ASTM D6988-03

(Guide)Standard Guide for Determination of Thickness of Plastic Film Test Specimens

Standard Guide for Determination of Thickness of Plastic Film Test Specimens

SCOPE

1.1 This guide covers the determination of the thickness of plastic films where the thickness is used directly in determining the results of tests for various properties. Use this practice except as otherwise required in material specifications or in applicable test standards.

Note 1—Films are defined as having thicknesses 0.250 mm [ 0.010 in.].

Note 2—Alternative methods are acceptable if they meet the requirements of measurement precision as noted in this guide.

Note 3—This guide is not intended to address the sampling techniques or the measurement of film thickness for the commercial classification of commercial products or for quality control purposes.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

Note 4—ISO 4593 is similar but differs in technical content and scope.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6988–03

Standard Guide for

Determination of Thickness of Plastic Film Test Specimens

This standard is issued under the fixed designation D 6988; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This guide covers the determination of the thickness of 3.1 Definitions—See Terminologies D 883 and D 4805, and

plasticfilmswherethethicknessisuseddirectlyindetermining ISO 472 for definitions pertinent to this guide.

the results of tests for various properties. Use this practice 3.2 Definitions of Terms Specific to This Standard:

except as otherwise required in material specifications or in 3.2.1 absolute uncertainty (of a measurement), n—the

applicable test standards. smallest division that can be read directly on the instrument

used for measurement.

NOTE 1—Films are defined as having thicknesses # 0.250 mm [#

3.2.2 calibration, n—the set of operations that establishes,

0.010 in.].

under specified conditions, the relationship between values

NOTE 2—Alternative methods are acceptable if they meet the require-

measured or indicated by an instrument or system, and the

ments of measurement precision as noted in this guide.

NOTE 3—This guide is not intended to address the sampling techniques

corresponding reference standard or known values derived

or the measurement of film thickness for the commercial classification of

from the appropriate reference standards.

commercial products or for quality control purposes.

3.2.3 dead-weight micrometer, n—an instrument capable of

1.2 The values stated in SI units are to be regarded as the measuringthethicknessofthinfilmsutilizingaweighttoapply

standard.

uniform pressure to the specimen.

1.3 This standard does not purport to address all of the 3.2.4 verification, n—proof, with the use of calibrated

safety concerns, if any, associated with its use. It is the

standards or standard reference materials that the calibrated

responsibility of the user of this standard to establish appro- instrument is operating within specified requirements.

priate safety and health practices and determine the applica-

4. Summary of Methods

bility of regulatory requirements prior to use.

4.1 This guide describes four different methods for the

NOTE 4—ISO 4593 is similar but differs in technical content and scope.

thickness measurement of plastic film specimens.The methods

(identified as MethodsA, B, C, and D) use different microme-

2. Referenced Documents

ters that actuate the weights in different manners or utilize

2.1 ASTM Standards:

different means of reading the thickness.

D 618 Practice for Conditioning Plastics Material for Test-

4.2 It is permissible to use other instruments, including

ing

non-contact instruments and instruments using alternative

D 883 Terminology Relating to Plastics

readout systems in place of dials provided they meet or exceed

D 4805 Terminology for Plastics Standards

the precision requirements noted in this practice.

D 5947 Test Methods for Physical Dimensions of Solid

Plastics Specimens

5. Significance and Use

D 6287 Practice for Cutting Film and Sheeting Test Speci-

5.1 This guide shall be followed where precise dimensions

mens

are necessary for the calculation of properties expressed in

2.2 ISO Standard:

3 physical units. It is not intended to replace practical thickness

ISO 472 Plastics—Vocabulary

measurements based on commercial portable tools, nor is it

implied that thickness measurements made by the procedures

will agree exactly.

This guide is under the jurisdiction of ASTM Committee D20 on Plastics and

is the direct responsibility of Subcommittee D20.19 on Films and Sheeting.

Current edition approved Dec. 1, 2003. Published January 2004.

6. Apparatus

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1 The instruments described in this guide share many

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on common features:

the ASTM website.

