ASTM F2282-03(2009)

(Specification)Standard Specification for Quality Assurance Requirements for Carbon and Alloy Steel Wire, Rods, and Bars for Mechanical Fasteners

Standard Specification for Quality Assurance Requirements for Carbon and Alloy Steel Wire, Rods, and Bars for Mechanical Fasteners

ABSTRACT

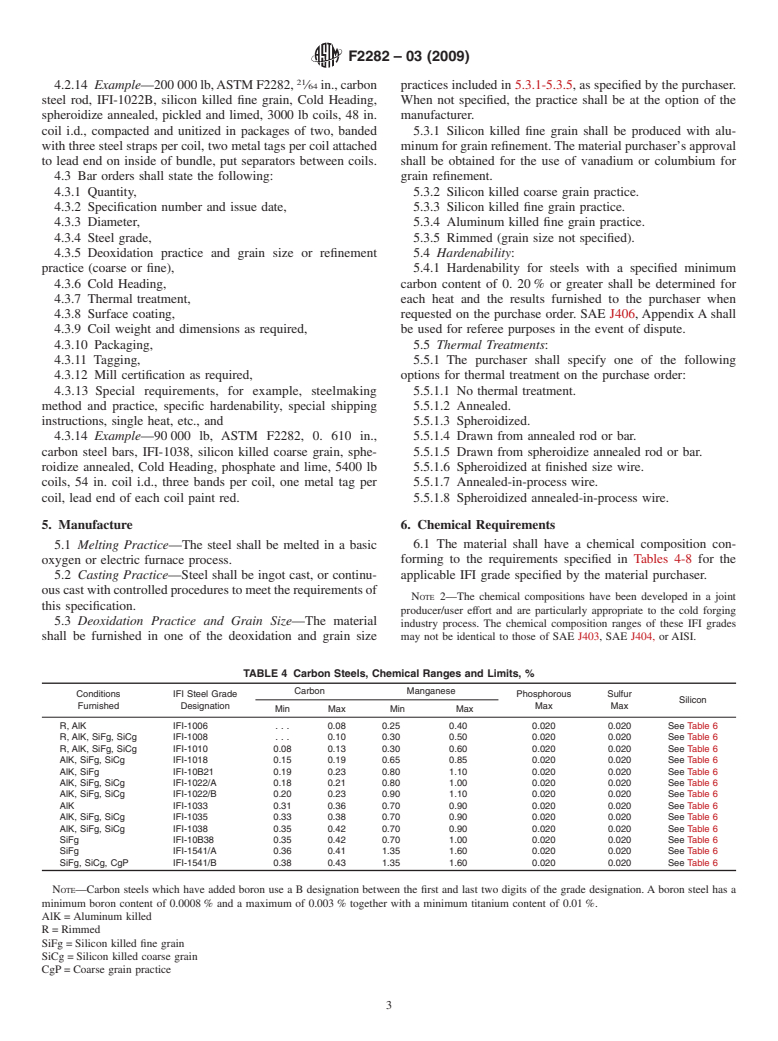

This specification establishes quality assurance requirements for carbon and alloy steel wire, rods, and bars for mechanical fasteners. Manufacturing of materials shall conform to the melting, casting, deoxidation, grain size, hardenability, and thermal treatment practices of this specification. Chemical requirements shall conform to the specified limits of chemical composition for carbon steel. Requirements of metallurgical structure shall include course austenitic grain size, fine autenitic grain size, and speheroidized annealed material. The material shall be tested for decarburization, maximum tensile strength, reduction area, hardenability, grain size, calibration, dimensions, and tolerances. Surface condition, coating, workmanship, finish, appearance, and packaging shall also conform to the requirements of this specification.

SCOPE

1.1 This specification establishes quality assurance requirements for the physical, mechanical, and metallurgical requirements for carbon and alloy steel wire, rods, and bars in coils intended for the manufacture of mechanical fasteners which includes: bolts, nuts, rivets, screws, washers, and special parts manufactured cold.

Note 1—The Steel Industry uses the term “quality” to designate characteristics of a material which make it particularly well suited to a specific fabrication and/or application and does not imply “quality” in the usual sense.

1.2 Wire size range includes 0.062 to 1.375 in.

1.3 Rod size range usually includes 7/32 in. (0.219) to 47/64 in. (0.734) and generally offered in 1/64 increments (0.0156).

1.4 Bar size range includes 3/8 in. (0.375) to 1½ in. (1.500).

1.5 Sizes for wire, rod and bar outside the ranges of paragraphs 1.2-1.4 may be ordered by agreement between purchaser and supplier.

