ASTM D7658-17(2021)

(Test Method)Standard Test Method for Direct Microscopy of Fungal Structures from Tape

Standard Test Method for Direct Microscopy of Fungal Structures from Tape

SIGNIFICANCE AND USE

5.1 The significance of this test method is to standardize the analysis of the detection of removable fungal structures lifted from a surface with tape to improve consistency between laboratories and analysts.

5.2 This test method is intended to ensure consistent data to the end user.

5.3 Fungal structures are identified and semi-quantified regardless of whether they would or would not grow in culture.

5.4 It must be emphasized that the detector in this test method is the analyst, and therefore results are subjective, depending on the experience, training, qualification, optical acuity, and mental fatigue of the analyst.

5.5 This test method can be used to assess the presence and characteristics of fungal material on a surface.

SCOPE

1.1 This test method uses optical microscopy for the detection, semi-quantification, and identification of fungal structures in tape lift preparations.

1.2 This test method describes the preparation techniques for tape-lift matrices, the procedure for confirming the presence of fungal structures, and the reporting of observed fungal structures

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7658 − 17 (Reapproved 2021)

Standard Test Method for

Direct Microscopy of Fungal Structures from Tape

This standard is issued under the fixed designation D7658; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 fungal structure (sing.), n—a collective term for a

fragment-orgroupsoffragmentsfromfungi,includingbutnot

1.1 This test method uses optical microscopy for the

limited to conidia, conidiophores, hyphae, and spores.

detection, semi-quantification, and identification of fungal

3.2.2 magnification/resolution combination 1, n—

structures in tape lift preparations.

~100–400× total magnification and a point to point resolution

1.2 This test method describes the preparation techniques

of 0.7 µm or better.

for tape-lift matrices, the procedure for confirming the pres-

3.2.3 magnification/resolution combination 2, n— ~400× or

ence of fungal structures, and the reporting of observed fungal

greatertotalmagnificationandapointtopointresolutionof0.5

structures

µm or better.

1.3 The values stated in SI units are to be regarded as

3.2.4 mounting medium, n—a liquid, for example, lactic

standard. No other units of measurement are included in this

acid or prepared stain, used to immerse the sample particulate

standard.

matter and to attach a cover slip to the sample.

1.4 This standard does not purport to address all of the

3.2.5 tape lift sample, n—material lifted from a surface

safety concerns, if any, associated with its use. It is the

using clear, transparent, single sided, adhesive collection

responsibility of the user of this standard to establish appro-

medium, typically tape or commercially available prepared

priate safety, health, and environmental practices and deter-

slides.

mine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accor-

4. Summary of Test Method

dance with internationally recognized principles on standard-

4.1 A tape lift sample is prepared.

ization established in the Decision on Principles for the

4.2 The prepared sample is examined on an optical micro-

Development of International Standards, Guides and Recom-

scope for the presence, type and semi-quantification of fungal

mendations issued by the World Trade Organization Technical

structures and reported.

Barriers to Trade (TBT) Committee.

5. Significance and Use

2. Referenced Documents

2 5.1 Thesignificanceofthistestmethodistostandardizethe

2.1 ASTM Standards:

analysis of the detection of removable fungal structures lifted

D1193Specification for Reagent Water

from a surface with tape to improve consistency between

D1356Terminology Relating to Sampling and Analysis of

laboratories and analysts.

Atmospheres

5.2 This test method is intended to ensure consistent data to

3. Terminology

the end user.

3.1 Definitions—For definitions of other terms used in this

5.3 Fungal structures are identified and semi-quantified

test method, refer to Terminology D1356.

regardlessofwhethertheywouldorwouldnotgrowinculture.

3.2 Definitions of Terms Specific to This Standard:

5.4 It must be emphasized that the detector in this test

method is the analyst, and therefore results are subjective,

depending on the experience, training, qualification, optical

This test method is under the jurisdiction of ASTM Committee D22 on Air

Quality and is the direct responsibility of Subcommittee D22.08 on Assessment,

acuity, and mental fatigue of the analyst.

Sampling, and Analysis of Microorganisms.

5.5 This test method can be used to assess the presence and

Current edition approved Sept. 1, 2021. Published September 2021. Originally

approved in 2017. Last previous edition approved in 2017 as D7658 – 17. DOI:

characteristics of fungal material on a surface.

