ASTM E1361-02(2007)

(Guide)Standard Guide for Correction of Interelement Effects in X-Ray Spectrometric Analysis

Standard Guide for Correction of Interelement Effects in X-Ray Spectrometric Analysis

SIGNIFICANCE AND USE

Accuracy in quantitative X-ray spectrometric analysis depends upon adequate accounting for interelement effects either through sample preparation or through mathematical correction procedures, or both. This guide is intended to serve as an introduction to users of X-ray fluorescence correction methods. For this reason, only selected mathematical models for correcting interelement effects are presented. The reader is referred to several texts for a more comprehensive treatment of the subject (2-7).

SCOPE

1.1 This guide is an introduction to mathematical procedures for correction of interelement (matrix) effects in quantitative X-ray spectrometric analysis.

1.1.1 The procedures described correct only for the interelement effect(s) arising from a homogeneous chemical composition of the specimen. Effects related to either particle size, or mineralogical or metallurgical phases in a specimen are not treated.

1.1.2 These procedures apply to both wavelength and energy-dispersive X-ray spectrometry where the specimen is considered to be infinitely thick, flat, and homogeneous with respect to the depth of penetration of the exciting X rays (2-5).

1.2 This document is not intended to be a comprehensive treatment of the many different techniques employed to compensate for interelement effects. Consult Refs () for descriptions of other commonly used techniques such as standard addition, internal standardization, etc.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1361 − 02 (Reapproved2007)

Standard Guide for

Correction of Interelement Effects in X-Ray Spectrometric

Analysis

This standard is issued under the fixed designation E1361; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.2 analyte—an element in the specimen whose concen-

tration is to be determined.

1.1 This guide is an introduction to mathematical proce-

dures for correction of interelement (matrix) effects in quanti- 3.2.3 characteristic radiation—X radiation produced by an

tative X-ray spectrometric analysis.

element in the specimen as a result of electron transitions

1.1.1 Theproceduresdescribedcorrectonlyfortheinterele- between different atomic shells.

ment effect(s) arising from a homogeneous chemical compo-

3.2.4 coherent (Rayleigh) scatter—the emission of energy

sition of the specimen. Effects related to either particle size, or

from a loosely bound electron that has undergone collision

mineralogical or metallurgical phases in a specimen are not

with an incident X-ray photon and has been caused to vibrate.

treated.

The vibration is at the same frequency as the incident photon

1.1.2 These procedures apply to both wavelength and

and the photon loses no energy. (See 3.2.7.)

energy-dispersive X-ray spectrometry where the specimen is

3.2.5 dead-time—time interval during which the X-ray de-

considered to be infinitely thick, flat, and homogeneous with

tection system, after having responded to an incident photon,

respect to the depth of penetration of the exciting X rays (1).

cannot respond properly to a successive incident photon.

1.2 This document is not intended to be a comprehensive

3.2.6 fluorescence yield—a ratio of the number of photons

treatment of the many different techniques employed to com-

of all X-ray lines in a particular series divided by the number

pensateforinterelementeffects.ConsultRefs (2-5)fordescrip-

of shell vacancies originally produced.

tions of other commonly used techniques such as standard

addition, internal standardization, etc.

3.2.7 incoherent (Compton) scatter—theemissionofenergy

from a loosely bound electron that has undergone collision

2. Referenced Documents

withanincidentphotonandtheelectronhasrecoiledunderthe

2.1 ASTM Standards:

impact, carrying away some of the energy of the photon.

E135Terminology Relating to Analytical Chemistry for

3.2.8 influence coeffıcient—designated by α (β, γ, δ and

Metals, Ores, and Related Materials

other Greek letters are also used in certain mathematical

models), a correction factor for converting apparent mass

3. Terminology

fractions to actual mass fractions in a specimen. Other terms

3.1 For definitions of terms used in this guide, refer to

commonly used are alpha coefficient and interelement effect

Terminology E135.

coefficient.

3.2 Definitions of Terms Specific to This Standard:

3.2.9 mass absorption coeffıcient—designated by µ, an

3.2.1 absorption edge—the maximum wavelength (mini-

atomic property of each element which expresses the X-ray

mum X-ray photon energy) that can expel an electron from a

absorption per unit mass per unit area, cm /g.

given level in an atom of a given element.