1.6 Material is furnished in many application variations. The purchaser should advise the supplier regarding the manufacturing process and finished product application as appropriate. Five application variations are: Cold Heading Recessed Head Socket Head Scrapless Nut Tubular Rivet

1.6.1 Wire is furnished for all five application variations.

1.6.2 Rod and bar are furnished to the single application variation; Cold Heading.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F2282 – 03 (Reapproved 2009)

Standard Specification for

Quality Assurance Requirements for Carbon and Alloy Steel

1

Wire, Rods, and Bars for Mechanical Fasteners

This standard is issued under the fixed designation F2282; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Hot-Wrought, General Requirements for

A370 Test Methods and Definitions for Mechanical Testing

1.1 This specification establishes quality assurance require-

of Steel Products

ments for the physical, mechanical, and metallurgical require-

A700 PracticesforPackaging,Marking,andLoadingMeth-

ments for carbon and alloy steel wire, rods, and bars in coils

ods for Steel Products for Shipment

intended for the manufacture of mechanical fasteners which

A751 Test Methods, Practices, andTerminology for Chemi-

includes: bolts, nuts, rivets, screws, washers, and special parts

cal Analysis of Steel Products

manufactured cold.

E4 Practices for Force Verification of Testing Machines

NOTE 1—The Steel Industry uses the term “quality” to designate

E10 Test Method for Brinell Hardness of Metallic Materials

characteristics of a material which make it particularly well suited to a

E29 Practice for Using Significant Digits in Test Data to

specific fabrication and/or application and does not imply “quality” in the

Determine Conformance with Specifications

usual sense.

E112 Test Methods for Determining Average Grain Size

1.2 Wire size range includes 0.062 to 1.375 in.

E381 Method of Macroetch Testing Steel Bars, Billets,

7 47

1.3 Rodsizerangeusuallyincludes ⁄32in.(0.219)to ⁄64in.

Blooms, and Forgings

1

(0.734) and generally offered in ⁄64 increments (0.0156).

E407 Practice for Microetching Metals and Alloys

3 1

1.4 Bar size range includes ⁄8 in. (0.375) to 1 ⁄2 in. (1.500).

E1077 Test Methods for Estimating the Depth of Decarbur-

1.5 Sizes for wire, rod and bar outside the ranges of

ization of Steel Specimens

paragraphs 1.2-1.4 may be ordered by agreement between

F1470 Practice for Fastener Sampling for Specified Me-

purchaser and supplier.

chanical Properties and Performance Inspection

1.6 Material is furnished in many application variations.

F1789 Terminology for F16 Mechanical Fasteners

The purchaser should advise the supplier regarding the manu-

2.2 AIAG Standard:

facturing process and finished product application as appropri- 3

B-5 Primary Metals Tag Application Standard

ate. Five application variations are:

2.3 IFI Standard:

Cold Heading

IFI-140 Carbon and Alloy Steel Wire, Rods, and Bars for

Recessed Head

4

Mechanical Fasteners

Socket Head

Scrapless Nut

2.4 SAE Standards:

Tubular Rivet 5

J403 Chemical Compositions of SAE Carbon Steels

5

1.6.1 Wire is furnished for all five application variations. J404 Chemical Compositions of SAE Alloy Steels

5

J406 Methods of Determining Hardenability of Steels

1.6.2 Rod and bar are furnished to the single application

5

variation; Cold Heading. J415 Definitions of Heat Treating Terms

3. Terminology

2. Referenced Documents

2

2.1 ASTM Standards: 3.1 Definitions:

3.1.1 annealing—a process of heating to and holding steel

A29/A29M Specification for Steel Bars, Carbon and Alloy,

at a given temperature for a given time and then cooling at a

given rate, used to soften or produce changes, or both, in the

1

This specification is under the jurisdiction of ASTM Committee F16 on

microstructure of the steel to enhance formability and reduce

Fasteners and is the direct responsibility of Subcommittee F16.93 on Quality

tensile strength.

Assurance Provisions for Fasteners.

Current edition approved May 1, 2009. Published October 2009. Originally

approved in 2003. Last previous edition approved in 2003 as F2282 – 03. DOI:

3

10.1520/F2282-03R09. Available fromAutomotive IndustryAction Group (AIAG), 26200 Lahser Rd.,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Suite 200, Southfield, MI 48033, http://www.aiag.org.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from IFI, 1717 E. 9th St., Suite 1105, Cleveland, OH 44114-2879.

5

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F2282 – 03 (2009)

TABLE 2 Rod Size Tolerances

3.1.2 bars—produced from hot rolled or cast billets or

blooms rolled single strand into coils. Bars have a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.