ASTM E127-10

(Practice)Standard Practice for Fabricating and Checking Aluminum Alloy Ultrasonic Standard Reference Blocks

Standard Practice for Fabricating and Checking Aluminum Alloy Ultrasonic Standard Reference Blocks

SIGNIFICANCE AND USE

Reference blocks fabricated to this practice will exhibit specific area-amplitude and distance-amplitude relationships only with an immersion test at 5 MHz using the search unit, test instrument, and test parameters described in this practice. Comparison tests at other frequencies or with uncalibrated test systems will not necessarily give the same relationships shown in this practice.

Note 2—The 1964 and prior issues of this practice required a test frequency of 15 MHz. Blocks conforming to earlier issues of this practice may not produce ultrasonic responses that conform to this issue. See Section 13 regarding provision for recertification or correction curves and tables.

Although the primary ultrasonic evaluation of blocks is performed at a specified frequency, the blocks may be used to standardize ultrasonic tests at any frequency and with any pulse-echo ultrasonic test system. Establishment of distance-amplitude and area-amplitude characteristics is necessary for each application. This use may be inappropriate for other materials and curved surfaces without special compensation. Also see (3) for cautions regarding use of standard blocks for test standardization.

SCOPE

1.1 This practice covers a procedure for fabricating aluminum alloy ultrasonic standard reference blocks that can be used for checking performance of ultrasonic testing equipment and for standardization and control of ultrasonic tests of aluminum alloy products using pulsed longitudinal waves introduced into test material either by the direct-contact method or by the immersion method. A recommended procedure for checking blocks is described and calibration data for a number of reference blocks are tabulated. Statements concerning procedures are provided without a discussion of the technical background for the preference. The necessary technical background can be found in Refs. (1-16).

Note 1—Practice E428 and Guide E1158 also describe procedures for selecting material, fabricating blocks, and checking response. Unlike this practice, there is no requirement for evaluation relative to a specified standard target.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E127 −10

StandardPractice for

Fabricating and Checking Aluminum Alloy Ultrasonic

1

Standard Reference Blocks

This standard is issued under the fixed designation E127; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope than Aluminum, Reference Blocks Used in Ultrasonic

Testing

1.1 This practice covers a procedure for fabricating alumi-

E1158Guide for Material Selection and Fabrication of

numalloyultrasonicstandardreferenceblocksthatcanbeused

Reference Blocks for the Pulsed Longitudinal Wave Ul-

for checking performance of ultrasonic testing equipment and

trasonic Testing of Metal and Metal Alloy Production

for standardization and control of ultrasonic tests of aluminum

Material

alloyproductsusingpulsedlongitudinalwavesintroducedinto

E1316Terminology for Nondestructive Examinations

test material either by the direct-contact method or by the

E1324GuideforMeasuringSomeElectronicCharacteristics

immersion method. A recommended procedure for checking

of Ultrasonic Testing Instruments

blocks is described and calibration data for a number of

reference blocks are tabulated. Statements concerning proce-

3. Terminology

dures are provided without a discussion of the technical

background for the preference. The necessary technical back-

3.1 Definitions—For definitions of terms not specific to this

2

ground can be found in Refs. (1-15). practice, refer to Terminology E1316.

3.2 Definitions of Terms Specific to This Standard:

NOTE 1—Practice E428 and Guide E1158 also describe procedures for

3.2.1 angular error—the condition observed in ultrasonic

selecting material, fabricating blocks, and checking response. Unlike this

practice, there is no requirement for evaluation relative to a specified

tests of reference blocks when the response from the hole

standard target.

bottom is not maximum while the search unit is positioned to

1.2 This standard does not purport to address all of the

obtain either a maximum number of back reflections from a

safety concerns, if any, associated with its use. It is the reference block or a maximum indication from its entry

responsibility of the user of this standard to establish appro-

surface. Angular error results when the entry surface, hole

priate safety and health practices and determine the applica-

bottom, and back surface are not parallel to each other.

bility of regulatory limitations prior to use.

3.2.2 area-amplitude response curve—a curve showing the

relationshipbetweendifferentareasofreflectingtargetslocated

2. Referenced Documents

ataconstantdistanceinanultrasonictransmittingmediumand

3

2.1 ASTM Standards:

their respective amplitudes of ultrasonic response.

