ASTM D2766-95(2000)

(Test Method)Standard Test Method for Specific Heat of Liquids and Solids

Standard Test Method for Specific Heat of Liquids and Solids

SCOPE

1.1 This test method covers the determination of the heat capacity of liquids and solids. It is applicable to liquids and solids that are chemically compatible with stainless steel, that have a vapor pressure less than 13.3 kPa (100 torr), and that do not undergo phase transformation throughout the range of test temperatures. The specific heat of materials with higher vapor pressures can be determined if their vapor pressures are known throughout the range of test temperatures.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 2766 – 95 (Reapproved 2000)

Standard Test Method for

Specific Heat of Liquids and Solids

This standard is issued under the fixed designation D2766; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

R = resistance of nominal 1-V standard resistor,

R = resistance of nominal 100-V standard resistor,

1.1 This test method covers the determination of the heat

R = resistance of nominal 10 000-V standard re-

capacity of liquids and solids. It is applicable to liquids and 10 000

sistor,

solids that are chemically compatible with stainless steel, that

E = emf across nominal 1-V standard resistor,

haveavaporpressurelessthan13.3kPa(100torr),andthatdo

E = emf across nominal 100-V standard resistor,

not undergo phase transformation throughout the range of test

E = emf across nominal 10 000-V standard resis-

10 000

temperatures. The specific heat of materials with higher vapor

tor,

pressurescanbedeterminediftheirvaporpressuresareknown

t = time of application of calibration heater cur-

c

throughout the range of test temperatures.

rent, s,

1.2 The values stated in SI units are to be regarded as the

q = total heat developed by calibration heater, cal,

standard. The values given in parentheses are for information

DE = total heat effect for container, mV,

c

only.

DE = total heat effect for sample+container, mV,

s

1.3 This standard does not purport to address all of the

De = total heat effect for calibration of calorimeter

c

safety concerns, if any, associated with its use. It is the

system during container run, mV,

responsibility of the user of this standard to establish appro-

De = total heat effect for calibration of calorimeter

s

priate safety and health practices and determine the applica-

system during sample run, mV,

bility of regulatory limitations prior to use.

DH = total enthalpy change for container changing

c

from T to T ,

f c

2. Referenced Documents

DH = total enthalpy change for sample plus con-

T

2.1 ASTM Standards:

tainer changing from T to T ,

f c

D1217 Test Method for Density and Relative Density DH = total enthalpy change for sample changing

s

(Specific Gravity) of Liquids by Bingham Pycnometer

from T to T ,

f c

F = calorimeter factor,

3. Terminology

W = weight of sample corrected for air buoyancy

d = density of sample at T,

3.1 Definitions of Terms Specific to This Standard:

f f

d = density of sample at T ,

3.1.1 specific heat—the ratio of the amount of heat needed c c

V = total volume of sample container,

to raise the temperature of a mass of the substance by a T

V = volume of sample vapor at T ,

f f

specified amount to that required to raise the temperature of an

V = volume of sample vapor at T ,

c c

equal mass of water by the same amount, assuming no phase

P = vapor pressure of sample at T,

f f

change in either case.

P = vapor pressure of sample at T ,

c c

3.2 Symbols:

N = moles sample vapor at T,

f f

N = moles sample vapor at T ,

c c

N = moles sample vapor condensed,

T = temperature of hot zone, °C,

f

DH = heat of vaporization of sample,

v

T = initial temperature of calorimeter, °C,

c

R = gas constant, and

T8 = T −T =temperature differential, °C,

f c

K = heat of vaporization correction.

3.3 Abbreviations:Units:

3.3.1 The energy and thermal (heat) capacity units used in

This test method is under jurisdiction ofASTM Committee D02 on Petroleum

this method are defined as follows:

ProductsandLubricantsandisthedirectresponsibilityofSubcommitteeD02.11on

1 cal (International Table)=4.1868 J

Engineering Science of High Performance Fluids and Solids.

Current edition approved Aug. 15, 1995. Published October 1995. Originally

1 Btu (British thermal unit, International Table)=

published as D2766–68T. Last previous edition D2766–91.

