ASTM D6550-10(2015)

(Test Method)Standard Test Method for Determination of Olefin Content of Gasolines by Supercritical-Fluid Chromatography

Standard Test Method for Determination of Olefin Content of Gasolines by Supercritical-Fluid Chromatography

SIGNIFICANCE AND USE

5.1 Gasoline-range olefinic hydrocarbons have been demonstrated to contribute to photochemical reactions in the atmosphere, which result in the formation of photochemical smog in susceptible urban areas.

5.2 The California Air Resources Board (CARB) has specified a maximum allowable limit of total olefins in motor gasoline. This necessitates an appropriate analytical test method for determination of total olefins to be used both by regulators and producers.

5.3 This test method compares favorably with Test Method D1319 (FIA) for the determination of total olefins in motor gasolines. It does not require any sample preparation, has a comparatively short analysis time of about 10 min, and is readily automated. Alternative methods for determination of olefins in gasoline include Test Methods D6839 and D6296.

SCOPE

1.1 This test method covers the determination of the total amount of olefins in blended motor gasolines and gasoline blending stocks by supercritical-fluid chromatography (SFC). Results are expressed in terms of mass % olefins. The application range is from 1 mass % to 25 mass % total olefins.

1.2 This test method can be used for analysis of commercial gasolines, including those containing varying levels of oxygenates, such as methyl tert/butyl ether (MTBE), diisopropyl ether (DIPE), methyl tert/amyl ether (TAME), and ethanol, without interference.

Note 1: This test method has not been designed for the determination of the total amounts of saturates, aromatics, and oxygenates.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6550 −10(Reapproved 2015)

Standard Test Method for

Determination of Olefin Content of Gasolines by

Supercritical-Fluid Chromatography

This standard is issued under the fixed designation D6550; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D6296 Test Method for Total Olefins in Spark-ignition

Engine Fuels by Multidimensional Gas Chromatography

1.1 This test method covers the determination of the total

D6299 Practice for Applying Statistical Quality Assurance

amount of olefins in blended motor gasolines and gasoline

and Control Charting Techniques to Evaluate Analytical

blending stocks by supercritical-fluid chromatography (SFC).

Measurement System Performance

Results are expressed in terms of mass % olefins. The

D6839 Test Method for Hydrocarbon Types, Oxygenated

application range is from 1 mass % to 25 mass % total olefins.

Compounds, and Benzene in Spark Ignition Engine Fuels

1.2 This test method can be used for analysis of commercial

by Gas Chromatography

gasolines, including those containing varying levels of

oxygenates, such as methyl tert/butyl ether (MTBE), diisopro-

3. Terminology

pyl ether (DIPE), methyl tert/amyl ether (TAME), and ethanol,

3.1 Definitions of Terms Specific to This Standard:

without interference.

3.1.1 critical pressure, n—the pressure needed to condense

NOTE 1—This test method has not been designed for the determination

a gas to a liquid at the critical temperature.

of the total amounts of saturates, aromatics, and oxygenates.

3.1.2 critical temperature, n—the highest temperature at

1.3 The values stated in SI units are to be regarded as

which a gaseous fluid can be condensed to a liquid by means

standard. No other units of measurement are included in this

of compression.

standard.

3.1.3 supercritical fluid, n—a fluid maintained above its

1.4 This standard does not purport to address all of the

critical temperature and critical pressure.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1.4 supercritical-fluid chromatography (SFC), n—a type

priate safety and health practices and determine the applica-

of chromatography that employs a supercritical fluid as the

bility of regulatory limitations prior to use.

mobile phase.

2. Referenced Documents

4. Summary of Test Method

2.1 ASTM Standards:

4.1 A small aliquot of the fuel sample is injected onto a set

D1319 Test Method for Hydrocarbon Types in Liquid Petro-

of two chromatographic columns connected in series and

leum Products by Fluorescent Indicator Adsorption

transported using supercritical carbon dioxide (CO)asthe

D4052 Test Method for Density, Relative Density, and API

mobile phase. The first column is packed with high-surface-

Gravity of Liquids by Digital Density Meter

area silica particles. The second column contains either high-

D5186 Test Method for Determination of the Aromatic

surface-area silica particles loaded with silver ions or strong-

Content and Polynuclear Aromatic Content of Diesel

cation-exchange material loaded with silver ions.

