ASTM D5792-95

(Practice)Standard Practice for Generation of Environmental Data Related to Waste Management Activities: Development of Data Quality Objectives

Standard Practice for Generation of Environmental Data Related to Waste Management Activities: Development of Data Quality Objectives

SCOPE

1.1 This practice covers the process of development of data quality objectives (DQOs) for the acquisition of environmental data. Optimization of sampling and analysis design is a part of the DQO process. This practice describes the DQO process in detail. The various strategies for design optimization are too numerous to include in this practice. Many other documents outline alternatives for optimizing sampling and analysis design. Therefore, only an overview of design optimization is included. Some design aspects are included in the practice's examples for illustration purposes.

1.2 DQO development is the first of three parts of data generation activities. The other two aspects are ( 1) implementation of the sampling and analysis strategies, see Guide D 6311 and (2) data quality assessment, see Guide D 6233.

1.3 This guide should be used in concert with Practices D 5283, D 6250, and Guide D 6044. Practice D 5283 outlines the quality assurance (QA) processes specified during planning and used during implementation. Guide D 6044 outlines a process by which a representative sample may be obtained from a population, identifies sources that can affect representativeness and describes the attributes of a representative sample. Practice D 6250 describes how a decision point can be calculated.

1.4 Environmental data related to waste management activities include, but are not limited to, the results from the sampling and analyses of air, soil, water, biota, process or general waste samples, or any combinations thereof.

1.5 The DQO process is a planning process and should be completed prior to sampling and analysis activities.

1.6 This practice presents extensive requirements of management, designed to ensure high-quality environmental data. The words "must" and "shall" (requirements), "should" (recommendation), and "may" (optional), have been selected carefully to reflect the importance placed on many of the statements in this practice. The extent to which all requirements will be met remains a matter of technical judgment.

1.7 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5792 – 95

Standard Practice for

Generation of Environmental Data Related to Waste

Management Activities: Development of Data Quality

Objectives

This standard is issued under the fixed designation D 5792; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This practice covers the process of development of data

quality objectives (DQOs) for the acquisition of environmental

2. Referenced Documents

data. Optimization of sampling and analysis design is a part of

2.1 ASTM Standards:

the DQO process. This practice describes the DQO process in

C 970 Guide for Sampling Special Nuclear Materials in

detail. The various strategies for design optimization are too

Multi-Container Lots

numerous to include in this practice. Many other documents

C 1215 Guide for Preparing and Interpreting Precision and

outline alternatives for optimizing sampling and analysis

Bias Statements in Test Method Standards Used in the

design. Therefore, only an overview of design optimization is

Nuclear Industry

included. Some design aspects are included in the practice’s

D 5283 Practice for Generation of Environmental Data

examples for illustration purposes.

Related to Waste Management Activities: Quality Assur-

1.2 DQO development is the first of three parts of data

ance and Quality Control Planning and Implementation

generation activities. The other two aspects are (1) implemen-

tation of the sampling and analysis strategies and (2) data

3. Terminology

quality assessment. This guide should be used in concert with

3.1 Definitions—Where applicable, the originating refer-

Practice D 5283, which outlines the quality assurance (QA)

ence is associated with the definition and follows the definition

processes specified during planning and used during imple-

in boldface type.

mentation.

3.1.1 accuracy (see bias)—(1) bias; (2) the closeness of a

1.3 Environmental data related to waste management activi-

measured value to the true value; (3) the closeness of a

ties include, but are not limited to, the results from the

measured value to an accepted reference or standard value.

sampling and analyses of air, soil, water, biota, or waste

3.1.1.1 Discussion—For many investigators, accuracy is

samples, or any combinations thereof.

attained only if a procedure is both precise and unbiased (see

1.4 The DQO process should be developed and initiated

bias). Because this blending of precision and accuracy can lead

prior to the application of planning, implementation, and

to confusion, ASTM requires a statement on bias instead of

assessment of sampling and analysis activities.

accuracy. D 5283

1.5 This practice presents extensive requirements of man-

3.1.2 action level—the numerical value that causes the

agement, designed to ensure high-quality environmental data.

decision maker to choose one of the alternative actions (for

The words “must” and “shall” (requirements), “should” (rec-

example, compliance or noncompliance). It may be a regula-

ommendation), and “may” (optional), have been selected

tory threshold standard, such as maximum contaminant level

carefully to reflect the importance placed on many of the

for drinking water, a risk-based concentration level, a techno-

statements in this practice. The extent to which all require-

logical limitation, or reference-based standard.

ments will be met remains a matter of technical judgement.