1055.06 J

Annual Book of ASTM Standards, Vol 05.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 2766 – 95 (2000)

1 Btu/lb °F=1 cal/g °C

1 Btu/lb °F=4.1868 J/g K

3.3.2 For all but the most precise measurements made with

this method the rounded-off value of 4.19 J/cal can be used as

this is adequate for the precision of the test and avoids the

difficulty caused by the dual definition of the calorie.

4. Summary of Test Method

4.1 The enthalpy change, DH , that occurs when an empty

c

sample container is transferred from a hot zone of constant

temperature to an adiabatic calorimeter at a fixed initial

temperature is measured for selected hot zone temperatures

evenly spread over the temperature range of interest.

4.2 Theenthalpychange, DH ,thatoccurswhenacontainer

T

filled with the test specimen is transferred from a hot zone of

constant temperature, T , to an adiabatic calorimeter at a fixed

c

initial temperature is measured for selected hot-zone tempera-

tures evenly spread over the temperature range of interest.

4.3 The net enthalpy change per gram of sample is then

expressed as an analytical power function of the temperature

differential T8.The first derivative of this function with respect

to the actual temperature, T , yields the specific heat of the

f

sample as a function of temperature. Actual values of the

specific heat may be obtained from solutions of this equation

which is valid over the same range of temperatures over which

the total enthalpy changes, DH , were measured.

T

5. Significance and Use

5.1 The specific heat or heat capacity of a substance is a

thermodynamic property that is a measure of the amount of

energy required to produce a given temperature change within

a unit quantity of that substance. It is used in engineering

calculations that relate to the manner in which a given system

may react to thermal stresses.

6. Apparatus

6.1 Drop-Method-of-Mixtures Calorimeter, consisting es-

FIG. 1 Specific Heat Apparatus

sentially of a vertically mounted, thermostatically controlled,

tube furnace and a water-filled adiabatic calorimeter. The

furnace is mounted with respect to the calorimeter in such a

6.4 Resistor,1-V precision type.

way that it may be swung from a remote position to a location

6.5 Resistor, 100-V precision type.

directlyoverthecalorimeterandreturnedrapidlytotheremote

6.6 Resistor, 10 000-V precision type.

position. The sample container may thus be dropped directly

6.7 Amplifier, zero centered range, linear response with

into the calorimeter with a minimum transfer of radiation from

preset ranges to include 625 µnV,6 100 µV, 6200 µV, 6500µ

furnace to calorimeter. Details of construction are shown in

V, 61000 µV, and 62000 µV; with error not to exceed

Fig. 1.