Fuels and Aviation Turbine Fuels By Supercritical Fluid

Chromatography

4.2 Two switching valves are used to direct the different

classes of components through the chromatographic system to

This test method is under the jurisdiction of ASTM Committee D02 on

the detector. In a forward-flow mode, saturates (normal and

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

branchedalkanes,cyclicalkanes)passthroughbothcolumnsto

Subcommittee D02.04.0C on Liquid Chromatography.

the detector, while the olefins are trapped on the silver-loaded

Current edition approved April 1, 2015. Published June 2015. Originally

column and the aromatics and oxygenates are retained on the

approved in 2000. Last previous edition approved in 2010 as D6550 – 10. DOI:

10.1520/D6550-10R15.

silica column. Aromatic compounds and oxygenates are sub-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

sequently eluted from the silica column to the detector in a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

back-flush mode. Finally, the olefins are back-flushed from the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. silver-loaded column to the detector.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6550−10 (2015)

TABLE 1 Typical Columns

Silica Column Silver-loaded Column

Vendor Merck Vendor Hypersil, Phenomenex, Selerity

Packing material Lichrospher SI 60 Packing material Hypersil SCX, Selectosil SCX, Ag+ form

Particle size, µm 5 Particle size, µm 5

Length, mm 250 Length, mm 100 or 50

Internal diameter, mm 4.6 Internal diameter, mm 4.6

4.3 A flame-ionization detector (FID) is used for quantita- 6.1.2.1 AUVdetectorwithaverysmalldeadvolumecanbe

tion. Calibration is based on the area of the chromatographic inserted between the column and the FID and operated in

signal for olefins, relative to standard reference materials, series.

which contain a known mass % of total olefins as corrected for 6.1.2.2 A post-column splitting device, consisting of a

density. T-junctionwithanappropriateflowrestrictortotheFID,canbe

inserted between the column and the UV detector. Using the

5. Significance and Use

T-junction, the two detectors can be operated in parallel. The

combination of restrictors (before the FID and after the UV

5.1 Gasoline-range olefinic hydrocarbons have been dem-

detector) shall allow the pump and detector to perform as

onstrated to contribute to photochemical reactions in the

specified.

atmosphere, which result in the formation of photochemical

6.1.3 Sample-inlet System—A liquid-sample injection

smog in susceptible urban areas.

valve is required, capable of introducing (sub-)microlitre

5.2 The CaliforniaAir Resources Board (CARB) has speci-

volume with a precision better than 0.5 %. A 1 µL injection

fied a maximum allowable limit of total olefins in motor

volume was found to be adequate in combination with 4.6 mm

gasoline. This necessitates an appropriate analytical test

inside diameter columns. Corresponding injection volumes are

method for determination of total olefins to be used both by

200 nL and 50 nL for columns with inside diameters of 2 mm

regulators and producers.

and 1 mm, respectively. The sample inlet system shall be

5.3 This test method compares favorably with Test Method

installed and operated in a manner such that the chromato-

D1319 (FIA) for the determination of total olefins in motor

graphic separation is not negatively affected.

gasolines. It does not require any sample preparation, has a

6.1.4 Columns—Two columns of equal inside diameter are

comparatively short analysis time of about 10 min, and is

required:

readily automated. Alternative methods for determination of

6.1.4.1 A high-surface-area-silica column, capable of sepa-

olefins in gasoline include Test Methods D6839 and D6296.

rating alkanes and olefins from aromatics as specified in

Section 8. Typically, one or several 250 mm long columns are

6. Apparatus

used. These columns are packed with particles having an

6.1 Supercritical-fluid Chromatograph (SFC)—Any SFC average diameter of 5 µm or less, 600 nm (60 Å) pores, and a

instrumentation can be used that has the following character-

surface area of ≥350 m /g.

istics and meets the performance requirements specified in

NOTE 3—Columns suitable forTest Method D5186 are also suitable for

Section 8.

the present method. A typical example is shown in Table 1.

