ASTM E751/E751M-17(2022)

(Practice)Standard Practice for Acoustic Emission Monitoring During Resistance Spot-Welding

Standard Practice for Acoustic Emission Monitoring During Resistance Spot-Welding

SIGNIFICANCE AND USE

5.1 The AE produced during the production of a spot-weld can be related to weld quality parameters such as the strength and size of the nugget, the amount of expulsion, and the amount of cracking. Therefore, in-process AE monitoring can be used both as an examination method, and as a means for providing feedback control.

SCOPE

1.1 This practice describes procedures for the measurement, processing, and interpretation of the acoustic emission (AE) response associated with selected stages of the resistance spot-welding process.

1.2 This practice also provides recommendations for feedback control by utilizing the measured AE response signals during the spot-welding process.

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E751/E751M − 17 (Reapproved 2022)

Standard Practice for

Acoustic Emission Monitoring During Resistance Spot-

Welding

This standard is issued under the fixed designation E751/E751M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ASNT Standards:

SNT-TC-1A Recommended Practice for Nondestructive

1.1 This practice describes procedures for the measurement,

Testing Personnel Qualification and Certification

processing, and interpretation of the acoustic emission (AE)

ANSI/ASNT CP-189 Standard for Qualification and Certifi-

response associated with selected stages of the resistance

cation of Nondestructive Testing Personnel

spot-welding process.

2.3 AIA Standard:

1.2 This practice also provides recommendations for feed-

NAS-410 Certification and Qualification of Nondestructive

back control by utilizing the measured AE response signals

Personnel (Quality Assurance Committee)

during the spot-welding process. 5

2.4 ISO Standard:

ISO 9712 Non-Destructive Testing: Qualification and Certi-

1.3 Units—The values stated in either SI units or inch-

pound units are to be regarded separately as standard. The fication of NDT Personnel

values stated in each system may not be exact equivalents;

3. Terminology

therefore, each system shall be used independently of the other.

3.1 Definitions—For definitions of terms relating to acoustic

Combining values from the two systems may result in non-

emission testing, see Section B of Terminology E1316.

conformance with the standard.

