ASTM D2229-04

(Test Method)Standard Test Method for Adhesion Between Steel Tire Cords and Rubber

Standard Test Method for Adhesion Between Steel Tire Cords and Rubber

SCOPE

1.1 This test method covers the determination of the force required to pull a steel cord from a block of vulcanized rubber.

1.2 Although designed primarily for steel cord, this test method may be applied with modifications to wire used in rubber products.

1.3 This test method can also be used for evaluating rubber compound performance with respect to adhesion to steel cord.

1.4 The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: D 2229 – 04

Standard Test Method for

1

Adhesion Between Steel Tire Cords and Rubber

This standard is issued under the fixed designation D2229; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1.1 The following terms are relevant to this standard:

adhesion, rubber compound, and steel cord.

1.1 This test method covers the determination of the force

3.1.2 For definitions of terms relating to rubber, refer to

required to pull a steel cord from a block of vulcanized rubber.

Terminology D1566.

1.2 Although designed primarily for steel cord, this test

3.1.3 For definitions of other terms related to textiles, refer

method may be applied with modifications to wire used in

to Terminology D123.

rubber products.

1.3 This test method can also be used for evaluating rubber

4. Summary of Test Method

compound performance with respect to adhesion to steel cord.

4.1 Thesteelcordsarevulcanizedintoablockofrubberand

1.4 The values stated in SI units are to be regarded as the

the force necessary to pull the cords linearly out of the rubber

standard. No other units of measurement are included in this

is measured.

standard.

1.5 This standard does not purport to address all of the

5. Significance and Use

safety concerns, if any, associated with its use. It is the

5.1 This test method is considered satisfactory for the

responsibility of the user of this standard to establish appro-

acceptance testing of commercial shipments of steel tire cord

priate safety and health practices and determine the applica-

because current estimates of between-laboratory precision for

bility of regulatory limitations prior to use.

single materials are considered acceptable and the method has

been used extensively in the trade for acceptance testing.

2. Referenced Documents

2

5.1.1 If there are differences or practical significances be-

2.1 ASTM Standards:

tween reported test results for two laboratories (or more),

D76 SpecificationforTensileTestingMachinesforTextiles

comparative tests should be performed to determine if there is

D123 Terminology Relating to Textiles

a statistical bias between them, using competent statistical

D1566 Terminology Relating to Rubber

assistance.Asaminimum,thetestsamplesshouldbeusedthat

D2904 PracticeforInterlaboratoryTestingofaTextileTest

are as homogenous as possible, that are drawn from the

Method that Produces Normally Distributed Data

material from which the disparate test results were obtained,

D6477 Terminology Relating to Tire Cord, Bead Wire,

and that are randomly assigned in equal numbers to each

Hose Reinforcing Wire,and Fabrics

laboratory for testing. Other materials with established test

E105 Practice for Probability Sampling of Materials

values may be used for this purpose. The test results from the

E122 Practice for Choice of Sample Size to Estimate a

two laboratories should be compared using a statistical test for

Measure of Quality for a Lot or Process

unpaired data, at a probability level chosen prior to the testing

3. Terminology series. If a bias is found, either its cause must be found and

corrected, or future test results must be adjusted in consider-

3.1 Definitions

ation of the known bias.

3.1.1 Fordefinitionsoftermsrelatingtotirecord,beadwire,

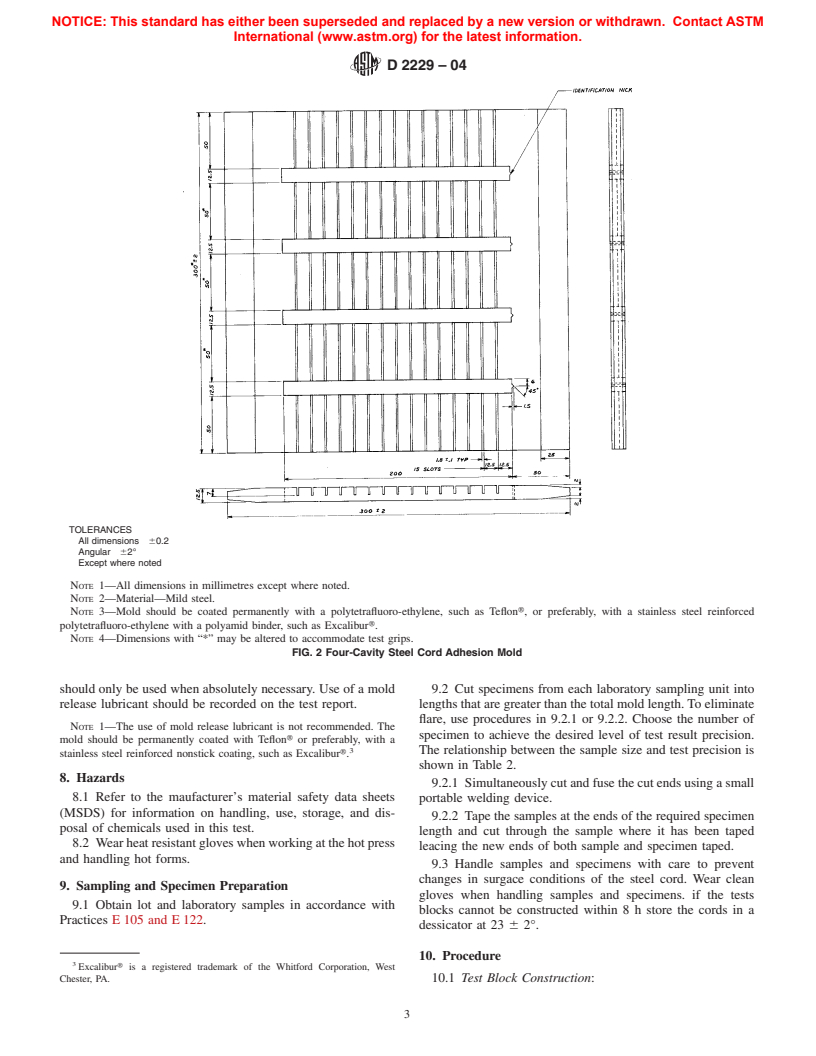

5.2 The mold described in this test method is primarily

hose wire, and tire cord fabrics, refer to Terminology D6477.

designedforqualityacceptancetestingforsteelcordwherethe

sample size for each cord is 4 or a multiple thereof, but any

mold/cavity combination which will provide the required test

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD13onTextiles

block dimensions (Figs. 1 and 2) is acceptable.

and is the direct responsibility of Subcommittee D13.19 on Tire Cord and Fabrics.

5.3 AppendixX1containssuggestedrangesofenvironmen-

Current edition approved Oct. 1, 2004. Published October 2004. Originally

published as D2229–63T. Last previous edition D2229–02.

tal conditions for aging tests.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.4 The property measured by this test method indicates

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

whether the adhesion of the steel cord to the rubber is greater

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. than the cohesion of the rubber, that is, complete rubber

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superseded an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.