ASTM F2282-03(2009)

(Specification)Standard Specification for Quality Assurance Requirements for Carbon and Alloy Steel Wire, Rods, and Bars for Mechanical Fasteners

Standard Specification for Quality Assurance Requirements for Carbon and Alloy Steel Wire, Rods, and Bars for Mechanical Fasteners

ABSTRACT

This specification establishes quality assurance requirements for carbon and alloy steel wire, rods, and bars for mechanical fasteners. Manufacturing of materials shall conform to the melting, casting, deoxidation, grain size, hardenability, and thermal treatment practices of this specification. Chemical requirements shall conform to the specified limits of chemical composition for carbon steel. Requirements of metallurgical structure shall include course austenitic grain size, fine autenitic grain size, and speheroidized annealed material. The material shall be tested for decarburization, maximum tensile strength, reduction area, hardenability, grain size, calibration, dimensions, and tolerances. Surface condition, coating, workmanship, finish, appearance, and packaging shall also conform to the requirements of this specification.

SCOPE

1.1 This specification establishes quality assurance requirements for the physical, mechanical, and metallurgical requirements for carbon and alloy steel wire, rods, and bars in coils intended for the manufacture of mechanical fasteners which includes: bolts, nuts, rivets, screws, washers, and special parts manufactured cold.

Note 1—The Steel Industry uses the term “quality” to designate characteristics of a material which make it particularly well suited to a specific fabrication and/or application and does not imply “quality” in the usual sense.

1.2 Wire size range includes 0.062 to 1.375 in.

1.3 Rod size range usually includes 7/32 in. (0.219) to 47/64 in. (0.734) and generally offered in 1/64 increments (0.0156).

1.4 Bar size range includes 3/8 in. (0.375) to 1½ in. (1.500).

1.5 Sizes for wire, rod and bar outside the ranges of paragraphs 1.2-1.4 may be ordered by agreement between purchaser and supplier.

1.6 Material is furnished in many application variations. The purchaser should advise the supplier regarding the manufacturing process and finished product application as appropriate. Five application variations are: Cold Heading Recessed Head Socket Head Scrapless Nut Tubular Rivet

1.6.1 Wire is furnished for all five application variations.

1.6.2 Rod and bar are furnished to the single application variation; Cold Heading.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F2282 – 03 (Reapproved 2009)

Standard Specification for

Quality Assurance Requirements for Carbon and Alloy Steel

Wire, Rods, and Bars for Mechanical Fasteners

This standard is issued under the fixed designation F2282; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Hot-Wrought, General Requirements for

A370 Test Methods and Definitions for Mechanical Testing

1.1 This specification establishes quality assurance require-

of Steel Products

ments for the physical, mechanical, and metallurgical require-

A700 PracticesforPackaging,Marking,andLoadingMeth-

ments for carbon and alloy steel wire, rods, and bars in coils

ods for Steel Products for Shipment

intended for the manufacture of mechanical fasteners which

A751 Test Methods, Practices, andTerminology for Chemi-

includes: bolts, nuts, rivets, screws, washers, and special parts

cal Analysis of Steel Products

manufactured cold.

E4 Practices for Force Verification of Testing Machines

NOTE 1—The Steel Industry uses the term “quality” to designate

E10 Test Method for Brinell Hardness of Metallic Materials

characteristics of a material which make it particularly well suited to a

E29 Practice for Using Significant Digits in Test Data to

specific fabrication and/or application and does not imply “quality” in the

Determine Conformance with Specifications

usual sense.

E112 Test Methods for Determining Average Grain Size

1.2 Wire size range includes 0.062 to 1.375 in.

E381 Method of Macroetch Testing Steel Bars, Billets,

7 47

1.3 Rodsizerangeusuallyincludes ⁄32in.(0.219)to ⁄64in.

Blooms, and Forgings

(0.734) and generally offered in ⁄64 increments (0.0156).

