ASTM A623-02a

(Specification)Standard Specification for Tin Mill Products, General Requirements

Standard Specification for Tin Mill Products, General Requirements

SCOPE

1.1 This specification covers a group of common requirements which, unless otherwise specified in the purchase order or in an individual specification, shall apply to tin mill products.

1.2 In case of any conflict in requirements, the requirements of the purchase order, the individual material specification, and this general specification shall prevail in the sequence named.

Note 1—A complete metric companion to Specification A 623 has been developed-Specification A 623M; therefore no metric equivalents are presented in this specification.

1.3 The following safety caveat pertains to through of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 623 – 02a

Standard Specification for

1

Tin Mill Products, General Requirements

This standard is issued under the fixed designation A 623; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2.2 U.S. Military Standards:

7

MIL-STD-129 Marking for Shipment and Storage

1.1 This specification covers a group of common require-

MIL-STD-163 Steel Mill Products, Preparation for Marking

ments which, unless otherwise specified in the purchase order

7

and Storage

or in an individual specification, shall apply to tin mill

2.3 U.S. Federal Standard:

products.

7

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

1.2 In case of any conflict in requirements, the requirements

of the purchase order, the individual material specification, and

3. Terminology

this general specification shall prevail in the sequence named.

3.1 Definitions:

NOTE 1—A complete metric companion to Specification A 623 has

3.1.1 base box, n—a unit of area equivalent to 112 sheets 14

been developed—Specification A 623M; therefore no metric equivalents

2 2

by 20 in. or 31 360 in. (217.78 ft ) (see Annex A1).

are presented in this specification.

3.1.2 base weight, n—a term used to describe the thickness

1.3 The following safety caveat pertains to Annex A3

of tin mill products. The designated base weight multiplied by

through Annex A10 of this specification: This standard does

a factor of 0.00011 is the nominal decimal thickness, in inches

not purport to address all of the safety concerns, if any,

of the material. Although it is customary industry-wide to use

associated with its use. It is the responsibility of the user of this

the term “pound” (for example, 75 lb), following the base

standard to establish appropriate safety and health practices

weight designation, base weight is correctly used only to define

and determine the applicability of regulatory limitations prior

material thickness, and is not a measure of the weight of a base

to use.

box.

3.1.3 black plate, n—light-gage, low-carbon, cold-reduced

2. Referenced Documents

steel intended for use in the untinned state or for the production

2.1 ASTM Standards:

of other tin mill products. It is supplied only in a dry or oiled

A 370 Test Methods and Definitions for Mechanical Testing

condition.

2

of Steel Products

3.1.4 box annealing, n—a process involving slow heating of

A 700 Practices for Packaging, Marking, and Loading

coils to a subcritical temperature, holding, and cooling there-

3

Methods for Steel Products for Domestic Shipment

from, to soften the strip and relieve stresses produced during

A 987 Test Method for Measuring Shape Characteristics of

cold reduction. It is accomplished in a sealed container. By

4

Tin Mill Products

introducing and maintaining an inert or slightly reducing

D 1125 Test Methods for Electrical Conductivity and Re-

atmosphere during the cycle, a relatively bright surface is

5

sistivity of Water

obtained.

E 18 Test Methods for Rockwell Hardness and Rockwell

3.1.5 bright finish, n—a surface that has a melted tin

6

Superficial Hardness of Metallic Materials

coating.

E 112 Test Methods for Determining the Average Grain

3.1.6 bundle, n—a unit containing two or more packages of

6

Size

a cut size, supported by a platform, generally consisting of ten

or more packages. (Also commonly referred to as a multiple-

package lift containing two or more packages.)

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

3.1.7 burr, n—metal displaced beyond the plane of the

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

surface by slitting or shearing (see 9.1.7 and 9.2.6).

A01.20 on Tin Mill Products.

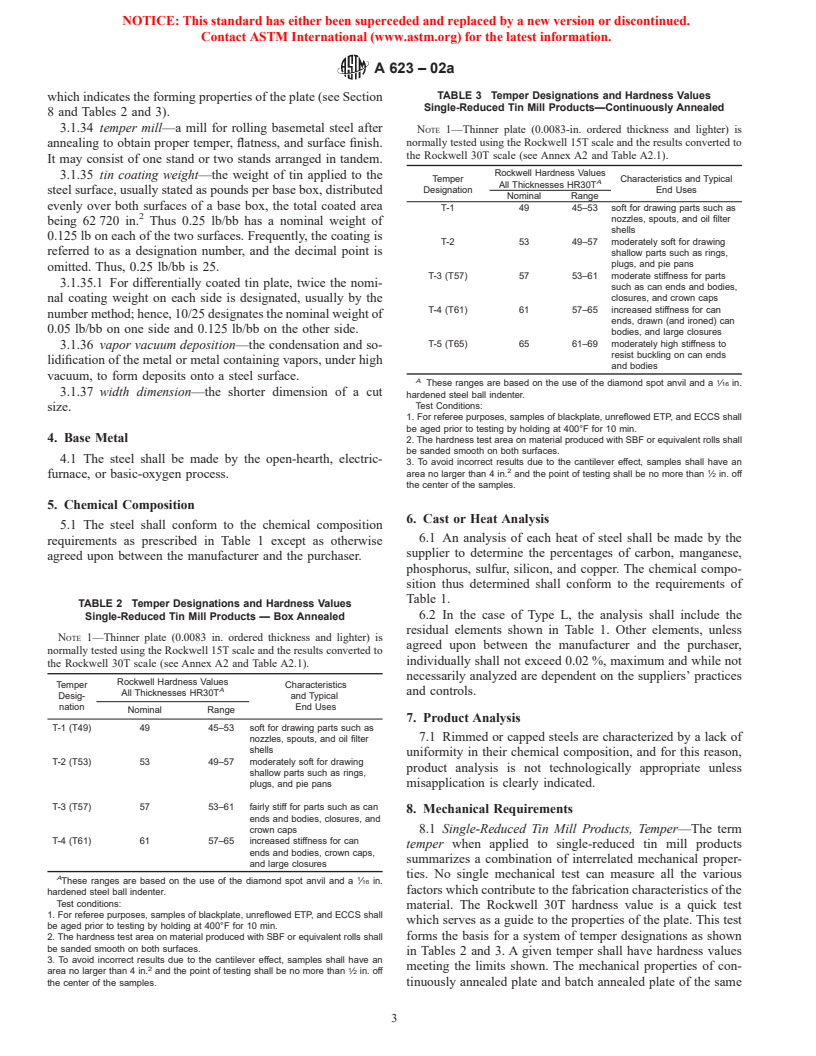

Current edition approved November 10, 2002. Published January 2003. Origi- 3.1.8 camber, n—the greatest deviation of a coil edge from

nally published as A 623 – 68. Last previous edition A 623 – 02.

a straight line. The measurement is taken on the concave side

2

Annual Book of ASTM Standards, Vol 01.03.

3

Annual Book of ASTM Standards, Vol 01.05.

4

Annual Book of ASTM Standards, Vol 01.06.

5 7

Annual Book of ASTM Standards, Vol 11.01. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

6

Annual Book of ASTM Standards, Vol 03.01. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superceded and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.