ASTM D1898-68(1989)

(Practice)Standard Practice for Sampling of Plastics (Withdrawn 1998)

Standard Practice for Sampling of Plastics (Withdrawn 1998)

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1898 – 68 (Reapproved 1989)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Practice for

1

Sampling of Plastics

This standard is issued under the fixed designation D 1898; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

Specific 12 to 15

Apendixes:

1.1 This practice is primarily a statement of principles to

Glossary X1

guide purchasers of plastic materials purchased under specifi-

Inspection by Attributes X2

Inspection by Variables X3

cations to prepare sampling plans that will describe sampling

Example of Use of Previous Data for Judging the

procedures and that will enable them to determine within

Qualities of Lots and for Setting Specification

practical limits whether or not the products meet the specifi- Limits X4

cations.

1.8 The values stated in SI units are to be regarded as the

1.2 The same principles may be used to guide the prepara-

standard.

tion of specifications in quantitative terms.

1.9 This standard may involve hazardous materials, opera-

1.3 Some of the same principles may be used to determine

tions, and equipment. This standard does not purport to

the actual quality of a product, including its average and

address all of the safety problems associated with its use. It is

variation above and below that average, with respect to a

the responsibility of the user of this standard to establish

particular property.

appropriate safety and health practices and determine the

1.4 Since the design of probability sampling depends upon

applicability of regulatory limitations prior to use.

the ultimate use of the samples and the resulting data, consid-

eration must be given to the intended inspection of the samples.

2. Referenced Documents

Hence, the design of plans for examination and testing of

2.1 ASTM Standards:

samples for both their attributes and their variables is included.

E 122 Practice for Choice of Sample Size to Estimate the

1.5 This practice is intended for general guidance when 2

Average Quality of a Lot or Process

little information is available on the variability of the material

3

2.2 Military Standards:

and of the method of inspection. In some cases, quality control

MIL-STD-105 Sampling Procedures and Tables for Inspec-

chart methods may be substituted for the procedures herein. In

tion by Attributes

any event, a statistician should be consulted if difficulty is

MIL-STD-414 Sampling Procedures and Tables for Inspec-

encountered in applying the recommendations herein to the

tion by Variables for Percent Defective

design of a specific sampling problem.

1.6 There is no intent to guide the disposition of material

3. Significance and Use

that is found to be off-specification by sampling and inspection;

3.1 The purpose of the sample may be as follows:

disposition is a contractual matter.

3.1.1 To estimate properties of a lot or shipment, such as the

1.7 The following outline is presented to facilitate use of

percentage of some constituent, the fraction of the items that

this practice:

fail to meet a specific requirement, the average weight or

Section

property of an item, or the quality or total weight of the

shipment, or simple identity.

General Philosophy 4

Sampling of Attributes 5 3.1.2 To dispose of the lot or shipment rationally, without

Sampling for Variables 6

the intermediate step of the formation of an estimate.

Means and Standard Deviations 7

3.1.3 To define new materials in terms of their properties.

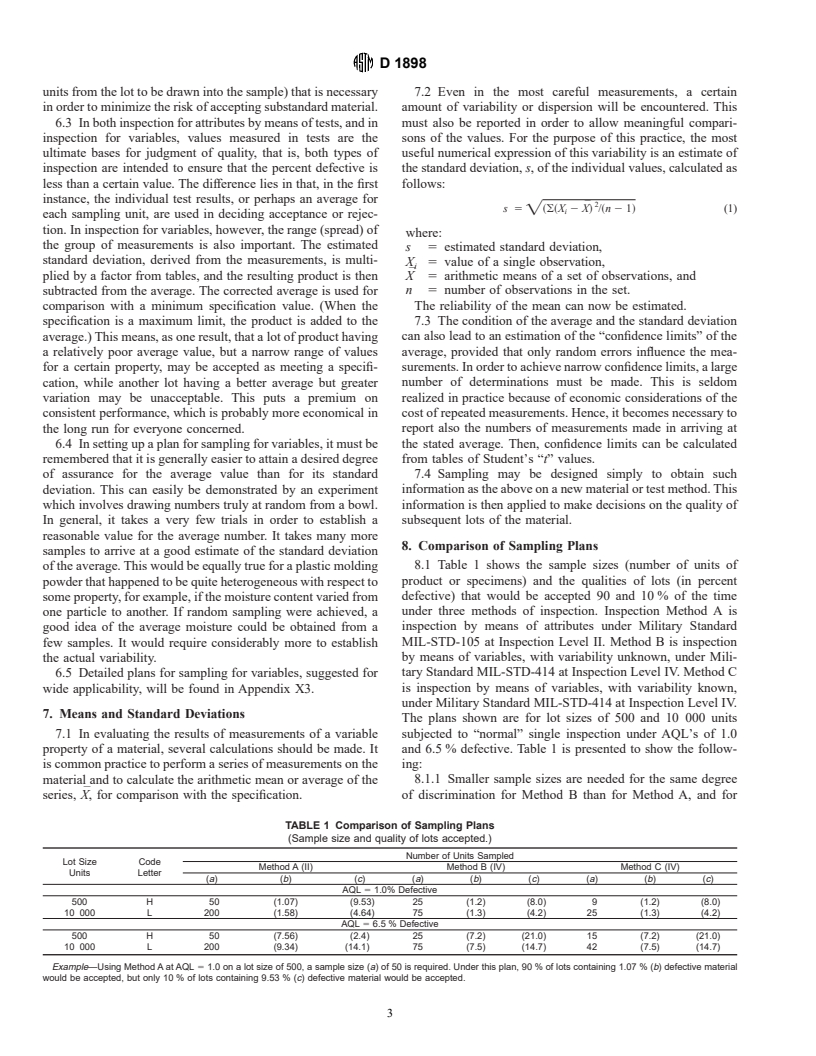

Comparison of Sampling Plans 8

Sampling Procedures:

3.1.4 To provide material for evaluation of a test method.

General 9 to 11

Random 10

4. General Philosophy

Stratified 11

4.1 Sampling is a means employed to meet the problem of

estimating the quality of a lot from the inspection of only part

1

This practice is under the jurisdiction of ASTM Committee D-20 on Plastics

2

and is the direct responsibility of Subcommittee D20.13 on Statistical Techniques. Annual Book of ASTM Standard, Vol 14.02.

3

Current edition approved Jan. 10, 1968. Published March 1968. Originally Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

published as D 1898 – 61 T. Last previous edition D 1898 – 61 T. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

1

---------------------- Page: 1 ----------------------

D 1898

of the lot. When 100 % inspection (“screening”) of a lot is part by the frequency of occurrence of their attributes, that is,

performed, sampling

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.