60.04%ofoutput;withzerodriftafterwarm-upnottoexceed

6.2 Sample Container—A stainless steel sample container

60.5 µV offset within which drift will not exceed 60.2

with a polytetrafluoroethylene seal suitable for use at tempera-

µV/min. Equivalent instrumentation with different fixed poten-

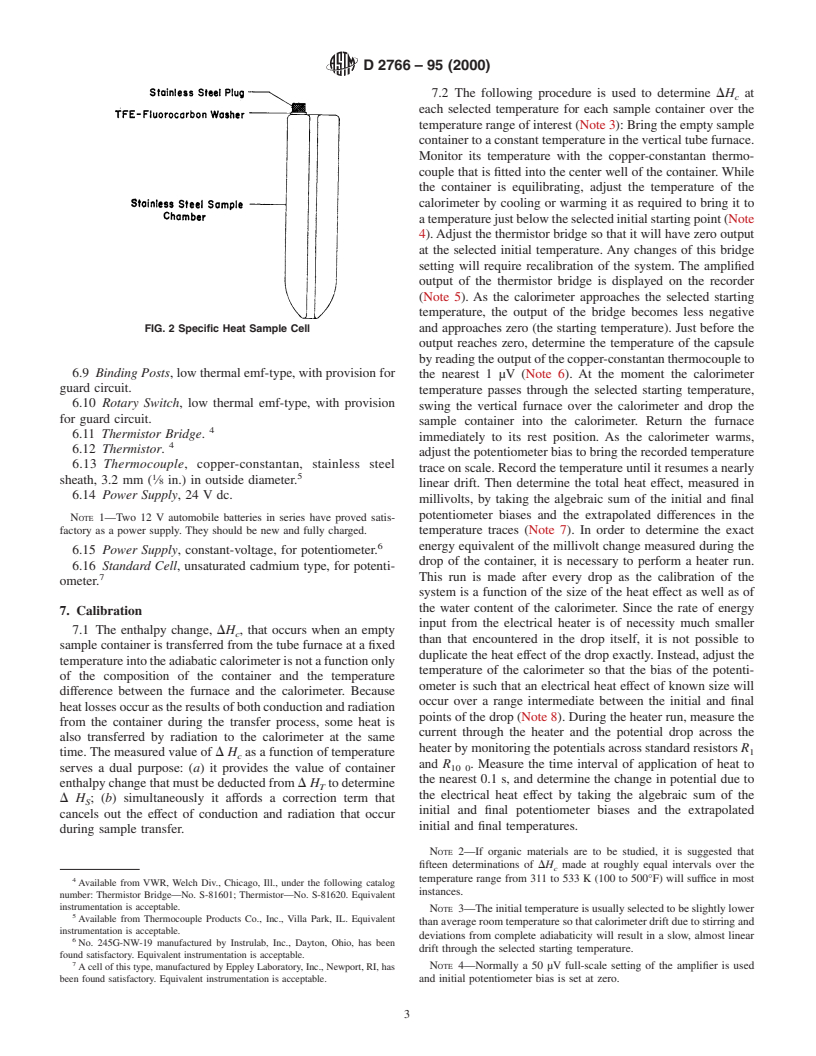

tures up to 533 K (500°F) is shown in Fig. 2.

tial ranges is acceptable provided the same overall potential

6.3 Potential Measuring Devices (two required), potential

ranges are covered.

measuring device capable of measurement of up to 1 V with a

−6

6.8 Strip Chart Recorder, with nominal 25 cm chart, 65

precision of 10 V or a potentiometer assembly with sensitiv-

mV, zero center.

ity of at least 1 µV or a digital multimeter with equivalent

sensitivity, range, and a minimum of six digit resolution is

acceptable. A direct reading digital temperature indicating

device may be substituted for the potential measuring device

Models 9330/1, 9330/100, 9330/10K manufactured by Guidlines Instruments,

for the purpose of measuring the temperature of the capsule

Inc., 103 Commerce St., Ste 160, Lake May, FL 32795-2590. Equivalent instru-

while in the tube furnace. See Fig. 3. mentation is acceptable.

D 2766 – 95 (2000)

7.2 The following procedure is used to determine DH at

c

each selected temperature for each sample container over the

temperaturerangeofinterest(Note3):Bringtheemptysample

containertoaconstanttemperatureintheverticaltubefurnace.

Monitor its temperature with the copper-constantan thermo-

couple that is fitted into the center well of the container.While

the container is equilibrating, adjust the temperature of the

calorimeter by cooling or warming it as required to bring it to

atemperaturejustbelowtheselectedinitialstartingpoint(Note

4).Adjust the thermistor bridge so that it will have zero output

at the selected initial temperature. Any changes of this bridge

setting will require recalibration of the system. The amplified

output of the thermistor bridge is displayed on the recorder

(Note 5). As the calorimeter approaches the selected starting

temperature, the output of the bridge becomes less negative

FIG. 2 Specific Heat Sample Cell and approaches zero (the starting temperature). Just before the

output reaches zero, determine the temperature of the capsule

byreadingtheoutputofthecopper-constantanthermocoupleto

6.9 Binding Posts,lowthermalemf-type,withprovisionfor

the nearest 1 µV (Note 6). At the moment the calorimeter

guard circuit.

temperature passes through the selected starting temperature,

6.10 Rotary Switch, low thermal emf-type, with provision

swing the vertical furnace over the calorimeter and drop the

for guard circuit.

sample container into the calorimeter. Return the furnace

6.11 Thermistor Bridge.

immediately to its rest position. As the calorimeter warms,

6.12 Thermistor.

adjustthepotentiometerbiastobringtherecordedtemperature

6.13 Thermocouple, copper-constantan, stainless steel

traceonscale.Recordthetemperatureuntilitresumesanearly

sheath, 3.2 mm ( ⁄8 in.) in outside diameter.

linear drift. Then determine the total heat effect, measured in

6.14 Power Supply, 24 V dc.

millivolts, by taking the algebraic sum of the initial and final

potentiometer biases and the extrapolated differences in the

NOTE 1—Two 12 V automobile batteries in series have proved satis-

factory as a power supply. They should be new and fully charged. temperature traces (Note 7). In order to determine the exact

energy equivalent of the millivolt change measured during the

6.15 Power Supply, constant-voltage, for potentiometer.

drop of the container, it is necessary to perform a heater run.