EPA QA/G-4 (1)

1.6 The values stated in SI units are to be regarded as the

3.1.3 bias (see accuracy)—the difference between the popu-

standard. The values given in parentheses are for information

lation mean of the test results and an accepted reference value.

only.

3.1.3.1 Discussion—Bias represents a constant error as

1.7 This standard does not purport to address all of the

opposed to a random error. A method bias can be estimated by

safety concerns, if any, associated with its use. It is the

the difference (or relative difference) between a measured

responsibility of the user of this standard to establish appro-

1 2

This practice is under the jurisdiction of ASTM Committee D34 on Waste Annual Book of ASTM Standards, Vol 12.01.

Management and is the direct responsibility of Subcommittee D34.01.01 on Annual Book of ASTM Standards, Vol 11.04.

Planning for Sampling. The boldface numbers in parentheses refer to the list of references at the end of

Current edition approved Nov. 10, 1995. Published January 1996. this practice.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 5792

average and an accepted standard or reference value. The data by a decision rule when action should not be taken.

from which the estimate is obtained should be statistically

3.1.9 decision rule—a set of directions in the form of a

analyzed to establish bias in the presence of random error.A

conditional statement that specify the following: (1) how the

thorough bias investigation of a measurement procedure re-

sample data will be compared to the action level, (2) which

quires a statistically designed experiment to repeatedly mea- decision will be made as a result of that comparison, and (3)

sure, under essentially the same conditions, a set of standards

what subsequent action will be taken based on the decisions.

or reference materials of known value that cover the range of

3.1.10 precision—a generic concept used to describe the

application. Bias often varies with the range of application and

dispersion of a set of measured values.

should be reported accordingly. C 1215, D 5283

3.1.10.1 Discussion—It is important that some quantitative

3.1.4 confidence interval—an interval used to bound the

measure be used to specify precision. A statement such as “the

value of a population parameter with a specified degree of precision is 1.54 g” is useless. Measures frequently used to

confidence (this is an interval that has different values for

express precision are standard deviation, relative standard

different samples). deviation, variance, repeatability, reproducibility, confidence

3.1.4.1 Discussion—When providing a confidence interval, interval, and range. In addition to specifying the measure and

analysts should give the number of observations on which the the precision, it is important that the number of repeated

interval is based. The specified degree of confidence is usually measurements upon which the estimated precision is based

90, 95, or 99 %. The form of a confidence interval depends on also be given. D 5283

underlying assumptions and intentions. Confidence intervals 3.1.11 quality assurance (QA)—an integrated system of

are usually taken to be symmetric, but that is not necessarily so,

management activities involving planning, quality control,

as in the case of confidence intervals for variances. C 1215 quality assessment, reporting, and quality improvement to

3.1.5 confidence level—the probability, usually expressed as ensure that a process or service (for example, environmental

data) meets defined standards of quality with a stated level of

a percent, that a confidence interval will contain the parameter

of interest (see discussion of confidence interval). confidence. EPA QA/G-4

3.1.12 quality control (QC)—the overall system of technical

3.1.6 data quality objectives (DQOs)—qualitative and

activities whose purpose is to measure and control the quality

quantitative statements derived from the DQO process describ-

of a product or service so that it meets the needs of users. The

ing the decision rules and the uncertainties of the decision(s)

aim is to provide quality that is satisfactory, adequate, depend-

within the context of the problem(s).

able, and economical. EPA QA/G-4

3.1.6.1 Discussion—DQOs clarify the study objectives, de-

3.1.13 random error—(1) the chance variation encountered

fine the most appropriate type of data to collect, determine the

in all measurement work, characterized by the random occur-

most appropriate conditions from which to collect the data, and

rence of deviations from the mean value; (2) an error that

establish acceptable levels of decision errors that will be used

affects each member of a set of data (measurements) in a

as the basis for establishing the quantity and quality of data

different manner. D 5283

needed to support the decision. The DQOs are used to develop

a sampling and analysis design. 3.1.14 risk—the probability or expectation that an adverse

effect will occur.