1.4 This standard does not purport to address all of the

4. Summary of Practice

safety concerns, if any, associated with its use. It is the

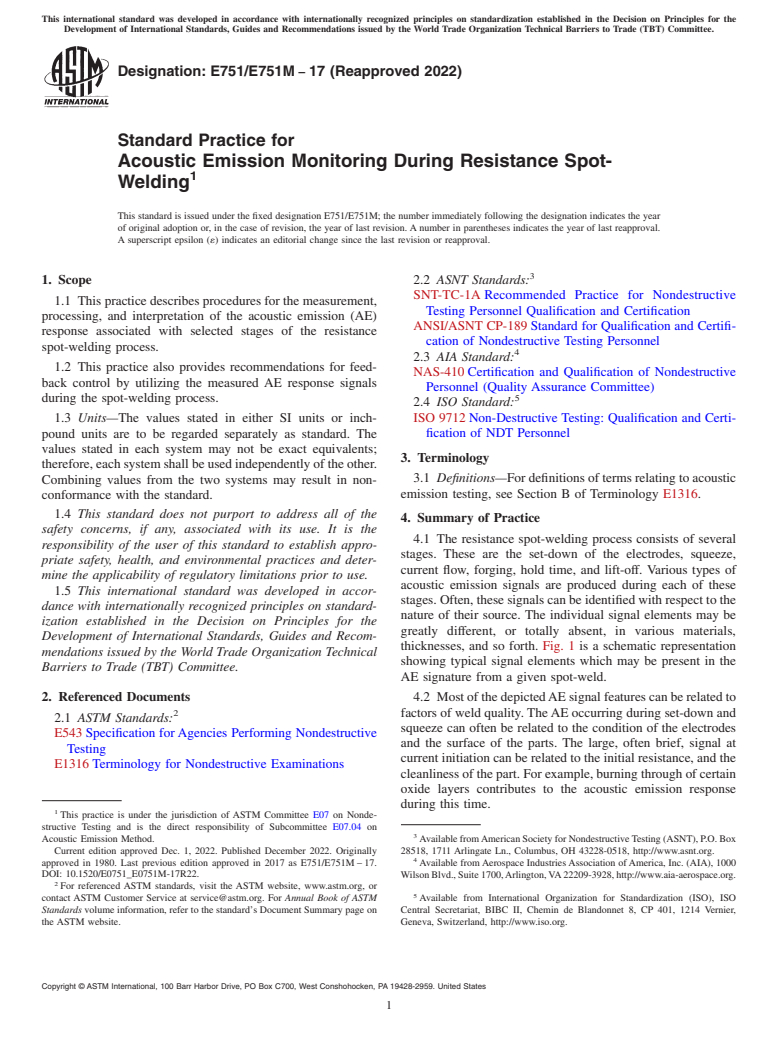

4.1 The resistance spot-welding process consists of several

responsibility of the user of this standard to establish appro-

stages. These are the set-down of the electrodes, squeeze,

priate safety, health, and environmental practices and deter-

current flow, forging, hold time, and lift-off. Various types of

mine the applicability of regulatory limitations prior to use.

acoustic emission signals are produced during each of these

1.5 This international standard was developed in accor-

stages. Often, these signals can be identified with respect to the

dance with internationally recognized principles on standard-

nature of their source. The individual signal elements may be

ization established in the Decision on Principles for the

greatly different, or totally absent, in various materials,

Development of International Standards, Guides and Recom-

thicknesses, and so forth. Fig. 1 is a schematic representation

mendations issued by the World Trade Organization Technical

showing typical signal elements which may be present in the

Barriers to Trade (TBT) Committee.

AE signature from a given spot-weld.

2. Referenced Documents 4.2 Most of the depictedAE signal features can be related to

factors of weld quality. TheAE occurring during set-down and

2.1 ASTM Standards:

squeeze can often be related to the condition of the electrodes

E543 Specification for Agencies Performing Nondestructive

and the surface of the parts. The large, often brief, signal at

Testing

current initiation can be related to the initial resistance, and the

E1316 Terminology for Nondestructive Examinations

cleanliness of the part. For example, burning through of certain

oxide layers contributes to the acoustic emission response

during this time.

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.04 on

Acoustic Emission Method. AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

Current edition approved Dec. 1, 2022. Published December 2022. Originally 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

approved in 1980. Last previous edition approved in 2017 as E751/E751M – 17. Available fromAerospace IndustriesAssociation ofAmerica, Inc. (AIA), 1000

DOI: 10.1520/E0751_E0751M-17R22. WilsonBlvd.,Suite1700,Arlington,VA22209-3928,http://www.aia-aerospace.org.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from International Organization for Standardization (ISO), ISO

Standards volume information, refer to the standard’s Document Summary page on Central Secretariat, BIBC II, Chemin de Blandonnet 8, CP 401, 1214 Vernier,

the ASTM website. Geneva, Switzerland, http://www.iso.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E751/E751M − 17 (2022)