NOTE 2—The SFC instruments suitable for Test Method D5186 are

6.1.4.2 A silver-loaded-silica column or a cation-exchange

suitable for this test method, if equipped with two switching valves, as

column in the silver form. Cation-exchange columns are

described under 6.1.7.

claimed to yield more stable columns. Typically, one 50 mm

6.1.1 Pump—The SFC pump shall be able to operate at the

or 100 mm long column packed with particles with an average

required pressures (typically up to about 30 MPa) and deliver

diameter of 5 µm is used for the analysis.

a sufficiently stable flow to meet the requirements of retention-

NOTE 4—Some columns that have been used successfully are shown in

time precision (better than 0.3 %) and detection background

Table 1.

(see Section 8). The characteristics of the pump will largely

6.1.5 Column-temperature Control—The chromatograph

determine the optimum column diameter. The use of 4.6 mm

shall be capable of column temperature control to within

internal diameter (i.d.) columns requires a pump capacity of at

0.5 °C or less.

least 1 mL⁄min of liquid CO . Columns with an inside

6.1.6 Computor or Electronic Integrator—Means shall be

diameterof2 mmand1 mmrequireminimumpumpcapacities

providedforthedeterminationofaccumulatedpeakareas.This

of 200 µL⁄min and 50 µL⁄min, respectively.

can be done by means of a computer or electronic integrator.

6.1.2 Detectors—A FID is required for quantitation. A flow

The computer or integrator shall have the capability of correct-

restrictor shall be installed immediately before the FID. This

ing for baseline shifts during the run.

restrictor serves to maintain the required pressure in the

column, while allowing the pump and detector to perform as

specified. A (diode-array or variable wavelength) UV detector

Sample valves with loop volumes down to 50 nL are commercially available

for establishing optimum switching times (see Sections 8 and

from Valco (Houston, TX).

9) is optional. Such a detector can be incorporated in two

Anderson, P. E., Demirbueker, M., and Blomberg, L. G., Journal of

different manners. Chromatography, 596, 1991, pp. 301-311.

D6550−10 (2015)

