ASTM D7343-12(2017)

(Practice)Standard Practice for Optimization, Sample Handling, Calibration, and Validation of X-ray Fluorescence Spectrometry Methods for Elemental Analysis of Petroleum Products and Lubricants

Standard Practice for Optimization, Sample Handling, Calibration, and Validation of X-ray Fluorescence Spectrometry Methods for Elemental Analysis of Petroleum Products and Lubricants

SIGNIFICANCE AND USE

3.1 Accurate elemental analyses of samples of petroleum and petroleum products are required for the determination of chemical properties, which are in turn used to establish compliance with commercial and regulatory specifications.

SCOPE

1.1 This practice covers information relating to sampling, calibration and validation of X-ray fluorescence instruments for elemental analysis, including all kinds of wavelength dispersive (WDXRF) and energy dispersive (EDXRF) techniques. This practice includes sampling issues such as the selection of storage vessels, transportation, and sub-sampling. Treatment, assembly, and handling of technique-specific sample holders and cups are also included. Technique-specific requirements during analytical measurement and validation of measurement for the determination of trace elements in samples of petroleum and petroleum products are described. For sample mixing, refer to Practice D5854. Petroleum products covered in this practice are considered to be a single phase and exhibit Newtonian characteristics at the point of sampling.

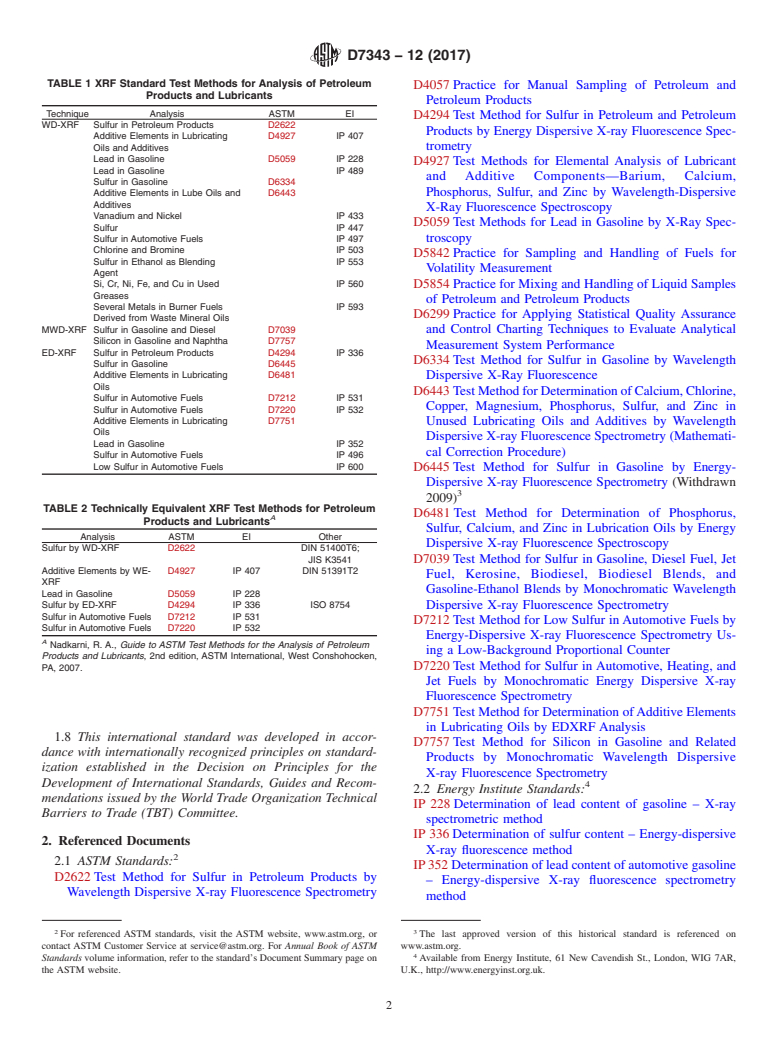

1.2 Applicable Test Methods—This practice is applicable to the XRF methods under the jurisdiction of ASTM Subcommittee D02.03 on Elemental Analysis, and those under the jurisdiction of the Energy Institute’s Test Method Standardization Committee (Table 1). Some of these methods are technically equivalent though they may differ in details (Table 2).

