ASTM D1072-06(2012)

(Test Method)Standard Test Method for Total Sulfur in Fuel Gases by Combustion and Barium Chloride Titration

Standard Test Method for Total Sulfur in Fuel Gases by Combustion and Barium Chloride Titration

ABSTRACT

This test method is for the determination of total sulfur in combustible fuel gases and is applicable to natural gases, manufactured gases, mixed gases, and other miscellaneous gaseous fuels. For the use of barium chloride titration following collection of sulfur dioxide by alternative procedures, ammonia, amines, substances producing water soluble cations, and fluorides will interfere with the titration. The apparatus includes the following: (1) burner, (2) chimneys, absorbers, and spray traps, (3) flow meter, (4) vacuum system, (5) air-purifying system, and (6) monometer. The schematic diagrams of the gas burner, combustion and absorption apparatus, suction system, and purified air system are provided. Reagent grade chemicals shall be used in all tests and include: (1) water, (2) denatured ethyl or isopropyl alcohol, (3) barium chloride, standard solution, (4) hydrochloric acid, (5) hydrogen peroxide, (6) iso-propanol, (7) potassium hydrogen phthalate, (8) phenolphthalein, (9) methyl orange indicator solution, (10) silver nitrate solution, (11) sodium carbonate solution, (12) sodium hydroxide solution, (13) sulfuric acid, (14) tetrahydroxyquinone indicator, and (15) thorin indicator. The procedure for the following are detailed: (1) calibration and standardization of sodium hydroxide, sulfuric acid, and barium chloride solutions, (2) preparation of apparatus, (3) sulfur determination, (4) analysis of absorbent, and (5) quality assurance. The formula of calculating the volume of gas in standard cubic feet burned during the determination and the concentration of sulfur from the results of titration are given.

SCOPE

1.1 This test method is for the determination of total sulfur in combustible fuel gases, when present in sulfur concentrations between approximately 25 and 700 mg/m3 (1 to 30 grains per 100 cubic feet). It is applicable to natural gases, manufactured gases, mixed gases, and other miscellaneous gaseous fuels.

1.2 The values stated in inch-pound units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1072 − 06 (Reapproved 2012)

Standard Test Method for

Total Sulfur in Fuel Gases by Combustion and Barium

1

Chloride Titration

This standard is issued under the fixed designation D1072; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope alternative procedures are cautioned that ammonia, amines,

substances producing water soluble cations, and fluorides will

1.1 This test method is for the determination of total sulfur

interfere with the titration.

in combustible fuel gases, when present in sulfur concentra-

3

tions between approximately 25 and 700 mg/m (1 to 30 grains

5. Apparatus

per 100 cubic feet). It is applicable to natural gases, manufac-

5.1 Burner (Fig. 1), as specified in the Appendix X1.

tured gases, mixed gases, and other miscellaneous gaseous

fuels.

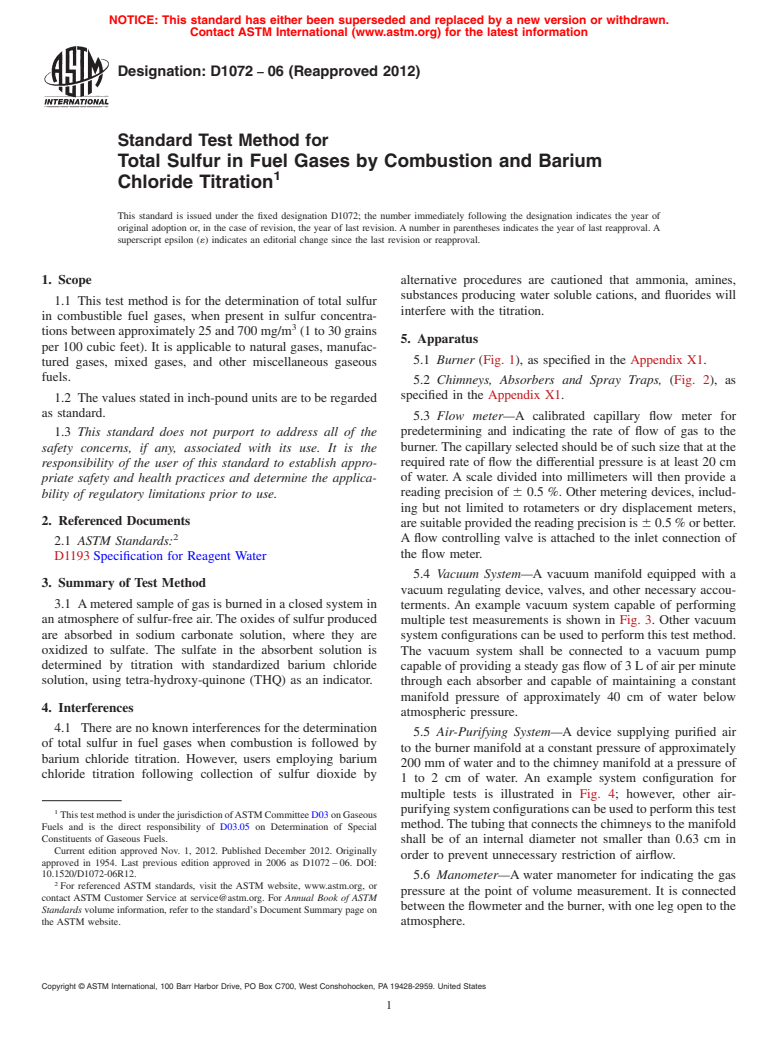

5.2 Chimneys, Absorbers and Spray Traps, (Fig. 2), as

specified in the Appendix X1.

