ASTM F1476-07

(Specification)Standard Specification for Performance of Gasketed Mechanical Couplings for Use in Piping Applications

Standard Specification for Performance of Gasketed Mechanical Couplings for Use in Piping Applications

ABSTRACT

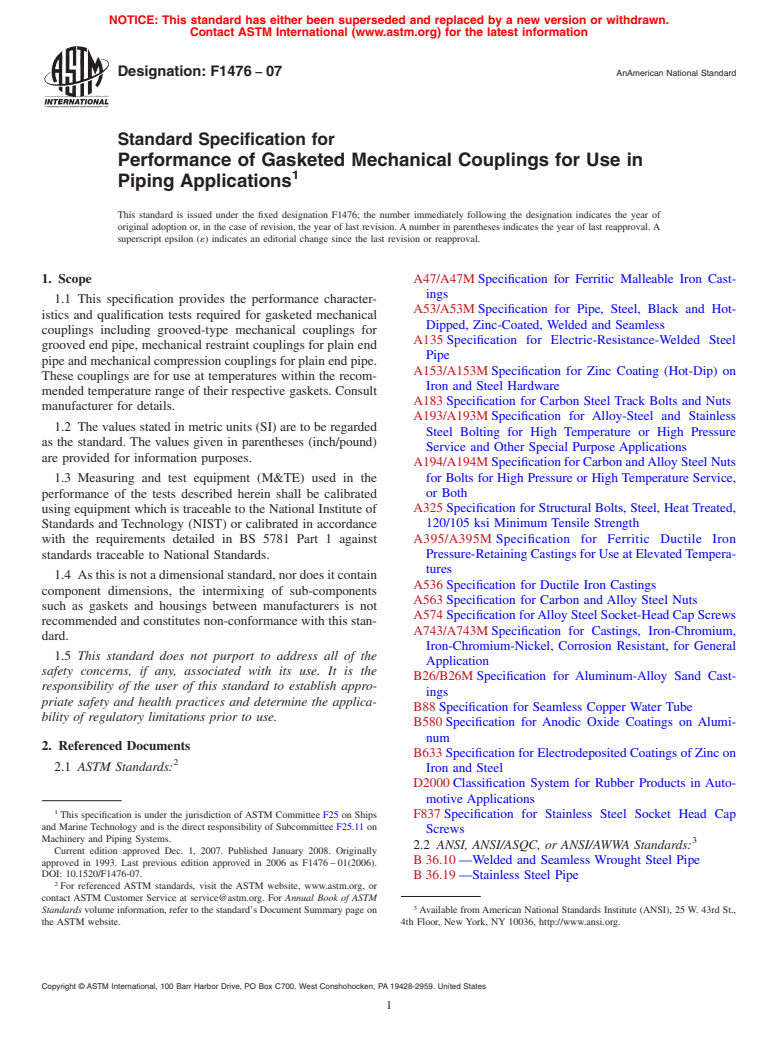

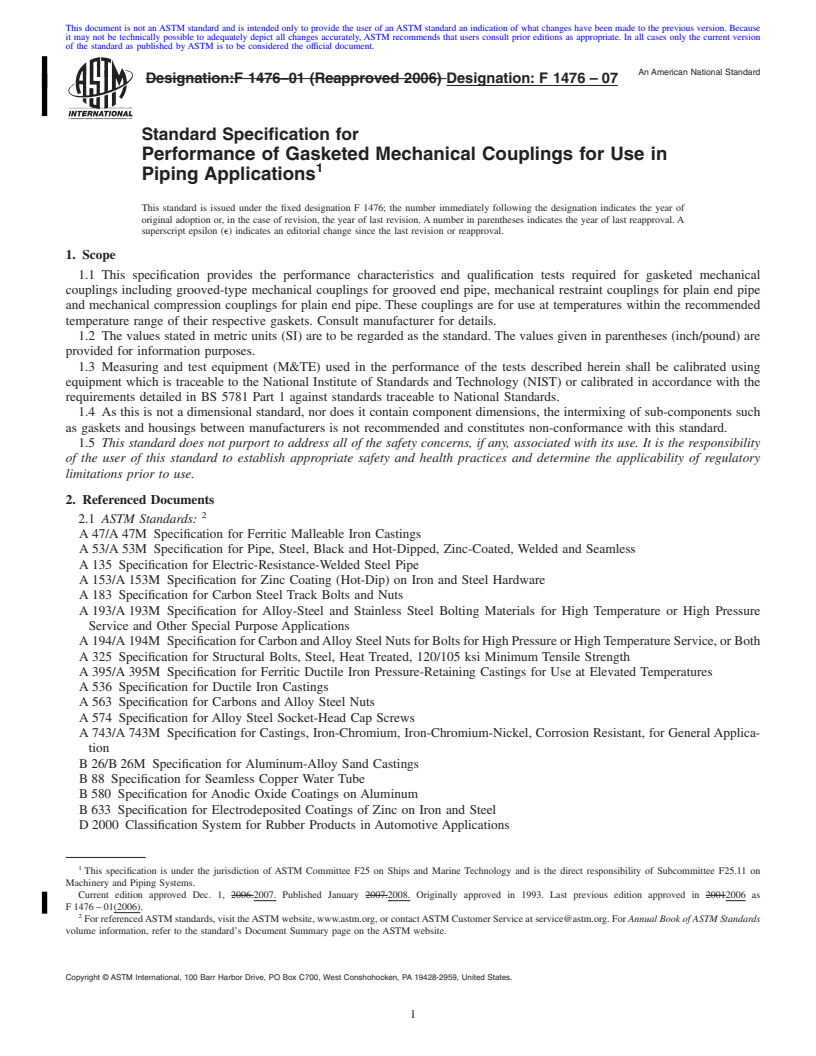

This specification provides the performance characteristics and qualification tests required for gasket mechanical couplings (GMCs) including grooved-type mechanical couplings for grooved end pipe, mechanical restraint couplings for plain end pipe and mechanical compression couplings for plain end pipe. These couplings are for use at temperatures within the recommended temperature range of their respective gaskets. The GMCs are classified into two types: Type I which are the groove mechanical couplings and Type II which are plain end mechanical couplings. Also, they can be classified into various grades based on successful completion of testing. They can also be grouped into three classes in accordance to joint characteristics: Class 1 which is rigid and restrained, Class 2 which is flexible and restrained, and Class 3 which is flexible and unrestrained. The housings of grooved GMCs shall be made from either ductile iron, aluminum alloy, or iron-chromium-nickel alloy. Bolts of these couplings shall be made from carbon steel and corrosion resistant materials. As for plain end GMCs, their housings or center sleeves shall be made from either ductile iron or steel materials. Their bolts shall be constructed with carbon steel and corrosion resistant materials. Standard qualification tests for GMC shall consist of the following: performance test, specimen examination, pneumatic proof test, vacuum test, hydrostatic proof test, flexibility test, hydrostatic burst test, rigidity test, bending moment proof test, and bending moment ultimate test.

SCOPE

1.1 This specification provides the performance characteristics and qualification tests required for gasketed mechanical couplings including grooved-type mechanical couplings for grooved end pipe, mechanical restraint couplings for plain end pipe and mechanical compression couplings for plain end pipe. These couplings are for use at temperatures within the recommended temperature range of their respective gaskets. Consult manufacturer for details.

1.2 The values stated in metric units (SI) are to be regarded as the standard. The values given in parentheses (inch/pound) are provided for information purposes.

1.3 Measuring and test equipment (M&TE) used in the performance of the tests described herein shall be calibrated using equipment which is traceable to the National Institute of Standards and Technology (NIST) or calibrated in accordance with the requirements detailed in BS 5781 Part 1 against standards traceable to National Standards.