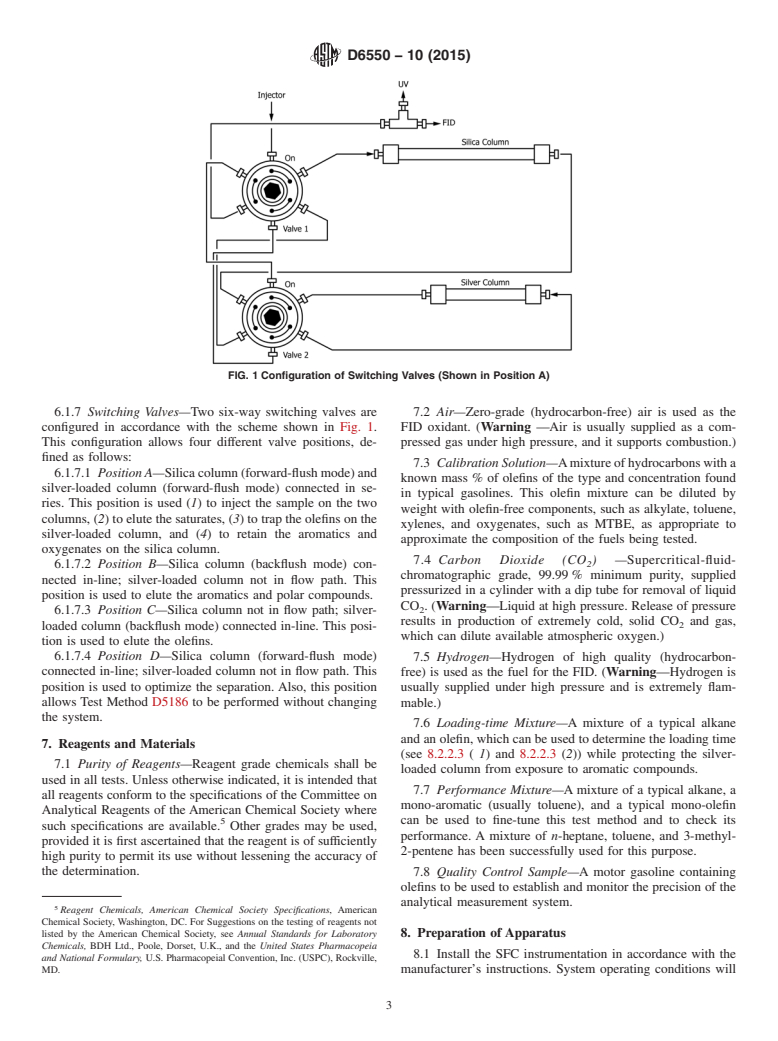

FIG. 1Configuration of Switching Valves (Shown in Position A)

6.1.7 Switching Valves—Two six-way switching valves are 7.2 Air—Zero-grade (hydrocarbon-free) air is used as the

configured in accordance with the scheme shown in Fig. 1. FID oxidant. (Warning —Air is usually supplied as a com-

This configuration allows four different valve positions, de- pressed gas under high pressure, and it supports combustion.)

fined as follows:

7.3 CalibrationSolution—Amixtureofhydrocarbonswitha

6.1.7.1 PositionA—Silicacolumn(forward-flushmode)and

known mass % of olefins of the type and concentration found

silver-loaded column (forward-flush mode) connected in se-

in typical gasolines. This olefin mixture can be diluted by

ries. This position is used (1) to inject the sample on the two

weight with olefin-free components, such as alkylate, toluene,

columns, (2) to elute the saturates, (3) to trap the olefins on the

xylenes, and oxygenates, such as MTBE, as appropriate to

silver-loaded column, and (4) to retain the aromatics and

approximate the composition of the fuels being tested.

oxygenates on the silica column.

7.4 Carbon Dioxide (CO)—Supercritical-fluid-

6.1.7.2 Position B—Silica column (backflush mode) con-

chromatographic grade, 99.99 % minimum purity, supplied

nected in-line; silver-loaded column not in flow path. This

pressurized in a cylinder with a dip tube for removal of liquid

position is used to elute the aromatics and polar compounds.

CO.(Warning—Liquid at high pressure. Release of pressure

6.1.7.3 Position C—Silica column not in flow path; silver-

results in production of extremely cold, solid CO and gas,

loaded column (backflush mode) connected in-line. This posi-

which can dilute available atmospheric oxygen.)

tion is used to elute the olefins.

6.1.7.4 Position D—Silica column (forward-flush mode)

7.5 Hydrogen—Hydrogen of high quality (hydrocarbon-

connected in-line; silver-loaded column not in flow path. This free) is used as the fuel for the FID. (Warning—Hydrogen is

position is used to optimize the separation. Also, this position

usually supplied under high pressure and is extremely flam-

allows Test Method D5186 to be performed without changing mable.)

the system.

7.6 Loading-time Mixture—A mixture of a typical alkane

and an olefin, which can be used to determine the loading time

7. Reagents and Materials

(see 8.2.2.3 ( 1) and 8.2.2.3 (2)) while protecting the silver-

7.1 Purity of Reagents—Reagent grade chemicals shall be

loaded column from exposure to aromatic compounds.

used in all tests. Unless otherwise indicated, it is intended that

7.7 Performance Mixture—A mixture of a typical alkane, a

all reagents conform to the specifications of the Committee on

mono-aromatic (usually toluene), and a typical mono-olefin

Analytical Reagents of the American Chemical Society where

5 can be used to fine-tune this test method and to check its

such specifications are available. Other grades may be used,

performance. A mixture of n-heptane, toluene, and 3-methyl-

provided it is first ascertained that the reagent is of sufficiently

2-pentene has been successfully used for this purpose.

high purity to permit its use without lessening the accuracy of

the determination. 7.8 Quality Control Sample—A motor gasoline containing

olefins to be used to establish and monitor the precision of the

analytical measurement system.