3.2.10 primary absorption—absorption of incident X rays

1 by the specimen.The extent of primary absorption depends on

This guide is under the jurisdiction of ASTM Committee E01 on Analytical

ChemistryforMetals,Ores,andRelatedMaterialsandisthedirectresponsibilityof

the composition of the specimen and the X-ray source primary

Subcommittee E01.20 on Fundamental Practices.

spectral distribution.

Current edition approved Jan. 15, 2007. Published January 2007. Originally

approved in 1990. Last previous edition approved in 2002 as E1361–02. DOI:

3.2.11 primary spectral distribution—the output X-ray

10.1520/E1361-02R07.

spectral distribution usually from an X-ray tube. The X-ray

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

continuum is usually expressed in units of absolute intensity

this standard.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or per unit wavelength per electron per unit solid angle.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.2.12 relative intensity—the ratio of an analyte X-ray line

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. intensity measured from the specimen to that of the pure

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1361 − 02 (2007)

analyte element. It is sometimes expressed relative to the

analyte element in a multi-component reference material.

3.2.13 secondary absorption—the absorption of the charac-

teristicXradiationproducedinthespecimenbyallelementsin

the specimen.

3.2.14 secondary fluorescence (enhancement)—the genera-

tion of X rays from the analyte caused by characteristic X rays

from other elements in the sample whose energies are greater

than the absorption edge of the analyte.

3.2.15 mass fraction—a concentration unit expressed as a

ratio of the mass of analyte to the total mass.

3.2.16 X-ray source—an excitation source which produces

XrayssuchasanX-raytube,radioactiveisotope,orsecondary

target emitter.

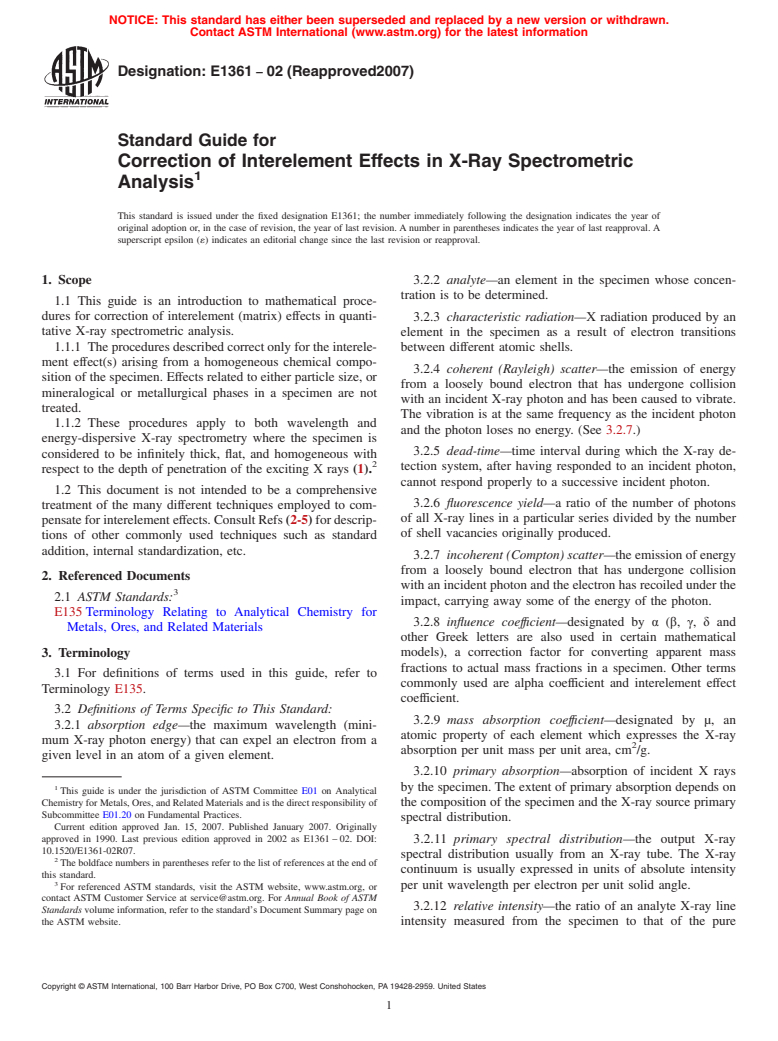

Curve A—Linear calibration curve.

