ASTM D6226-98e1

(Test Method)Standard Test Method for Open Cell Content of Rigid Cellular Plastics

Standard Test Method for Open Cell Content of Rigid Cellular Plastics

SCOPE

1.1 This test method covers cellular plastics, which are composed of membranes or walls of polymer separating small cavities or cells. These cells may be interconnecting (open cell), non-connecting (closed cell), or any combination of these types. This test method determines numerical values for open cells. It is a porosity determination, measuring the accessible cellular volume of a material. The remaining volume is that occupied by closed cells and cell walls. Since any conveniently sized specimen can only be obtained by some cutting operation, a fraction of the closed cells will be opened by specimen preparation and will be included as open cells, (see Note 2).

1.2 This test method provides good accuracy on predominantly highly open-celled materials. By not accounting for closed cells that were opened during specimen preparation, the accuracy decreases as the closed cell content increases and as the cell size increases.

1.3 The values as stated in SI units are to be regarded as the standard. The values in parentheses are given for reference only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—This test method and ISO 4590-1981 use the same basic principles but are significantly different in experimental detail.

Note 2—Two procedures for correcting for cells opened during specimen preparation are described in Appendix X1.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: D 6226 – 98

Standard Test Method for

Open Cell Content of Rigid Cellular Plastics

This standard is issued under the fixed designation D 6226; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorially corrected Equation A2.5 in April 2002.

1. Scope D 2842 Test Method forWaterAbsorption of Rigid Cellular

Plastics

1.1 This test method covers cellular plastics, which are

D 3576 Test Method for Cell Size of Rigid Cellular Plas-

composed of membranes or walls of polymer separating small

tics

cavities or cells. These cells may be interconnecting (open

E 691 Practice for Conducting an Interlaboratory Study to

cell),non-connecting(closedcell),oranycombinationofthese

Determine the Precision of a Test Method

types. This test method determines numerical values for open

2.2 ISO Standard:

cells. It is a porosity determination, measuring the accessible

ISO 4590-1981 Cellular Plastics—Determination of Vol-

cellular volume of a material. The remaining volume is that

ume Percentage of Open and Closed Cells of Rigid

occupiedbyclosedcellsandcellwalls.Sinceanyconveniently

Materials

sized specimen can only be obtained by some cutting opera-

tion, a fraction of the closed cells will be opened by specimen

3. Terminology

preparation and will be included as open cells, (see Note 2).

3.1 Definitions:

1.2 This test method provides good accuracy on predomi-

3.1.1 Terms relating to plastics as given in Terminology

nantly highly open-celled materials. By not accounting for

D 883 shall be used where applicable.

closed cells that were opened during specimen preparation, the

3.2 Definitions of Terms Specific to This Standard:

accuracy decreases as the closed cell content increases and as

3.2.1 closed cell—a cell totally enclosed by its walls and

the cell size increases.

hence not interconnecting with other cells.

1.3 The values as stated in SI units are to be regarded as the

3.2.2 open cell—a cell not totally enclosed by its walls and

standard. The values in parentheses are given for reference

open to the surface either directly or by interconnecting with

only.

other cells.

1.4 This standard does not purport to address all of the

3.2.3 volume of closed cells and cell walls—inaccessible

safety concerns, if any, associated with its use. It is the

internal volume, consisting of an aggregate of solid polymer

responsibility of the user of this standard to establish appro-

volume (cell walls, struts), filler volume, when applicable

priate safety and health practices and determine the applica-

(solid particles or fibers), the volume of individual closed cells,

bility of regulatory limitations prior to use.

andthevolumeofsmallcellgroupsinterconnectedbyruptured

NOTE 1—This test method and ISO 4590-1981 use the same basic

cell walls but otherwise inaccessible.

principles but are significantly different in experimental detail.

3.2.4 uncorrected volume of open cells—theaggregatemea-

NOTE 2—Two procedures for correcting for cells opened during speci-

surement of both the internal porous volume of the material

men preparation are described in Appendix X1.1.

and the various irregular volumes accessible at the cut-cell

2. Referenced Documents surface of the test specimen.

3.3 Symbols:

2.1 ASTM Standards:

3.3.1 d—specimen diameter, cm.

D 618 Practice for Conditioning Plastics and Electrical

3.3.2 h—specimen height, cm.

Insulation Materials for Testing

3.3.3 l—specimen length, cm.

D 883 Terminology Related to Plastics

3.3.4 O —volume, percent open cells.

v

3.3.5 V—geometric volume of specimen, cm .

ThistestmethodisunderthejurisdictionofASTMCommitteeD-20onPlastics

and is the direct responsibility of Subcommittee D20.22 on Cellular Materials— Annual Book of ASTM Standards, Vol 08.02.