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

listed by the American Chemical Society, see Annual Standards for Laboratory 8. Preparation of Apparatus

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

8.1 Install the SFC instrumentation in accordance with the

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

MD. manufacturer’s instructions. System operating conditions will

D6550−10 (2015)

depend on the column used and optimization of performance. thought to have occurred if the detector value (S ) has

End

The conditions listed in Table 1 have been used successfully. If returned to the baseline value observed before the elution of

the performance characteristics in terms of retention and any peaks (S ) to within 0.1 % of the height of the

Baseline

resolution, specified in 8.2, are not achieved, the temperature, aromatics peak (h ), that is,

Aromatics

pressure, or mobile-phase flow rate can be modified to achieve

S # S 1h /1000 (2)

End Baseline Aromatics

compliance.Asilica column of low activity can be reactivated

8.2.2.3 Silver-loaded Column—This column is operated ex-

by solvent rinsing, using accepted liquid-chromatographic

clusively as an olefin tr

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6550 − 10 D6550 − 10 (Reapproved 2015)

Standard Test Method for

Determination of Olefin Content of Gasolines by

Supercritical-Fluid Chromatography

This standard is issued under the fixed designation D6550; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*Scope

1.1 This test method covers the determination of the total amount of olefins in blended motor gasolines and gasoline blending

stocks by supercritical-fluid chromatography (SFC). Results are expressed in terms of mass % olefins. The application range is

from 11 mass % to 25 mass 25 mass % total olefins.

1.2 This test method can be used for analysis of commercial gasolines, including those containing varying levels of oxygenates,

such as methyl tert/butyl ether (MTBE), diisopropyl ether (DIPE), methyl tert/amyl ether (TAME), and ethanol, without

interference.

NOTE 1—This test method has not been designed for the determination of the total amounts of saturates, aromatics, and oxygenates.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D1319 Test Method for Hydrocarbon Types in Liquid Petroleum Products by Fluorescent Indicator Adsorption

D4052 Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter

D5186 Test Method for Determination of the Aromatic Content and Polynuclear Aromatic Content of Diesel Fuels and Aviation

Turbine Fuels By Supercritical Fluid Chromatography

D6296 Test Method for Total Olefins in Spark-ignition Engine Fuels by Multidimensional Gas Chromatography

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

D6839 Test Method for Hydrocarbon Types, Oxygenated Compounds, and Benzene in Spark Ignition Engine Fuels by Gas

Chromatography

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 critical pressure, n—the pressure needed to condense a gas to a liquid at the critical temperature.

3.1.2 critical temperature, n—the highest temperature at which a gaseous fluid can be condensed to a liquid by means of

compression.

3.1.3 supercritical fluid, n—a fluid maintained above its critical temperature and critical pressure.

3.1.4 supercritical-fluid chromatography (SFC), n—a type of chromatography that employs a supercritical fluid as the mobile

phase.

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.04.0C on Liquid Chromatography.

Current edition approved Oct. 1, 2010April 1, 2015. Published November 2010June 2015. Originally approved in 2000. Last previous edition approved in 20052010 as

D6550D6550 – 10.–05. DOI: 10.1520/D6550-10.10.1520/D6550-10R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6550 − 10 (2015)

4. Summary of Test Method

4.1 A small aliquot of the fuel sample is injected onto a set of two chromatographic columns connected in series and transported

using supercritical carbon dioxide (CO ) as the mobile phase. The first column is packed with high-surface-area silica particles.

The second column contains either high-surface-area silica particles loaded with silver ions or strong-cation-exchange material

loaded with silver ions.

