ASTM C1322-15(2019)

(Practice)Standard Practice for Fractography and Characterization of Fracture Origins in Advanced Ceramics

Standard Practice for Fractography and Characterization of Fracture Origins in Advanced Ceramics

SIGNIFICANCE AND USE

5.1 This practice is suitable for monolithic and some composite ceramics, for example, particulate- and whisker-reinforced and continuous-grain-boundary phase ceramics. (Long- or continuous-fiber reinforced ceramics are excluded.) For some materials, the location and identification of fracture origins may not be possible due to the specific microstructure.

5.2 This practice is principally oriented towards characterization of fracture origins in specimens loaded in so-called fast fracture testing, but the approach can be extended to include other modes of loading as well.

5.3 The procedures described within are primarily applicable to mechanical test specimens, although the same procedures may be relevant to component fracture analyses as well. It is customary practice to test a number of specimens (constituting a sample) to permit statistical analysis of the variability of the material’s strength. It is usually not difficult to test the specimens in a manner that will facilitate subsequent fractographic analysis. This may not be the case with component fracture analyses. Component fracture analysis is sometimes aided by cutting test pieces from the component and fracturing the test pieces. Fracture markings and fracture origins from the latter may aid component interpretation.

5.4 Optimum fractographic analysis requires examination of as many similar specimens or components as possible. This will enhance the chances of successful interpretations. Examination of only one or a few specimens can be misleading. Of course, in some instances the fractographer may have access to only one or a few fractured specimens or components.

5.5 Successful and complete fractography also requires careful consideration of all ancillary information that may be available, such as microstructural characteristics, material fabrication, properties and service histories, component or specimen machining, or preparation techniques.

5.6 Fractographic inspection and analysis can b...

SCOPE

1.1 The objective of this practice is to provide an efficient and consistent methodology to locate and characterize fracture origins in advanced ceramics. It is applicable to advanced ceramics that are brittle; that is, fracture that takes place with little or no preceding plastic deformation. In such materials, fracture commences from a single location which is termed the fracture origin. The fracture origin in brittle ceramics normally consists of some irregularity or singularity in the material which acts as a stress concentrator. In the parlance of the engineer or scientist, these irregularities are termed flaws or defects. The latter word should not be construed to mean that the material has been prepared improperly or is somehow faulty.

1.2 Although this practice is primarily intended for laboratory test piece analysis, the general concepts and procedures may be applied to component fracture analyses as well. In many cases, component fracture analysis may be aided by cutting laboratory test pieces out of the component. Information gleaned from testing the laboratory pieces (for example, flaw types, general fracture features, fracture mirror constants) may then aid interpretation of component fractures. For more information on component fracture analysis, see Refs (1, 2).2

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1322 − 15 (Reapproved 2019)

Standard Practice for

Fractography and Characterization of Fracture Origins in

1

Advanced Ceramics

This standard is issued under the fixed designation C1322; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

