ASTM F1373-93(1999)

(Test Method)Standard Test Method for Determination of Cycle Life of Automatic Valves for Gas Distribution System Components

Standard Test Method for Determination of Cycle Life of Automatic Valves for Gas Distribution System Components

SCOPE

1.1 This test method covers the testing of automatic valves for cycle life utilizing static, no-flow conditions. This no-flow condition is felt to be a realistic test to determine the valve's cycle life.

1.2 This test method applies to automatically operated valves. It is intended to measure the cycle life of the valve itself including the seat and body sealing. It does not include cycle testing of the actuator. Testing must include both pressure testing and helium leak testing and must include vacuum test conditions when appropriate. This test method may be applied to a broad range of valve sizes.

1.3 Limitations:

1.3.1 This test is not designed to evaluate the performance of the actuator. This test method addresses the gas system contamination aspects of the valve performance, that is, seat and body leakage and diaphragm or bellows failure. If the actuator fails during the evaluation, the valve is deemed as a failure.

1.3.2 While the requirements of a valve's performance might include items such as particulate generation levels, this test method only attempts to evaluate cycle life and performance degradation as they relate to the ability of the valve to operate and shut off flow.

1.3.3 This test method is written with the assumption that the operator understands the use of the apparatus at a level equivalent to six months of experience.

1.4 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F 1373–93 (Reapproved 1999)

Standard Test Method for

Determination of Cycle Life of Automatic Valves for Gas

Distribution System Components

This standard is issued under the fixed designation F 1373; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Semiconductor clean rooms are serviced by high-purity gas distribution systems. This test method

presentsaprocedurethatmaybeappliedfortheevaluationofoneormorecomponentsconsideredfor

use in such systems.

1. Scope 1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the testing of automatic valves

responsibility of the user of this standard to establish appro-

for cycle life utilizing static, no-flow conditions. This no-flow

priate safety and health practices and determine the applica-

condition is felt to be a realistic test to determine the valve’s

bility of regulatory limitations prior to use. Specific hazard

cycle life.

statements are given in Section 7.

1.2 This test method applies to automatically operated

valves.Itisintendedtomeasurethecyclelifeofthevalveitself

2. Referenced Document

including the seat and body sealing. It does not include cycle

2.1 SEMATECH Standard:

testing of the actuator. Testing must include both pressure

2.1.1 Test Method for Determination of Helium Leak Rate

testing and helium leak testing and must include vacuum test

for Gas Distribution Systems Components, Provisional SE-

conditions when appropriate. This test method may be applied

MASPEC #90120391 B-STD. Feb. 22, 1993.

to a broad range of valve sizes.

1.3 Limitations:

3. Terminology

1.3.1 This test is not designed to evaluate the performance

3.1 Definitions of Terms Specific to This Standard:

of the actuator. This test method addresses the gas system

3.1.1 actuation cycle—operationofvalvefromfullyopened

contamination aspects of the valve performance, that is, seat

to fully closed and back to fully opened.

and body leakage and diaphragm or bellows failure. If the

3.1.2 actuator— a gas (compressed air nitrogen)-operated

actuator fails during the evaluation, the valve is deemed as a

deviceconnectedtothevalvestemtoopenandclosethevalve.

failure.

3.1.3 actuator pressure—range of actuator gas line pressure

1.3.2 While the requirements of a valve’s performance

required to fully open and close the valve.

might include items such as particulate generation levels, this

3.1.4 automatic valve—a valve with an actuation device

test method only attempts to evaluate cycle life and perfor-

that can be operated remotely, such as a pneumatically or

mance degradation as they relate to the ability of the valve to

electrically controlled valve.

operate and shut off flow.

3.1.5 cycle life—the cycle life of a valve involves two

1.3.3 This test method is written with the assumption that

characteristics:catastrophicvalvefailure,thatisasinglevalue;

the operator understands the use of the apparatus at a level

and a degraded performance, that is, a plot of helium leak rate

equivalent to six months of experience.

versus cycles.

1.4 The values stated in SI units are to be regarded as the

3.1.6 failure—the termination of the ability of the valve to

standard. The inch-pound units given in parentheses are for

perform its required function.

information only.

3.1.7 failure mode—the mode by which a failure is ob-

served to occur.

This test method is under the jurisdiction of ASTM Committee F-1 on

Electronics and is the direct responsibility of Subcommittee F01.10 on Processing

Environments.

Current edition approved Apr. 15, 1993. Published June 1993. Originally

published as F1373–92. Last previous edition F1373–92. Available from SEMATECH, 2706 Montopolis Dr., Austin, TX 78741-6499.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1373–93 (1999)

3.1.7.1 Discussion—Failure mode types include a cata-

strophic failurethatisbothsuddenandcompleteand degraded

failure that is gradual, partial, or both.

