ASTM E1025-05

(Practice)Standard Practice for Design, Manufacture, and Material Grouping Classification of Hole-Type Image Quality Indicators (IQI) Used for Radiology

Standard Practice for Design, Manufacture, and Material Grouping Classification of Hole-Type Image Quality Indicators (IQI) Used for Radiology

ABSTRACT

This practice covers the design, material grouping classification, and manufacture of hole-type image quality indicators (IQI) used to indicate the quality of X-ray and gamma-ray radiologic images.

SCOPE

1.1 This practice covers the design, material grouping classification, and manufacture of hole-type image quality indicators (IQI) used to indicate the quality of radiologic images.

1.2 This practice is applicable to X-ray and gamma-ray radiology.

1.3 The values stated in inch-pound units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1025 – 05

Standard Practice for

Design, Manufacture, and Material Grouping Classification

of Hole-Type Image Quality Indicators (IQI) Used for

1

Radiology

This standard is issued under the fixed designation E1025; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope N06025, N06045, and N06696)* and Nickel-Chromium-

2 Cobalt-Molybdenum Alloy (UNS N06617) Rod, Bar, and

1.1 This practice covers the design, material grouping

Wire

classification, and manufacture of hole-type image quality

E746 Practice for Determining Relative Image Quality

indicators (IQI) used to indicate the quality of radiologic

Response of Industrial Radiographic Imaging Systems

images.

E747 Practice for Design, Manufacture and Material

1.2 This practice is applicable to X-ray and gamma-ray

Grouping Classification of Wire Image Quality Indicators

radiology.

(IQI) Used for Radiology

1.3 The values stated in inch-pound units are to be regarded

E1735 Test Method for Determining Relative Image Qual-

as standard.

ity of Industrial Radiographic Film Exposed to

1.4 This standard does not purport to address all of the

X-Radiation from 4 to 25 MeV

safety concerns, if any, associated with its use. It is the

E1316 Terminology for Nondestructive Examinations

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3. Terminology

bility of regulatory limitations prior to use.

3.1 Definitions—Thedefinitionsoftermsrelatingtogamma

2. Referenced Documents andX-radiologyinTerminologyE1316,SectionD,shallapply

3

to the terms used in this practice.

2.1 ASTM Standards:

B139/B139M Specification for Phosphor Bronze Rod, Bar,

4. Hole-Type IQI Requirements

and Shapes

4.1 Image quality indicators (IQIs) used to determine

B150M Specification forAluminum Bronze, Rod, Bar, and

4 radiologic-image quality levels shall conform to the following

Shapes [Metric]

requirements.

B161 Specification for Nickel Seamless Pipe and Tube

4.1.1 Standard Hole-Type IQIs:

B164 Specification for Nickel-Copper Alloy Rod, Bar, and

4.1.1.1 Image quality indicators (IQIs) shall be fabricated

Wire

from materials or alloys identified or listed in accordance with

B166 Specification for Nickel-Chromium-Iron Alloys

7.3. Other materials may be used in accordance with 7.4.

(UNS N06600, N06601, N06603, N06690, N06693,

4.1.1.2 Image quality indicators (IQIs) shall dimensionally

conform to the requirements of Fig. 1.

4.1.1.3 Both the rectangular and the circular IQI shall be

1

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

identified with number(s) made of lead or a material of similar

structive Testing and is the direct responsibility of Subcommittee E07.01 on

radiation opacity. The number shall be bonded to the rectan-

Radiographic Practice and Penetrameters.

gular IQI’s and shall be placed adjacent to circular IQI’s to

Current edition approved June 1, 2005. Published June 2005. Originally

approved in 1984. Last previous edition approved in 1998 as E1025-98. DOI: provide identification of the IQI on the image. The identifica-

10.1520/E1025-05.

tion numbers shall indicate the thickness of the IQI in

2

For ASME Boiler and Pressure Vessel Code applications see related Practice

thousandths of an inch, that is, a number 10 IQI is 0.010 in.

SE-1025 in Section II of that Code.

3

thick, a number 100 IQI is 0.100 in. thick, etc. Additional

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

identification requirements are provided in 7.2.