Curve B—Absorption of analyte by matrix. For example, R versus C in

Ni Ni

4. Significance and Use

Ni-Fe binary alloys where nickel is the analyte element and iron is the matrix

4.1 Accuracy in quantitative X-ray spectrometric analysis element.

Curve C—Negative absorption of analyte by matrix. For example, R versus

Ni

depends upon adequate accounting for interelement effects

C in Ni-Al alloys where nickel is the analyte element and aluminum is the

Ni

either through sample preparation or through mathematical

matrix element.

Curve D—Enhancement of analyte by matrix. For example, R versus C in

correction procedures, or both. This guide is intended to serve Fe Fe

Fe-Ni alloys where iron is the analyte element and nickel is the matrix ele-

as an introduction to users of X-ray fluorescence correction

ment.

methods. For this reason, only selected mathematical models

for correcting interelement effects are presented. The reader is FIG. 1 Interelement Effects in X-Ray Fluorescence Analysis

referredtoseveraltextsforamorecomprehensivetreatmentof

the subject (2-7).

ary absorption effect is often referred to simply as absorption.

The magnitude of the displacement of Curve B from CurveA

5. Description of Interelement Effects

in Fig. 1, for example, is typical of the strong absorption of

5.1 Matrix effects in X-ray spectrometry are caused by

nickel nickel K-L (K ) X rays in Fe-Ni alloys. Curve C

2,3 α

absorption and enhancement of X rays in the specimen.

represents the general case where the matrix elements in the

PrimaryabsorptionoccursasthespecimenabsorbstheX-rays

specimenabsorbtheprimaryXraysorcharacteristicXrays,or

from the source. The extent of primary absorption depends on

both, to a lesser degree than the analyte alone. This type of

thecompositionofthespecimen,theoutputenergydistribution

secondary absorption is often referred to as negative absorp-

oftheexcitingsource,suchasanX-raytube,andthegeometry

tion. The magnitude of the displacement of Curve C from

of the spectrometer. Secondary absorption occurs as the char-

CurveAinFig.1,forexample,istypicalofalloysinwhichthe

acteristic X radiation produced in the specimen is absorbed by

atomicnumberofthematrixelement(forexample,aluminum)

the elements in the specimen. When matrix elements emit

is much lower than the analyte (for example, nickel). Curve D

characteristicX-raylinesthatlieontheshort-wavelength(high

in Fig. 1 illustrates an enhancement effect as defined

energy) side of the analyte absorption edge, the analyte can be

previously, and represents in this case the enhancement of iron

excited to emit characteristic radiation in addition to that

K-L (K ) X rays by nickel K-L (K ) X rays in Fe-Ni

2,3 α 2,3 α

excited directly by the X-ray source. This is called secondary

binaries.

fluorescence or enhancement.

NOTE 1—The relative intensity rather than absolute intensity of the

5.2 These effects can be represented as shown in Fig. 1

analytewillbeusedinthisdocumentforpurposesofconvenience.Itisnot

usingbinaryalloysasexamples.Whenmatrixeffectsareeither

meant to imply that measurement of the pure element is required, unless

under special circumstances as described in 9.1.

negligible or constant, Curve A in Fig. 1 would be obtained.

That is, a plot of analyte relative intensity (corrected for

6. General Comments Concerning Interelement

background, dead-time, etc.) versus analyte mass fraction

Correction Procedures

wouldyieldastraightlineoverawidemassfractionrangeand

would be independent of the other elements present in the 6.1 Historically, the development of mathematical methods

specimen (Note 1). Linear relationships often exist in thin for correction of interelement effects has evolved into two

specimens, or in cases where the matrix composition is approaches, which are currently employed in quantitative

constant. Low alloy steels, for example, exhibit constant X-ray analysis.When the field of X-ray spectrometric analysis

interelement effects in that the mass fractions of the minor was new, researchers proposed mathematical expressions,

constituents vary, but the major constituent, iron, remains which required prior knowledge of corrective factors called

relatively constant. In general, Curve B is obtained when the influence coefficients or alphas prior to analysis of the speci-

absorptionbythematrixelementsinthespecimenofeitherthe mens. These factors were usually determined experimentally

primary X rays or analyte characteristic X rays, or both, is by regression analysis using reference materials, and for this

greater than the absorption by the analyte alone. This second- reason are typically referred to as empirical or semi-empirical