E407 Practice for Microetching Metals and Alloys

3 1

1.4 Bar size range includes ⁄8 in. (0.375) to 1 ⁄2 in. (1.500).

E1077 Test Methods for Estimating the Depth of Decarbur-

1.5 Sizes for wire, rod and bar outside the ranges of

ization of Steel Specimens

paragraphs 1.2-1.4 may be ordered by agreement between

F1470 Practice for Fastener Sampling for Specified Me-

purchaser and supplier.

chanical Properties and Performance Inspection

1.6 Material is furnished in many application variations.

F1789 Terminology for F16 Mechanical Fasteners

The purchaser should advise the supplier regarding the manu-

2.2 AIAG Standard:

facturing process and finished product application as appropri- 3

B-5 Primary Metals Tag Application Standard

ate. Five application variations are:

2.3 IFI Standard:

Cold Heading

IFI-140 Carbon and Alloy Steel Wire, Rods, and Bars for

Recessed Head

Mechanical Fasteners

Socket Head

Scrapless Nut

2.4 SAE Standards:

Tubular Rivet 5

J403 Chemical Compositions of SAE Carbon Steels

1.6.1 Wire is furnished for all five application variations. J404 Chemical Compositions of SAE Alloy Steels

J406 Methods of Determining Hardenability of Steels

1.6.2 Rod and bar are furnished to the single application

variation; Cold Heading. J415 Definitions of Heat Treating Terms

3. Terminology

2. Referenced Documents

2.1 ASTM Standards: 3.1 Definitions:

3.1.1 annealing—a process of heating to and holding steel

A29/A29M Specification for Steel Bars, Carbon and Alloy,

at a given temperature for a given time and then cooling at a

given rate, used to soften or produce changes, or both, in the

This specification is under the jurisdiction of ASTM Committee F16 on

microstructure of the steel to enhance formability and reduce

Fasteners and is the direct responsibility of Subcommittee F16.93 on Quality

tensile strength.

Assurance Provisions for Fasteners.

Current edition approved May 1, 2009. Published October 2009. Originally

approved in 2003. Last previous edition approved in 2003 as F2282 – 03. DOI:

10.1520/F2282-03R09. Available fromAutomotive IndustryAction Group (AIAG), 26200 Lahser Rd.,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Suite 200, Southfield, MI 48033, http://www.aiag.org.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from IFI, 1717 E. 9th St., Suite 1105, Cleveland, OH 44114-2879.

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2282 – 03 (2009)

TABLE 2 Rod Size Tolerances

3.1.2 bars—produced from hot rolled or cast billets or

blooms rolled single strand into coils. Bars have a greater Diameter, Diameter 6 Out of Round

in. Tolerance, in. max, in.

precisionincrosssectionthanrods.SizetolerancesareinTable

7 47

⁄32 to ⁄64 0.012 0.018

1. Bars are finished as-rolled, annealed or spheroidize an-

(0.219 to 0.734)

nealed, and in sizes included in 1.4.

3.1.3 lap—a longitudinal surface discontinuity extending

into rod, bar, or wire caused by doubling over of metal during TABLE 3 Wire Size Tolerances and Out of Round

hot rolling.

Diameter, Diameter 6 Out of Round

in. Tolerance, in. max, in.

3.1.4 lot—a quantity of raw material of one size and heat

number submitted for testing at one time. < 0.076 0.0010 0.0010

0.076 < 0.500 0.0015 0.0015

3.1.5 rods—produced from hot rolled or cast billets, usually

$ 0.500 0.0020 0.0020

rolled in a multiple strand mill to a round cross section then

coiled into one continuous length to size tolerances shown in

Table 2. Rods are furnished as-rolled, annealed, or spheroidize Thermal treatment may also be employed when controlled

annealed in sizes found in 1.3.

mechanical properties are required for a specific application.

3.1.6 seam—a longitudinal discontinuity extending radially

3.2 Heat treating terms not defined in this standard are

into wire, rod, or bar. Seams in raw material used for the included in Terminology F1789 or SAE J415.

manufacture of fasteners or formed parts may lead to the

4. Ordering Information

formation of bursts.

4.1 Wire orders shall state the following:

3.1.7 spheroidizing—a form of annealing, involves pro-

4.1.1 Quantity,

longed heating at temperatures near the lower critical tempera-

4.1.2 Specification number and issue date,

ture, followed by slow cooling, with the object of forming

4.1.3 Diameter,

spheroidal metallic carbides that allow a higher degree of

4.1.4 Steel grade,

formability.