1.4 As this is not a dimensional standard, nor does it contain component dimensions, the intermixing of sub-components such as gaskets and housings between manufacturers is not recommended and constitutes non-conformance with this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1476 −07 AnAmerican National Standard

Standard Specification for

Performance of Gasketed Mechanical Couplings for Use in

1

Piping Applications

This standard is issued under the fixed designation F1476; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A47/A47MSpecification for Ferritic Malleable Iron Cast-

ings

1.1 This specification provides the performance character-

A53/A53MSpecification for Pipe, Steel, Black and Hot-

istics and qualification tests required for gasketed mechanical

Dipped, Zinc-Coated, Welded and Seamless

couplings including grooved-type mechanical couplings for

A135Specification for Electric-Resistance-Welded Steel

grooved end pipe, mechanical restraint couplings for plain end

Pipe

pipeandmechanicalcompressioncouplingsforplainendpipe.

A153/A153MSpecification for Zinc Coating (Hot-Dip) on

These couplings are for use at temperatures within the recom-

Iron and Steel Hardware

mended temperature range of their respective gaskets. Consult

A183Specification for Carbon Steel Track Bolts and Nuts

manufacturer for details.

A193/A193MSpecification for Alloy-Steel and Stainless

1.2 The values stated in metric units (SI) are to be regarded

Steel Bolting for High Temperature or High Pressure

as the standard. The values given in parentheses (inch/pound)

Service and Other Special Purpose Applications

are provided for information purposes.

A194/A194MSpecificationforCarbonandAlloySteelNuts

for Bolts for High Pressure or High Temperature Service,

1.3 Measuring and test equipment (M&TE) used in the

performance of the tests described herein shall be calibrated or Both

A325Specification for Structural Bolts, Steel, Heat Treated,

using equipment which is traceable to the National Institute of

Standards and Technology (NIST) or calibrated in accordance 120/105 ksi Minimum Tensile Strength

A395/A395M Specification for Ferritic Ductile Iron

with the requirements detailed in BS 5781 Part 1 against

standards traceable to National Standards. Pressure-RetainingCastingsforUseatElevatedTempera-

tures

1.4 Asthisisnotadimensionalstandard,nordoesitcontain

A536Specification for Ductile Iron Castings

component dimensions, the intermixing of sub-components

A563Specification for Carbon and Alloy Steel Nuts

such as gaskets and housings between manufacturers is not

A574SpecificationforAlloySteelSocket-HeadCapScrews

recommended and constitutes non-conformance with this stan-

A743/A743MSpecification for Castings, Iron-Chromium,

dard.

