ASTM D4321-09

(Test Method)Standard Test Method for Package Yield of Plastic Film

Standard Test Method for Package Yield of Plastic Film

SIGNIFICANCE AND USE

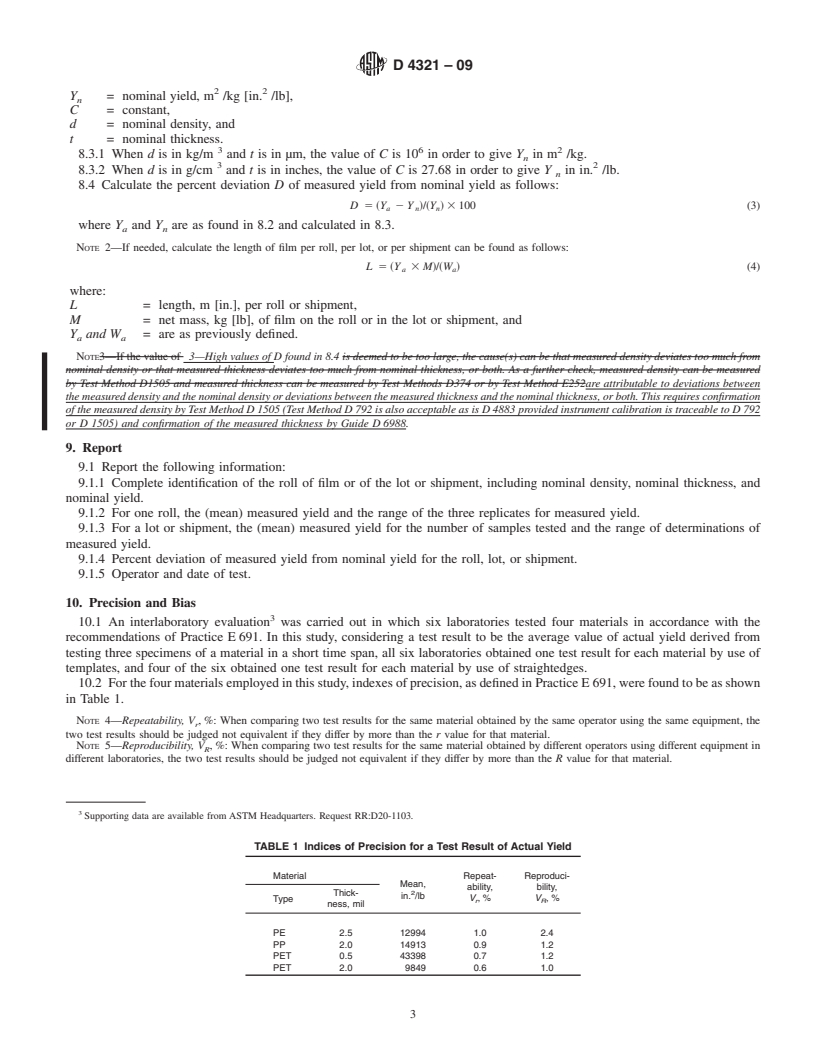

Actual yield is important to the film converter as this determines the actual number of units or packages that he can derive in a particular conversion from any given mass of film.

SCOPE

1.1 This test method covers the determination of yield (area per unit mass) of plastic film.

1.2 Also described in this test method is the means for calculating nominal yield, given values for nominal density, and nominal thickness. This is needed since, in material specifications, limits for yield are normally stated in terms of the percent deviation of actual yield from nominal yield.

1.3 The values stated in SI units are to be regarded as the standard. The values given in brackets are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—This test method and ISO 4591 address the same subject matter, but differ in technical content.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4321 − 09

StandardTest Method for

1

Package Yield of Plastic Film

This standard is issued under the fixed designation D4321; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3.1.1 density, apparent—the weight in air of a unit volume

of a material.

1.1 This test method covers the determination of yield (area

3.1.2 yield—the area per unit mass of a material.

per unit mass) of plastic film.

3.2 Definitions of Terms Specific to This Standard:

1.2 Also described in this test method is the means for

3.2.1 measured density—thedensityofthefabricatedfilmas

calculating nominal yield, given values for nominal density,

determined by actual measurement.

and nominal thickness. This is needed since, in material

3.2.1.1 Discussion—The measured density is not the value

specifications, limits for yield are normally stated in terms of

used to classify the material in accordance with a standard

the percent deviation of actual yield from nominal yield.

material specification. The measured value will depend on the

1.3 The values stated in SI units are to be regarded as the

manufacturing process of the film.

standard.Thevaluesgiveninbracketsareforinformationonly.

3.2.2 measured thickness—the thickness of the fabricated

1.4 This standard does not purport to address all of the

film as determined by actual measurement.

safety concerns, if any, associated with its use. It is the

3.2.3 nominal density—an estimated value of density of film

responsibility of the user of this standard to establish appro-

as agreed upon between the user and the supplier.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3.2.4 nominal thickness—the target value of film thickness

as agreed upon between the user and the supplier.