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6988–03

6.1.1 Adead-weight gage calibrated in accordance with the andalinearopticalencoderusingascaleofincrementsnotless

guidelines described in Appendix X2 and consisting of the than 100 lines/mm and capable of reading within 0.5 µm with

following: a 10 mm range.

6.5 Apparatus D—Automatically Operated Thickness Gage

NOTE 5—Additional guidance for calibration and verification of gages

with Digital Display:

can be found in Test Methods D 5947.

6.5.1 SimilartoApparatusBexceptitemploysanelectronic

NOTE 6—Since there is such a wide variety of instruments in use, there

device with a digital readout capable of a resolution not less

canbesignificantdifferencesintheaccuracyofdifferentinstrumenttypes.

than 0.5 µm and repeatable readings to within 6 1 µm at zero

The values stated for each type of apparatus are intended to be typical of

setting or on a steel gage block.

that type of instrument.

6.5.2 A preferred drop rate between 0.750 and 1.500 mm/s

6.1.1.1 Apresser foot that moves in an axis perpendicular to

between 0.625 and 0.025 mm on the dial and a capacity of at

the anvil face;

least 0.775 mm.

6.1.1.2 The surfaces of the presser foot and anvil (which

6.6 Other Instruments:

contact the specimen) parallel to within 2.5 µm;

6.6.1 Other instruments are commercially available that

6.1.1.3 Aspindle, vertically oriented if a dead-weight appa-

utilize different methods of measuring thickness. These are

ratus;

generally non-contact devices employing ultrasonic response,

6.1.1.4 An indicator essentially capable of repeatable read-

electricalcapacitance,orsimilarmaterialpropertiesthatcanbe

ings within 6 0.001 mm at zero setting, or on a steel gage

correlated to thickness. Some of these devices are also de-

block;

signed to provide a means of measuring discreet sections of

6.1.1.5 A frame, housing the indicator, of such rigidity that

film in a continuous scanning mode. Instruments of this nature

a load of 15 N applied to the housing, out of contact with the

are acceptable provided they meet or exceed the precision

presser foot spindle (or any weight attached thereto), will

requirements noted in this practice and the requirements of the

produce a deflection of the frame not greater than the smallest

applicable material or product specifications or applicable test

scale division or digital count on the indicator;

standards.

6.1.1.6 If employed, a dial diameter of at least 50 mm and

7. Test Specimens

graduated continuously to read directly to the nearest 2.5 µm.

The dial can be equipped with a revolution counter that 7.1 The test specimens shall be prepared from plastic films

displays the number of complete revolutions of the large hand, that have been cut to the required dimensions according to

or

Practice D 6287.

7.2 Prepare and condition each specimen in equilibrium

6.1.1.7 An electronic instrument having a digital readout in

with the appropriate standard laboratory test conditions or in

place of the dial indicator if that instrument meets all of the

accordance with the conditions specified in the test method

other requirements of this guide, and

applicable to the specific material for test.

6.1.1.8 The force applied to the presser foot spindle and the

7.3 For each specimen, take precautions to prevent damage

force necessary to register a change in the indicator reading

or contamination that will adversely affect the measurements.

shall be less than the force that will cause deformation of the

7.4 Unless otherwise specified, make all dimension mea-

specimen. The force applied to the presser foot spindle and the

surements at the standard laboratory atmosphere in accordance

forcenecessarytojustpreventachangeintheindicatorreading

with Practice D 618.

shallbemorethantheminimumpermissibleforcespecifiedfor

a specimen.

8. Procedure

6.2 Apparatus A—Manually Operated Thickness Gage:

8.1 General Guidelines:

6.2.1 Aninstrumenthavingapresserfootandspindlethatis

manually lifted and lowered.

NOTE 7—In this section, the word “method” denotes a combination of

both a specific apparatus and a procedure describing its use.

