ASTM D2990-09

(Test Method)Standard Test Methods for Tensile, Compressive, and Flexural Creep and Creep-Rupture of Plastics

Standard Test Methods for Tensile, Compressive, and Flexural Creep and Creep-Rupture of Plastics

SIGNIFICANCE AND USE

Data from creep and creep-rupture tests are necessary to predict the creep modulus and strength of materials under long-term loads and to predict dimensional changes that may occur as a result of such loads.

Data from these test methods can be used: (1) to compare materials, (2) in the design of fabricated parts, (3) to characterize plastics for long-term performance under constant load, and ( 4) under certain conditions, for specification purposes.

Before proceeding with this test method, reference shall be made to the specification of the material being tested. Any specimen preparation, conditioning, dimensions, and/or testing parameters covered in the material specification shall take precedence over those mentioned in this test method, except in cases where to do so would conflict with the purpose for conducting testing. If there are no material specifications, then the default conditions apply.

SCOPE

1.1 These test methods cover the determination of tensile and compressive creep and creep-rupture of plastics under specified environmental conditions (see 3.1.3).

1.2 While these test methods outline the use of three-point loading for measurement of creep in flexure, four-point loading (which is used less frequently) can also be used with the equipment and principles as outlined in Test Methods D 790.

1.3 For measurements of creep-rupture, tension is the preferred stress mode because for some ductile plastics rupture does not occur in flexure or compression.

1.4 Test data obtained by these test methods are relevant and appropriate for use in engineering design.

1.5 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. A specific warning statement is given in 6.8.2.

Note 1—This standard and ISO 899 Parts 1 and 2 address the same subject matter, but differ in technical content (and results cannot be directly compared between the two test methods). ISO 899 Part 1 addresses tensile creep and creep to rupture and ISO 899 Part 2 addresses flexural creep. Compressive creep is not addressed in ISO 899.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2990 − 09

Standard Test Methods for

Tensile, Compressive, and Flexural Creep and Creep-

1

Rupture of Plastics

This standard is issued under the fixed designation D2990; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* D618Practice for Conditioning Plastics for Testing

D638Test Method for Tensile Properties of Plastics

1.1 These test methods cover the determination of tensile

D695Test Method for Compressive Properties of Rigid

and compressive creep and creep-rupture of plastics under

Plastics

specified environmental conditions (see 3.1.3).

D790Test Methods for Flexural Properties of Unreinforced

1.2 While these test methods outline the use of three-point

and Reinforced Plastics and Electrical Insulating Materi-

loadingformeasurementofcreepinflexure,four-pointloading

als

(which is used less frequently) can also be used with the

D1822Test Method for Tensile-Impact Energy to Break

equipment and principles as outlined in Test Methods D790.

Plastics and Electrical Insulating Materials

D4000Classification System for Specifying Plastic Materi-

1.3 For measurements of creep-rupture, tension is the pre-

ferred stress mode because for some ductile plastics rupture als

D4065Practice for Plastics: Dynamic Mechanical Proper-

does not occur in flexure or compression.

ties: Determination and Report of Procedures

1.4 Testdataobtainedbythesetestmethodsarerelevantand

D4968Guide for Annual Review of Test Methods and

appropriate for use in engineering design.

Specifications for Plastics

1.5 The values stated in SI units are to be regarded as the

D5947Test Methods for Physical Dimensions of Solid

standard. The values in parentheses are for information only.

Plastics Specimens

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3. Terminology

responsibility of the user of this standard to establish appro-

3.1 Definitions of Terms Specific to This Standard:

priate safety and health practices and determine the applica-

3.1.1 creep modulus—the ratio of initial applied stress to

bility of regulatory limitations prior to use. Aspecific warning

creep strain.

statement is given in 6.8.2.

3.1.2 creep strain—the total strain, at any given time,

NOTE 1—This standard and ISO899 Parts 1 and 2 address the same

produced by the applied stress during a creep test.

subject matter, but differ in technical content (and results cannot be

3.1.2.1 Discussion—The term creep, as used in this test

directly compared between the two test methods). ISO899 Part 1

method,reflectscurrentplasticsengineeringusage.Inscientific

addresses tensile creep and creep to rupture and ISO899 Part 2 addresses

flexural creep. Compressive creep is not addressed in ISO899. practice, creep is often defined to be the nonelastic portion of

strain. However, this definition is not applicable to existing

2. Referenced Documents

engineering formulas. Plastics have a wide spectrum of retar-

2

2.1 ASTM Standards:

dation times, and elastic portions of strain cannot be separated

D543Practices for Evaluating the Resistance of Plastics to

in practice from nonelastic. Therefore, wherever “strain” is

Chemical Reagents

mentioned in these test methods, it refers to the sum of elastic

strain plus the additional strain with time.

1

These test methods are under the jurisdiction of ASTM Committee D20 on

3.1.3 deformation—a change in shape, size or position of a

Plastics and are the direct responsibility of Subcommittee D20.10 on Mechanical

test specimen as a result of compression, deflection, or exten-

Properties.