4.1.5 Deoxidation practice and grain size or refinement

3.1.8 void—ashallowpocketorhollowonthesurfaceofthe

practice (coarse or fine); see 5.3.1-5.3.5,

material.

4.1.6 Application variation per 1.6,

3.1.9 wire—produced from hot rolled or annealed rods or

4.1.7 Thermal treatment; see 5.5,

bars by cold drawing for the purpose of obtaining desired size,

4.1.8 Surface coating,

dimensional accuracy, surface finish, and mechanical proper-

4.1.9 Coil weight and dimensions as required,

ties.Wireisfurnishedinthefollowingconditions:directdrawn

4.1.10 Packaging,

(DD); drawn from annealed rod or bar (DFAR or DFAB);

4.1.11 Tagging,

drawn from spheroidized annealed rod or bar (DFSR or

4.1.12 Mill certification as required,

DFSB); drawn to size and spheroidized (SAFS); drawn,

4.1.13 Special requirements, for example, steel making

annealed in process, and finally lightly drawn to size (AIP);

method and practice, specific hardenability, special shipping

and drawn, spheroidize annealed in process, and finally lightly

instructions, single heat, etc., and

drawn to size (SAIP). Wire size tolerances are shown in Table

4.1.14 Example—40 000 lb, ASTM F2282, 0.250 in., car-

3. Sizes include those specified in 1.2.

bonsteelwire,IFI-1022A,siliconkilledcoarsegrain,Recessed

3.1.9.1 Discussion—Spheroidize annealed-at-finish size

Head, spheroidize annealed-in-process, phosphate and lube,

wire (SAFS) is wire that has been spheroidize annealed after

1500 lb coils, 28 in. coil i.d., on 18 in. tubular carriers, three

final cold reduction. One or more annealing treatments may

bands per carrier, one metal tag per coil, mill certification, do

precede the final cold reduction.

not ship Fridays.

3.1.9.2 Discussion—Annealed-in-Process (AIP) or Sphe-

4.2 Rod orders shall state the following:

roidizeAnnealed-in-Process (SAIP) wire is produced as drawn

4.2.1 Quantity,

carbon or alloy steel wire. In producing AIP and SAIP wire,

4.2.2 Specification number and issue date,

rods or bars are drawn to wire and thermal treatment (followed

4.2.3 Diameter,

by a separate cleaning and coating operation) is done prior to

4.2.4 Steel grade,

final drawing to produce a softer and more ductile wire for

4.2.5 Deoxidation practice and grain size or refinement

applications in which direct drawn wire would be too hard.

practice (coarse or fine),

4.2.6 Cold Heading,

TABLE 1 Bar Size Tolerances

4.2.7 Thermal treatment,

Fractional Diameter 6 Out of Round

4.2.8 Surface coating,

Diameter, in. Tolerance, in. max, in.

4.2.9 Coil weight and dimensions as required,

7 5

⁄16 to ⁄8 0.006 0.009

4.2.10 Packaging,

5 7

> ⁄8 to ⁄8 0.007 0.011

4.2.11 Tagging,

> ⁄8 to 1 0.008 0.012

>1 to 1 ⁄8 0.009 0.014 4.2.12 Mill certifications as required,

1 1

>1 ⁄8 to 1 ⁄4 0.010 0.015

4.2.13 Special requirements, for example, descaling prac-

1 3

>1 ⁄4 to 1 ⁄8 0.011 0.017

tice, steelmaking method and practice, specific hardenability,

3 1

>1 ⁄8 to 1 ⁄2 0.013 0.020

special shipping instructions, etc., and

F2282 – 03 (2009)

4.2.14 Example—200 000lb,ASTMF2282, ⁄64in.,carbon practices included in 5.3.1-5.3.5, as specified by the purchaser.

steel rod, IFI-1022B, silicon killed fine grain, Cold Heading, When not specified, the practice shall be at the option of the

spheroidize annealed, pickled and limed, 3000 lb coils, 48 in. manufacturer.