TABLE 1 XRF Standard Test Methods for Analysis of Petroleum Products and Lubricants

Technique

Analysis

ASTM

EI

WD-XRF

Sulfur in Petroleum Products

D2622

Additive Elements in Lubricating Oils and Additives

D4927

IP 407

Lead in Gasoline

D5059

IP 228

Lead in Gasoline

IP 489

Sulfur in Gasoline

D6334

Additive Elements in Lube Oils and Additives

D6443

Vanadium and Nickel

IP 433

Sulfur

IP 447

Sulfur in Automotive Fuels

IP 497

Chlorine and Bromine

IP 503

Sulfur in Ethanol as Blending Agent

IP 553

Si, Cr, Ni, Fe, and Cu in Used Greases

IP 560

Several Metals in Burner Fuels Derived from Waste Mineral Oils

IP 593

MWD-XRF

Sulfur in Gasoline and Diesel

D7039

Silicon in Gasoline and Naphtha

D7757

ED-XRF

Sulfur in Petroleum Products

D4294

IP 336

Sulfur in Gasoline

D6445

Additive Elements in Lubricating Oils

D6481

Sulfur in Automotive Fuels

D7212

IP 531

Sulfur in Automotive Fuels

D7220

IP 532

Additive Elements in Lubricating Oils

D7751

Lead in Gasoline

IP 352

Sulfur in Automotive Fuels

IP 496

Low Sulfur in Automotive Fuels

IP 600

TABLE 2 Technically Equivalent XRF Test Methods for Petroleum Products and LubricantsA

Analysis

ASTM

EI

Other

Sulfur by WD-XRF

D2622

DIN 51400T6;

JIS K3541

Additive Elements by WE-XRF

D4927

IP 407

DIN 51391T2

Lead in Gasoline

D5059

IP 228

Sulfur by ED-XRF

D4294

IP 336

ISO 8754

Sulfur in Automotive Fuels

D7212

IP 531

Sulfur in Automotive Fuels

D7220

IP 532

(A) Nadkarni, R. A., Guide to ASTM Test Methods for the Analysis of Petroleum Products and Lubricants, 2nd edition, ASTM International, West Conshohocken, PA, 2007.

1.3 Applicable Fluids—This practice is applicable to petroleum and petroleum products with vapor pressures at sampling and storage temperatures less than or equal to 101 kPa (14.7 psi). Use Practice D4057 or IP 475 to sample these materials. Refer to Practice D5842 when sampling materials that also require Reid vapor pressure (RVP) determination.

1.4 Non-applicable Fluids—Petroleum products whose vapor pressure at sampling and sample storage conditions are abov...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7343 − 12 (Reapproved 2017)

Designation: 558/07

Standard Practice for

Optimization, Sample Handling, Calibration, and Validation

of X-ray Fluorescence Spectrometry Methods for Elemental

Analysis of Petroleum Products and Lubricants

This standard is issued under the fixed designation D7343; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope tion Committee (Table 1). Some of these methods are techni-

cally equivalent though they may differ in details (Table 2).

1.1 This practice covers information relating to sampling,

calibration and validation of X-ray fluorescence instruments 1.3 Applicable Fluids—This practice is applicable to petro-

for elemental analysis, including all kinds of wavelength leum and petroleum products with vapor pressures at sampling

dispersive (WDXRF) and energy dispersive (EDXRF) tech- and storage temperatures less than or equal to 101 kPa

niques. This practice includes sampling issues such as the (14.7 psi). Use Practice D4057 or IP 475 to sample these

selection of storage vessels, transportation, and sub-sampling. materials. Refer to Practice D5842 when sampling materials

Treatment, assembly, and handling of technique-specific that also require Reid vapor pressure (RVP) determination.

sample holders and cups are also included. Technique-specific

1.4 Non-applicable Fluids—Petroleum products whose va-

requirements during analytical measurement and validation of

por pressure at sampling and sample storage conditions are

measurement for the determination of trace elements in

above 101 kPa (14.7 psi) and liquefied gases (that is, LNG,

samples of petroleum and petroleum products are described.

LPG, etc.) are not covered by this practice.

For sample mixing, refer to Practice D5854. Petroleum prod-

1.5 Sampling Methods—The physical sampling and meth-

ucts covered in this practice are considered to be a single phase

ods of sampling from a primary source are not covered by this

and exhibit Newtonian characteristics at the point of sampling.

guide. It is assumed that samples covered by this practice are

1.2 Applicable Test Methods—This practice is applicable to

a representative sample of the primary source liquid. Refer to

the XRF methods under the jurisdiction ofASTM Subcommit-

Practice D4057 or IP 475 for detailed sampling procedures.

tee D02.03 on Elemental Analysis, and those under the

1.6 The values stated in SI units are to be regarded as the

jurisdiction of the Energy Institute’s Test Method Standardiza-

standard.