Current edition approved Sept. 1, 2009. Published September 2009. Originally

sion:

approved in 1971. Last previous edition approved in 2001 as D2990-01. DOI:

3.1.4 compression—in a compressive creep test, the de-

10.1520/D2990-09.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

creaseinlengthproducedinthegagelengthofatestspecimen.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.1.5 deflection—in a flexural creep test, the change in

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. mid-span position of a test specimen.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

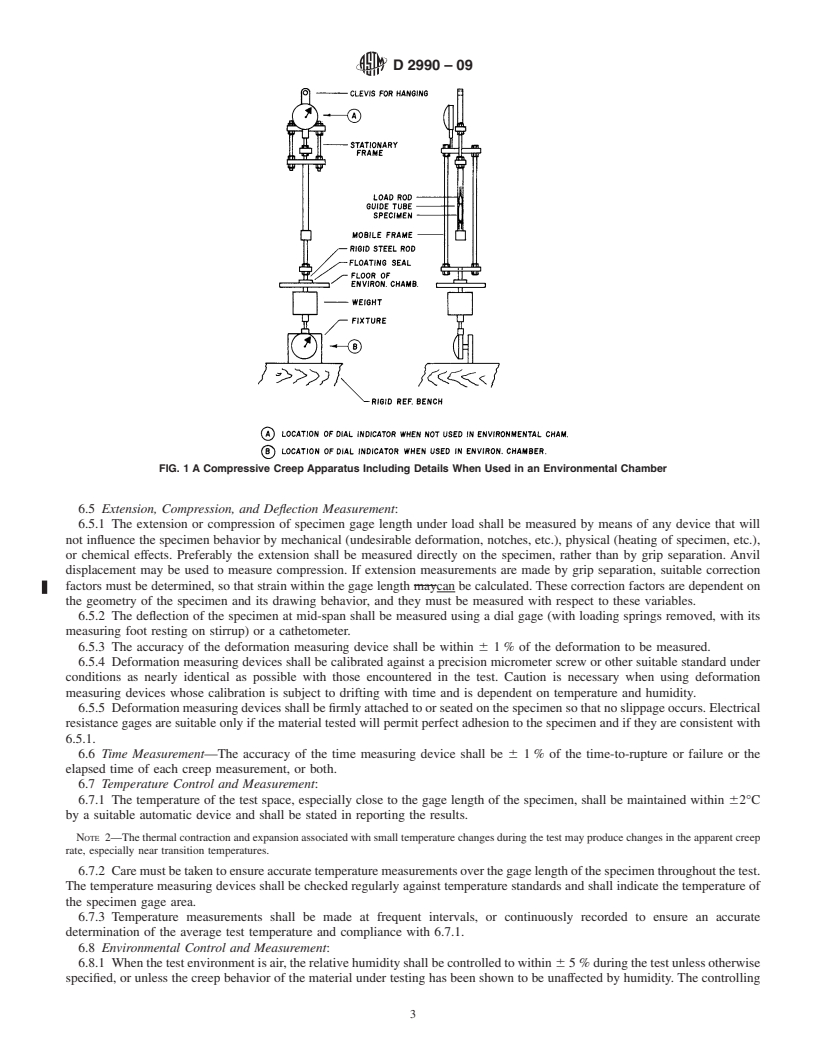

D2990 − 09

3.1.6 extension—in a tensile creep test, the increase in 5.3

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D2990–01 Designation:D2990–09

Standard Test Methods for

Tensile, Compressive, and Flexural Creep and Creep-

1

Rupture of Plastics

This standard is issued under the fixed designation D2990; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 These test methods cover the determination of tensile and compressive creep and creep-rupture of plastics under specified

environmental conditions (see 3.1.3).

1.2 While these test methods outline the use of three-point loading for measurement of creep in flexure, four-point loading

(which is used less frequently) can also be used with the equipment and principles as outlined in Test Methods D790.

1.3 For measurements of creep-rupture, tension is the preferred stress mode because for some ductile plastics rupture does not

occur in flexure or compression.

1.4 Test data obtained by these test methods are relevant and appropriate for use in engineering design.

1.5 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. A specific warning statement is given in 6.8.2.

NOTE1—ThisstandardandISO899aresimilarincontent,butarenotequivalent. 1—ThisstandardandISO899Parts1and2addressthesamesubject

matter,butdifferintechnicalcontent(andresultscannotbedirectlycomparedbetweenthetwotestmethods).ISO899Part1addressestensilecreepand

creep to rupture and ISO899 Part 2 addresses flexural creep. Compressive creep is not addressed in ISO899.

2. Referenced Documents

2

2.1 ASTM Standards:

D543 Practices for Evaluating the Resistance of Plastics to Chemical Reagents

D618 Practice for Conditioning Plastics for Testing D621Test Methods for Deformation of Plastics Under Load

D638 Test Method for Tensile Properties of Plastics

D695 Test Method for Compressive Properties of Rigid Plastics

D790 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

D1822 Test Method for Tensile-Impact Energy to Break Plastics and Electrical Insulating Materials D2236Test Method for

Dynamic Mechanical

Properties of Plastics

by Means of a Tor-

3

sional Pendulum

D4000 Classification System for Specifying Plastic Materials

D4968Guide for Annual Review of Test Methods and Specifications for Plastics 4065 Practice for Plastics: Dynamic

Mechanical Properties: Determination and Report of Procedures

D4968 Guide for Annual Review of Test Methods and Specifications for Plastics

D5947 Test Methods for Physical Dimensions of Solid Plastics Specimens

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 creep modulus—the ratio of initial applied stress to creep strain.

1

These test methods are under the jurisdiction ofASTM Committee D20 on Plastics and are the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

Current edition approvedAugust 10, 2001. Published October 2001. Originally published as D2990–71. Last previous edition D2990–95.These test methods and Practice

D2991 replace Practices D674, which has been discontinued.

Current edition approved Sept. 1, 2009. Published September 2009. Originally approved in 1971. Last previous edition approved in 2001 as D2990-01.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2990–09

3.1.2 creep strain—the total strain, at any given time, produced by the applied stress during a creep test.

3.1.2.1 Discussion—The term creep, as used in this test method, reflects current plastics engineering usage. In scientific

practice, creep is often defined to be the nonelastic portion

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.