ASTM D1946-90(2000)

(Practice)Standard Practice for Analysis of Reformed Gas by Gas Chromatography

Standard Practice for Analysis of Reformed Gas by Gas Chromatography

SCOPE

1.1 This practice covers the determination of the chemical composition of reformed gases and similar gaseous mixtures containing the following components: hydrogen, oxygen, nitrogen, carbon monoxide, carbon dioxide, methane, ethane, and ethylene.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1946–90(Reapproved 2000)

Standard Practice for

1

Analysis of Reformed Gas by Gas Chromatography

This standard is issued under the fixed designation D 1946; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Apparatus

1.1 This practice covers the determination of the chemical 5.1 Detector—The detector shall be a thermal conductivity

composition of reformed gases and similar gaseous mixtures type or its equivalent in stability and sensitivity. The thermal

containing the following components: hydrogen, oxygen, ni- conductivity detector must be sufficiently sensitive to produce

trogen, carbon monoxide, carbon dioxide, methane, ethane, a signal of at least 0.5 mV for 1 mol % methane in a 0.5-mL

and ethylene. sample.

1.2 This standard does not purport to address all of the 5.2 Recording Instruments—Either strip chart recorders or

safety concerns, if any, associated with its use. It is the electronic integrators, or both, are used to display the separated

responsibility of the user of this standard to establish appro- components. Although a strip chart recorder is not required

priate safety and health practices and determine the applica- when using electronic integration, it is highly desirable for

bility of regulatory limitations prior to use. evaluation of instrument performance.

5.2.1 Therecorder,whenused,shallbeastripchartrecorder

2. Referenced Documents

with a full-range scale of 5 mV or less (1 mV preferred). The

2.1 ASTM Standards: width of the chart shall be not less than 150 mm. A maximum

2

E 260 Practice for Packed Column Gas Chromatography

pen response time of2s(1s preferred) and a minimum chart

speed of 10 mm/min shall be required. Faster speeds up to 100

3. Summary of Practice

mm/min are desirable if the chromatogram is to be interpreted

3.1 Components in a sample of reformed gas are physically

using manual methods to obtain areas.

separatedbygaschromatographyandcomparedtocorrespond-

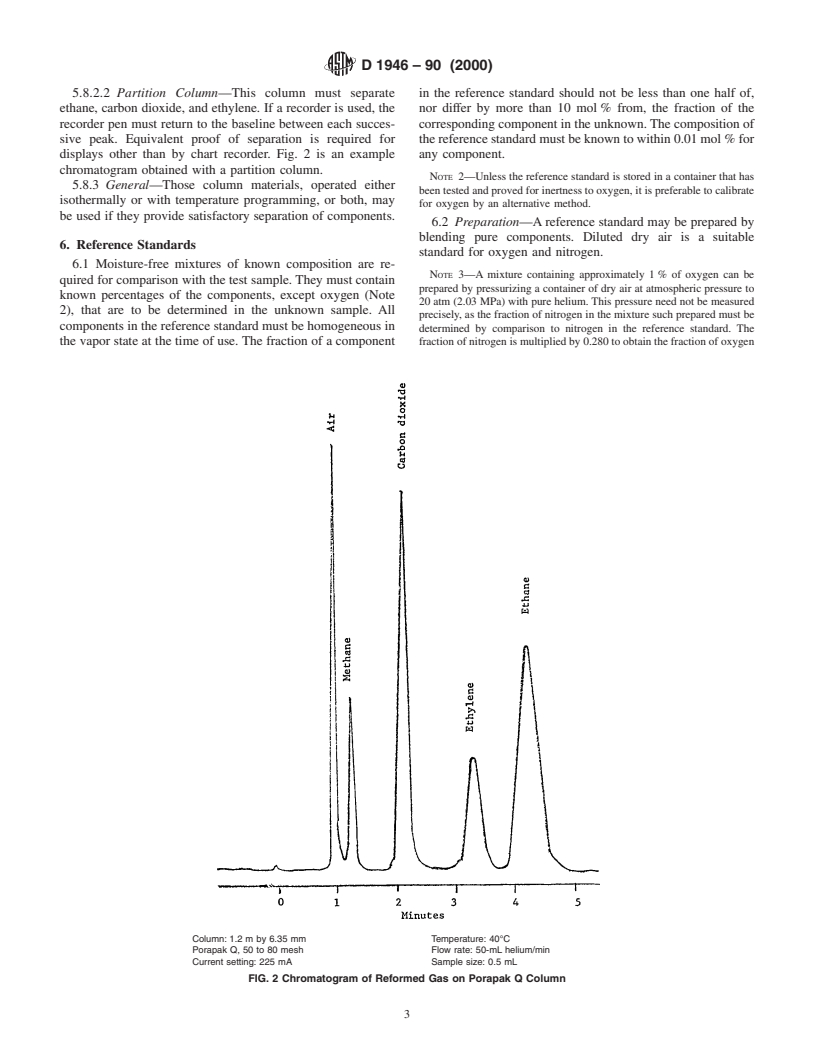

5.2.2 Electronic or Computing Integrators—Proof of sepa-

ing components of a reference standard separated under

ration and response equivalent to that for the recorder is

identical operating conditions, using a reference standard

required for displays other than by chart recorder.

mixture of known composition. The composition of the re-

5.3 Attenuator—If manual methods are used to interpret the

formed gas is calculated by comparison of either the peak

chromatogram, an attenuator must be used with the detector

height or area response of each component with the corre-

output signal to keep the peak maxima within the range of the

sponding value of that component in the reference standard.

recorder chart.The attenuator must be accurate to within 0.5 %

between the attenuator range steps.

4. Significance and Use

5.4 Sample Inlet System:

4.1 The information about the chemical composition can be

5.4.1 The sample inlet system must be constructed of

used to calculate physical properties of the gas, such as heating

materials that are inert and nonadsorptive with respect to the

(calorific) value and relative density. Combustion characteris-

components in the sample. The preferred material of construc-

tics, products of combustion, toxicity, and interchangeability

tion is stainless steel. Copper and copper-bearing alloys are

with other fuel gases may also be inferred from the chemical

unacceptable.

composition.

5.4.2 Provision must be made to introduce into the carrier

gas ahead of the analyzing column a gas-phase sample that has

beenentrappedineitherafixedvolumelooportubularsection.

1

This practice is under the jurisdiction of ASTM Committee D-3 on Gaseous

The injected volume must be reproducible such that successive

Fuels and is the direct responsibility of Subcommittee D03.07 on Analysis of

runs of the same sample agree within the limits of repeatability

Chemical Composition of Gaseous Fuels.

Current edition approved March 30, 1990. Published May 1990. Originally

for the concentration range as specified in 11.1.1.

published as 1946 – 62 T. Last previous edition D 1946 – 82.

2

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1946–90 (2000)

5.4.3 If the instrument is calibrated with pure components, 5.8.2 Either an adsorption-type column or a partition-type

the inlet system shall be equipped to introduce a sample at less column, or both, may be used to make the analysis.

than atmospheric pressure. The pressure-sensing device must

NOTE 1—Se

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.