6.3 Apparatus B—Automatically Operated Thickness Gage:

6.3.1 A pneumatic or motor-operated instrument having a

8.1.1 The selection of a method for measurement of film

presser foot spindle that is lifted and lowered either by a

thickness is influenced by the characteristics of the film for

pneumatic cylinder or by a constant-speed motor through a

measurement. Each material and, in some cases, film construc-

mechanicallinkagesuchthattherateofdescent(foraspecified

tion in the case of multi-layer structures, will differ in its

range of distances between the presser foot surface and anvil)

response to test method parameters, which include, but are not

and dwell time on the specimen are within the limits specified

limited to, compressibility, rate of loading, ultimate load, dwell

for the material being measured.

time, and dimensions of the presser foot and anvil. For a

6.3.2 A preferred drop rate between 0.750 and 1.500 mm/s specific plastic material or structure, these responses can, in

between 0.625 and 0.025 mm on the dial and a capacity of at some cases, cause measurements made using one method to

least 0.775 mm. differ significantly from measurements made using another

method. The procedures that follow are categorized according

6.4 Apparatus C—Manually Operated Thickness Gage with

to the materials to which each applies. See Appendix X1.

Linear Optical Encoder:

6.4.1 Similar to Apparatus A except it employs a digital

NOTE 8—The pressure exerted by the gage on the specimen being

device with an electronic readout capable of repeatable read-

measuredshallnotdistortordeformthespecimen.Forthinfilms,#0.025

ings to within 6 1 µm at zero setting or on a steel gage block mm [0.001 in.], or films which exhibit visual deformation during

D6988–03

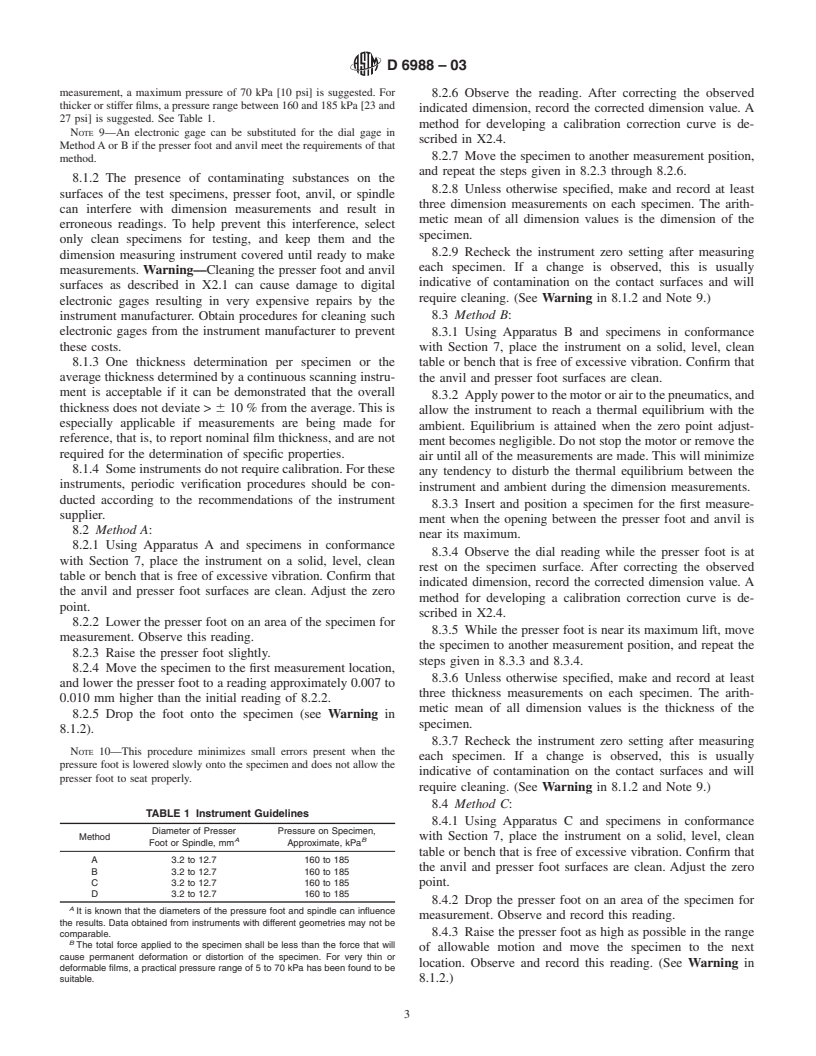

measurement, a maximum pressure of 70 kPa [10 psi] is suggested. For

8.2.6 Observe the reading. After correcting the observed

thicker or stiffer films, a pressure range between 160 and 185 kPa [23 and

indicated dimension, record the corrected dimension value. A

27 psi] is suggested. See Table 1.

method for developing a calibration correction curve is de-

NOTE 9—An electronic gage can be substituted for the dial gage in

scribed in X2.4.