1.6.1 Exception—The values given in parentheses are for

This practice is under the jurisdiction ofASTM Committee D02 on Petroleum

information only.

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom-

1.7 This standard does not purport to address all of the

mittee D02.03 on Elemental Analysis.

CurrenteditionapprovedJune1,2017.PublishedJuly2017.Originallyapproved

safety concerns, if any, associated with its use. It is the

in 2007. Last previous edition approved in 2012 as D7343 – 12. DOI: 10.1520/

responsibility of the user of this standard to establish appro-

D7343-12R17.

priate safety and health practices and determine the applica-

This practice was jointly prepared by ASTM International and the Energy

Institute. bility of regulatory limitations prior to use.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7343 − 12 (Reapproved 2017)

D7343 − 12 (2017)

TABLE 1 XRF Standard Test Methods for Analysis of Petroleum

D4057 Practice for Manual Sampling of Petroleum and

Products and Lubricants

Petroleum Products

Technique Analysis ASTM EI

D4294 Test Method for Sulfur in Petroleum and Petroleum

WD-XRF Sulfur in Petroleum Products D2622

Products by Energy Dispersive X-ray Fluorescence Spec-

Additive Elements in Lubricating D4927 IP 407

trometry

Oils and Additives

Lead in Gasoline D5059 IP 228

D4927 Test Methods for Elemental Analysis of Lubricant

Lead in Gasoline IP 489

and Additive Components—Barium, Calcium,

Sulfur in Gasoline D6334

Additive Elements in Lube Oils and D6443 Phosphorus, Sulfur, and Zinc by Wavelength-Dispersive

Additives

X-Ray Fluorescence Spectroscopy

Vanadium and Nickel IP 433

D5059 Test Methods for Lead in Gasoline by X-Ray Spec-

Sulfur IP 447

Sulfur in Automotive Fuels IP 497 troscopy

Chlorine and Bromine IP 503

D5842 Practice for Sampling and Handling of Fuels for

Sulfur in Ethanol as Blending IP 553

Volatility Measurement

Agent

Si, Cr, Ni, Fe, and Cu in Used IP 560

D5854 Practice for Mixing and Handling of Liquid Samples

Greases

of Petroleum and Petroleum Products

Several Metals in Burner Fuels IP 593

D6299 Practice for Applying Statistical Quality Assurance

Derived from Waste Mineral Oils

MWD-XRF Sulfur in Gasoline and Diesel D7039 and Control Charting Techniques to Evaluate Analytical

Silicon in Gasoline and Naphtha D7757

Measurement System Performance

ED-XRF Sulfur in Petroleum Products D4294 IP 336

D6334 Test Method for Sulfur in Gasoline by Wavelength

Sulfur in Gasoline D6445

Additive Elements in Lubricating D6481 Dispersive X-Ray Fluorescence

Oils

D6443 TestMethodforDeterminationofCalcium,Chlorine,

Sulfur in Automotive Fuels D7212 IP 531

Copper, Magnesium, Phosphorus, Sulfur, and Zinc in

Sulfur in Automotive Fuels D7220 IP 532

Additive Elements in Lubricating D7751

Unused Lubricating Oils and Additives by Wavelength

Oils

Dispersive X-ray Fluorescence Spectrometry (Mathemati-

Lead in Gasoline IP 352

cal Correction Procedure)

Sulfur in Automotive Fuels IP 496

Low Sulfur in Automotive Fuels IP 600

D6445 Test Method for Sulfur in Gasoline by Energy-

Dispersive X-ray Fluorescence Spectrometry (Withdrawn

2009)

TABLE 2 Technically Equivalent XRF Test Methods for Petroleum

D6481 Test Method for Determination of Phosphorus,

A

Products and Lubricants

Sulfur, Calcium, and Zinc in Lubrication Oils by Energy

Analysis ASTM EI Other

Dispersive X-ray Fluorescence Spectroscopy

Sulfur by WD-XRF D2622 DIN 51400T6;

JIS K3541 D7039 Test Method for Sulfur in Gasoline, Diesel Fuel, Jet

Additive Elements by WE- D4927 IP 407 DIN 51391T2

Fuel, Kerosine, Biodiesel, Biodiesel Blends, and

XRF

Gasoline-Ethanol Blends by Monochromatic Wavelength

Lead in Gasoline D5059 IP 228

Sulfur by ED-XRF D4294 IP 336 ISO 8754 Dispersive X-ray Fluorescence Spectrometry

Sulfur in Automotive Fuels D7212 IP 531

D7212 Test Method for Low Sulfur inAutomotive Fuels by

Sulfur in Automotive Fuels D7220 IP 532

Energy-Dispersive X-ray Fluorescence Spectrometry Us-

A

Nadkarni, R. A., Guide to ASTM Test Methods for the Analysis of Petroleum

ing a Low-Background Proportional Counter

Products and Lubricants, 2nd edition, ASTM International, West Conshohocken,

D7220 Test Method for Sulfur in Automotive, Heating, and

PA, 2007.

