ASTM E1508-98(2008)

(Guide)Standard Guide for Quantitative Analysis by Energy-Dispersive Spectroscopy

Standard Guide for Quantitative Analysis by Energy-Dispersive Spectroscopy

SIGNIFICANCE AND USE

This guide covers procedures for quantifying the elemental composition of phases in a microstructure. It includes both methods that use standards as well as standardless methods, and it discusses the precision and accuracy that one can expect from the technique. The guide applies to EDS with a solid-state X-ray detector used on an SEM or EPMA.

EDS is a suitable technique for routine quantitative analysis of elements that are 1) heavier than or equal to sodium in atomic weight, 2) present in tenths of a percent or greater by weight, and 3) occupying a few cubic micrometres, or more, of the specimen. Elements of lower atomic number than sodium can be analyzed with either ultra-thin-window or windowless spectrometers, generally with less precision than is possible for heavier elements. Trace elements, defined as 1.0 %,2 can be analyzed but with lower precision compared with analyses of elements present in greater concentration.

SCOPE

1.1 This guide is intended to assist those using energy-dispersive spectroscopy (EDS) for quantitative analysis of materials with a scanning electron microscope (SEM) or electron probe microanalyzer (EPMA). It is not intended to substitute for a formal course of instruction, but rather to provide a guide to the capabilities and limitations of the technique and to its use. For a more detailed treatment of the subject, see Goldstein, et al. This guide does not cover EDS with a transmission electron microscope (TEM).

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1508–98 (Reapproved 2008)

Standard Guide for

1

Quantitative Analysis by Energy-Dispersive Spectroscopy

This standard is issued under the fixed designation E1508; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Definitions of Terms Specific to This Standard:

3.2.1 accelerating voltage—the high voltage between the

1.1 This guide is intended to assist those using energy-

cathode and the anode in the electron gun of an electron beam

dispersive spectroscopy (EDS) for quantitative analysis of

instrument, such as an SEM or EPMA.

materials with a scanning electron microscope (SEM) or

3.2.2 beam current—the current of the electron beam mea-

electron probe microanalyzer (EPMA). It is not intended to

sured with a Faraday cup positioned near the specimen.

substitute for a formal course of instruction, but rather to

3.2.3 Bremsstrahlung—background X rays produced by

provide a guide to the capabilities and limitations of the

inelastic scattering (loss of energy) of the primary electron

technique and to its use. For a more detailed treatment of the

2

beam in the specimen. It covers a range of energies up to the

subject, see Goldstein, et al. This guide does not cover EDS

energy of the electron beam.

with a transmission electron microscope (TEM).

3.2.4 critical excitation voltage—the minimum voltage re-

1.2 Units—The values stated in SI units are to be regarded

quired to ionize an atom by ejecting an electron from a specific

as standard. No other units of measurement are included in this

electron shell.

standard.

3.2.5 dead time—the time during which the system will not

1.3 This standard does not purport to address all of the

process incoming X rays (real time less live time).

safety concerns, if any, associated with its use. It is the

3.2.6 k-ratio—the ratio of background-subtracted X-ray

responsibility of the user of this standard to establish appro-

intensity in the unknown specimen to that of the standard.

priate safety and health practices and determine the applica-

3.2.7 live time—the time that the system is available to

bility of regulatory limitations prior to use.

detect incoming X rays.

2. Referenced Documents 3.2.8 overvoltage—the ratio of accelerating voltage to the

3

critical excitation voltage for a particular X-ray line.

2.1 ASTM Standards:

3.2.9 shaping time—a measure of the time it takes the

E3 Guide for Preparation of Metallographic Specimens

amplifier to integrate the incoming charge; it depends on the

E7 Terminology Relating to Metallography

4

time constant of the circuitry.

E673 Terminology Relating to Surface Analysis

3.2.10 spectrum—the energy range of electromagnetic ra-

E691 Practice for Conducting an Interlaboratory Study to

diation produced by the method and, when graphically dis-

Determine the Precision of a Test Method

played, is the relationship of X-ray counts detected to X-ray

3. Terminology

energy.

