ASTM D7894/D7894M-14(2018)

(Test Method)Standard Test Method for Thermal Endurance of Coating Powders Used for Integral Bus Bar Insulation Systems

Standard Test Method for Thermal Endurance of Coating Powders Used for Integral Bus Bar Insulation Systems

SIGNIFICANCE AND USE

5.1 A major factor affecting the life of insulating materials is thermal degradation. It is possible that other factors, such as moisture and vibration, will cause failures after the material has been weakened by thermal degradation.

5.2 Electrical insulation is effective in electrical equipment only as long as it retains its physical and electrical integrity. The following are potential indicators of thermal degradation: weight change, porosity, crazing, and generally a reduction in flexibility. Thermal degradation is usually accompanied by an ultimate reduction in dielectric breakdown.

5.3 This test method is useful in determining the thermal endurance of coating powders applied over a copper or aluminum substrate material.

SCOPE

1.1 This test method provides a procedure for evaluating thermal endurance of coating powders by determining the length of aging time at selected elevated temperatures required to achieve dielectric breakdown at room temperature at a pre-determined proof voltage. Thermal endurance is expressed in terms of a temperature index.

1.2 This test method is applicable to insulating powders used over a substrate material of copper or aluminum.

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems is likely to result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 7.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7894/D7894M − 14 (Reapproved 2018)

Standard Test Method for

Thermal Endurance of Coating Powders Used for Integral

1

Bus Bar Insulation Systems

This standard is issued under the fixed designation D7894/D7894M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