E1361 − 02 (2007)

procedures (see 7.1.3, 7.2, and 7.8). During the late 1960s, Therefore,sixalphacoefficientsarerequiredtosolveforthe

another approach was introduced which involved the calcula- mass fractions C, C, and C (see Appendix X1). Once the

i j k

tion of interelement corrections directly from first principles influence coefficients are determined, Eq 3-5 can be solved for

expressions such as those given in Section 8. First principles the unknown mass fractions with a computer using iterative

expressions are derived from basic physical principles and techniques (see Appendix X2).

contain physical constants and parameters, for example, which 7.1.3 Determination of Influence (Alpha) Coeffıcients from

include absorption coefficients, fluorescence yields, primary

Regression Analysis—Alpha coefficients can be obtained ex-

spectral distributions, and spectrometer geometry. Fundamen- perimentallyusingregressionanalysisofreferencematerialsin

tal parameters method is a term commonly used to describe

which the elements to be measured are known and cover a

interelement correction procedures based on first principle broadmassfractionrange.Anexampleofthismethodisgiven

equations (see Section 8). in X1.1.1 of Appendix X1. Eq 1 can be rewritten for a binary

specimen in the form:

6.2 In recent years, several workers have proposed funda-

R

mental parameters methods to correct measured X-ray inten- C /R 21 5 α C (6)

~ !

i i ij j

sities directly for interelement effects or, alternatively, pro-

posedmathematicalexpressionsinwhichinfluencecoefficients R

where: α =influence coefficient obtained by regression

ij

arecalculatedfromfirstprinciples(seeSections7and8).Such

analysis. A plot of (C/R)−1 versus C gives a straight line

i i j

influencecoefficientexpressionsarereferredtoasfundamental R

with slope α (see Fig. X1.1 of Appendix X1). Note that the

ij

influence coefficient methods.

superscript LT is replaced by R because alphas obtained by

regression analysis of multi-component reference materials do

7. Influence Coefficient Correction Procedures

LT

notgenerallyhavethesamevaluesas α (asdeterminedfrom

ij

7.1 The Lachance-Traill Equation:

first principles calculations). This does not present a problem

7.1.1 Forthepurposesofthisguide,itisinstructivetobegin

generally in the results of analysis if the reference materials

with one of the simplest, yet fundamental, correction models

bracket each of the analyte elements over the mass fraction

within certain limits. Referring to Fig. 1, either Curve B or C

ranges that exist in the specimen(s). Best results are obtained

(thatis,absorptiononly)canberepresentedmathematicallyby

only when the specimens and reference materials are of the

a hyperbolic expression such as the Lachance-Traill equation

same type. The weakness of the multiple-regression technique

(LT) (8).Forabinaryspecimencontainingelements iand j,the

asappliedinX-rayanalysisisthattheaccuracyoftheinfluence

LT equation is:

coefficientsobtainedisnotknownunlessverified,forexample,

LT

C 5 R ~11α C ! (1)

i i ij j from first principles calculations. As the number of compo-

nentsinaspecimenincreases,thisbecomesmoreofaproblem.

Results of analysis should be checked for accuracy by incor-

where:

poratingreferencematerialsintheanalysisschemeandtreating

C = mass fraction of analyte i,

i

themasunknownspecimens.Comparisonoftheknownvalues

C = mass fraction of matrix element j,

j

with those found by analysis should give acceptable

R = the analyte intensity in the specimen expressed as a

i

agreement, if the influence coefficients are sufficiently accu-

ratio to the pure analyte element, and

LT

rate. This test is valid only when reference materials analyzed

α = the influence coefficient, a constant.

ij

as unknowns are not included in the set of reference materials

The subscript i denotes the analyte and the subscript j

from which the influence coefficients were obtained.

LT

denotes the matrix element. The subscript in α denotes the

ij

7.1.4 Determination of Influence Coeffıcients from First

influence of matrix element j on the analyte i in the binary

Principles—Influence coefficients can be calculated from fun-

specimen. The LT superscript denotes that the influence coef-

damentalparametersexpressions(seeX1.1.3ofAppendixX1).

ficient is that coefficient in the LT equation. The magnitude of

Thisisusuallydonebyarbitrarilyconsideringthecomposition

the displacement of Curves B and C from Curve A is

of a complex specimen to be made up of the analyte and one

LT

represented by α which takes on positive values for B type

ij

matrix element at a time (f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.