Jet Fuels by Monochromatic Energy Dispersive X-ray

Fluorescence Spectrometry

D7751 Test Method for Determination ofAdditive Elements

in Lubricating Oils by EDXRF Analysis

1.8 This international standard was developed in accor-

D7757 Test Method for Silicon in Gasoline and Related

dance with internationally recognized principles on standard-

Products by Monochromatic Wavelength Dispersive

ization established in the Decision on Principles for the

X-ray Fluorescence Spectrometry

Development of International Standards, Guides and Recom- 4

2.2 Energy Institute Standards:

mendations issued by the World Trade Organization Technical

IP 228 Determination of lead content of gasoline – X-ray

Barriers to Trade (TBT) Committee.

spectrometric method

IP 336 Determination of sulfur content – Energy-dispersive

2. Referenced Documents

X-ray fluorescence method

2.1 ASTM Standards:

IP352 Determination of lead content of automotive gasoline

D2622 Test Method for Sulfur in Petroleum Products by

– Energy-dispersive X-ray fluorescence spectrometry

Wavelength Dispersive X-ray Fluorescence Spectrometry

method

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

the ASTM website. U.K., http://www.energyinst.org.uk.

D7343 − 12 (2017)

IP407 Determinationofbarium,calcium,phosphorus,sulfur tamination. The development of clean area sample handling

and zinc by wavelength dispersive X-ray fluorescence protocols is encouraged.

spectrometry

IP 433 Determination of vanadium and nickel content – 5. Sample Preparation

Wavelength dispersive X-ray fluorescence spectrometry

5.1 Choice of Sample Carrier—XRF testing requires a

IP 447 Determination of sulfur content – Wavelength

sample cell and a support film to hold the liquid sample in

dispersive X-ray fluorescence spectrometry

place during analysis.The choice of the sample cell or cup, the

IP 475 Methods of test for petroleum and its products

material in which it is held, and the type of support film used

IP 489 Determination of low lead contents in gasolines –

can all influence the result.

Wavelength dispersive X-ray fluorescence spectrometry

5.1.1 Sample Cell—The most common cell is a plastic cup,

IP 496 Determination of sulfur content of automotive fuels

ofwhichvariousdesignsareavailable.Thesedesignsallowfor

– Energy-dispersive X-ray fluorescence spectrometry

a variety of sample types to be measured either in a liquid or

IP497 Determination of sulfur content of automotive fuels –

powder form. It is important to check that the cup type used is

Wavelength dispersive X-ray fluorescence spectrometry

best suited for the compositions of samples to be analyzed.

IP 503 Determination of chlorine and bromine content –

Liquid sample cups usually have a seal that ensures the film is

Wavelength dispersive X-ray fluorescence spectrometry

sealed to a level above that of the liquid in the cell and that the

IP 531 Determination of sulfur content of automotive fuels

film is taut with no wrinkles.

–Low-backgroundproportionalcounterenergy-dispersive

5.1.1.1 Within XRF spectrometers heat is produced, both

X-ray fluorescence spectrometry method

from the spectrometer components themselves and from the

IP 532 Determination of the sulfur content of automotive

interaction of X-rays with the sample. Petroleum products that

fuels – Polarized X-ray fluorescence spectrometry

are not stable due to volatility should only be placed into

IP 553 Ethanol as a Blending Component for Petrol –

vented sample cups or special sealed sample cups specifically

Determination of Sulfur Content – WDXRF Method

designed for volatile samples (see 8.3).

IP 560 Determination of Silicon, Chromium, nickel, Iron,

5.1.1.2 The cup size may be important. Depending on the

and Copper in Used Greases – WDXRF Method

film type used to support the liquid, different films will sag due

IP 593 Determination of Pb, Ni, Cr, Cu, Zn,As, Cd, Tl, Sb,

to the weight of sample and relax due to chemical interaction,

Co, Mn, and V in Burner Fuels derived from Waste

or heat, or both. To reduce this sagging effect, the smallest

Mineral Oils – WDXRF Method

diameter sample cups should be used. Cups with diameters

IP 600 Petroleum Products – Determination of Low Sulfur

well in excess of the area detected by the spectrometer are

Content of Automotive Fuels – EDXRF Spectrometry

likely to increase errors due to sagging.