MethodAor B if the presser foot and anvil meet the requirements of that

8.2.7 Move the specimen to another measurement position,

method.

and repeat the steps given in 8.2.3 through 8.2.6.

8.1.2 The presence of contaminating substances on the

8.2.8 Unless otherwise specified, make and record at least

surfaces of the test specimens, presser foot, anvil, or spindle

three dimension measurements on each specimen. The arith-

can interfere with dimension measurements and result in

metic mean of all dimension values is the dimension of the

erroneous readings. To help prevent this interference, select

specimen.

only clean specimens for testing, and keep them and the

8.2.9 Recheck the instrument zero setting after measuring

dimension measuring instrument covered until ready to make

each specimen. If a change is observed, this is usually

measurements. Warning—Cleaning the presser foot and anvil

indicative of contamination on the contact surfaces and will

surfaces as described in X2.1 can cause damage to digital

require cleaning. (See Warning in 8.1.2 and Note 9.)

electronic gages resulting in very expensive repairs by the

instrument manufacturer. Obtain procedures for cleaning such 8.3 Method B:

electronic gages from the instrument manufacturer to prevent 8.3.1 Using Apparatus B and specimens in conformance

these costs.

with Section 7, place the instrument on a solid, level, clean

8.1.3 One thickness determination per specimen or the table or bench that is free of excessive vibration. Confirm that

average thickness determined by a continuous scanning instru-

the anvil and presser foot surfaces are clean.

ment is acceptable if it can be demonstrated that the overall

8.3.2 Applypowertothemotororairtothepneumatics,and

thickness does not deviate > 6 10 % from the average. This is

allow the instrument to reach a thermal equilibrium with the

especially applicable if measurements are being made for

ambient. Equilibrium is attained when the zero point adjust-

reference, that is, to report nominal film thickness, and are not

ment becomes negligible. Do not stop the motor or remove the

required for the determination of specific properties.

air until all of the measurements are made. This will minimize

8.1.4 Some instruments do not require calibration. For these

any tendency to disturb the thermal equilibrium between the

instruments, periodic verification procedures should be con-

instrument and ambient during the dimension measurements.

ducted according to the recommendations of the instrument

8.3.3 Insert and position a specimen for the first measure-

supplier.

ment when the opening between the presser foot and anvil is

8.2 Method A:

near its maximum.

8.2.1 Using Apparatus A and specimens in conformance

8.3.4 Observe the dial reading while the presser foot is at

with Section 7, place the instrument on a solid, level, clean

rest on the specimen surface. After correcting the observed

table or bench that is free of excessive vibration. Confirm that

indicated dimension, record the corrected dimension value. A

the anvil and presser foot surfaces are clean. Adjust the zero

method for developing a calibration correction curve is de-

point.

scribed in X2.4.

8.2.2 Lower the presser foot on an area of the specimen for

8.3.5 While the presser foot is near its maximum lift, move

measurement. Observe this reading.

the specimen to another measurement position, and repeat the

8.2.3 Raise the presser foot slightly.

steps given in 8.3.3 and 8.3.4.

8.2.4 Move the specimen to the first measurement location,

8.3.6 Unless otherwise specified, make and record at least

and lower the presser foot to a reading approximately 0.007 to

three thickness measurements on each specimen. The arith-

0.010 mm higher than the initial reading of 8.2.2.

metic mean of all dimension values is the thickness of the

8.2.5 Drop the foot onto the specimen (see Warning in

specimen.

8.1.2).

8.3.7 Recheck the instrument zero setting after measuring

NOTE 10—This procedure minimizes small error

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.