Plastics and Elastomers. Annual Book of ASTM Standards, Vol 14.02

Current edition approved Jan. 10, 1998. Published January 1999. Available from American National Standards Institute, 11 W. 42nd St. 13th

Annual Book of ASTM Standards, Vol 08.01. Floor, New York, New York 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D6226–98

3.3.6 V —volume of the calibration standard, cm .

CALIB

3.3.7 V —volume of the sample chamber, cm .

CHAMBER

3.3.8 V —expansion reference volume, cm .

EXP

3.3.9 V —specimen displacement volume, cm , and,

SPEC

3.3.10 w—specimen width, cm.

4. Summary of Test Method

4.1 This test method is based on a determination of porosity

in which the accessible cellular volume of a cellular plastic is

determined by application of Boyle’s Law, which states that

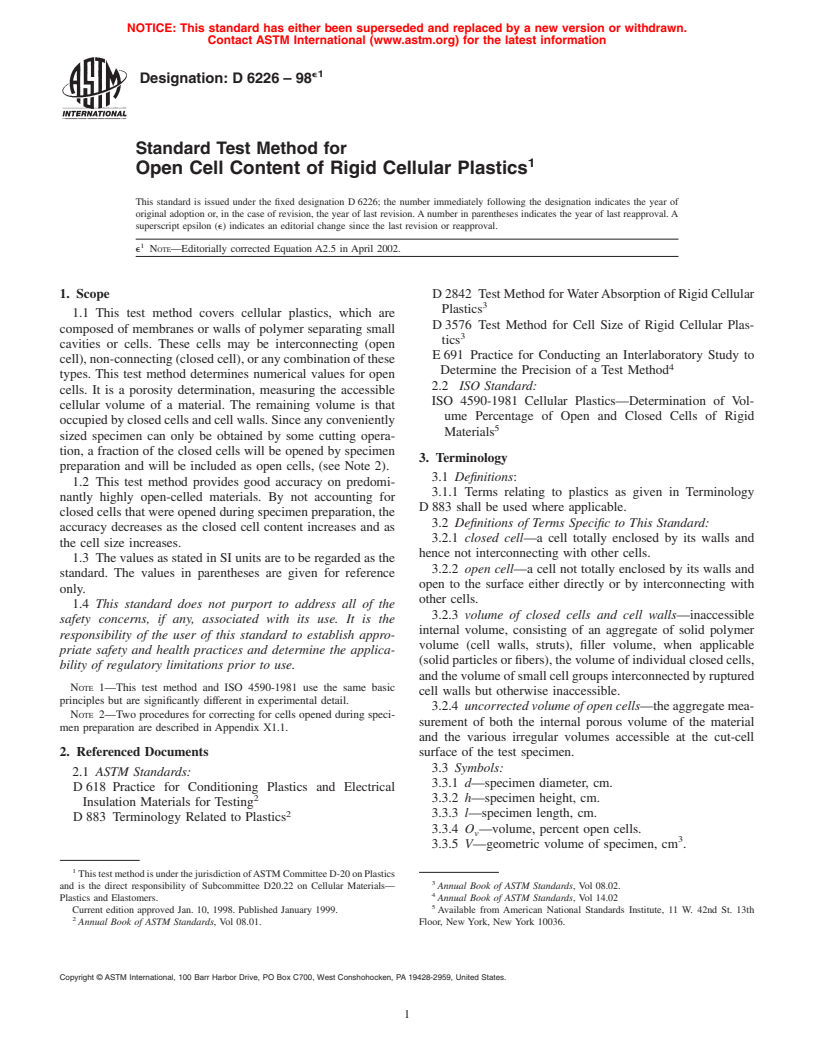

FIG. 1 Schematic Diagram of Gas Pycnometer

the increase in volume of a confined gas results in a propor-

tionate decrease in pressure. The apparatus consists of two

chambers of known volume connected by a valve. One of the

6.1.5 Filter, to prevent powder from contaminating the

chambers, the calibrated sample chamber, is accessible for

transducer and selector valves.

insertion of the test specimen and is connected to a source of

6.1.6 Input Flow Control Toggle and Needle Valves,or

high purity (at least 99.99 %) dry gas, such as nitrogen or

alternative means to control pressurization.

helium. The pressure in the sample chamber is increased to a

6.1.7 Output Flow Control Toggle and Needle Valves,or

predetermined pressure and this value, P , is noted. The valve

1 alternative means to vent the gas.

between the two chambers is then opened and the second,

6.1.8 Two-Way Selector Valve, to connect the reference

lower Pressure, P , is again noted. The ratio of the pressure

2 volume to the sample chamber.

change P /P , is directly related to the volume of the sample

1 2 6.1.9 Nonporous Calibration Standard, (for example a

chamber displaced by the specimen. The difference between 1

stainless steel sphere) of known volume which fills from ⁄3 to

this volume and the geometric volume of the specimen is a 2

⁄3 of the sample chamber.

measure of the open-cell volume.