5.1.1.3 A number of petroleum products require heating to

3. Significance and Use

ensurehomogenizationpriortoanalysisortoenabletransferto

3.1 Accurate elemental analyses of samples of petroleum

the sample cell; examples include fuel oils and wax products.

and petroleum products are required for the determination of

The sample cup should be able to withstand the temperature

chemical properties, which are in turn used to establish

used in this process. In general, most plastic sample cells

compliance with commercial and regulatory specifications.

should withstand temperatures up to 70 °C.

5.1.2 Sample Cell Holder—Many manufacturers recom-

4. Sample Handling

mend metal holders to hold sample cups while they are

transferred into the XRF instrument. These holders can be

4.1 It is necessary to use precautions to minimize the

possibility of contamination of trace elemental analysis made from aluminum, stainless steel, or other materials. It is

samples. Good laboratory practices in this area include: important to recognize that these represent a potential spectral

4.1.1 Samples received by the laboratory and required for contamination to the analysis either if the spectrometer is to

determine an analyte that the holder is made from or if the

trace element analysis should be stored in a designated specific

location for storage while awaiting analysis. This area, when- material from the holder causes an interference with the

ever possible, should not contain samples that could contami- analyte. Generally, this is not a problem for elements with

nate those requiring trace element analysis. atomic number <30. For elements with atomic number >30 it

is advisable to check the potential contamination from the

4.1.2 All laboratory equipment used specifically for trace

element analysis should be free of any source of contamina- sample cup holder using a blank.

tion.This may require that specific equipment be used only for

5.1.3 Sample Support Films—Many support films are avail-

trace element analysis. able from both XRF instrument manufacturers and accessory

4.1.3 Analyses of blank samples are highly recommended. suppliers. It is important to examine the film types specified in

4.1.4 Sample preparation should be carried out in a clean any method being used. There are four criteria that should be

area. This area should use surfaces that can be decontaminated considered when selecting a X-ray transmission sample sup-

easily if a spillage occurs. port film:

4.1.5 Operators should wear clean, fresh, protective gloves (1) Thickness of film,

for sample preparation for trace element analysis. Tests should (2) Composition of film,

be run to confirm that the gloves do not contain interfering (3) Chemical and physical resistance of film to the liquid

elements or elements of interest, since they may cause con- intend for analysis, and

D7343 − 12 (2017)

(4) Element contaminants contained within the film. they should be inspect

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7343 − 12 D7343 − 12 (Reapproved 2017)

Designation: 558/07

Standard Practice for

Optimization, Sample Handling, Calibration, and Validation

of X-ray Fluorescence Spectrometry Methods for Elemental

Analysis of Petroleum Products and Lubricants

This standard is issued under the fixed designation D7343; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*Scope

1.1 This practice covers information relating to sampling, calibration and validation of X-ray fluorescence instruments for

elemental analysis, including all kinds of wavelength dispersive (WDXRF) and energy dispersive (EDXRF) techniques. This

practice includes sampling issues such as the selection of storage vessels, transportation, and sub-sampling. Treatment, assembly,

and handling of technique-specific sample holders and cups are also included. Technique-specific requirements during analytical

measurement and validation of measurement for the determination of trace elements in samples of petroleum and petroleum

products are described. For sample mixing, refer to Practice D5854. Petroleum products covered in this practice are considered

to be a single phase and exhibit Newtonian characteristics at the point of sampling.

