ASTM C29/C29M-97(2003)

(Test Method)Standard Test Method for Bulk Density ("Unit Weight") and Voids in Aggregate

Standard Test Method for Bulk Density ("Unit Weight") and Voids in Aggregate

SCOPE

1.1 This test method covers the determination of bulk density ("unit weight") of aggregate in a compacted or loose condition, and calculated voids between particles in fine, coarse, or mixed aggregates based on the same determination. This test method is applicable to aggregates not exceeding 5 in. [125 mm] in nominal maximum size.

Note 1—Unit weight is the traditional terminology used to describe the property determined by this test method, which is weight per unit volume (more correctly, mass per unit volume or density).

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard, as appropriate for a specification with which this test method is used. An exception is with regard to sieve sizes and nominal size of aggregate, in which the SI values are the standard as stated in Specification E 11. Within the text, SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore each system must be used independently of the other, without combining values in any way.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

American Association of State

Designation:C29/C29M–97(Reapproved2003) Highway and Transportation Officials Standard

AASHTO No.: T19/T19M

Standard Test Method for

Bulk Density (“Unit Weight”) and Voids in Aggregate

This standard is issued under the fixed designation C29/C29M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope for Test Methods for Construction Materials

C702 Practice for Reducing Samples of Aggregate to

1.1 This test method covers the determination of bulk

Testing Size

density (“unit weight”) of aggregate in a compacted or loose

D75 Practice for Sampling Aggregates

condition, and calculated voids between particles in fine,

D123 Terminology Relating to Textiles

coarse, or mixed aggregates based on the same determination.

E11 Specification for Wire Cloth and Sieves for Testing

Thistestmethodisapplicabletoaggregatesnotexceeding5in.

Purposes

[125 mm] in nominal maximum size.

2.2 AASHTO Standard:

NOTE 1—Unitweightisthetraditionalterminologyusedtodescribethe

T19/T19M Method of Test for Unit Weight and Voids in

property determined by this test method, which is weight per unit volume

Aggregate

(more correctly, mass per unit volume or density).

1.2 The values stated in either inch-pound units or SI units 3. Terminology

are to be regarded separately as standard, as appropriate for a

3.1 Definitions—Definitions are in accordance with Termi-

specificationwithwhichthistestmethodisused.Anexception

nology C125 unless otherwise indicated.

is with regard to sieve sizes and nominal size of aggregate, in

3.1.1 bulk density, n—of aggregate, the mass of a unit

which the SI values are the standard as stated in Specification

volume of bulk aggregate material, in which the volume

E11. Within the text, SI units are shown in brackets. The

includes the volume of the individual particles and the volume

3 3

values stated in each system may not be exact equivalents;

ofthevoidsbetweentheparticles.Expressedinlb/ft [kg/m ].

thereforeeachsystemmustbeusedindependentlyoftheother,

3.1.2 unit weight, n—weight (mass) per unit volume. (Dep-

without combining values in any way.

recated term used–preferred term bulk density.)

1.3 This standard does not purport to address all of the

3.1.2.1 Discussion—Weightisequaltothemassofthebody

safety concerns, if any, associated with its use. It is the

multiplied by the acceleration due to gravity. Weight may be

responsibility of the user of this standard to establish appro-

expressed in absolute units (newtons, poundals) or in gravita-

priate safety and health practices and determine the applica-

tional units (kgf, lbf), for example: on the surface of the earth,

bility of regulatory limitations prior to use.

a body with a mass of 1 kg has a weight of 1 kgf (approxi-

mately 9.81 N), or a body with a mass of 1 lb has a weight of

2. Referenced Documents

1 lbf (approximately 4.45 N or 32.2 poundals). Since weight is

2.1 ASTM Standards:

equal to mass times the acceleration due to gravity, the weight

C125 Terminology Relating to Concrete and Concrete

of a body will vary with the location where the weight is

Aggregates

determined, while the mass of the body remains constant. On

C127 Test Method for Density, Relative Density (Specific

the surface of the earth, the force of gravity imparts to a body

Gravity), and Absorption of Coarse Aggregate

that is free to fall an acceleration of approximately 9.81 m/s

C128 Test Method for Density, Relative Density (Specific

(32.2 ft/s ). D 123

Gravity), and Absorption of Fine Aggregate

3.2 Definitions of Terms Specific to This Standard:

C138/C138M Test Method for Density (Unit Weight),

3.2.1 voids, n—in unit volume of aggregate, the space

Yield, and Air Content (Gravimetric) of Concrete

between particles in an aggregate mass not occupied by solid

C670 Practice for Preparing Precision and Bias Statements

mineral matter.