NOTE 1—This test method and ISO 4591 address the same subject

matter, but differ in technical content.

3.2.5 nominal yield—the target value of yield as agreed

upon between the user and the supplier.

2. Referenced Documents

3.2.6 package yield—the calculated value of yield as deter-

2

2.1 ASTM Standards:

mined by this test method.

D792 Test Methods for Density and Specific Gravity (Rela-

tive Density) of Plastics by Displacement

4. Significance and Use

D883 Terminology Relating to Plastics

4.1 Actual yield is important to the film converter as this

D1505 Test Method for Density of Plastics by the Density-

determines the actual number of units or packages that he can

Gradient Technique

derive in a particular conversion from any given mass of film.

D4883 Test Method for Density of Polyethylene by the

Ultrasound Technique

5. Apparatus

D6988 GuideforDeterminationofThicknessofPlasticFilm

5.1 Meansforpreparingtestspecimensofaccuratelyknown

Test Specimens

E691 Practice for Conducting an Interlaboratory Study to area and weighing at least 1 g.

5.1.1 When film width and thickness are such that a

Determine the Precision of a Test Method

specimen weighing at least 1 g will be produced, a rectangular

3. Terminology

metal template, nominally 100-mm [4-in.] wide, having a

3.1 Definitions:

length greater than the width of the film from which the

specimens are to be taken and having accurately parallel edges

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

in the length direction, is to be used for preparing specimens.

and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and

The width is to be accurately measured for subsequent use in

Molded Products.

calculating the specimen area. If slippage of film beneath the

Current edition approved Feb. 1, 2009. Published February 2009. Originally

template during the cutting operation is a problem, cement a

approved in 1983. Last previous edition approved in 2004 as D4321 - 04. DOI:

10.1520/D4321-09.

thin layer of cork, felt, or other suitable material onto the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact face of the template.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1.2 For narrower, thinner films for which the above

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. template would not produce a specimen weighing at least 1 g,

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4321 − 09

a steel straightedge may be used. Using the steel straightedge, shipment is being determined, obta

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4321–04 Designation:D4321–09

Standard Test Method for

1

Package Yield of Plastic Film

This standard is issued under the fixed designation D 4321; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of yield (area per unit mass) of plastic film.

1.2 Also described in this test method is the means for calculating nominal yield, given values for nominal density, and nominal

thickness. This is needed since, in material specifications, limits for yield are normally stated in terms of the percent deviation of

actual yield from nominal yield.

1.3 The values stated in SI units are to be regarded as the standard. The values given in brackets are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE1—This test method is not equivalent to ISO4591. 1—This test method and ISO 4591 address the same subject matter, but differ in technical

content.

2. Referenced Documents

2

2.1 ASTM Standards:

D374Test Methods for Thickness of Solid Electrical Insulation 792 Test Methods for Density and Specific Gravity (Relative

Density) of Plastics by Displacement

D 883 Terminology Relating to Plastics

D 1505 Test Method for Density of Plastics by the Density-Gradient Technique

D 4883 Test Method for Density of Polyethylene by the Ultrasound Technique

E252Test Method for Thickness of Thin Foil and Film by Weighing D 6988 Guide for Determination of Thickness of Plastic

Film Test Specimens

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions:

3.1.1 density, apparent—the weight in air of a unit volume of a material.

3.1.2 yield—the area per unit mass of a material.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 measured density—the density of the fabricated film as determined by actual measurement.

3.2.1.1 Discussion—The measured density is not the value used to classify the material in accordance with a standard material

specification. The measured value will depend on the manufacturing process of the film.

3.2.2 measured thickness—the thickness of the fabricated film as determined by actual measurement.

3.2.3 nominal density—an estimated value of density of film as agreed upon between the user and the supplier.

3.2.4 nominal thickness—the target value of film thickness as agreed upon between the user and the supplier.

3.2.5 nominal yield—the target value of yield as agreed upon between the user and the supplier.

3.2.6 package yield—the calculated value of yield as determined by this test method.

4. Significance and Use

4.1 Actual yield is important to the film converter as this determines the actual number of units or packages that he can derive

in a particular conversion from any given mass of film.

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.19 on Film and Sheeting .

Current edition approved JulyFeb. 1, 2004.2009. Published July 2004.February 2009. Originally approved in 1983. Last previous edition approved in 19992004 as

D4321-99.D 4321 - 04.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4321–09

5. Apparatus

5.1 Means for preparing test specimens of accurately known area and weighing at least 1 g.

5.1.1 When film width and thickness are such that a specimen weighing at least 1 g will be produced, a rectangular metal

template, nominally 100-mm [4-in.] wide, having a length greater than the width of the film from which the specimens are to be

taken and having accurately parallel edges in the length direction, is to be used for preparing specimens.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.