10.1520/D7658-17R21.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 6. Interferences

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1 Look-alike Non-fungal Particles—Certain types of par-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ticles of non-fungal origin may resemble fungal structures.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7658 − 17 (2021)

These particles and artifacts may include air or plant resin, thicknessaccordingtotherecommendationsofthemicroscope

bubbles, starch, talc or cosmetic particles, or combustion objective lens manufacturer.

products. Non-fungal reference slides (mounted similarly to

8.3 Microscope slides,glassslidestobeusedwhensamples

tape-liftsamples)shouldbeexaminedbylaboratoryanalyststo

are not taken on commercially available lift-samples.

know how to differentiate such particles. Examination of

8.4 Disinfectant, for cleaning of forceps or scalpel.

suspectparticlesusingopticalconditionsotherthanbrightfield

microscopy (for example, polarized light microscopy, phase

9. Hazards

contrast microscopy, differential interference contrast) may be

9.1 Components of re-hydrating liquids and stains may be

helpful whenever significant concentrations of look-alike par-

corrosive or hazardous. Consult the appropriate Safety Data

ticles are present. In some cases dust and debris can mimic the

Sheet for any reagents used.

morphology of particles of interest.

9.2 Sharpinstrumentsusedinsamplepreparationmaycause

6.2 Particle Overloading—High levels of non-fungal back-

injuryifnothandledwithcare.Thesesampleinstrumentsmay,

ground particulate may obscure or cover fungal structures.

at times, be contaminated with biological material capable of

6.3 Staining—Fungal structures of different fungal species

introducing organisms to the user.

absorb stains at different rates, under or over-staining makes

9.3 Samples shall be handled using good laboratory tech-

identification difficult. The problem can be minimized with

nique to minimize exposure.

careful control of stain concentrations.

10. Preparation of Apparatus

NOTE 1—Staining, while optional, may help the analyst differentiate

fungal structures from debris. Without staining, clear spores (especially

10.1 Microscope Alignment/Adjustments/Lens Cleaning—

small ones) may exhibit negative bias because the analyst has insufficient

Follow the manufacturer’s instructions.

contrast to detect them while scanning.

11. Calibration and Standardization

7. Apparatus

11.1 Graduation Spacing for Ocular Reticule:

7.1 Microscope or magnification system, having a precision

11.1.1 Measuring Gradations on the Ocular Reticule—For

x-ymechanicalstage.Themicroscopeormagnificationsystem

each magnification/resolution combination, verify the µm per

usedforanalysisshallbecapableofatleasttwomagnification/

graduation, using a stage micrometer, at the magnification(s)

resolution combinations as follows: magnification/resolution

used for counting at least once per year, and after any service

combination 1 shall be ~100–400× total magnification and a

or repair to the microscope. The graduations are used to

point to point resolution of 0.7 µm or better; magnification/

measure the size of spores as an aid to identification.

resolution combination 2 shall be ~400× or greater total

11.1.2 Resolution Check—Check the resolution of

magnification and a point to point resolution of 0.5 µm or

magnification/resolutioncombinations1and2atleastannually

better.Acceptableresolutionsforcombinations1and2shallbe

and after servicing, as in accordance with the manufacturer’s

checked using a resolution check slide.

instructions for the resolution check slide used.

NOTE 2—It is recommended that at least one microscope or magnifi-

cationsystembeavailablethatiscapableofmagnificationof~1000×total 12. Procedure

magnification and a point to point resolution of 0.3 µm or better.

12.1 Preparation of Tape Lift Samples:

7.2 Syringe or dropper, for dispensing liquid during sample

12.1.1 If the tape lift was not submitted on clear tape or

preparation.

prepared adhesive slide, then the sample may not be analyzed

using this test method.

7.3 Stage micrometer, traceable to the National Institute of

12.1.2 Remove the tape lift from its container.

Standards and Technology (NIST) or equivalent international

12.1.3 Mark each slide with a unique designation.

standard.

12.1.4 Mount sample in one of these three ways:

7.4 Forceps, for manipulating adhesive tape, cleaned to

12.1.4.1 For samples submitted affixed to a microscope

prevent cross contamination.

slide,gentlyliftoneendofthetapefromtheslidewithforceps

and place a drop of mounting medium under the sample area.