This test method is under the jurisdiction of ASTM Committee C09 on

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee Annual Book of ASTM Standards, Vol 04.03.

C09.20 on Normal Weight Aggregates. Annual Book of ASTM Standards, Vol 07.01.

Current edition approved July 10, 1997. Published September 1997. Originally Annual Book of ASTM Standards, Vol 14.02.

approved in 1920. Last previous edition approved in 1991 as C29/C29M–91a. Available from American Association of State Highway and Transportation

Annual Book of ASTM Standards, Vol 04.02. Officials, 444 N. Capitol St. NW, Suite 225, Washington, DC 20001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C29/C29M–97 (2003)

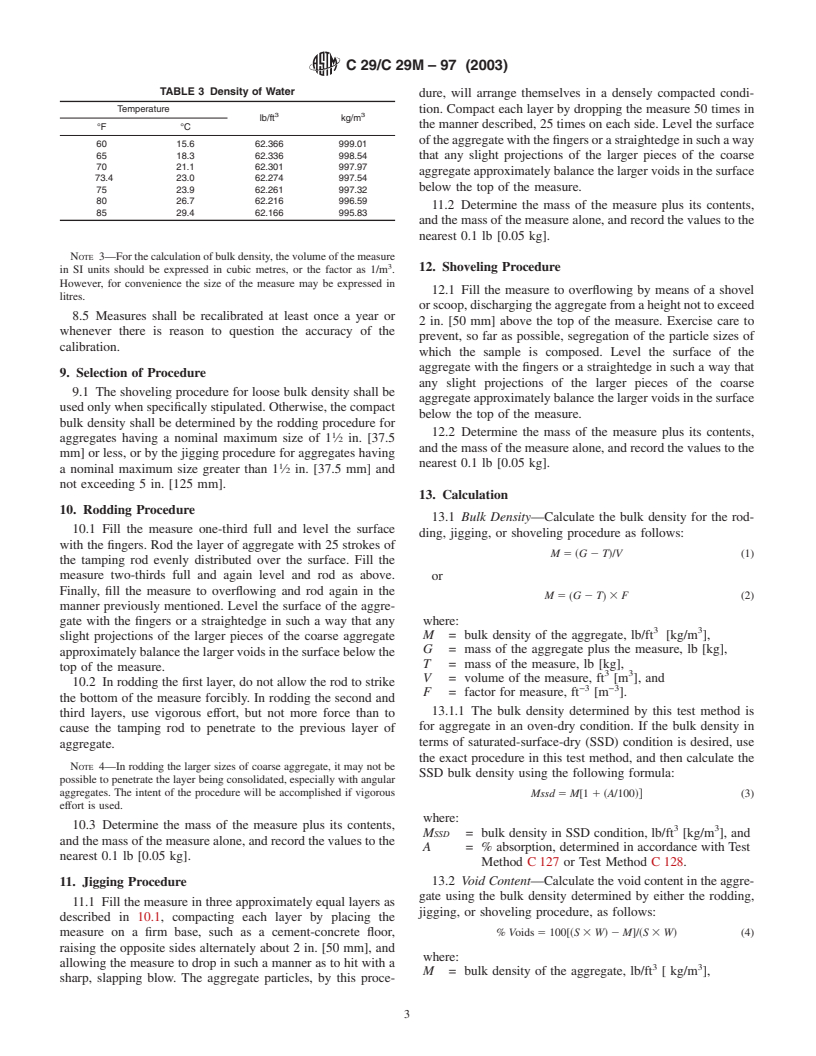

TABLE 2 Requirements for Measures

3.2.1.1 Discussion—Voids within particles, either perme-

able or impermeable, are not included in voids as determined Thickness of Metal, min

by this test method. 1

Upper 1 ⁄2 in.

Capacity of Measure

Bottom or 38 mm Remainder of wall

A

of wall

4. Significance and Use

Less than 0.4 ft 0.20 in. 0.10 in. 0.10 in.

4.1 This test method is often used to determine bulk density

3 3

0.4 ft to 1.5 ft , incl 0.20 in. 0.20 in. 0.12 in.

valuesthatarenecessaryforuseformanymethodsofselecting over 1.5 to 2.8 ft , incl 0.40 in. 0.25 in. 0.15 in.

over 2.8 to 4.0 ft , incl 0.50 in. 0.30 in. 0.20 in.

proportions for concrete mixtures.