E317PracticeforEvaluatingPerformanceCharacteristicsof

3.2.3 back reflection—the indication, observed on the dis-

Ultrasonic Pulse-Echo Testing Instruments and Systems

play screen of a test instrument, that represents the ultrasonic

without the Use of Electronic Measurement Instruments

energy reflected from the back surface of a reference block.

E428Practice for Fabrication and Control of Metal, Other

3.2.4 back surface—the end of a reference block that is

opposite the entry surface.

1

3.2.5 entry surface—the end of a reference block through

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.06 on

which ultrasonic energy must pass when reflections from the

Ultrasonic Method.

hole bottom are obtained.

Current edition approved Feb. 15, 2010. Published March 2010. Originally

approved in 1958. Last previous edition approved in 2007 as E127-07. DOI:

3.2.6 hole bottom—the flat reflecting surface in a reference

10.1520/E0127-10.

blockthatisobtainedbymakingtheentireendofadrilledhole

2

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

smooth and flat using best machining practices. The hole

this practice.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or bottom is parallel to the entry surface of the block.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.2.7 holesize—thediameteroftheholeinareferenceblock

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. that determines the area of the hole bottom.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E127−10

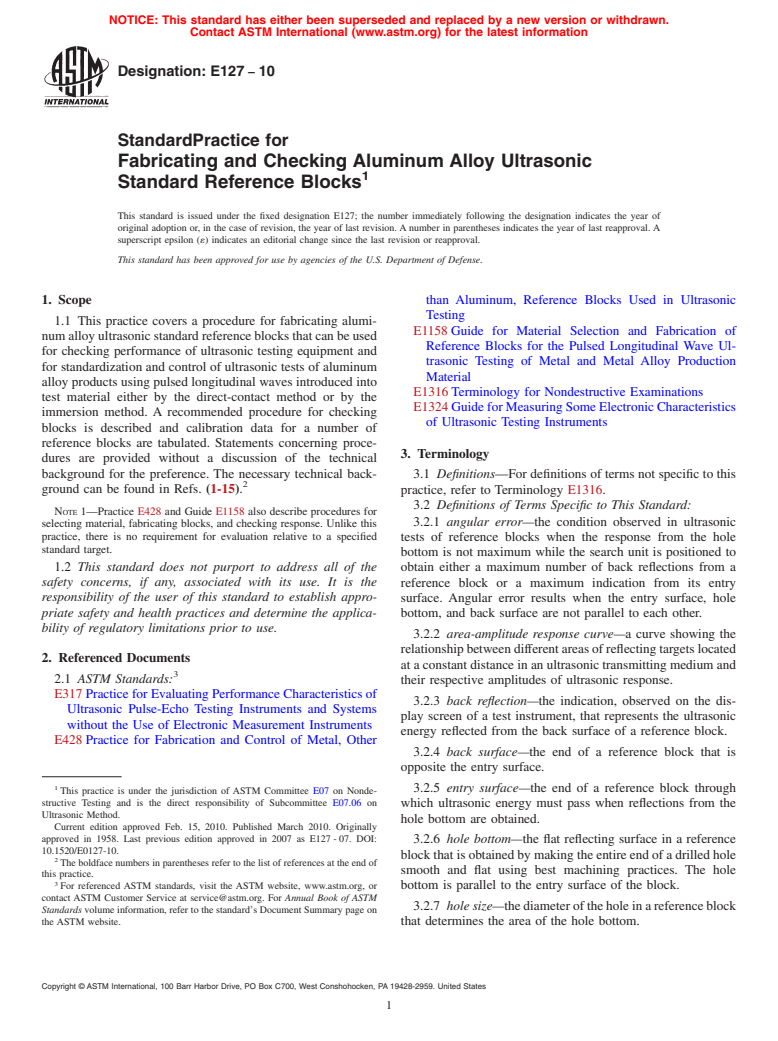

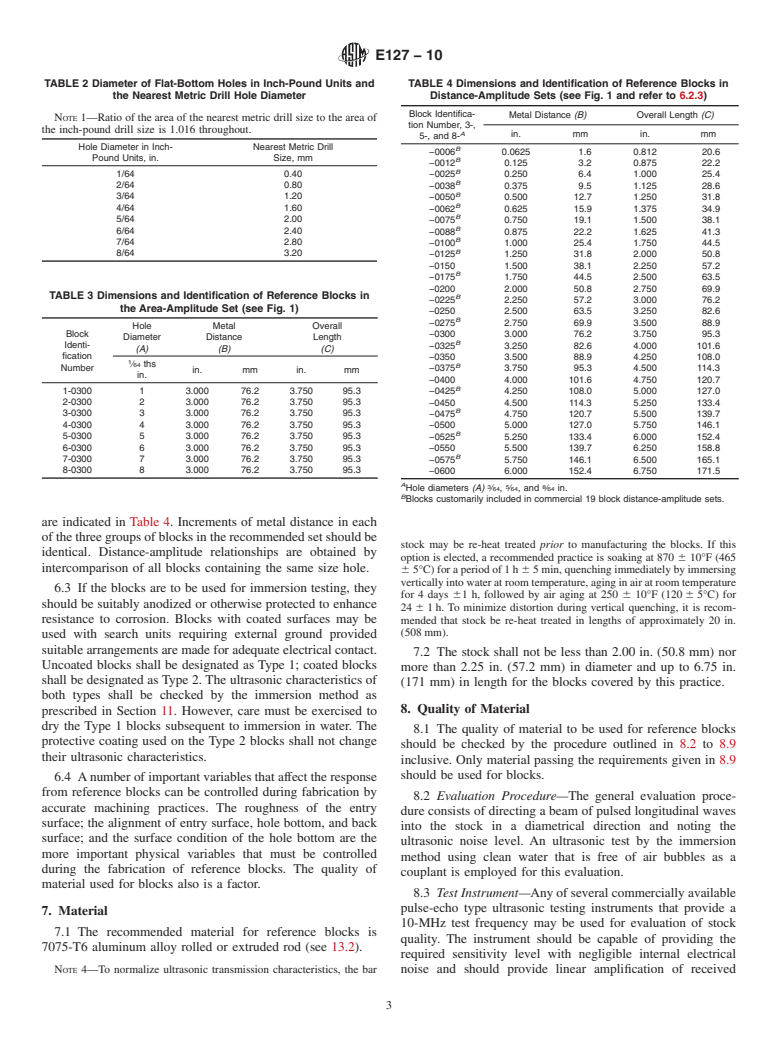

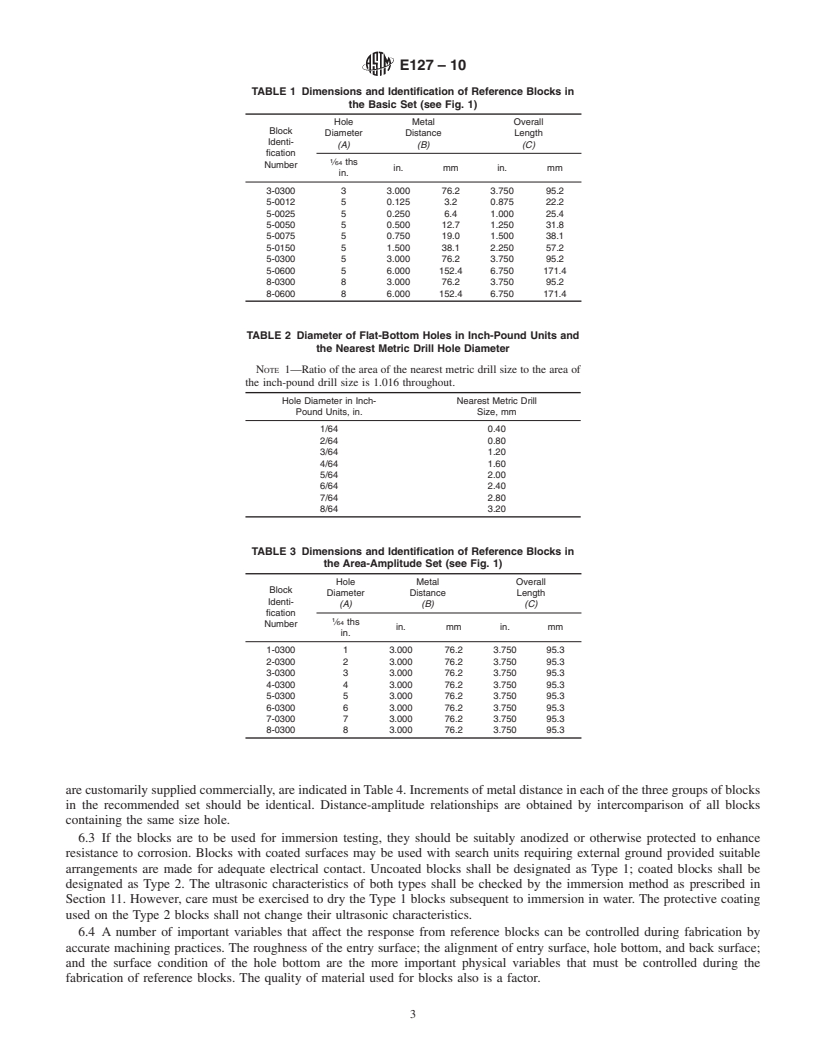

TABLE 1 Dimensions and Identification of Reference Blocks in

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E127–07 Designation: E127 – 10

Standard Practice for

Fabricating and Checking Aluminum Alloy Ultrasonic

