ASTM E2161-06

(Terminology)Standard Terminology Relating to Performance Validation in Thermal Analysis

Standard Terminology Relating to Performance Validation in Thermal Analysis

SCOPE

1.1 Validation of methods and apparatus is requested or required for quality initiatives or where results may be used for legal purposes.

1.2 This standard provides terminology relating to validating performance of thermal analysis methods and instrumentation. Terms that are generally understood or defined adequately in other readily available sources are not included.

1.3 The terminology described in this document is that of the validation process and may differ from that traditionally encountered in ASTM standards.

1.4 A definition is a single sentence with additional information included in a Discussion.

General Information

Relations

Standards Content (Sample)

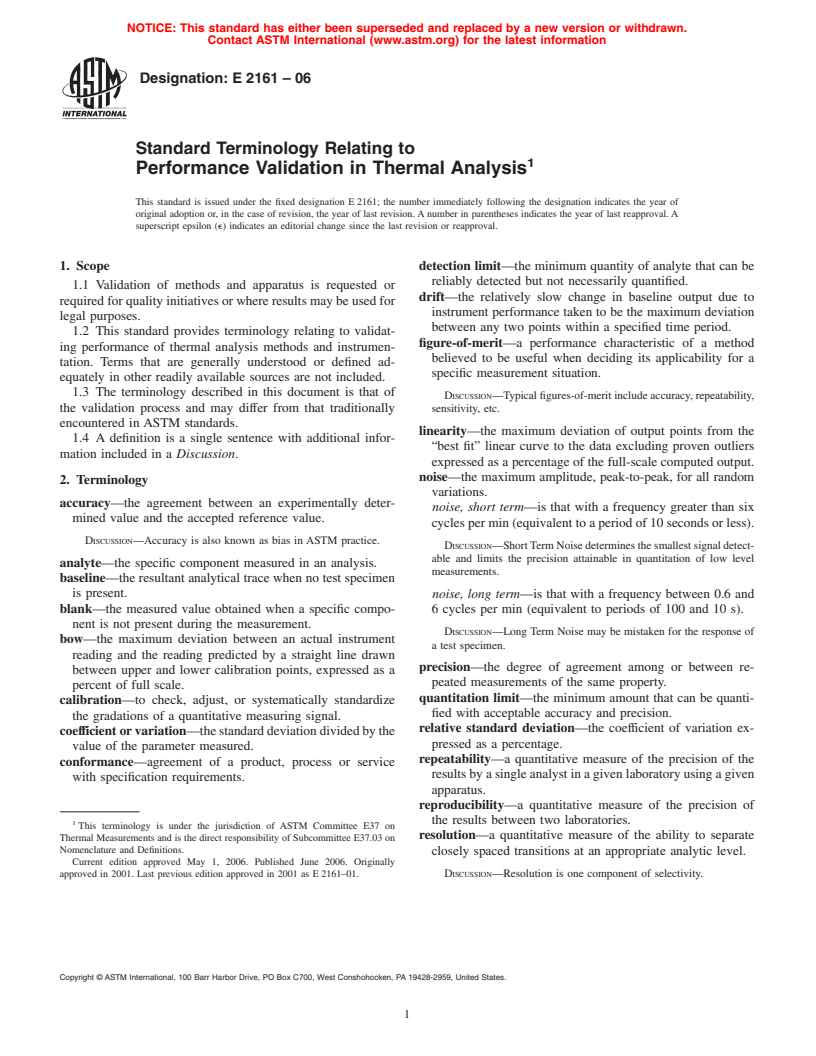

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2161–06

Standard Terminology Relating to

1

Performance Validation in Thermal Analysis

This standard is issued under the fixed designation E 2161; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope detection limit—the minimum quantity of analyte that can be

reliably detected but not necessarily quantified.

1.1 Validation of methods and apparatus is requested or

drift—the relatively slow change in baseline output due to

required for quality initiatives or where results may be used for

instrument performance taken to be the maximum deviation

legal purposes.

between any two points within a specified time period.

1.2 This standard provides terminology relating to validat-

figure-of-merit—a performance characteristic of a method

ing performance of thermal analysis methods and instrumen-

believed to be useful when deciding its applicability for a

tation. Terms that are generally understood or defined ad-

specific measurement situation.

equately in other readily available sources are not included.

1.3 The terminology described in this document is that of

DISCUSSION—Typical figures-of-merit include accuracy, repeatability,

the validation process and may differ from that traditionally

sensitivity, etc.

encountered in ASTM standards.

linearity—the maximum deviation of output points from the

1.4 A definition is a single sentence with additional infor-

“best fit” linear curve to the data excluding proven outliers

mation included in a Discussion.

expressed as a percentage of the full-scale computed output.

noise—the maximum amplitude, peak-to-peak, for all random

2. Terminology

variations.

accuracy—the agreement between an experimentally deter-

noise, short term—is that with a frequency greater than six

mined value and the accepted reference value.

cycles per min (equivalent to a period of 10 seconds or less).

DISCUSSION—Accuracy is also known as bias in ASTM practice.

DISCUSSION—ShortTerm Noise determines the smallest signal detect-

able and limits the precision attainable in quantitation of low level

analyte—the specific component measured in an analysis.

measurements.

baseline—the resultant analytical trace when no test specimen

is present.

noise, long term—is that with a frequency between 0.6 and

blank—the measured value obtained when a specific compo- 6 cycles per min (equivalent to periods of 100 and 10 s).

nent is not present during the measurement.

DISCUSSION—Long Term Noise may be mistaken for the response of

bow—the maximum deviation between an actual instrument

a test specimen.

reading and the reading predicted by a straight line drawn

precision—the degree of agreement among or between re-

between upper and lower calibration points, expressed as a

peated measurements of the same property.

percent of full scale.

quantitation limit—the minimum amount that can be quanti-

calibration—to check, adjust, or systematically standardize

fied with acceptable accuracy and precision.

the gradations of a quantitative measuring signal.

relative standard deviation—the coefficient of variation ex-

coefficient or variation—thestandarddeviationdividedbythe

pressed as a percentage.

value of the parameter measured.

repeatability—a quantitative measure of the precision of the

conformance—agreemen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.