6.16 Standard Cell, unsaturated cadmium type, for potenti-

This run is made after every drop as the calibration of the

ometer.

system is a function of the size of the heat effect as well as of

the water content of the calorimeter. Since the rate of energy

7. Calibration

input from the electrical heater is of necessity much smaller

7.1 The enthalpy change, DH , that occurs when an empty

c

than that encountered in the drop itself, it is not possible to

sample container is transferred from the tube furnace at a fixed

duplicate the heat effect of the drop exactly. Instead, adjust the

temperatureintotheadiabaticcalorimeterisnotafunctiononly

temperature of the calorimeter so that the bias of the potenti-

of the composition of the container and the temperature

ometer is such that an electrical heat effect of known size will

difference between the furnace and the calorimeter. Because

occur over a range intermediate between the initial and final

heatlossesoccurastheresultsofbothconductionandradiation

points of the drop (Note 8). During the heater run, measure the

from the container during the transfer process, some heat is

current through the heater and the potential drop across the

also transferred by radiation to the calorimeter at the same

heaterbymonitoringthepotentialsacrossstandardresistors R

time.The measured value of D H as a function of temperature

c

and R . Measure the time interval of application of heat to

10 0

serves a dual purpose: (a) it provides the value of container

the nearest 0.1 s, and determine the change in potential due to

enthalpychangethatmustbedeductedfrom D H todetermine

T

the electrical heat effect by taking the algebraic sum of the

D H;(b) simultaneously it affords a correction term that

S

initial and final potentiometer biases and the extrapolated

cancels out the effect of conduction and radiation that occur

initial and final temperatures.

during sample transfer.

NOTE 2—If organic materials are to be studied, it is suggested that

fifteen determinations of DH made at roughly equal intervals over the

c

4 temperature range from 311 to 533 K (100 to 500°F) will suffice in most

Available from VWR, Welch Div., Chicago, Ill., under the following catalog

instances.

number: Thermistor Bridge—No. S-81601; Thermistor—No. S-81620. Equivalent

instrumentation is acceptable.

NOTE 3—Theinitialtemperatureisusuallyselectedtobeslightlylower

Available from Thermocouple Products Co., Inc., Villa Park, IL. Equivalent

thanaverageroomtemperaturesothatcalorimeterdriftduetostirringand

instrumentation is acceptable.

deviations from complete adiabaticity will result in a slow, almost linear

No. 245G-NW-19 manufactured by Instrulab, Inc., Dayton, Ohio, has been

drift through the selected starting temperature.

found satisfactory. Equivalent instrumentation is acceptable.

NOTE 4—Normally a 50 µV full-scale setting of the amplifier is used

Acell of this type, manufactured by Eppley Laboratory, Inc., Newport, RI, has

been found satisfactory. Equivalent instrumentation is acceptable. and initial potentiometer bias is set at zero.

D 2766 – 95 (2000)

FIG. 3 Specific Heat Measuring and Control Circuit Diagram

NOTE 5—Provided that an accurate calibration of the thermocouple is

8. Procedure

madepriortoitsuse,itshouldbepossibletodeterminethetemperatureto

8.1 Fill the sample container with a weighed amount of the

the nearest 0.1°C with accuracy.

sample. Make appropriate air-buoyancy corrections in deter-

NOTE 6—To compensate for differences in the initial and final rates of

drift, it is good practice to extrapolate both initial and final rates to that

miningtheweightofthesamplefollowingtheprinciplesgiven

pointintimeatwhichonehalfofthetotalheateffecthasoccurred.Forthe

inthePreparationofApparatussectionofTestMethodD1217.

heat effect occurring after a drop, it has been found that one half of the

Repeat the procedure described in 7.2 for each temperature at

total heat effect occurs so rapidly that no significant error occurs in

which it is desired to determine the value of DH for the filled

T

extrapolating the final drift back to the initial time. For heater runs, it is

sample container.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.