FIG. 1 Typical AE Response Signals During Resistance Spot Welding

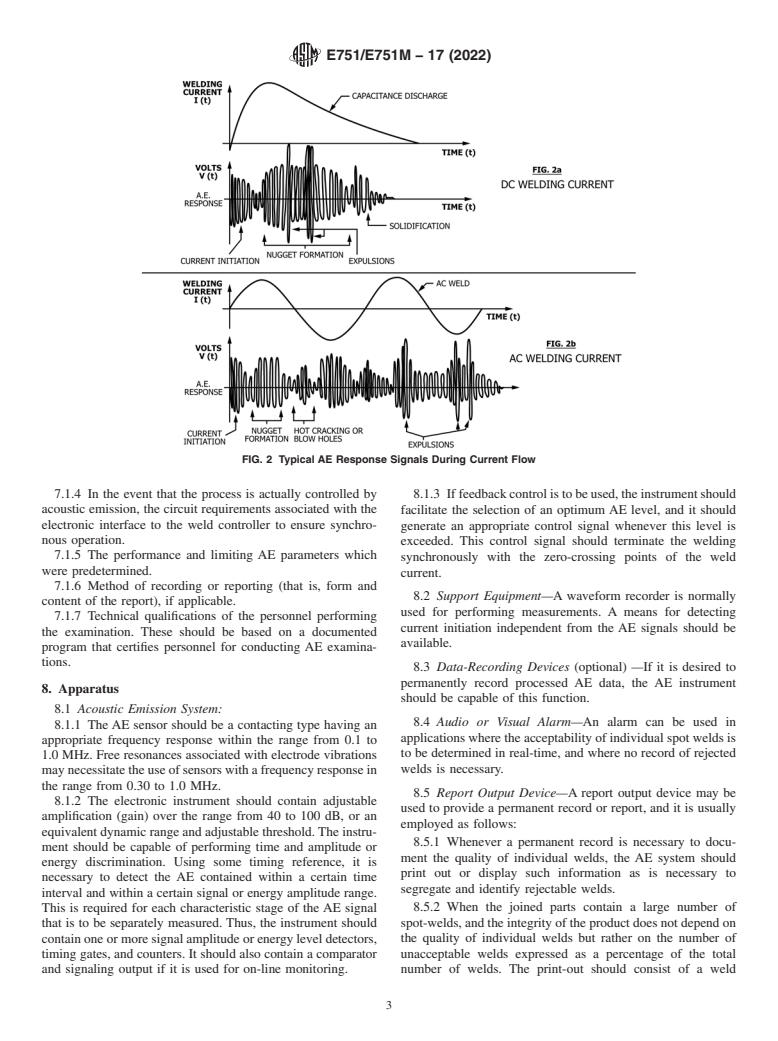

4.2.1 During current flow, plastic deformation, nugget 6.2 Personnel Qualification:

expansion, friction, melting, and expulsions produce AE sig-

6.2.1 If specified in the contractual agreement, personnel

nals. The signals caused by expulsion (spitting or flashing, or performing examinations to this standard shall be qualified in

both) generally have large amplitudes and can be distinguished

accordance with a nationally or internationally recognized

from the rest of the acoustic emission associated with nugget NDT personnel qualification practice or standard such as

formation. Fig. 2 shows typical AE response signals during

ANSI/ASNT CP-189, SNT-TC-1A, NAS-410, ISO 9712, or a

current flow for both d-c and a-c welding. similar document and certified by the employer or certifying

4.2.2 Following termination of the welding current, some

agency, as applicable. The practice or standard used and its

materials exhibit appreciable AE during solidification which applicable revision shall be identified in the contractual agree-

can be related to nugget size and inclusions. As the nugget

ment between the using parties.

cools during the hold period, AE can result from solid-solid

6.3 Qualification of Nondestructive Agencies—If specified

phase transformations and cracking.

in the contractual agreement, NDT agencies shall be qualified

4.2.3 During the lift-off stage, separation of the electrode

and evaluated as described in Practice E543. The applicable

from the part produces signals that can be related to the

edition of Practice E543 shall be specified in the contractual

condition of the electrode as well as the cosmetic condition of

agreement.

the weld.

6.4 Procedures and Techniques—The procedures and tech-

4.3 Using time, and amplitude or energy discrimination, or

niques to be utilized shall be as specified in the contractual

both, the AE response corresponding to each stage can be

agreement.

separately detected and analyzed. Although the AE associated

with each stage of the spot-welding process can be relevant to

7. Ordering Information

weld quality, this practice only gives detailed consideration to

7.1 If the spot-weld monitoring or process control methods

the AE generated by nugget formation and expansion,

described in this practice are performed as a service, the

expulsion, and cracking.

following items should be addressed in the purchase

5. Significance and Use

specification, and are subject to agreement between the pur-

chaser and the supplier:

5.1 The AE produced during the production of a spot-weld

7.1.1 Description of the welded parts in terms of geometry,

can be related to weld quality parameters such as the strength

dimensions, number and position of welds, and materials.

and size of the nugget, the amount of expulsion, and the

amount of cracking. Therefore, in-process AE monitoring can 7.1.2 Description of the welding machine, type and dimen-

sions of the electrodes, type of weld controller, welding

be used both as an examination method, and as a means for

providing feedback control. schedule, and distance between the welding head and the

controller.

6. Basis of Application

7.1.3 Location and mounting method for the acoustic emis-

6.1 The following items are subject to contractual agree- sion sensors, and design of the mounting fixture, as appropri-

ment between the parties using or referencing this standard. ate.

E751/E751M − 17 (2022)

FIG. 2 Typical AE Response Signals During Current Flow

7.1.4 In the event that the process is actually controlled by 8.1.3 Iffeedbackcontrolistobeused,theinstrumentshould

acoustic emission, the circuit requirements associated with the facilitate the selection of an optimum AE level, and it should

electronic interface to the weld controller to ensure synchro- generate an appropriate control signal whenever this level is

nous operation.

exceeded. This control signal should terminate the welding

7.1.5 The performance and limiting AE parameters which

synchronously with the zero-crossing points of the weld

were predetermined.

current.

7.1.6 Method of recording or reporting (that is, form and

8.2 Support Equipment—A waveform recorder is normally

content of the report), if applicable.

used for performing measurements. A means for detecting

7.1.7 Technical qualifications of the personnel performing

current initiation independent from the AE signals should be

the examination. These should be based on a documented

available.

program that certifies personnel for conducting AE examina-

tions.