6.1.10 Digital Meter, for reading the pressure from the

transducer to 0.007 kPa (0.001 psig).

NOTE 3—The criteria for selecting a dry gas are that the gas shall not

6.1.11 Sample Chamber Closure, with O-ring seal.

exhibit significant non-ideal behavior, dissolve the matrix, or readily

diffuse into the matrix.

6.1.12 Calibration Procedure, for the gas pycnometer is

outlined in A2.2

5. Significance and Use

6.2 Cutting Device, for specimen preparation, such as a

5.1 This test method is intended to be used in specifications bandsaw or hobby jigsaw, the blade of which must be capable

where porosity of cellular plastics has a direct bearing on their of producing a smooth cut. This will require a blade with at

end use. For example, for thermal insulation applications, a least four teeth/cm (10 teeth/in.).Acellular hole cutter can also

high percentage of closed cells is necessary to prevent escape be used.

of gases and to promote low thermal conductivity. In flotation 6.3 Vernier Calipers, or micrometre measuring device, ca-

applications, high closed-cell content generally reduces water pable of measuring specimens to the nearest 0.003 cm (0.001

absorption. in.).

5.2 Before proceeding with this test method, reference

7. Sampling and Test Specimen Preparation

shouldbemadetothespecificationofthematerialbeingtested.

Any test specimen preparation, conditioning, or dimensions, or

7.1 The standard test specimen is two cubes having a

both, and testing parameters covered in the materials specifi-

nominal dimension of 2.5 by 2.5 by 2.5 cm (1.0 by 1.0 by 1.0

cation shall take precedence over those mentioned in this test in.), (see Note 4).An alternative configuration is two cylinders

method. If there are no material specifications, then the default

with nominal cross sectional areas of 6.25 cm (0.97 in.) by 2.5

conditions apply. cm (1.0 in.) in height, (see Note 5). It may be practical in some

instances (for example, when using smaller sized sample

6. Apparatus chambers or when there is a limited amount of material) to use

onlyonecubeoronecylinder.Howeverthespecimendisplace-

6.1 Gas Pycnometer—Aschematic diagram of the pycnom-

ment volume (V ) should be at least 15 % of the sample

eter apparatus is shown in Fig. 1. It should be constructed from SPEC

chamber volume.

metal and have the following features:

6.1.1 Sample Chamber (V ), having a volume ap-

CHAMBER NOTE 4—The analyst should not substitute a single 5 by 2.5 by 2.5 cm

3 3

proximately between 30 and 150 cm (1.8 and 9.2 in. ),

rectangular prism for the two cubes because the surface areas are not

3 3

equal.

calibrated to the nearest 0.1 cm (0.006 in. ).

NOTE 5—The cylindrical configuration is not recommended for aniso-

6.1.2 Expansion Reference Volume (V ), a precisely cali-

EXP

3 3 tropic materials.

brated volume known to the nearest 0.1 cm (0.006 in. ).

6.1.3 Gage Pressure Transducer, capable of measuring 0 to 7.2 Unless otherwise agreed upon, at least three sets of two

175kPa(0to25psig)withminimumvolumedisplacementand cubes or two cylinders, selected at random, shall be tested.All

linear within 0.1%. specimens having obvious defects shall be omitted.

6.1.4 Pressure Relief Valve, to avoid over pressurization of 7.3 Sample selection on commercially available materials

the transducer. shall be by agreement between the supplier and the user.

e1

D6226–98

7.4 Test specimens shall be machined or sawed from the 9.13 Close the flow valve and allow the pressure to stabilize

sample so as to have smooth surfaces. All machined or sawed or wait a fixed period of time (10 to 15 s give best results for

surfaces may be further smoothed by slicing techniques or most samples) and record the final pressure as P . Report the

sanding with a number 400 or finer sandpaper. Resulting dust time used if the pressure did not stabilize.

should be blown from the specimens. 9.14 Immediatelyoperatethetwo-wayselectorvalvesothat

it again connects the expansion volume (reference) chamber

8. Conditioning

with the rest of the system and allow the pressure to stabilize

8.1 Condition specimens at standard laboratory atmosphere

or wait the same fixed period of time as in 9.13. Record the

23 6 2°C (73.4 6 3.6°F) and 50 6 5 % relative humidity for

final pressure as P .

a minimum of 24 h.