Less than 11 L 5.0 mm 2.5 mm 2.5 mm

4.2 The bulk density also may be used for determining

11 to 42 L, incl 5.0 mm 5.0 mm 3.0 mm

mass/volume relationships for conversions in purchase agree- over 42 to 80 L, incl 10.0 mm 6.4 mm 3.8 mm

over 80 to 133 L, incl 13.0 mm 7.6 mm 5.0 mm

ments. However, the relationship between degree of compac-

A

The added thickness in the upper portion of the wall may be obtained by

tion of aggregates in a hauling unit or stockpile and that

placing a reinforcing band around the top of the measure.

achievedinthistestmethodisunknown.Further,aggregatesin

hauling units and stockpiles usually contain absorbed and

surface moisture (the latter affecting bulking), while this test

are satisfactorily parallel if the slope between pieces of plate glass in

method determines the bulk density on a dry basis. contact with the top and bottom does not exceed 0.87% in any direction.

4.3 Aprocedureisincludedforcomputingthepercentageof

5.3.1 If the measure is to also be used for testing for bulk

voidsbetweentheaggregateparticlesbasedonthebulkdensity

density of freshly-mixed concrete according to Test Method

determined by this test method.

C138, the measure shall be made of steel or other suitable

metal not readily subject to attack by cement paste. Reactive

5. Apparatus

materials, such as aluminum alloys are permitted, where as a

5.1 Balance—A balance or scale accurate within 0.1% of

consequence of an initial reaction, a surface film is formed

the test load at any point within the range of use, graduated to

which protects the metal against further corrosion.

at least 0.1 lb [0.05 kg]. The range of use shall be considered

5.3.2 Measures larger than nominal 1 ft (28 L) capacity

to extend from the mass of the measure empty to the mass of

shall be made of steel for rigidity, or the minimum thicknesses

3 3

the measure plus its contents at 120 lb/ft [1920 kg/m ].

of metal listed in Table 2 shall be suitably increased.

5.2 Tamping Rod—A round, straight steel rod, ⁄8 in. [16

5.4 Shovel or Scoop—Ashovel or scoop of convenient size

mm]indiameterandapproximately24in.[600mm]inlength,

for filling the measure with aggregate.

havingthetampingend,orbothends,roundedtoahemispheri-

5.5 Calibration Equipment—A piece of plate glass, prefer-

cal tip, the diameter of which is ⁄8 in. (16 mm).

ably at least ⁄4 in. [6 mm] thick and at least 1 in. [25 mm]

5.3 Measure—Acylindrical metal measure, preferably pro-

larger than the diameter of the measure to be calibrated. A

vided with handles. It shall be watertight, with the top and

supply of water-pump or chassis grease that can be placed on

bottom true and even, and sufficiently rigid to retain its form

the rim of the container to prevent leakage.

under rough usage. The measure shall have a height approxi-

mately equal to the diameter, but in no case shall the height be 6. Sampling

less than 80% nor more than 150% of the diameter. The

6.1 ObtainthesampleinaccordancewithPracticeD75,and

capacity of the measure shall conform to the limits in Table 1

reduce to test sample size in accordance with Practice C702.

fortheaggregatesizetobetested.Thethicknessofmetalinthe

measure shall be as described in Table 2. The top rim shall be

7. Test Sample

smooth and plane within 0.01 in. [0.25 mm] and shall be

7.1 The size of the sample shall be approximately 125 to

paralleltothebottomwithin0.5°(Note2).Theinteriorwallof

200% of the quantity required to fill the measure, and shall be

the measure shall be a smooth and continuous surface.

handled in a manner to avoid segregation. Dry the aggregate

sample to essentially constant mass, preferably in an oven at

NOTE 2—The top rim is satisfactorily plane if a 0.01-in. [0.25-mm]

feeler gage cannot be inserted between the rim and a piece of ⁄4-in. 230 6 9°F [110 6 5°C].

[6-mm] or thicker plate glass laid over the measure. The top and bottom

8. Calibration of Measure

8.1 Fill the measure with water at room temperature and

TABLE 1 Capacity of Measures

cover with a piece of plate glass in such a way as to eliminate

Nominal Maximum

A

Capacity of Measure bubbles and excess water.

Size of Aggregate

8.2 Determine the mass of the water in the measure using

3 3

in. mm ft L(m )

the balance described in 5.1.

1 1

⁄2 12.5 ⁄10 2.8 (0.0028)

8.3 Measure the temperature of the water and determine its

1 25.0 ⁄3 9.3 (0.0093)

1 1 density from Table 3, interpolating if necessary.

1 ⁄2 37.5 ⁄2 14 (0.014)

3 75 1 28 (0.028)

8.4 Calculate the volume, V, of the measure

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.