1

Standard Reference Blocks

This standard is issued under the fixed designation E127; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This specification has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This practice covers a procedure for fabricating aluminum alloy ultrasonic standard reference blocks that can be used for

checking performance of ultrasonic testing equipment and for standardization and control of ultrasonic tests of aluminum alloy

products using pulsed longitudinal waves introduced into test material either by the direct-contact method or by the immersion

method. A recommended procedure for checking blocks is described and calibration data for a number of reference blocks are

tabulated.Statementsconcerningproceduresareprovidedwithoutadiscussionofthetechnicalbackgroundforthepreference.The

2

necessary technical background can be found in Refs. (1-16).

NOTE 1—Practice E428 and Guide E1158 also describe procedures for selecting material, fabricating blocks, and checking response. Unlike this

practice, there is no requirement for evaluation relative to a specified standard target.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

3

2.1 ASTM Standards:

E317 Practice for Evaluating Performance Characteristics of Ultrasonic Pulse-Echo Testing Instruments and Systems without

the Use of Electronic Measurement Instruments

E428 Practice for Fabrication and Control of Metal, Other than Aluminum, Reference Blocks Used in Ultrasonic Testing

E1158 Guide for Material Selection and Fabrication of Reference Blocks for the Pulsed Longitudinal Wave Ultrasonic Testing

of Metal and Metal Alloy Production Material

E1316 Terminology for Nondestructive Examinations

E1324 Guide for Measuring Some Electronic Characteristics of Ultrasonic Examination Instruments