7.5 Scalpel, or other cutting tool, if needed for cutting tape,

Additional manipulation of the sample may be necessary to

cleaned to prevent cross contamination.

attain uniform contact with the glass slide. Return the lifted

portion of the tape to the slide taking care to minimize the

8. Reagents and Materials

amount of bubbles.

8.1 Mounting medium (with or without stain), for re-

12.1.4.2 For samples submitted on a prepared adhesive

hydrating spores, optimal resolution, and securing the cover

slide, place a drop of mounting medium to the center of the

slip to the sample. For example, lactic acid, lacto-cotton blue

sample.Acoverslipisappliedatsuchananglethatbubblesare

stain,lacto-phenol-cottonbluestain,lacto-fuchsinestain,glyc-

minimized.

erin jelly (see Appendix X2 for examples of stain prepara-

12.1.4.3 For all other submitted samples, cut a representa-

tions).

tive portion of a tape lift with scalpel and mount sample-side

8.2 Microscope cover slips, large enough to cover the tape up on a microscope slide with forceps.Anchor on each side if

preparation. For optimum performance, choose a cover slip needed.Adropofmountingmediumisappliedtothecenterof

D7658 − 17 (2021)

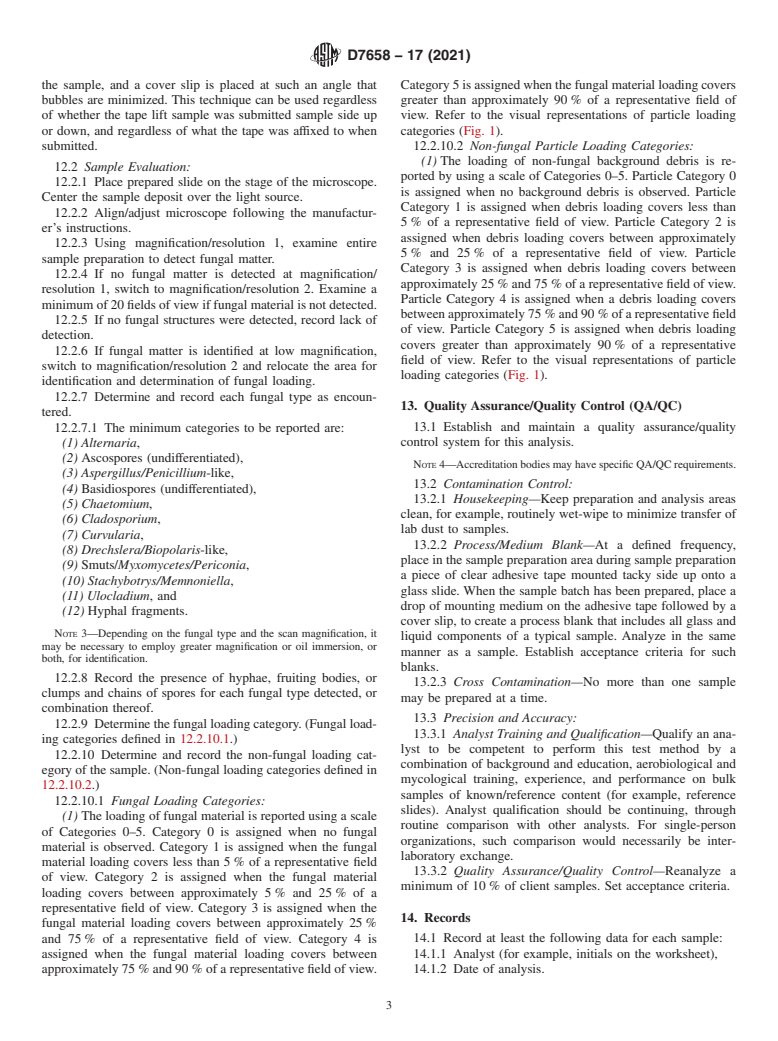

the sample, and a cover slip is placed at such an angle that Category5isassignedwhenthefungalmaterialloadingcovers

bubbles are minimized. This technique can be used regardless greater than approximately 90% of a representative field of

of whether the tape lift sample was submitted sample side up view. Refer to the visual representations of particle loading

or down, and regardless of what the tape was affixed to when categories (Fig. 1).

submitted. 12.2.10.2 Non-fungal Particle Loading Categories:

(1)The loading of non-fungal background debris is re-

12.2 Sample Evaluation:

ported by using a scale of Categories 0–5. Particle Category 0

12.2.1 Place prepared slide on the stage of the microscope.

is assigned when no background debris is observed. Particle

Center the sample deposit over the light source.