4.2 Two switching valves are used to direct the different classes of components through the chromatographic system to the

detector. In a forward-flow mode, saturates (normal and branched alkanes, cyclic alkanes) pass through both columns to the

detector, while the olefins are trapped on the silver-loaded column and the aromatics and oxygenates are retained on the silica

column. Aromatic compounds and oxygenates are subsequently eluted from the silica column to the detector in a back-flush mode.

Finally, the olefins are back-flushed from the silver-loaded column to the detector.

4.3 A flame-ionization detector (FID) is used for quantitation. Calibration is based on the area of the chromatographic signal

for olefins, relative to standard reference materials, which contain a known mass % of total olefins as corrected for density.

5. Significance and Use

5.1 Gasoline-range olefinic hydrocarbons have been demonstrated to contribute to photochemical reactions in the atmosphere,

which result in the formation of photochemical smog in susceptible urban areas.

5.2 The California Air Resources Board (CARB) has specified a maximum allowable limit of total olefins in motor gasoline.

This necessitates an appropriate analytical test method for determination of total olefins to be used both by regulators and

producers.

5.3 This test method compares favorably with Test Method D1319 (FIA) for the determination of total olefins in motor

gasolines. It does not require any sample preparation, has a comparatively short analysis time of about 10 min, and is readily

automated. Alternative methods for determination of olefins in gasoline include Test Methods D6839 and D6296.

6. Apparatus

6.1 Supercritical-fluid Chromatograph (SFC)—Any SFC instrumentation can be used that has the following characteristics and

meets the performance requirements specified in Section 8.

NOTE 2—The SFC instruments suitable for Test Method D5186 are suitable for this test method, if equipped with two switching valves, as described

under 6.1.7.

6.1.1 Pump—The SFC pump shall be able to operate at the required pressures (typically up to about 30 MPa) 30 MPa) and

deliver a sufficiently stable flow to meet the requirements of retention-time precision (better than 0.3 %) and detection background

(see Section 8). The characteristics of the pump will largely determine the optimum column diameter. The use of 4.6-mm4.6 mm

internal diameter (i.d.) columns requires a pump capacity of at least 11 mL ⁄ mL/min min of liquid CO . Columns with an inside

diameter of 22 mm and 1 mm 1 mm require minimum pump capacities of 200200 μL ⁄min and 5050 μL ⁄ μL/min, min, respectively.

6.1.2 Detectors—A FID is required for quantitation. A flow restrictor shall be installed immediately before the FID. This

restrictor serves to maintain the required pressure in the column, while allowing the pump and detector to perform as specified.

A (diode-array or variable wavelength) UV detector for establishing optimum switching times (see Sections 8 and 9) is optional.

Such a detector can be incorporated in two different manners.

6.1.2.1 A UV detector with a very small dead volume can be inserted between the column and the FID and operated in series.

6.1.2.2 A post-column splitting device, consisting of a T-junction with an appropriate flow restrictor to the FID, can be inserted

between the column and the UV detector. Using the T-junction, the two detectors can be operated in parallel. The combination of

restrictors (before the FID and after the UV detector) shall allow the pump and detector to perform as specified.

6.1.3 Sample-inlet System—A liquid-sample injection valve is required, capable of introducing (sub-)microlitre volume with

a precision better than 0.5 %. A 1-μL1 μL injection volume was found to be adequate in combination with 4.6-mm4.6 mm inside

diameter columns. Corresponding injection volumes are 200200 nL and 50 nL 50 nL for columns with inside diameters of 22 mm

and 1 mm, 1 mm, respectively. The sample inlet system shall be installed and operated in a manner such that the chromatographic

separation is not negatively affected.

Sample valves with loop volumes down to 50 nL 50 nL are commercially available from Valco (Houston, TX).