NOTE 7—If the pressure reading drifts continuously to lower pressures,

8.2 Since this test method depends on very accurate mea-

the cells may be rupturing or the test gas may be diffusing through the cell

surement of gas pressures, the temperature of the environment,

walls. Under these conditions, an accurate open-cell content cannot be

the apparatus, the specimen, and the sample cup must be kept

determined.

constant within 62°C.

9.15 Open the vent valve and allow the pressure to fall to 0

8.3 The temperature at which the calibration is performed

kPa (0 psig).

shall be within 62°C of the temperature at which the analysis

9.16 Return to 9.9 if multiple determinations are to be made

is performed.

on this specimen.

9.17 Remove the specimen from the sample chamber.

9. Procedure

9.18 If the instrument is to remain idle for an extended

9.1 Measure and record the length, l, height, h, and width,

period (days), close the sample chamber and shut off the gas

w,ofthespecimenstothenearest0.003cm(0.001in.).Ifusing

supply.

cylindrical specimens measure the height, h, and diameter, d.

9.19 Calculate the specimen volume from the general equa-

9.2 Close the flow valve if not already closed.

tion:

9.3 Operate the two-way selector valve so that it isolates the

V 5 V –V / @~P /P !–1#. (1)

expansion volume (reference) chamber from the rest of the SPEC CHAMBER EXP 1 2

system.

NOTE 8—Several companies produce both manually operated and

9.4 Open the vent valve if not already open.

automatically operated gas pycnometers which meet the specifications

9.5 Removethesamplechambercapifnotalreadyopenand described herein. Please refer to the specific operating manuals for

additional details on operation and calibration.

remove any previous specimen.

9.6 Insertthenewspecimenandsecurelyreplacethesample

10. Calculation

chamber cap.

10.1 Calculate the geometric volume, V, in cubic centem-

9.7 Air,andvaporstrappedwithinpores,crevices,oramong

the pieces of the specimen will be removed from the specimen etres of the specimen by adding together the volumes of its

component specimens determined from their measurements of

by a prolonged purge when all valves are opened. Report the

time used. However, these impurity gases are much more length, width, and height as follows:

rapidly removed by alternately increasing and decreasing the

If two cubes: V 5 l 3 w 3 h 1 l 3 w 3 h (2)

~ ! ~ !

1 1 1 2 2 2

gas pressure in the sample chamber.

9.8 Close the vent valve and open the flow valve.Allow the

2 2

Or if two cylinders: V 5 p3 d 3 h !/4 1 p3 d 3 h !/4 .

@~ # @~ #

1 1 2 2

pressure to rise to 20 kPa (2.9 psig), then close the flow valve

(3)

and open the vent valve. When the pressure has fallen to less

10.2 Calculate the open-cell content, O , of each specimen

s

than 3 kPa (0.4 psig), close the vent valve. This purging

expressed as the percentage of the calculated volume, V, as

process should be repeated at least twice more. The vent valve

follows:

must remain open at the completion of the purge process.

O 5 @~V – V !/V# 3 100 (4)

Report the number of purge cycles used.

V SPEC

9.9 Operate the two-way selector valve so that it connects

10.3 If desired the percent volume occupied by the closed

the expansion volume (reference) chamber with the rest of the

cells and cell walls, CW , can be calculated from the equation:

V

system.Allow the pressure to fall to a steady value, correcting

CW 5 100 – O (5)

V V

the pressure display with the zero control as necessary.

10.4 When the specific gravity of the material in its solid

9.10 Operate the two-way selector valve so that it again

form is known the percent volumes occupied by the cell walls,

isolates the expansion volume (reference) chamber from the

W , and the closed cells, C , can be calculated individually.

rest of the system, ensuring that the pressure display does not V V

The cell wall volume percentage is calculated as follows:

shift from zero. If a shift occurs, repeat 9.9.

9.11 Closetheventvalveneglectinganychangeinpressure.

W 5 m / sg 3 V 3 100 (6)

@ ~ !#

V

9.12 Opentheflowvalveandfillthechamberto20kPa(2.9

where:

psig) as shown on the pressure indicator.

m = the mass of the specimen, g,

NOTE 6—It may be desirable in some instances to use pressures less

sg = t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.