ASTM G63-99(2007)

(Guide)Standard Guide for Evaluating Nonmetallic Materials for Oxygen Service

Standard Guide for Evaluating Nonmetallic Materials for Oxygen Service

SIGNIFICANCE AND USE

The purpose of this guide is to furnish qualified technical personnel with pertinent information for use in selecting materials for oxygen service in order to minimize the probability of ignition and the risk of explosion or fire. It is not intended as a specification for approving materials for oxygen service.

SCOPE

1.1 This guide applies to nonmetallic materials, (hereinafter called materials) under consideration for oxygen or oxygen-enriched fluid service, direct or indirect, as defined below. It is intended for use in selecting materials for applications in connection with the production, storage, transportation, distribution, or use of oxygen. It is concerned primarily with the properties of a material associated with its relative susceptibility to ignition and propagation of combustion; it does not involve mechanical properties, potential toxicity, outgassing, reactions between various materials in the system, functional reliability, or performance characteristics such as aging, shredding, or sloughing of particles, except when these might contribute to an ignition.

1.2 When this document was originally published in 1980, it addressed both metals and nonmetals. Its scope has been narrowed to address only nonmetals and a separate standard Guide G 94 has been developed to address metals.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—The American Society for Testing and Materials takes no position respecting the validity of any evaluation methods asserted in connection with any item mentioned in this guide. Users of this guide are expressly advised that determination of the validity of any such evaluation methods and data and the risk of use of such evaluation methods and data are entirely their own responsibility.

Note 2—In evaluating materials, any mixture with oxygen exceeding atmospheric concentration at pressures higher than atmospheric should be evaluated from the hazard point of view for possible significant increase in material combustibility.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G63 − 99 (Reapproved2007)

Standard Guide for

1

Evaluating Nonmetallic Materials for Oxygen Service

ThisstandardisissuedunderthefixeddesignationG63;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This guide applies to nonmetallic materials, (hereinafter 2.1 ASTM Standards:

called materials) under consideration for oxygen or oxygen- D217Test Methods for Cone Penetration of Lubricating

enriched fluid service, direct or indirect, as defined below. It is Grease

intended for use in selecting materials for applications in D566TestMethodforDroppingPointofLubricatingGrease

connection with the production, storage, transportation, D1264Test Method for Determining the Water Washout

distribution, or use of oxygen. It is concerned primarily with Characteristics of Lubricating Greases

the properties of a material associated with its relative suscep- D1743Test Method for Determining Corrosion Preventive

tibility to ignition and propagation of combustion; it does not Properties of Lubricating Greases

involve mechanical properties, potential toxicity, outgassing, D1748Test Method for Rust Protection by Metal Preserva-

reactions between various materials in the system, functional tives in the Humidity Cabinet

reliability, or performance characteristics such as aging, D2512Test Method for Compatibility of Materials with

shredding, or sloughing of particles, except when these might Liquid Oxygen (Impact Sensitivity Threshold and Pass-

contribute to an ignition. Fail Techniques)

D2863Test Method for Measuring the Minimum Oxygen

1.2 Whenthisdocumentwasoriginallypublishedin1980,it

Concentration to Support Candle-Like Combustion of

addressed both metals and nonmetals. Its scope has been

Plastics (Oxygen Index)

narrowed to address only nonmetals and a separate standard

D4809Test Method for Heat of Combustion of Liquid

Guide G94 has been developed to address metals.

Hydrocarbon Fuels by Bomb Calorimeter (Precision

1.3 This standard does not purport to address all of the

Method)

safety concerns, if any, associated with its use. It is the

G72Test Method for Autogenous Ignition Temperature of

responsibility of the user of this standard to establish appro-

Liquids and Solids in a High-Pressure Oxygen-Enriched

priate safety and health practices and determine the applica-

Environment

bility of regulatory limitations prior to use.

G74Test Method for Ignition Sensitivity of Materials to

Gaseous Fluid Impact

NOTE 1—The American Society for Testing and Materials takes no

position respecting the validity of any evaluation methods asserted in

G86Test Method for Determining Ignition Sensitivity of

connection with any item mentioned in this guide. Users of this guide are

Materials to Mechanical Impact in Ambient Liquid Oxy-

expresslyadvisedthatdeterminationofthevalidityofanysuchevaluation

gen and Pressurized Liquid and Gaseous Oxygen Envi-

methods and data and the risk of use of such evaluation methods and data

ronments

are entirely their own responsibility.