3.1.7 data quality objectives process—a quality manage-

3.1.14.1 Discussion—Risk is frequently used to describe the

ment tool based on the scientific method and developed by the

adverse effect on health or on economics. Health-based risk is

U.S. Environmental Protection Agency (EPA) to facilitate the

the probability of induced diseases in persons exposed to

planning of environmental data collection activities. The DQO

physical, chemical, biological, or radiological insults over

process enables planners to focus their planning efforts by

time. This risk probability depends on the concentration or

specifying the use of the data (the decision), decision criteria

level of the insult, which is expressed by a mathematical model

(action level), and decision maker’s acceptable decision error

describing the dose and risk relationship. Risk is also associ-

rates. The products of the DQO process are the DQOs.

ated with economics when decision makers have to select one

3.1.7.1 Discussion—DQOs result from an iterative process

action from a set of available actions. Each action has a

between the decision makers and the technical team to develop

corresponding cost. The risk or expected loss is the cost

qualitative and quantitative statements that describe the prob-

multiplied by the probability of the outcome of a particular

lem and the certainty and uncertainty that decision makers are

action. Decision makers should adopt a strategy to select

willing to accept in the results derived from the environmental

actions that minimize the expected loss.

data. This acceptable level of uncertainty should then be used

3.1.15 standard deviation—the square root of the sum of the

as the basis for the design specifications for project data

squares of the individual deviations from the sample average

collection and data assessment. All of the information from the

divided by one less than the number of results involved.

first six steps of the DQO process are used in designing the

study and assessing the data adequacy. EPA QA/G-4

n

¯

~X 2 X!

3.1.8 decision error (

j

j 5 1

˛

S 5

3.1.8.1 false negative error—this occurs when environmen-

n 2 1

tal data mislead decision maker(s) into not taking action

where:

specified by a decision rule when action should be taken.

S = sample standard deviation,

3.1.8.2 false positive error—this occurs when environmen-

n = number of results obtained,

tal data mislead decision maker(s) into taking action specified

D 5792

5.3 To determine the level of assurance necessary to support

X = jth individual result, and

j

¯ the decision, an iterative process must be used by decision

X = sample average.

makers, data collectors, and users. This practice emphasizes

3.1.15.1 Discussion—The use of the standard deviation to

the iterative nature of the process of DQO development.

describe precision implies that the uncertainty is independent

Objectives may need to be reevaluated and modified as

of the measurement value. The practice of associating the 6

information related to the level of data quality is gained. This

symbol with standard deviation (or RSD) is not recommended.

means that DQOs are the product of the DQO process and are

The 6 symbol denotes an interval. The standard deviation is

subject to change as data are gathered and assessed.

not an interval, and it should not be treated as such. D 5283

5.4 This practice defines the process of developing DQOs.

4. Summary of Practice

Each step of the planning process is described.