Category 1 is assigned when debris loading covers less than

12.2.2 Align/adjust microscope following the manufactur-

5% of a representative field of view. Particle Category 2 is

er’s instructions.

assigned when debris loading covers between approximately

12.2.3 Using magnification/resolution 1, examine entire

5% and 25% of a representative field of view. Particle

sample preparation to detect fungal matter.

Category 3 is assigned when debris loading covers between

12.2.4 If no fungal matter is detected at magnification/

approximately25%and75%ofarepresentativefieldofview.

resolution 1, switch to magnification/resolution 2. Examine a

Particle Category 4 is assigned when a debris loading covers

minimumof20fieldsofviewiffungalmaterialisnotdetected.

betweenapproximately75%and90%ofarepresentativefield

12.2.5 If no fungal structures were detected, record lack of

of view. Particle Category 5 is assigned when debris loading

detection.

covers greater than approximately 90% of a representative

12.2.6 If fungal matter is identified at low magnification,

field of view. Refer to the visual representations of particle

switch to magnification/resolution 2 and relocate the area for

loading categories (Fig. 1).

identification and determination of fungal loading.

12.2.7 Determine and record each fungal type as encoun-

13. Quality Assurance/Quality Control (QA/QC)

tered.

13.1 Establish and maintain a quality assurance/quality

12.2.7.1 The minimum categories to be reported are:

(1) Alternaria, control system for this analysis.

(2)Ascospores (undifferentiated),

NOTE4—AccreditationbodiesmayhavespecificQA/QCrequirements.

(3) Aspergillus/Penicillium-like,

13.2 Contamination Control:

(4)Basidiospores (undifferentiated),

13.2.1 Housekeeping—Keep preparation and analysis areas

(5) Chaetomium,

clean, for example, routinely wet-wipe to minimize transfer of

(6) Cladosporium,

lab dust to samples.

(7) Curvularia,

13.2.2 Process/Medium Blank—At a defined frequency,

(8) Drechslera/Biopolaris-like,

placeinthesamplepreparationareaduringsamplepreparation

(9)Smuts/Myxomycetes/Periconia,

a piece of clear adhesive tape mounted tacky side up onto a

(10) Stachybotrys/Memnoniella,

glass slide. When the sample batch has been prepared, place a

(11) Ulocladium, and

drop of mounting medium on the adhesive tape followed by a

(12)Hyphal fragments.

cover slip, to create a process blank that includes all glass and

NOTE 3—Depending on the fungal type and the scan magnification, it

liquid components of a typical sample. Analyze in the same

may be necessary to employ greater magnification or oil immersion, or

manner as a sample. Establish acceptance criteria for such

both, for identification.

blanks.

12.2.8 Record the presence of hyphae, fruiting bodies, or

13.2.3 Cross Contamination—No more than one sample

clumps and chains of spores for each fungal type detected, or

may be prepared at a time.

combination thereof.

13.3 Precision and Accuracy:

12.2.9 Determinethefungalloadingcategory.(Fungalload-

13.3.1 Analyst Training and Qualification—Qualify an ana-

ing categories defined in 12.2.10.1.)

lyst to be competent to perform this test method by a

12.2.10 Determine and record the non-fungal loading cat-

combination of background and education, aerobiological and

egoryofthesample.(Non-fungalloadingcategoriesdefinedin

mycological training, experience, and performance on bulk

12.2.10.2.)

samples of known/reference content (for example, reference

12.2.10.1 Fungal Loading Categories:

slides). Analyst qualification should be continuing, through

(1)The loading of fungal material is reported using a scale

routine comparison with other analysts. For single-person

of Categories 0–5. Category 0 is assigned when no fungal

organizations, such comparison would necessarily be inter-

material is observed. Category 1 is assig

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.