3.1.8 standard conditions—101.3 kPa, 0.0°C (14.73 psia,

32.0°F).

3.1.9 valve—any component designed to provide positive

shutoff of fluid media with the capability of being externally

operated.

4. Significance and Use

4.1 The purpose of this test method is to define a procedure

for testing components being considered for installation into a

high-purity gas distribution system. Application of this test

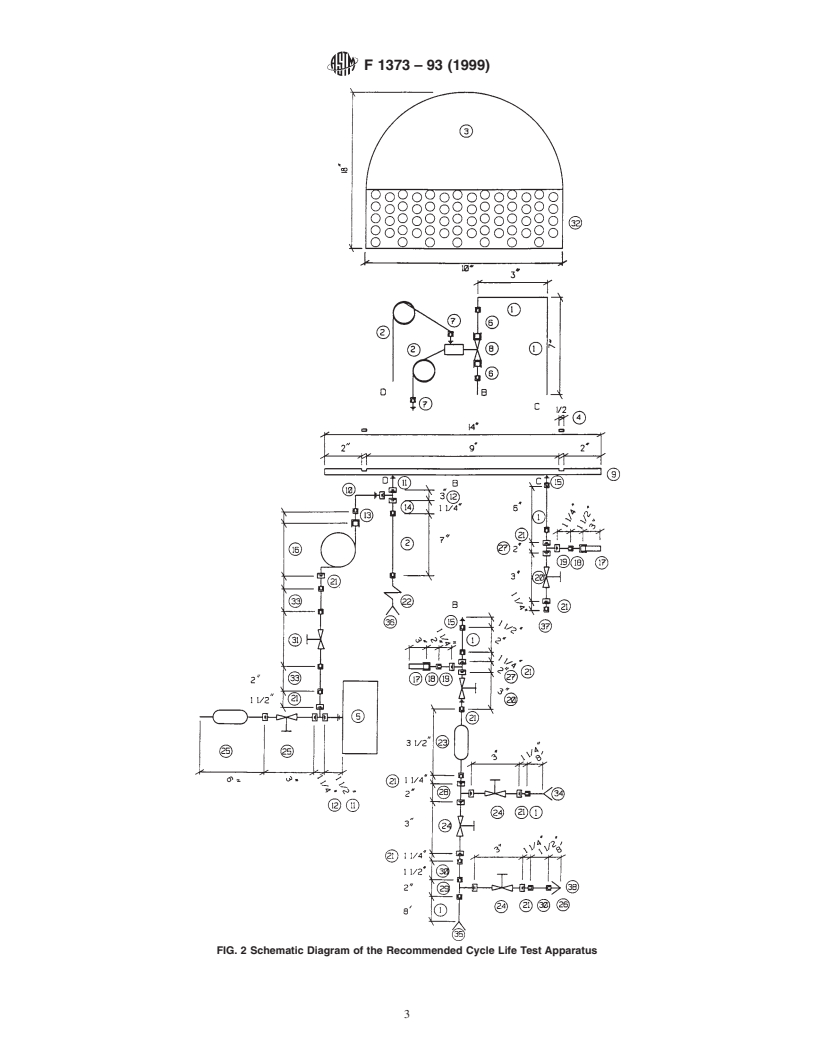

FIG. 1 Cycle Life Test Schematic

method is expected to yield comparable data among compo-

nents tested for the purposes of qualification for this installa-

through the isolation valve. The test valve is isolated between

tion.

two isolation valves to allow for pressurization of the test

componentduringcyclingandleaktesting.Heliumgasneeded

5. Apparatus

forleaktestingisprovidedfromanultrahighpurityheliumgas

5.1 Helium Mass Spectrometer Leak Detector.

cylinder.

5.2 Cycle Counter.

8.3 The test component is installed inside a borosilicate bell

5.3 Upstream and Downstream Pressure Indicators or

jar placed above a stainless steel base plate to provide a

Transducers, capable of handling the test pressure ranges; a

leak-tightenclosurerequiredforboththeinboardandoutboard

vacuum pump for vacuum service valves, an isolation valve

helium leak tests. Ports are provided in the base plate for the

and test valve, some pressure transducers or gages, and a cycle

inlet and outlet lines of the test component, for the actuator

controller to provide consistent cycling are required.

line, and for a port for the actuator exhaust to release the

5.4 Instrument to Detect Failure of the Valve to Hold

exhaust outside the bell jar. The base plate is sealed to the bell

Pressure, for example, a data logger tied to the outlet pressure

jar by a rubber gasket during outboard leak testing of the test

transducer. A data logging instrument is preferred but any

component.

instrument such as a dual strip chart recorder capable of

8.4 Both the inlet and outlet pressures are measured imme-

detecting the failure is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.