TABLE 1 Typical Columns

Silica Column Silver-loaded Column

Vendor Merck Vendor Hypersil, Phenomenex, Selerity

Packing material Lichrospher SI 60 Packing material Hypersil SCX, Selectosil SCX, Ag+ form

Particle size, μm 5 Particle size, μm 5

Length, mm 250 Length, mm 100 or 50

Internal diameter, mm 4.6 Internal diameter, mm 4.6

D6550 − 10 (2015)

6.1.4 Columns—Two columns of equal inside diameter are required:

6.1.4.1 A high-surface-area-silica column, capable of separating alkanes and olefins from aromatics as specified in Section 8.

Typically, one or several 250-mm250 mm long columns are used. These columns are packed with particles having an average

diameter of 5 μm 5 μm or less, 600-nm (60-Å)600 nm (60 Å) pores, and a surface area of ≥350 m≥350 m /g.

NOTE 3—Columns suitable for Test Method D5186 are also suitable for the present method. A typical example is shown in Table 1.

6.1.4.2 A silver-loaded-silica column or a cation-exchange column in the silver form. Cation-exchange columns are claimed

to yield more stable columns. Typically, one 5050 mm or 100-mm100 mm long column packed with particles with an average

diameter of 5 μm 5 μm is used for the analysis.

NOTE 4—Some columns that have been used successfully are shown in Table 1.

6.1.5 Column-temperature Control—The chromatograph shall be capable of column temperature control to within 0.5°C0.5 °C

or less.

6.1.6 Computor or Electronic Integrator—Means shall be provided for the determination of accumulated peak areas. This can

be done by means of a computer or electronic integrator. The computer or integrator shall have the capability of correcting for

baseline shifts during the run.