3. Terminology

3.1 Definitions—For definitions of terms not specific to this practice, refer to Terminology E1316.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 angular error—the condition observed in ultrasonic tests of reference blocks when the response from the hole bottom is

not maximum while the search unit is positioned to obtain either a maximum number of back reflections from a reference block

or a maximum indication from its entry surface.Angular error results when the entry surface, hole bottom, and back surface are

not parallel to each other.

3.2.2 area-amplitude response curve—a curve showing the relationship between different areas of reflecting targets located at

a constant distance in an ultrasonic transmitting medium and their respective amplitudes of ultrasonic response.

3.2.3 back reflection—the indication, observed on the display screen of a test instrument, that represents the ultrasonic energy

reflected from the back surface of a reference block.

3.2.4 back surface—the end of a reference block that is opposite the entry surface.

1

ThispracticeisunderthejurisdictionofASTMCommitteeE07onNondestructiveTestingandisthedirectresponsibilityofSubcommitteeE07.06onUltrasonicMethod.

CurrenteditionapprovedDec.1,2007.PublishedJanuary2008.Originallyapprovedin1958.Lastpreviouseditionapprovedin2006asE127-06.DOI:10.1520/E0127-07.

Current edition approved Feb. 15, 2010. Published March 2010. Originally approved in 1958. Last previous edition approved in 2007 as E127-07. DOI:

10.1520/E0127-10.

2

The boldface numbers in parentheses refer to the list of references at the end of this practice.

3

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E127 – 10

3.2.5 entry surface—the end of a reference block through which ultrasonic energy mus

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.