8.3 Data-Recording Devices (optional) —If it is desired to

permanently record processed AE data, the AE instrument

8. Apparatus

should be capable of this function.

8.1 Acoustic Emission System:

8.4 Audio or Visual Alarm—An alarm can be used in

8.1.1 The AE sensor should be a contacting type having an

applications where the acceptability of individual spot welds is

appropriate frequency response within the range from 0.1 to

to be determined in real-time, and where no record of rejected

1.0 MHz. Free resonances associated with electrode vibrations

welds is necessary.

maynecessitatetheuseofsensorswithafrequencyresponsein

the range from 0.30 to 1.0 MHz.

8.5 Report Output Device—A report output device may be

8.1.2 The electronic instrument should contain adjustable

used to provide a permanent record or report, and it is usually

amplification (gain) over the range from 40 to 100 dB, or an

employed as follows:

equivalent dynamic range and adjustable threshold.The instru-

8.5.1 Whenever a permanent record is necessary to docu-

ment should be capable of performing time and amplitude or

ment the quality of individual welds, the AE system should

energy discrimination. Using some timing reference, it is

print out or display such information as is necessary to

necessary to detect the AE contained within a certain time

segregate and identify rejectable welds.

interval and within a certain signal or energy amplitude range.

8.5.2 When the joined parts contain a large number of

This is required for each characteristic stage of the AE signal

spot-welds, and the integrity of the product does not depend on

that is to be separately measured. Thus, the instrument should

contain one or more signal amplitude or energy level detectors, the quality of individual welds but rather on the number of

unacceptable welds expressed as a percentage of the total

timing gates, and counters. It should also contain a comparator

and signaling output if it is used for on-line monitoring. number of welds. The print-out should consist of a weld

E751/E751M − 17 (2022)

sequence number and a running percentage of unacceptable considerations associated with each of the various examination

welds when the individual spot-welds are identifiable by parameters are discussed in 10.1 – 10.4.

sequence number.

9.2.2 Repeated Applications—If AE monitoring was previ-

8.5.3 If weld identification is not possible, then the welding

ouslyappliedtoaparticularcontrollingormonitoringproblem,

apparatus should be equipped with an automatic marking the purpose of the preliminary measurement is to reestablish

attachment. With the markings and the records, the acceptabil-

the known and recorded original test conditions. The heat and

ity of the welded part can be based on the percentage of

the weld time settings on the weld controller, and the gain,

unacceptable welds and their location distribution.

threshold level, timing, and other settings on the AE instru-

mentation should be made identical to those on record. A few

9. Procedure

sample welds should be made to verify that the general

appearance of the total AE signal exhibits the expected

9.1 Sensor and Preamplifier Attachment—The sensor

characteristic features, and that the average count falls within

should be mounted to the lower (grounded) electrode or

the range of past measurements.

electrode holder. If the measurements are to be made only as a

periodic sampling of weld quality, a liquid couplant may be

10. Weld Quality Parameters That Produce AE

used provided that it is periodically replenished and standard-

ization of the system response is maintained. For sustained

10.1 AE During Nugget Formation:

monitoring, such as on-lineAE examination or control of each

10.1.1 When the material in the welding zone is heated, the

nugget, the sensor should be permanently mounted using an

pressureappliedbythetopelectrodewillplasticallydeformthe

epoxy adhesive or a similar material. A preamplifier is usually

material and AE will be generated. The amplitude of the AE

positioned near the sensor. However, when the instrumentation

signals associated with this process is affected by both elec-

is located less than1m[3ft] from the sensor, the gain

trode pressure and the “cleanliness” of the parts. These AE

otherwise supplied by the preamplifier may be incorporated

signals may be gated out since they provide no useful infor-

into the main amplifier of the instrument.

mation relative to the quality of the weld.

10.1.2 Further heating results in melting within the welding

9.2 Preliminary Measurements—The AE signal from a

single spot-weld should be displayed on a waveform recorder. zone and growth of the nugget. Nugget formation and expan-

sionproduceAEsignalsthatcanbecorrelatedwiththestrength

A wire coil or Hall effect sensor positioned near an electrode

can be used as a current sensor, thus providing a timing of the weld.

reference and trigger signal for viewing and measuring theAE 10.1.3 As soon as the welding current starts to decrease, the

signal. This reference signal can be also obtained through an

nugget begins to solidify and residual str

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.