coil i.d., compacted and unitized in packages of two, banded 5.3.1 Silicon killed fine grain shall be produced with alu-

with three steel straps per coil, two metal tags per coil attached minum for grain refinement.The material purchaser’s approval

to lead end on inside of bundle, put separators between coils. shall be obtained for the use of vanadium or columbium for

4.3 Bar orders shall state the following: grain refinement.

4.3.1 Quantity, 5.3.2 Silicon killed coarse grain practice.

4.3.2 Specification number and issue date, 5.3.3 Silicon killed fine grain practice.

4.3.3 Diameter, 5.3.4 Aluminum killed fine grain practice.

4.3.4 Steel grade, 5.3.5 Rimmed (grain size not specified).

4.3.5 Deoxidation practice and grain size or refinement 5.4 Hardenability:

practice (coarse or fine), 5.4.1 Hardenability for steels with a specified minimum

4.3.6 Cold Heading, carbon content of 0. 20 % or greater shall be determined for

4.3.7 Thermal treatment, each heat and the results furnished to the purchaser when

4.3.8 Surface coating, requested on the purchase order. SAE J406, Appendix A shall

4.3.9 Coil weight and dimensions as required, be used for referee purposes in the event of dispute.

4.3.10 Packaging, 5.5 Thermal Treatments:

4.3.11 Tagging, 5.5.1 The purchaser shall specify one of the following

4.3.12 Mill certification as required, options for thermal treatment on the purchase order:

4.3.13 Special requirements, for example, steelmaking 5.5.1.1 No thermal treatment.

method and practice, specific hardenability, special shipping 5.5.1.2 Annealed.

instructions, single heat, etc., and 5.5.1.3 Spheroidized.

4.3.14 Example—90 000 lb, ASTM F2282, 0. 610 in., 5.5.1.4 Drawn from annealed rod or bar.

carbon steel bars, IFI-1038, silicon killed coarse grain, sphe- 5.5.1.5 Drawn from spheroidize annealed rod or bar.

roidize annealed, Cold Heading, phosphate and lime, 5400 lb 5.5.1.6 Spheroidized at finished size wire.

coils, 54 in. coil i.d., three bands per coil, one metal tag per 5.5.1.7 Annealed-in-process wire.

coil, lead end of each coil paint red. 5.5.1.8 Spheroidized annealed-in-process wire.