Iron-Chromium-Nickel, Corrosion Resistant, for General

1.5 This standard does not purport to address all of the

Application

safety concerns, if any, associated with its use. It is the

B26/B26MSpecification for Aluminum-Alloy Sand Cast-

responsibility of the user of this standard to establish appro-

ings

priate safety and health practices and determine the applica-

B88Specification for Seamless Copper Water Tube

bility of regulatory limitations prior to use.

B580Specification for Anodic Oxide Coatings on Alumi-

num

2. Referenced Documents

B633SpecificationforElectrodepositedCoatingsofZincon

2

2.1 ASTM Standards:

Iron and Steel

D2000Classification System for Rubber Products in Auto-

motive Applications

1

This specification is under the jurisdiction ofASTM Committee F25 on Ships

F837Specification for Stainless Steel Socket Head Cap

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

Screws

Machinery and Piping Systems.

3

2.2 ANSI, ANSI/ASQC, or ANSI/AWWA Standards:

Current edition approved Dec. 1, 2007. Published January 2008. Originally

B36.10—Welded and Seamless Wrought Steel Pipe

approved in 1993. Last previous edition approved in 2006 as F1476–01(2006).

DOI: 10.1520/F1476-07.

B36.19—Stainless Steel Pipe

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1476−07

C151/A21.51—Ductile-Iron Pipe, Centrifugally Cast in fitting, forming a joint. Grooves conform to ANSI/AWWA

Metal Molds or Sand-Lined Molds, for Water or Other Standard C606–87 as applicable. Groove dimensions for tub-

Liquids ing and other sizes and types of pipes shall be as specified by

C606—Grooved and Shouldered Jo

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:F 1476–01 (Reapproved 2006) Designation: F 1476 – 07

Standard Specification for

Performance of Gasketed Mechanical Couplings for Use in

1

Piping Applications

This standard is issued under the fixed designation F 1476; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification provides the performance characteristics and qualification tests required for gasketed mechanical

couplings including grooved-type mechanical couplings for grooved end pipe, mechanical restraint couplings for plain end pipe

and mechanical compression couplings for plain end pipe. These couplings are for use at temperatures within the recommended

temperature range of their respective gaskets. Consult manufacturer for details.

1.2 The values stated in metric units (SI) are to be regarded as the standard. The values given in parentheses (inch/pound) are

provided for information purposes.

1.3 Measuring and test equipment (M&TE) used in the performance of the tests described herein shall be calibrated using

equipment which is traceable to the National Institute of Standards and Technology (NIST) or calibrated in accordance with the

requirements detailed in BS 5781 Part 1 against standards traceable to National Standards.

1.4 As this is not a dimensional standard, nor does it contain component dimensions, the intermixing of sub-components such

as gaskets and housings between manufacturers is not recommended and constitutes non-conformance with this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A47/A47M Specification for Ferritic Malleable Iron Castings

A53/A53M Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

A135 Specification for Electric-Resistance-Welded Steel Pipe

A153/A153M Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware

A183 Specification for Carbon Steel Track Bolts and Nuts

A193/A193M Specification for Alloy-Steel and Stainless Steel Bolting Materials for High Temperature or High Pressure

Service and Other Special Purpose Applications

A194/A194M SpecificationforCarbonandAlloySteelNutsforBoltsforHighPressureorHighTemperatureService,orBoth

A325 Specification for Structural Bolts, Steel, Heat Treated, 120/105 ksi Minimum Tensile Strength

A395/A395M Specification for Ferritic Ductile Iron Pressure-Retaining Castings for Use at Elevated Temperatures

A536 Specification for Ductile Iron Castings

A563 Specification for Carbons and Alloy Steel Nuts

A574 Specification for Alloy Steel Socket-Head Cap Screws

A743/A743M Specification for Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, for GeneralApplica-

tion

B26/B26M Specification for Aluminum-Alloy Sand Castings

B88 Specification for Seamless Copper Water Tube

B580 Specification for Anodic Oxide Coatings on Aluminum

B633 Specification for Electrodeposited Coatings of Zinc on Iron and Steel

D2000 Classification System for Rubber Products in Automotive Applications

1

This specification is under the jurisdiction of ASTM Committee F25 on Ships and Marine Technology and is the direct responsibility of Subcommittee F25.11 on

Machinery and Piping Systems.

Current edition approved Dec. 1, 2006.2007. Published January 2007.2008. Originally approved in 1993. Last previous edition approved in 20012006 as

F1476–01(2006).

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 1476 – 07

F837 Specification for Stainless Steel Socket Head Cap Screws

3

2.2 ANSI, ANSI/ASQC, or ANSI/AWWA Standards:

B36.10 —Welded and Seamless Wrought Steel Pipe

B36.19 —Stainless Steel Pipe

C151/A21.51 —Ductile-Iron Pipe, Centrifugally Cast in Metal Molds or Sand-Lined Molds, for Water or Other Liqui

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.