1.2 The values stated in inch-pound units are to be regarded

as standard.

5.3 Flow meter—A calibrated capillary flow meter for

predetermining and indicating the rate of flow of gas to the

1.3 This standard does not purport to address all of the

burner. The capillary selected should be of such size that at the

safety concerns, if any, associated with its use. It is the

required rate of flow the differential pressure is at least 20 cm

responsibility of the user of this standard to establish appro-

of water. A scale divided into millimeters will then provide a

priate safety and health practices and determine the applica-

reading precision of 6 0.5 %. Other metering devices, includ-

bility of regulatory limitations prior to use.

ing but not limited to rotameters or dry displacement meters,

2. Referenced Documents

aresuitableprovidedthereadingprecisionis 60.5%orbetter.

2

A flow controlling valve is attached to the inlet connection of

2.1 ASTM Standards:

the flow meter.

D1193 Specification for Reagent Water

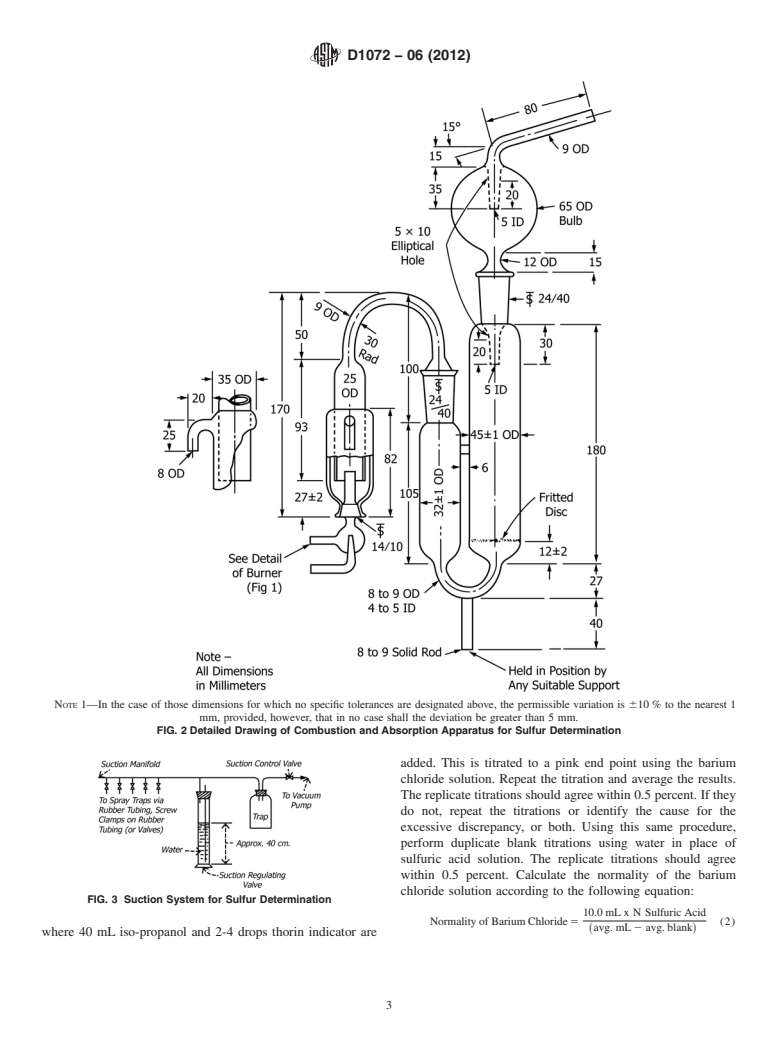

5.4 Vacuum System—A vacuum manifold equipped with a

3. Summary of Test Method

vacuum regulating device, valves, and other necessary accou-

3.1 Ametered sample of gas is burned in a closed system in

terments. An example vacuum system capable of performing

an atmosphere of sulfur-free air. The oxides of sulfur produced multiple test measurements is shown in Fig. 3. Other vacuum

are absorbed in sodium carbonate solution, where they are

system configurations can be used to perform this test method.

oxidized to sulfate. The sulfate in the absorbent solution is

The vacuum system shall be connected to a vacuum pump

determined by titration with standardized barium chloride

capable of providing a steady gas flow of 3 Lof air per minute

solution, using tetra-hydroxy-quinone (THQ) as an indicator.

through each absorber and capable of maintaining a constant

manifold pressure of approximately 40 cm of water below

4. Interferences

atmospheric pressure.

4.1 There are no known interferences for the determination

5.5 Air-Purifying System—A device supplying purified air

of total sulfur in fuel gases when combustion is followed by

to the burner manifold at a constant pressure of approximately

barium chloride titration. However, users employing barium

200 mm of water and to the chimney manifold at a pressure of

chloride titration following collection of sulfur dioxide by

1 to 2 cm of water. An example system configuration for

multiple tests is illustrated in Fig. 4; however, other air-

purifyingsystemconfigurationscanbeusedtoperformthistest

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD03onGaseous

method.The tubing that connects the chimneys to the manifold

Fuels and is the direct responsibility of D03.05 on Determination of Special

Constituents of Gaseous Fuels.

shall be of an internal diameter not smaller than 0.63 cm in

Current edition approved Nov. 1, 2012. Published December 2012. Originally

order to prevent unnecessary restriction of airflow.

approved in 1954. Last previous edition approved in 2006 as D1072 – 06. DOI:

10.1520/D1072-06R12.

5.6 Manometer—A water manometer for indicating the gas

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

pressure at the point of volume measurement. It is connected

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

between the flowmeter and the burner, with one leg open to the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. atmosphere.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1072 − 06 (2012)

6.10 Met

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.