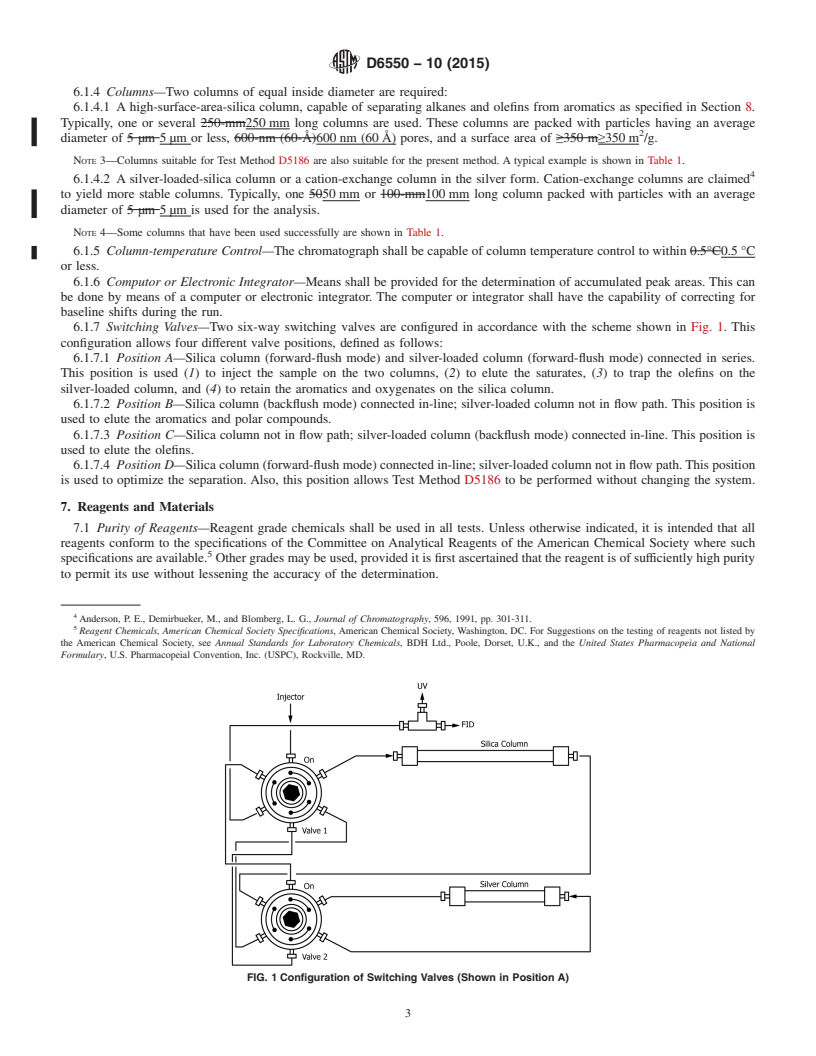

6.1.7 Switching Valves—Two six-way switching valves are configured in accordance with the scheme shown in Fig. 1. This

configuration allows four different valve positions, defined as follows:

6.1.7.1 Position A—Silica column (forward-flush mode) and silver-loaded column (forward-flush mode) connected in series.

This position is used (1) to inject the sample on the two columns, (2) to elute the saturates, (3) to trap the olefins on the

silver-loaded column, and (4) to retain the aromatics and oxygenates on the silica column.

6.1.7.2 Position B—Silica column (backflush mode) connected in-line; silver-loaded column not in flow path. This position is

used to elute the aromatics and polar compounds.

6.1.7.3 Position C—Silica column not in flow path; silver-loaded column (backflush mode) connected in-line. This position is

used to elute the olefins.

6.1.7.4 Position D—Silica column (forward-flush mode) connected in-line; silver-loaded column not in flow path. This position

is used to optimize the separation. Also, this position allows Test Method D5186 to be performed without changing the system.

7. Reagents and Materials

7.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society where such

specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high purity

to permit its use without lessening the accuracy of the determination.

Anderson, P. E., Demirbueker, M., and Blomberg, L. G., Journal of Chromatography, 596, 1991, pp. 301-311.

Reagent Chemicals, American Chemical Society Specifications, American Chemical Society, Washington, DC. For Suggestions on the testing of reagents not listed by

the American Chemical Society, see Annual Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

FIG. 1 Configuration of Switching Valves (Shown in Position A)

D6550 − 10 (2015)

7.2 Air—Zero-grade (hydrocarbon-free) air is used as the FID oxidant. (Warning —Air is usually supplied as a compressed gas

under high pressure, and it supports combustion.)

7.3 Calibration Solution—A mixture of hydrocarbons with a known mass % of olefins of the type and concentration found in

typical gasolines. This olefin mixture can be diluted by weight with olefin-free components, such as alkylate, toluene, xylenes, and

oxygenates, such as MTBE, as appropriate to approximate the composition of the fuels being tested.

7.4 Carbon Dioxide (CO ) —Supercritical-fluid-chromatographic grade, 99.99 % minimum purity, supplied pressurized in a

cylinder with a dip tube for removal of liquid CO . (Warning—Liquid at high pressure. Release of pressure results in production

of extremely cold, solid CO and gas, which can dilute available atmospheric oxygen.)

7.5 Hydrogen—Hydrogen of high quality (hydrocarbon-free) is used as the fuel for the FID. (Warning—Hydrogen is usually

supplied under high pressure and is extremely flammable.)

7.6 Loading-time Mixture—A mixture of a typical alkane and an olefin, which can be used to determine the loading time (see

8.2.2.3 ( 1) and 8.2.2.3 (2)) while protecting the silver-loaded column from exposure to aromatic compounds.

7.7 Performance Mixture—A mixture of a typical alkane, a mono-aromatic (usually toluene), and a typical mono-olefin can be

used to fine-tune this test method and to check its performance. A mixture of n-heptane, toluene, and 3-methyl-2-pentene has been

successfully used for this purpose.

7.8 Quality Control Sample—A motor gasoline containing olefins to be used to establish and monitor the precision of the

analytical measurement system.

8. Preparation of Apparatus

8.1 Install the SFC instrumentation in accordance with the manufacturer’s instructions. System operating conditions will depend

on the column used and optimization of performance. The conditions listed in Table 1 have been used successfully. If the

performance characteristics in terms of retention an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.