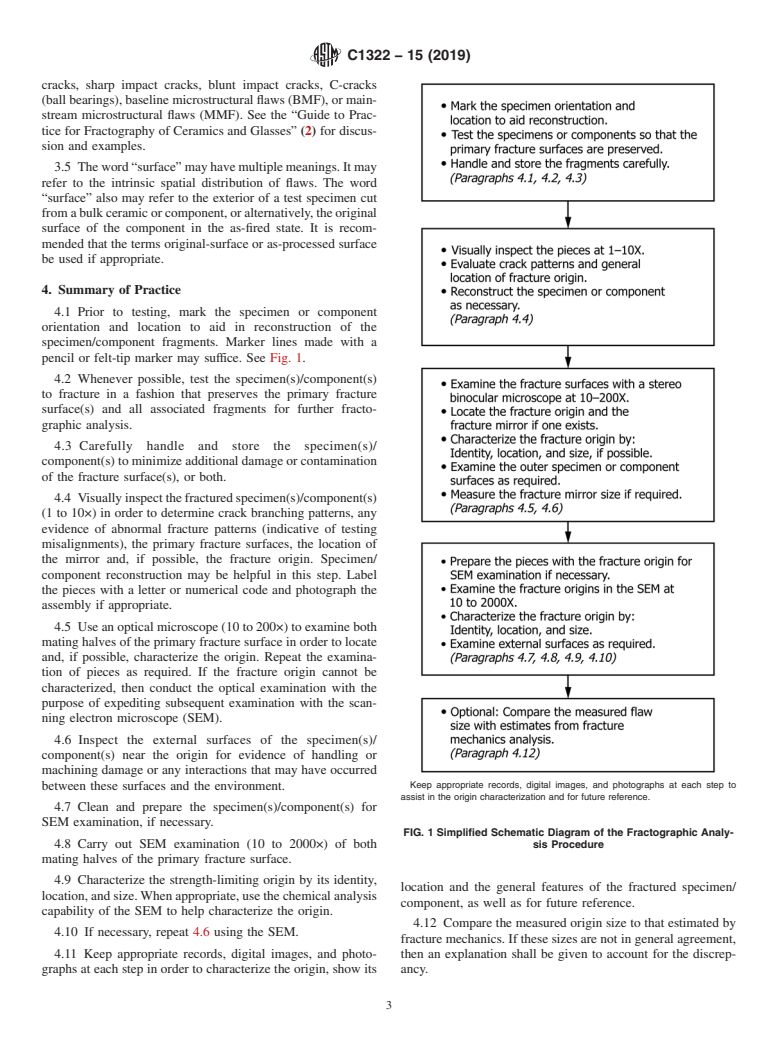

1. Scope 2. Referenced Documents

3

1.1 The objective of this practice is to provide an efficient 2.1 ASTM Standards:

and consistent methodology to locate and characterize fracture C162Terminology of Glass and Glass Products

origins in advanced ceramics. It is applicable to advanced C242Terminology of Ceramic Whitewares and Related

ceramics that are brittle; that is, fracture that takes place with Products

little or no preceding plastic deformation. In such materials, C1036Specification for Flat Glass

fracturecommencesfromasinglelocationwhichistermedthe C1145Terminology of Advanced Ceramics

fractureorigin.Thefractureorigininbrittleceramicsnormally C1161Test Method for Flexural Strength of Advanced

consists of some irregularity or singularity in the material Ceramics at Ambient Temperature

which acts as a stress concentrator. In the parlance of the C1211Test Method for Flexural Strength of Advanced

engineer or scientist, these irregularities are termed flaws or Ceramics at Elevated Temperatures

defects. The latter word should not be construed to mean that C1239Practice for Reporting Uniaxial Strength Data and

the material has been prepared improperly or is somehow EstimatingWeibull Distribution Parameters forAdvanced

faulty. Ceramics

C1499Test Method for Monotonic Equibiaxial Flexural

1.2 Although this practice is primarily intended for labora-

Strength of Advanced Ceramics at Ambient Temperature

tory test piece analysis, the general concepts and procedures

C1678Practice for Fractographic Analysis of Fracture Mir-

may be applied to component fracture analyses as well. In

ror Sizes in Ceramics and Glasses

many cases, component fracture analysis may be aided by

F109Terminology Relating to Surface Imperfections on

cutting laboratory test pieces out of the component. Informa-

Ceramics

tion gleaned from testing the laboratory pieces (for example,

4

2.2 NIST Standard:

flaw types, general fracture features, fracture mirror constants)

NIST Special Publication SP 960-16Guide to Practice for

may then aid interpretation of component fractures. For more

2

Fractography of Ceramics and Glasses (2)

information on component fracture analysis, see Refs (1, 2).

5

2.3 CEN Standard:

1.3 This standard does not purport to address all of the

EN 843-6 Advanced Technical Ceramics—Mechanical

safety concerns, if any, associated with its use. It is the

Properties of Monolithic Ceramics at Room

responsibility of the user of this standard to establish appro-

Temperature—Part 6: Guidance for Fractographic Inves-

priate safety, health, and environmental practices and deter-

tigation

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor-

3. Terminology

dance with internationally recognized principles on standard-

3.1 Definitions:

ization established in the Decision on Principles for the

3.1.1 General—Thefollowingtermsaregivenasabasisfor

Development of International Standards, Guides and Recom-

identifying fracture origins in advanced ceramics. It should be

mendations issued by the World Trade Organization Technical

recognized that origins can manifest themselves differently in

Barriers to Trade (TBT) Committee.

1 3

This practice is under the jurisdiction ofASTM Committee C28 on Advanced For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Ceramics and is the direct responsibility of Subcommittee C28.01 on Mechanical contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Properties and Performance. Standards volume information, refer to the standard’s Document Summary page on

CurrenteditionapprovedJuly1,2019.PublishedJuly2019.Originallyapproved the ASTM website.

4

in 1996. Last previous edition approved in 2015 as C1322–15. DOI: 10.1520/ Available from National Institute of Standards and Technology (NIST), 100

C1322-15R19. Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

2 5

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof Available from European Committee for Standardization (CEN), Avenue

this standard. Marnix 17, B-1000, Brussels, Belgium, http://www.cen.eu.

Copyright © ASTM International, 100 Barr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.