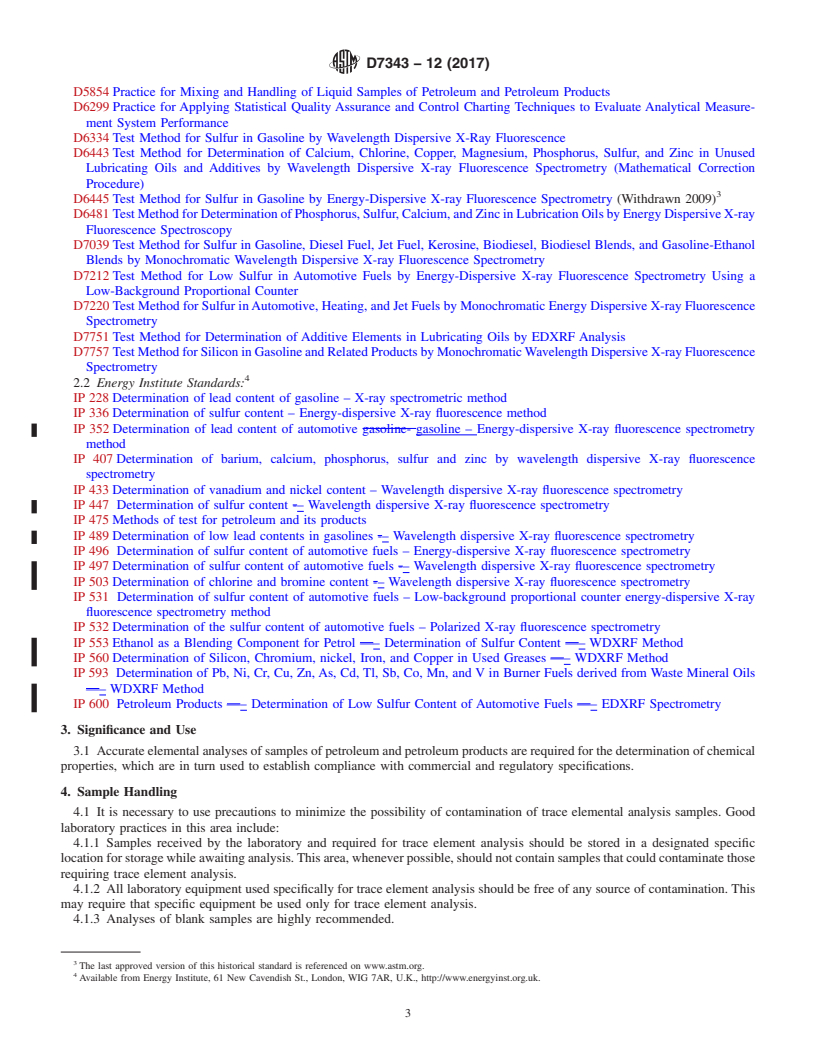

1.2 Applicable Test Methods—This practice is applicable to the XRF methods under the jurisdiction of ASTM Subcommittee

D02.03 on Elemental Analysis, and those under the jurisdiction of the Energy Institute’s Test Method Standardization Committee

(Table 1). Some of these methods are technically equivalent though they may differ in details (Table 2).

1.3 Applicable Fluids—This practice is applicable to petroleum and petroleum products with vapor pressures at sampling and

storage temperatures less than or equal to 101 kPa (14.7 psi). 101 kPa (14.7 psi). Use Practice D4057 or IP 475 to sample these

materials. Refer to Practice D5842 when sampling materials that also require Reid vapor pressure (RVP) determination.

1.4 Non-applicable Fluids—Petroleum products whose vapor pressure at sampling and sample storage conditions are above 101

kPa (14.7 psi) 101 kPa (14.7 psi) and liquefied gases (that is, LNG, LPG, etc.) are not covered by this practice.

1.5 Sampling Methods—The physical sampling and methods of sampling from a primary source are not covered by this guide.

It is assumed that samples covered by this practice are a representative sample of the primary source liquid. Refer to Practice

D4057 or IP 475 for detailed sampling procedures.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6.1 Exception—The values given in parentheses are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.03 on Elemental Analysis.

Current edition approved Dec. 1, 2012June 1, 2017. Published December 2012July 2017. Originally approved in 2007. Last previous edition approved in 20072012 as

D7343D7343 – 12.–07. DOI: 10.1520/D7343-07.10.1520/D7343-12R17.

This practice was jointly prepared by ASTM International and the Energy Institute.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7343 − 12 (2017)