NOTE 2—In evaluating materials, any mixture with oxygen exceeding G88Guide for Designing Systems for Oxygen Service

atmosphericconcentrationatpressureshigherthanatmosphericshouldbe

G93Practice for Cleaning Methods and Cleanliness Levels

evaluated from the hazard point of view for possible significant increase

for Material and Equipment Used in Oxygen-Enriched

in material combustibility.

Environments

G94Guide for Evaluating Metals for Oxygen Service

1

ThisguideisunderthejurisdictionofASTMCommitteeG04onCompatibility

and Sensitivity of Materials in Oxygen Enriched Atmospheres and is the direct

2

responsibility of Subcommittee G04.02 on Recommended Practices. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 15, 2007. Published May 2007. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1980. Last previous edition approved in 1999 as G63–99. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/G0063-99R07. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

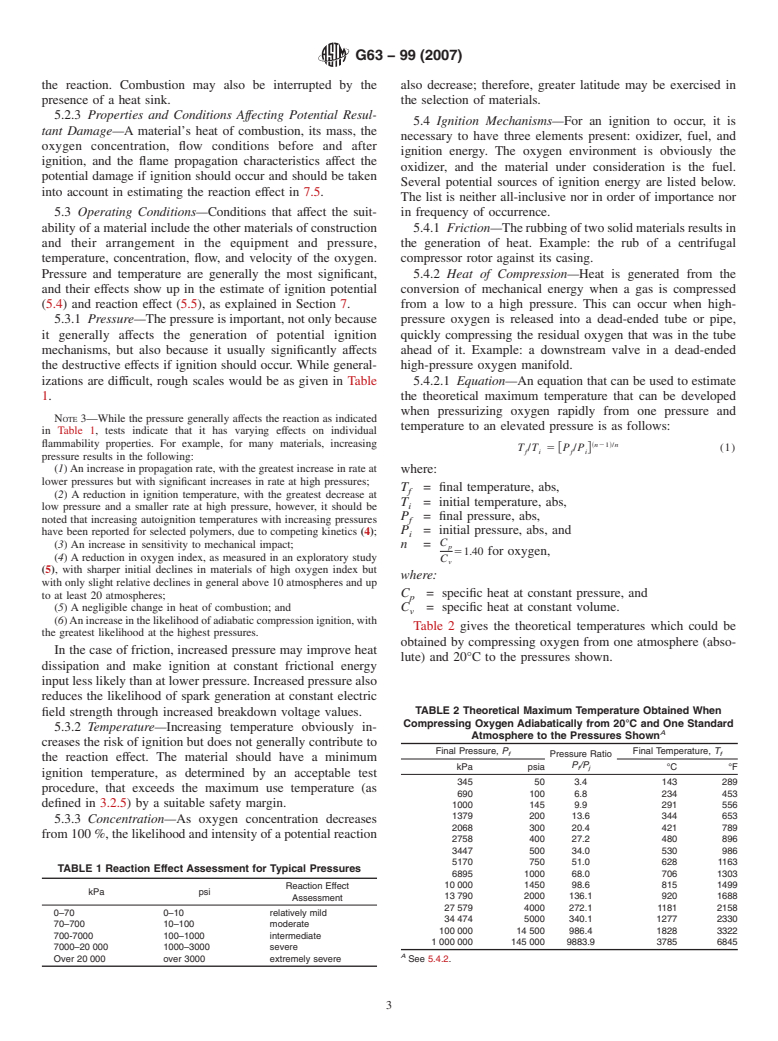

G63 − 99 (2007)

2.2 Federal Standard: experience, know how to apply physical and chemical prin-

Fed.TestMethodStd.91BCorrosionProtectionbyCoating: ciples involved in the reactions between oxygen and other

3

Salt Spray (Fog) Test materials.

2.3 Other Standard:

3.2.11 reactioneffect—thepersonnelinjury,facilitydamage,

BS 3N:100: 1985Specification

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.