3.1 Definitions—For definitions of terms used in this guide,

4. Summary of Practice

see Terminologies E7 and E673.

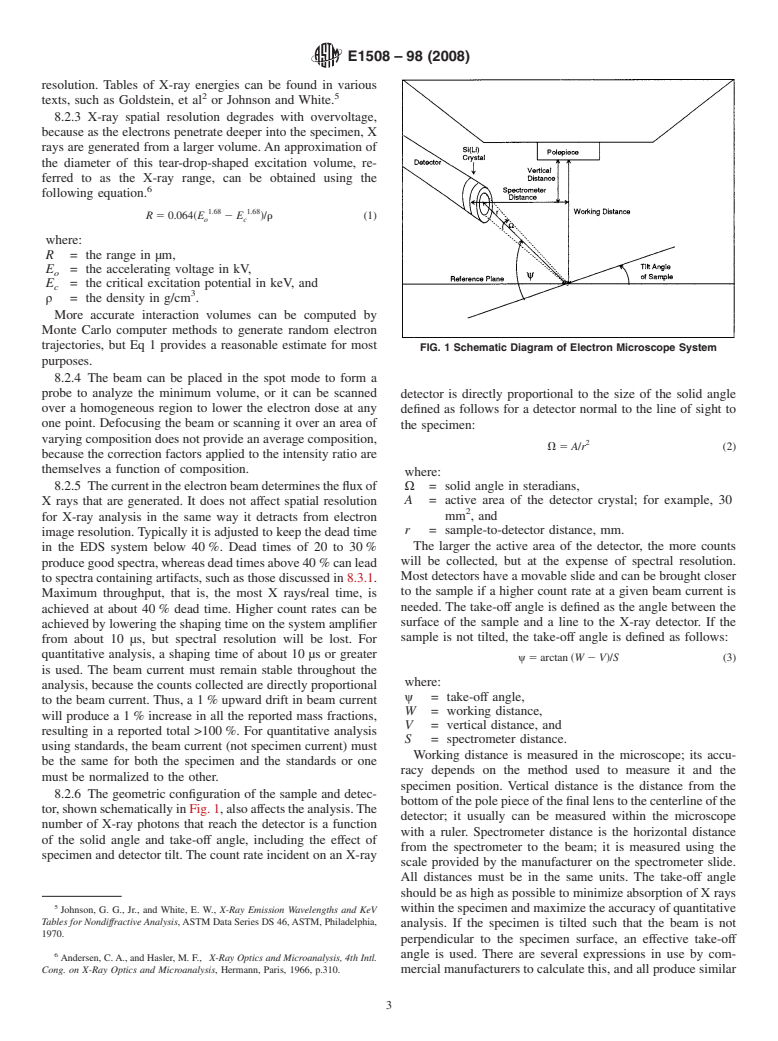

4.1 As high-energy electrons produced with an SEM or

EPMAinteract with the atoms within the top few micrometres

1

ThisguideisunderthejurisdictionofASTMCommitteeE04onMetallography

of a specimen surface, X rays are generated with an energy

and is the direct responsibility of Subcommittee E04.11 on X-Ray and Electron

Metallography. characteristic of the atom that produced them. The intensity of

Current edition approved June 1, 2008. Published September 2008. Originally

such X rays is proportional to the mass fraction of that element

approved in 1993. Last previous edition approved in 2003 as E1508 – 98(2003).

in the specimen. In energy-dispersive spectroscopy, X rays

DOI: 10.1520/E1508-98R08.

2

from the specimen are detected by a solid-state spectrometer

Goldstein,J.I.,Newbury,D.E.,Echlin,P.,Joy,D.C.,Romig,A.D.,Jr.,Lyman,

C. D., Fiori, C., and Lifshin, E., Scanning Electron Microscopy and X-ray

that converts them to electrical pulses proportional to the

Microanalysis, 3rd ed., Plenum Press, New York, 2003.

characteristic X-ray energies. If the X-ray intensity of each

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

element is compared to that of a standard of known composi-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on tion and suitably corrected for the effects of other elements

the ASTM website.

present, then the mass fraction of each element can be

4

Withdrawn. The last approved version of this historical standard is referen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.