TABLE 1 XRF Standard Test Methods for Analysis of Petroleum

Products and Lubricants

Technique Analysis ASTM EI

WD-XRF Sulfur in Petroleum Products D2622

Additive Elements in Lubricating D4927 IP 407

Oils and Additives

Lead in Gasoline D5059 IP 228

Lead in Gasoline IP 489

Sulfur in Gasoline D6334

Additive Elements in Lube Oils and D6443

Additives

Vanadium and Nickel IP 433

Sulfur IP 447

Sulfur in Automotive Fuels IP 497

Chlorine and Bromine IP 503

Sulfur in Ethanol as Blending IP 553

Agent

Si, Cr, Ni, Fe, and Cu in Used IP 560

Greases

Several Metals in Burner Fuels IP 593

Derived from Waste Mineral Oils

MWD-XRF Sulfur in Gasoline and Diesel D7039

Silicon in Gasoline and Naphtha D7757

ED-XRF Sulfur in Petroleum Products D4294 IP 336

Sulfur in Gasoline D6445

Additive Elements in Lubricating D6481

Oils

Sulfur in Automotive Fuels D7212 IP 531

Sulfur in Automotive Fuels D7220 IP 532

Additive Elements in Lubricating D7751

Oils

Lead in Gasoline IP 352

Sulfur in Automotive Fuels IP 496

Low Sulfur in Automotive Fuels IP 600

TABLE 2 Technically Equivalent XRF Test Methods for Petroleum

A

Products and Lubricants

Analysis ASTM EI Other

Sulfur by WD-XRF D2622 DIN 51400T6;

JIS K3541

Additive Elements by WE- D4927 IP 407 DIN 51391T2

XRF

Lead in Gasoline D5059 IP 228

Sulfur by ED-XRF D4294 IP 336 ISO 8754

Sulfur in Automotive Fuels D7212 IP 531

Sulfur in Automotive Fuels D7220 IP 532

A

Nadkarni, R. A., Guide to ASTM Test Methods for the Analysis of Petroleum

Products and Lubricants, 2nd edition, ASTM International, West Conshohocken,

PA, 2007.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D2622 Test Method for Sulfur in Petroleum Products by Wavelength Dispersive X-ray Fluorescence Spectrometry

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4294 Test Method for Sulfur in Petroleum and Petroleum Products by Energy Dispersive X-ray Fluorescence Spectrometry

D4927 Test Methods for Elemental Analysis of Lubricant and Additive Components—Barium, Calcium, Phosphorus, Sulfur,

and Zinc by Wavelength-Dispersive X-Ray Fluorescence Spectroscopy

D5059 Test Methods for Lead in Gasoline by X-Ray Spectroscopy

D5842 Practice for Sampling and Handling of Fuels for Volatility Measurement

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

D7343 − 12 (2017)

D5854 Practice for Mixing and Handling of Liquid Samples of Petroleum and Petroleum Products

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

D6334 Test Method for Sulfur in Gasoline by Wavelength Dispersive X-Ray Fluorescence

D6443 Test Method for Determination of Calcium, Chlorine, Copper, Magnesium, Phosphorus, Sulfur, and Zinc in Unused

Lubricating Oils and Additives by Wavelength Dispersive X-ray Fluorescence Spectrometry (Mathematical Correction

Procedure)

D6445 Test Method for Sulfur in Gasoline by Energy-Dispersive X-ray Fluorescence Spectrometry (Withdrawn 2009)

D6481 Test Method for Determination of Phosphorus, Sulfur, Calcium, and Zinc in Lubrication Oils by Energy Dispersive X-ray

Fluorescence Spectroscopy

D7039 Test Method for Sulfur in Gasoline, Diesel Fuel, Jet Fuel, Kerosine, Biodiesel, Biodiesel Blends, and Gasoline-Ethanol

Blends by Monochromatic Wavelength Dispersive X-ray Fluorescence Spectrometry

D7212 Test Method for Low Sulfur in Automotive Fuels by Energy-Dispersive X-ray Fluorescence Spectrometry Using a

Low-Background Proportional Counter

D7220 Test Method for Sulfur in Automotive, Heating, and Jet Fuels by Monochromatic Energy Dispersive X-ray Fluorescence

Spectrometry

D7751 Test Method for Determination of Additive Elements in Lubricating Oils by EDXRF Analysis

D7757 Test Method for Silicon in Gasoline and Related Products by Monochromatic Wavelength Dispersive X-ray Fluorescence

Spectrometry

2.2 Energy Institute Standards:

IP 228 Determination of lead content of gasoline – X-ray spectrometric method

IP 336 Determination of sulfur content – Energy-dispersive X-ray fluorescence method

IP 352 Determination of lead content of automotive gasoline- gasoline – Energy-dispersive X-ray fluorescence spectrometry

method

IP 407 Determination of barium, calcium, phosphorus, sulfur and zinc by wavelength dispersive X-ray fluorescence

spectrometry

IP 433 Determination of vanadium and nickel content – Wavelength dispersive X-ray fluorescence spectrometry

IP 447 Determination of sulfur content -– Wavelength dispersive X-ray fluorescence spectrometry

IP 475 Methods of test for petroleum and its products

IP 489 Determination of low lead contents in gasolines -– Wavelength dispersive X-ray fluorescence spectrometry

