ASTM D1867-07

(Specification)Standard Specification for Copper-Clad Thermosetting Laminates for Printed Wiring

Standard Specification for Copper-Clad Thermosetting Laminates for Printed Wiring

ABSTRACT

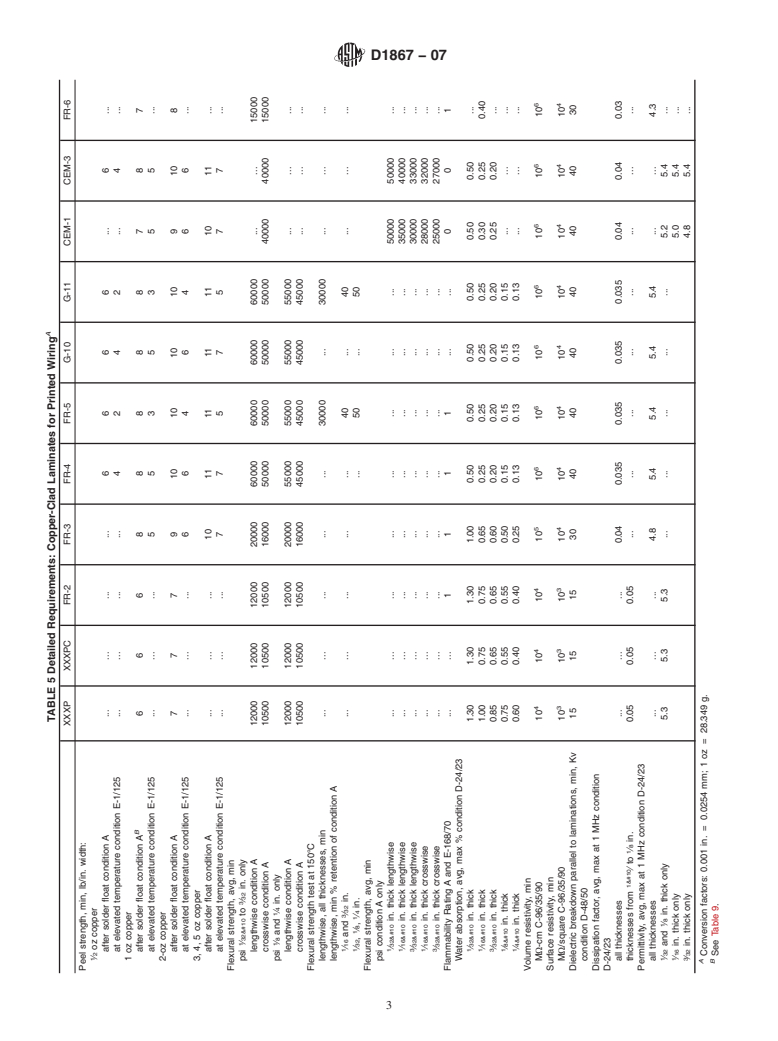

This specification covers twelve grades of thermosetting laminate with copper foil cladded to one or both surfaces. These combination forms are intended primarily for use in fabrication of printed (etched) wiring or circuit boards. The laminates shall meet the following requirements: peel strength after solder float and at elevated temperature conditions; lengthwise and crosswise flexural strengths; flammability rating; water absorption; volume resistivity; dielectric breakdown parallel to laminations; dissipation factor; and permittivity. Warp or twist, and blistering requirements shall also be tested for conformance.

SCOPE

1.1 This specification covers twelve grades of thermosetting laminate with copper foil bonded to one or both surfaces. These combination forms are intended primarily for use in fabrication of printed (etched) wiring or circuit boards.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1867 −07 AnAmerican National Standard

Standard Specification for

1

Copper-Clad Thermosetting Laminates for Printed Wiring

This standard is issued under the fixed designation D1867; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 4. Classification

1.1 This specification covers twelve grades of thermosetting

4.1 Base Laminate Grades—Where applicable, the dielec-

laminatewithcopperfoilbondedtooneorbothsurfaces.These

tric material forming the base of the copper-clad laminate of

combinationformsareintendedprimarilyforuseinfabrication

the types listed in Table 1 and Table 2 shall conform to the

of printed (etched) wiring or circuit boards.

property requirements of that specific grade shown in Specifi-

cation D709.

1.2 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are for

4.2 Copper Foil Surfaces—The surfaces shall be copper

information only.

foil,eitherrolledorelectrodeposited,havingaminimumpurity

1.3 This standard does not purport to address all of the

of 99.50 % (silver considered as equal to copper). The thick-

safety concerns, if any, associated with its use. It is the

ness tolerances of the copper foil shall conform to the

responsibility of the user of this standard to establish appro-

requirements of Table 3.

priate safety and health practices and determine the applica-

4.3 Thickness Tolerance Classes—Copper-clad laminates

bility of regulatory limitations prior to use.

are available in two classes of thickness tolerance. Class I

2. Referenced Documents represents those tolerances of standard manufacturing practice.

2 Class II represents a closer tolerance product than Class I.Any

2.1 ASTM Standards:

specified class shall conform to the requirements shown in

D709 Specification for Laminated Thermosetting Materials

Table 4.

D1711 Terminology Relating to Electrical Insulation

4.3.1 For sheets of laminate equal to or greater than 18 by

D3636 Practice for Sampling and Judging Quality of Solid

2

18 in. (approximately 2.3 ft ) at least 90 % of all thickness test

Electrical Insulating Materials

measurements made upon any sheet of laminate shall be within

D5109 Test Methods for Copper-Clad Thermosetting Lami-

the limits specified in Table 4. For metric size sheets this 90 %

nates for Printed Wiring Boards

requirement shall apply to sheet sizes of 0.5 by 0.5 m or 0.25

2.2 Other Standards:

2

m area.

MIL-P-13949 Plastic Sheet, Laminated, Metal Clad (for

3

Printed Wiring Boards) 4.3.2 The deviation of any single thickness test measure-

4

NEMA Publication Number LI-1 ment value (see Practice D3636) from the nominal overall

thickness listed in Table 4 shall not exceed 125 % of the

3. Terminology

tolerance listed in Table 4.

3.1 For definitions of terms used in this standard, refer to

4.3.3 Any overall laminate thickness not listed in Table 4

Terminology D1711.

shall meet the tolerance requirements of the next highest

nominal thickness listed in Table 4.

4.3.4 For cut panels (for example, laminate sheets cut to

1

This specification is under the jurisdiction of the ASTM Committee D09 on

2 2

area less than 2.3 ft or less than 0.25 m ) at least 98 % of all

Electrical and Electronic Insulating Materials and is the direct responsibility of

Subcommittee D09.07 on Flexible and Rigid Insulating Materials. thickness test measurements shall be within the specified

Current edition approved May 1, 2007. Published June 2007. Originally

overall laminate thickness tolerance values of Table 4.

approved in 1961. Last previous edition approved in 2001 as D1867 – 01. DOI:

10.1520/D1867-07.

2

5. Ordering Information

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1 Orders for copper-clad laminates shall specify the grade

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

of laminate base (see 4.1); the type of copper foil (either rolled

3

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

or electrodeposited); the nominal weight of the copper foil (see

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

4

4.2); one- or two-side cladding; nominal overall laminate

Available from National Electrical Manufacturers Association, 2101 L St.,

N.W., Washington, DC 20037. thickness; and the thickness tolerance class (see 4.3).

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.