5. Manufacture 6. Chemical Requirements

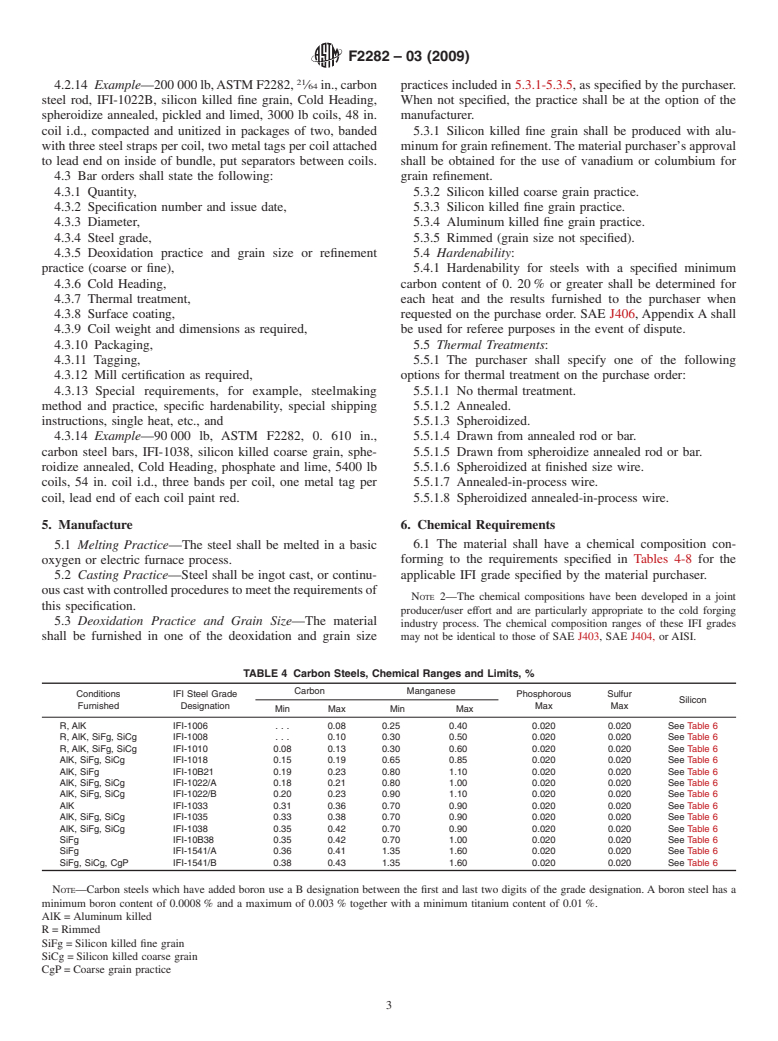

5.1 Melting Practice—The steel shall be melted in a basic 6.1 The material shall have a chemical composition con-

forming to the requirements specified in Tables 4-8 for the

oxygen or electric furnace process.

5.2 Casting Practice—Steel shall be ingot cast, or continu- applicable IFI grade specified by the material purchaser.

ouscastwithcontrolledprocedurestomeettherequirementsof

NOTE 2—The chemical compositions have been developed in a joint

this specification.

producer/user effort and are particularly appropriate to the cold forging

5.3 Deoxidation Practice and Grain Size—The material

industry process. The chemical composition ranges of these IFI grades

shall be furnished in one of the deoxidation and grain size may not be identical to those of SAE J403, SAE J404, or AISI.

TABLE 4 Carbon Steels, Chemical Ranges and Limits, %

Carbon Manganese

Conditions IFI Steel Grade Phosphorous Sulfur

Silicon

Furnished Designation Max Max

Min Max Min Max

R, AlK IFI-1006 . . . 0.08 0.25 0.40 0.020 0.020 See Table 6

R, AlK, SiFg, SiCg IFI-1008 . . . 0.10 0.30 0.50 0.020 0.020 See Table 6

R, AlK, SiFg, SiCg IFI-1010 0.08 0.13 0.30 0.60 0.020 0.020 See Table 6

AlK, SiFg, SiCg IFI-1018 0.15 0.19 0.65 0.85 0.020 0.020 See Table 6

AlK, SiFg IFI-10B21 0.19 0.23 0.80 1.10 0.020 0.020 See Table 6

AlK, SiFg, SiCg IFI-1022/A 0.18 0.21 0.80 1.00 0.020 0.020 See Table 6

AlK, SiFg, SiCg IFI-1022/B 0.20 0.23 0.90 1.10 0.020 0.020 See Table 6

AlK IFI-1033 0.31 0.36 0.70 0.90 0.020 0.020 See Table 6

AlK, SiFg, SiCg IFI-1035 0.33 0.38 0.70 0.90 0.020 0.020 See Table 6

AlK, SiFg, SiCg IFI-1038 0.35 0.42 0.70 0.90 0.020 0.020 See Table 6

SiFg IFI-10B38 0.35 0.42 0.70 1.00 0.020 0.020 See Table 6

SiFg IFI-1541/A 0.36 0.41 1.35 1.60 0.020 0.020 See Table 6

SiFg, SiCg, CgP IFI-1541/B 0.38 0.43 1.35 1.60 0.020 0.020 See Table 6

NOTE—Carbon steels which have added boron use a B designation between the first and last two digits of the grade designation. A boron steel has a

minimum boron content of 0.0008 % and a maximum of 0.003 % together with a minimum titanium content of 0.01 %.

AlK = Aluminum killed

R = Rimmed

SiFg = Silicon killed fine grain

SiCg = Silicon killed coarse grain

CgP = Coarse grain practice

F2282 – 03 (2009)

TABLE 5 Permissible Variations from Specified Chemical

6.4.2 Rimmed or capped steels are characterized by a lack

Ranges, and Limits for Carbon Steel, %

of uniformity in their chemical composition, especially for the

Limit or Max of Variation % Over Max Limit

elements carbon, phosphorus, and sulfur, and for this reason

Element

Specified Range, % or Under Min Limit

product analysis is not technologically appropriate unless

Carbon To 0.25

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.