Standards volume information, refer to the standard’s Document Summary page on

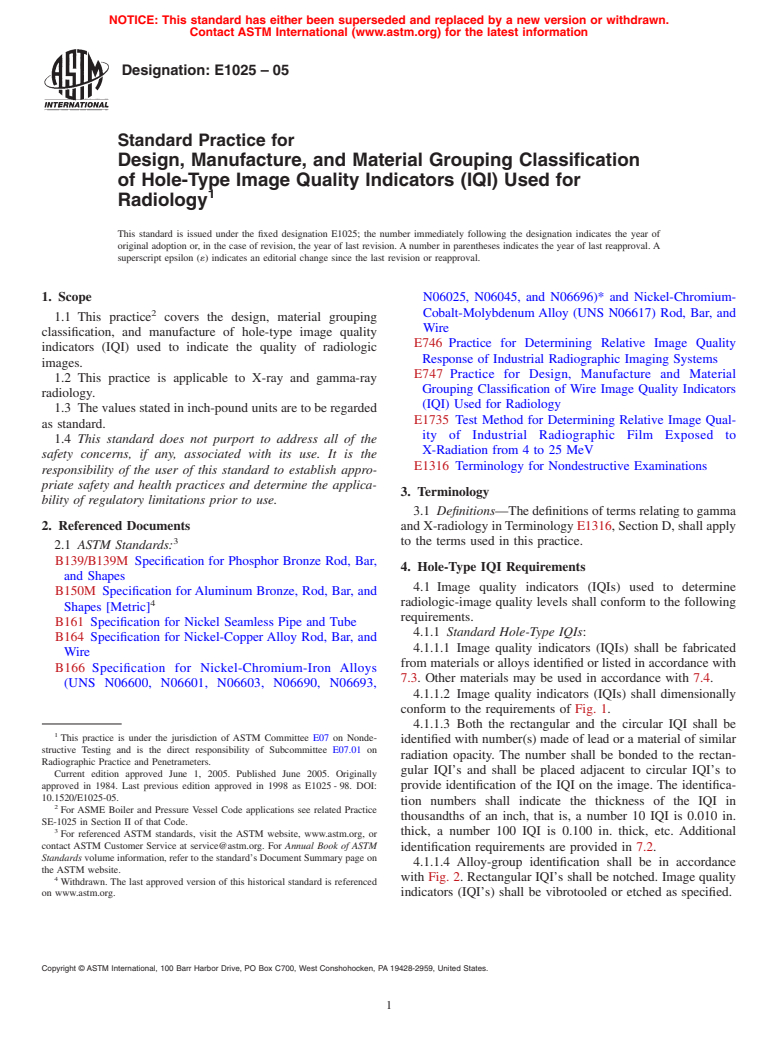

4.1.1.4 Alloy-group identification shall be in accordance

the ASTM website.

4 with Fig. 2. Rectangular IQI’s shall be notched. Image quality

Withdrawn. The last approved version of this historical standard is referenced

indicators (IQI’s) shall be vibrotooled or etched as specified.

on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1025 – 05

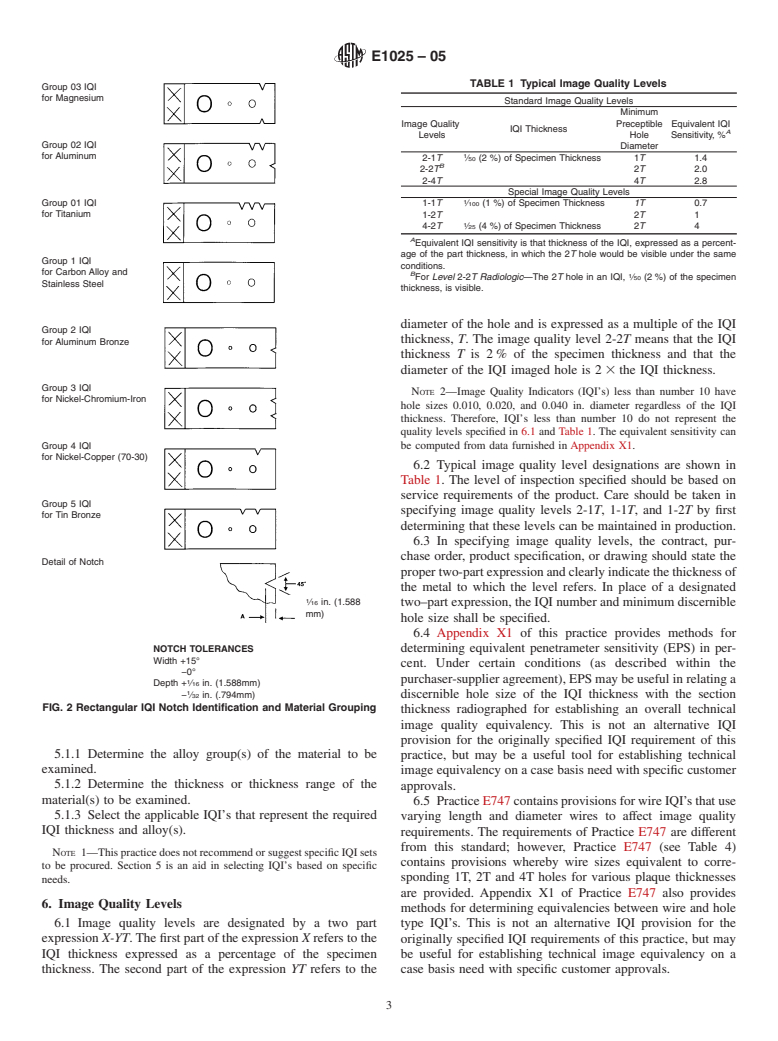

NOTE 1—All dimensions in inches (Note 6).

NOTE 2—Tolerances for IQI thickness and hole diameter.

NOTE 3—XX identification number equals T in .001 inches.

NOTE 4—IQIs No. 1 through 9 are not 1T,2T, and 4T.

NOTE 5—Holes shall be true and normal to the IQI. Do not chamfer.

NOTE 6—To convert inch dimensions to metric, multiply by 25.4.

Identification

Number T Tolerances

(Note 3)A B C D E F (Note 2)

1–4 1.500 0.750 0.438 0.250 0.500 0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.