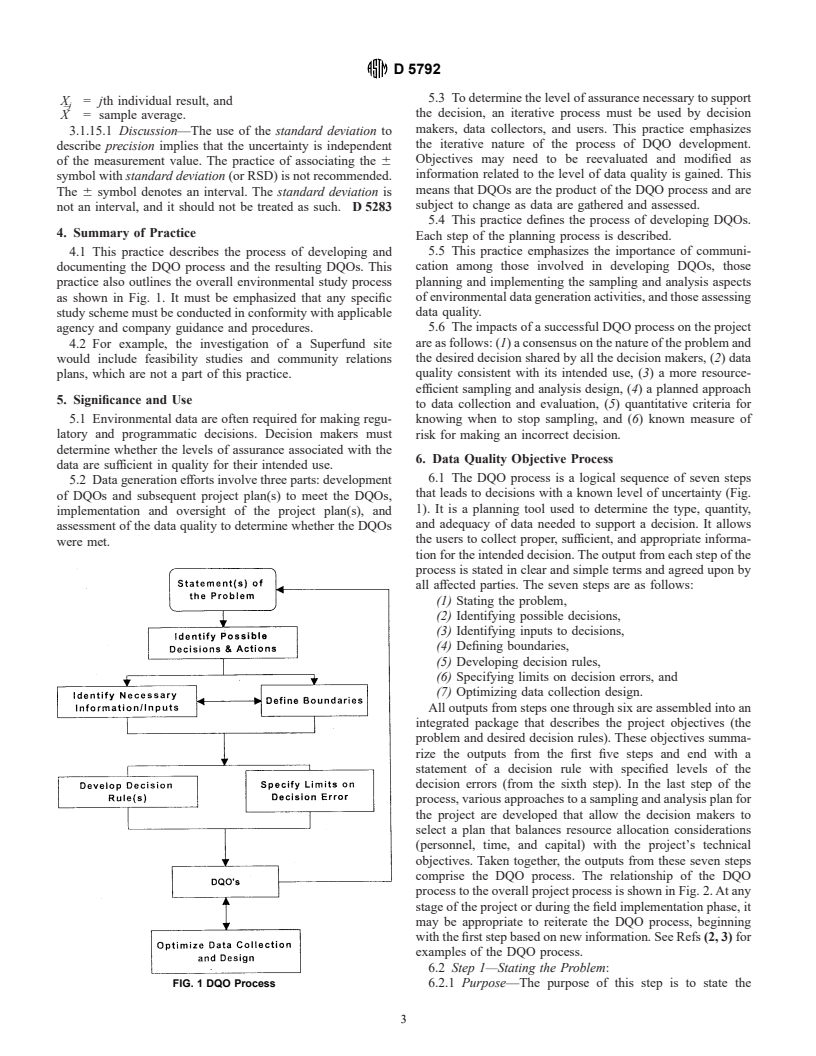

4.1 This practice describes the process of developing and 5.5 This practice emphasizes the importance of communi-

cation among those involved in developing DQOs, those

documenting the DQO process and the resulting DQOs. This

practice also outlines the overall environmental study process planning and implementing the sampling and analysis aspects

of environmental data generation activities, and those assessing

as shown in Fig. 1. It must be emphasized that any specific

study scheme must be conducted in conformity with applicable data quality.

5.6 The impacts of a successful DQO process on the project

agency and company guidance and procedures.

4.2 For example, the investigation of a Superfund site are as follows: (1) a consensus on the nature of the problem and

the desired decision shared by all the decision makers, (2) data

would include feasibility studies and community relations

plans, which are not a part of this practice. quality consistent with its intended use, (3) a more resource-

efficient sampling and analysis design, (4) a planned approach

5. Significance and Use

to data collection and evaluation, (5) quantitative criteria for

5.1 Environmental data are often required for making regu- knowing when to stop sampling, and (6) known measure of

latory and programmatic decisions. Decision makers must risk for making an incorrect decision.

determine whether the levels of assurance associated with the

6. Data Quality Objective Process

data are sufficient in quality for their intended use.

6.1 The DQO process is a logical sequence of seven steps

5.2 Data generation efforts involve three parts: development

that leads to decisions with a known level of uncertainty (Fig.

of DQOs and subsequent project plan(s) to meet the DQOs,

1). It is a planning tool used to determine the type, quantity,

implementation and oversight of the project plan(s), and

and adequacy of data needed to support a decision. It allows

assessment of the data quality to determine whether the DQOs

the users to collect proper, sufficient, and appropriate informa-

were met.

tion for the intended decision. The output from each step of the

process is stated in clear and simple terms and agreed upon by

all affected parties. The seven steps are as follows:

(1) Stating the problem,

(2) Identifying possible decisions,

(3) Identifying inputs to decisions,

(4) Defining boundaries,

(5) Developing decision rules,

(6) Specifying limits on decision errors, and

(7) Optimizing data collection design.

All outputs from s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.