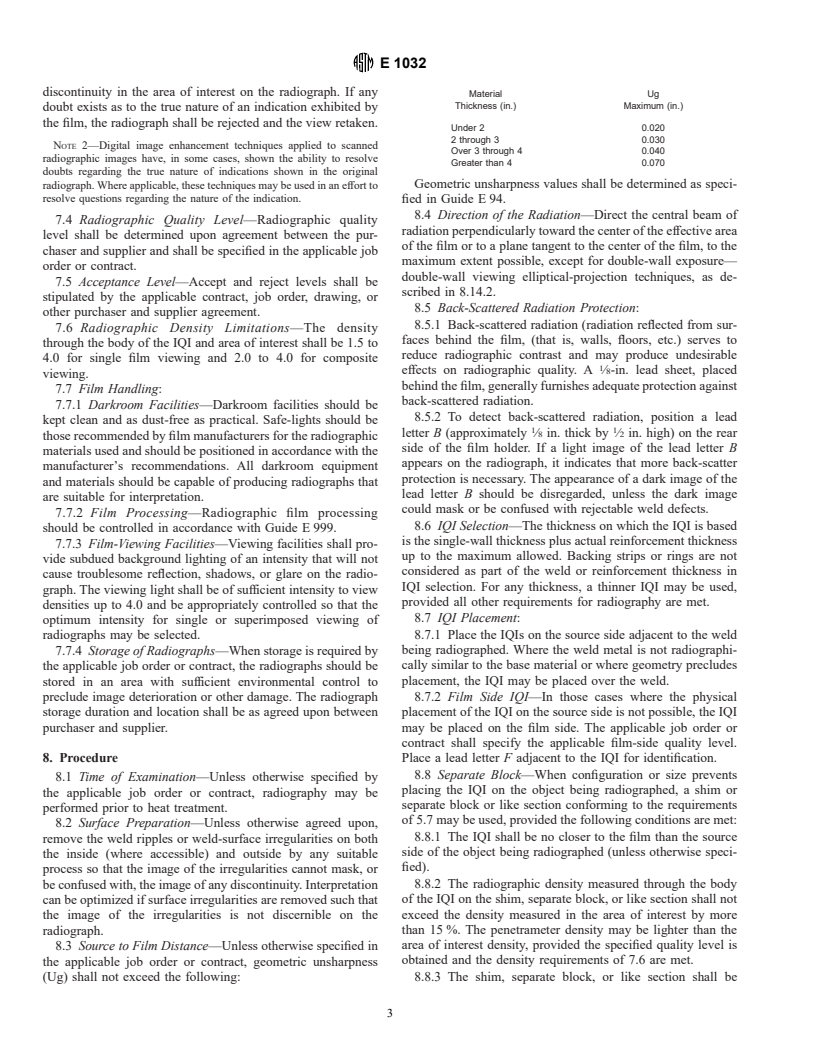

Material Ug

Thickness (in.) Maximum (in.)

doubt exists as to the true nature of an indication exhibited by

the film, the radiograph shall be rejected and the view retaken.

Under 2 0.020

2 through 3 0.030

NOTE 2—Digital image enhancement techniques applied to scanned

Over 3 through 4 0.040

radiographic images have, in some cases, shown the ability to resolve

Greater than 4 0.070

doubts regarding the true nature of indications shown in the original

Geometric unsharpness values shall be determined as speci-

radiograph. Where applicable, these techniques may be used in an effort to

resolve questions regarding the nature of the indication.

fied in Guide E 94.

8.4 Direction of the Radiation—Direct the central beam of

7.4 Radiographic Quality Level—Radiographic quality

radiation perpendicularly toward the center of the effective area

level shall be determined upon agreement between the pur-

of the film or to a plane tangent to the center of the film, to the

chaser and supplier and shall be specified in the applicable job

maximum extent possible, except for double-wall exposure—

order or contract.

double-wall viewing elliptical-projection techniques, as de-

7.5 Acceptance Level—Accept and reject levels shall be

scribed in 8.14.2.

stipulated by the applicable contract, job order, drawing, or

8.5 Back-Scattered Radiation Protection:

other purchaser and supplier agreement.

8.5.1 Back-scattered radiation (radiation reflected from sur-

7.6 Radiographic Density Limitations—The density

faces behind the film, (that is, walls, floors, etc.) serves to

through the body of the IQI and area of interest shall be 1.5 to

reduce radiographic contrast and may produce undesirable

4.0 for single film viewing and 2.0 to 4.0 for composite

effects on radiographic quality. A ⁄8-in. lead sheet, placed

viewing.

behind the film, generally furnishes adequate protection against

7.7 Film Handling:

back-scattered radiation.

7.7.1 Darkroom Facilities—Darkroom facilities should be

8.5.2 To detect back-scattered radiation, position a lead

kept clean and as dust-free as practical. Safe-lights should be

1 1

letter B (approximately ⁄8 in. thick by ⁄2 in. high) on the rear

those recommended by film manufacturers for the radiographic

side of the film holder. If a light image of the lead letter B

materials used and should be positioned in accordance with the

appears on the radiograph, it indicates that more back-scatter

manufacturer’s recommendations. All darkroom equipment

protection is necessary. The appearance of a dark image of the

and materials should be capable of producing radiographs that

lead letter B should be disregarded, unless the dark image

are suitable for interpretation.

could mask or be confused with rejectable weld defects.

7.7.2 Film Processing—Radiographic film processing

8.6 IQI Selection—The thickness on which the IQI is based

should be controlled in accordance with Guide E 999.

is the single-wall thickness plus actual reinforcement thickness

7.7.3 Film-Viewing Facilities—Viewing facilities shall pro-

up to the maximum allowed. Backing strips or rings are not

vide subdued background lighting of an intensity that will not

considered as part of the weld or reinforcement thickness in

cause troublesome reflection, shadows, or glare on the radio-

IQI selection. For any thickness, a thinner IQI may be used,

graph. The viewing light shall be of sufficient intensity to view

provided all other requirements for radiography are met.

densities up to 4.0 and be appropriately cont

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.