IP 496 Determination of sulfur content of automotive fuels – Energy-dispersive X-ray fluorescence spectrometry

IP 497 Determination of sulfur content of automotive fuels -– Wavelength dispersive X-ray fluorescence spectrometry

IP 503 Determination of chlorine and bromine content -– Wavelength dispersive X-ray fluorescence spectrometry

IP 531 Determination of sulfur content of automotive fuels – Low-background proportional counter energy-dispersive X-ray

fluorescence spectrometry method

IP 532 Determination of the sulfur content of automotive fuels – Polarized X-ray fluorescence spectrometry

IP 553 Ethanol as a Blending Component for Petrol —– Determination of Sulfur Content —– WDXRF Method

IP 560 Determination of Silicon, Chromium, nickel, Iron, and Copper in Used Greases —– WDXRF Method

IP 593 Determination of Pb, Ni, Cr, Cu, Zn, As, Cd, Tl, Sb, Co, Mn, and V in Burner Fuels derived from Waste Mineral Oils

—– WDXRF Method

IP 600 Petroleum Products —– Determination of Low Sulfur Content of Automotive Fuels —– EDXRF Spectrometry

3. Significance and Use

3.1 Accurate elemental analyses of samples of petroleum and petroleum products are required for the determination of chemical

properties, which are in turn used to establish compliance with commercial and regulatory specifications.

4. Sample Handling

4.1 It is necessary to use precautions to minimize the possibility of contamination of trace elemental analysis samples. Good

laboratory practices in this area include:

4.1.1 Samples received by the laboratory and required for trace element analysis should be stored in a designated specific

location for storage while awaiting analysis. This area, whenever possible, should not contain samples that could contaminate those

requiring trace element analysis.

4.1.2 All laboratory equipment used specifically for trace element analysis should be free of any source of contamination. This

may require that specific equipment be used only for trace element analysis.

4.1.3 Analyses of blank samples are highly recommended.

The last approved version of this historical standard is referenced on www.astm.org.

Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR, U.K., http://www.energyinst.org.uk.

D7343 − 12 (2017)

4.1.4 Sample preparation should be carried out in a clean area. This area should use surfaces that can be decontaminated easily

if a spillage occurs.

4.1.5 Operators should wear clean, fresh, protective gloves for sample preparation for trace element analysis. Tests should be

run to confirm that the gloves do not contain interfering elements or elements of interest, since they may cause contamination. The

development of clean area sample handling protocols is encouraged.

5. Sample Preparation

5.1 Choice of Sample Carrier—XRF testing requires a sample cell and a support film to hold the liquid sample in place during

analysis. The choice of the sample cell or cup, the material in which it is held, and the type of support film used can all influence

the result.

5.1.1 Sample Cell—The most common cell is a plastic cup, of which various designs are available. These designs allow for a

variety of sample types to be measured either in a liquid or powder form. It is important to check that the cup type used is best

suited for the compositions of samples to be analyzed. Liquid sample cups usually have a seal that ensures the film is sealed to

a level above that of the liquid in the cell and that the film is taut with no wrinkles.

5.1.1.1 Within XRF spectrometers heat is produced, both from the spectrometer components themselves and from the

interaction of X-rays with the sample. Petroleum products that are not stable due to volatility should only be placed into vented

sample cups or special sealed sample cups specifically designed for volatile samples (see 8.3).

5.1.1.2 The cup size may be important. Depending on the film type used to support the liquid, different films will sag due to

the weight of sample and relax due to chemical interaction, or heat, or both. To reduce this sagging effect, the smallest diameter

sample cups should be used. Cups with diameters well in excess of the area detected by the spectrometer are likely to increase

errors due to sagging.

5.1.1.3 A number of petroleum products require heating to ensure homogenization prior to analysis or to enable transfer to the

sample cell; examples include fuel oils and wax products. The sample cup should be able to withstand the temperature used in this

process. In general, most plastic sample cells should withstand temperatures up to 70°C.70 °C.

5.1.2 Sample Cell Holder—Many manufacturers recommend metal holders to hold sample cups while they are transferred into

the XRF instrument. These holders can be made from aluminum, stainless steel, or other materials. It is important to recognize that

these represent a potential spectral contamination to the analysis either if the spectrometer is to determine an analyte that the holder

is made from or if the material from the holder causes an interference with the analyte. Generally, this is not a problem for elements

with atomic number <30. For elements with atomic number >30 it is advisable to check the potential contamination from the

sample cup holder using a blank.

5.1.3 Sample Support Films—Many support films are avail

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.