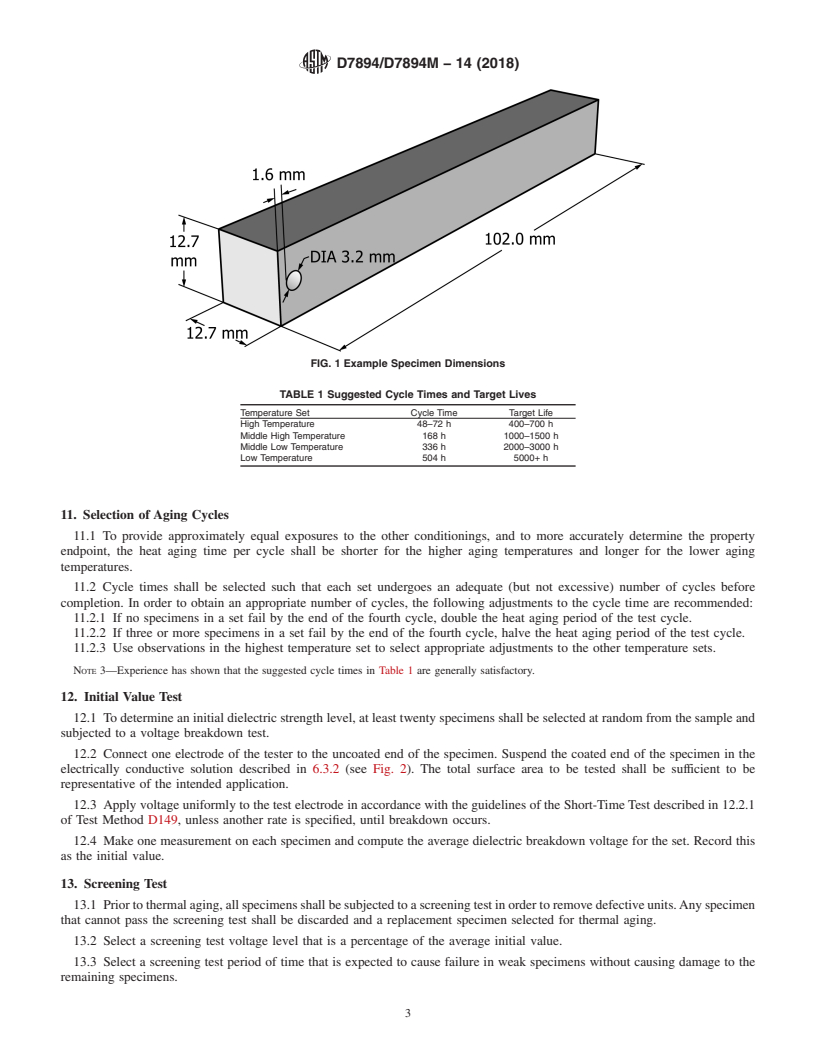

1. Scope at Commercial Power Frequencies

D1711 Terminology Relating to Electrical Insulation

1.1 This test method provides a procedure for evaluating

D5423 Specification for Forced-Convection Laboratory Ov-

thermal endurance of coating powders by determining the

ens for Evaluation of Electrical Insulation

length of aging time at selected elevated temperatures required

3

2.2 IEEE Document:

to achieve dielectric breakdown at room temperature at a

IEEE 101A Simplified Method for Calculation of the Re-

pre-determined proof voltage. Thermal endurance is expressed

gression Line

in terms of a temperature index.

1.2 This test method is applicable to insulating powders

3. Terminology

used over a substrate material of copper or aluminum.

3.1 Definitions—For definitions of terms used in this test

1.3 Units—The values stated in either SI units or inch-

method refer to Terminology D1711.

pound units are to be regarded separately as standard. The

4. Summary of Test Method

values stated in each system are not necessarily exact equiva-

lents; therefore, each system shall be used independently of the

4.1 Specimens are aged in air at a minimum of three

other. Combining values from the two systems is likely to

temperatures above the expected use temperature of the mate-

result in non-conformance with the standard.

rial. Exposure to ambient stress conditions, followed by

dielectric proof voltage tests in an electrically conductive

1.4 This standard does not purport to address all of the

solution, are periodically conducted to determine the time of

safety concerns, if any, associated with its use. It is the

aging at each elevated temperature required to reduce the

responsibility of the user of this standard to establish appro-

breakdown voltage to a pre-selected percentage of the original

priate safety, health, and environmental practices and deter-

breakdown value. These thermal life values are used to

mine the applicability of regulatory limitations prior to use.

construct a thermal endurance graph by means of which it is

Specific precautionary statements are given in Section 7.

possible to estimate a temperature index, corresponding to a

1.5 This international standard was developed in accor-

thermal life as specified in the material specification or as

dance with internationally recognized principles on standard-

agreed upon between the user and the supplier. It is possible

ization established in the Decision on Principles for the

that a material will have multiple indices, each corresponding

Development of International Standards, Guides and Recom-

to a different thermal life as required by a given application.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

5. Significance and Use

2. Referenced Documents

5.1 Amajorfactoraffectingthelifeofinsulatingmaterialsis

2

thermal degradation. It is possible that other factors, such as

2.1 ASTM Standards:

moisture and vibration, will cause failures after the material

D149 Test Method for Dielectric Breakdown Voltage and

has been weakened by thermal degradation.

Dielectric Strength of Solid Electrical Insulating Materials

5.2 Electrical insulation is effective in electrical equipment

1 only as long as it retains its physical and electrical integrity.

This test method is under the jurisdiction of ASTM Committee D09 on

Electrical and Electronic Insulating Materials and is the direct responsibility of The following are potential indicators of thermal degradation:

Subcommittee D09.01 on Electrical Insulating Products.

weight change, porosity, crazing, and generally a reduction in

Current edition approved Nov. 1, 2018. Published November 2018. Originally

flexibility. Thermal degradation is usually accompanied by an

approved in 2014. Last previous edition approved in 2014 as D7894/D7894M – 14.

ultimate reduction in dielectric breakdown.

DOI: 10.1520/D7894_D7894M-14R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE),

the ASTM website. 445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331, http://www.ieee.org.

Copyright ©

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7894/D7894M − 14 D7894/D7894M − 14 (Reapproved 2018)

Standard Test Method for

Thermal Endurance of Coating Powders Used for Integral

1

Bus Bar Insulation Systems

This standard is issued under the fixed designation D7894/D7894M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method provides a procedure for evaluating thermal endurance of coating powders by determining the length of

aging time at selected elevated temperatures required to achieve dielectric breakdown at room temperature at a pre-determined

proof voltage. Thermal endurance is expressed in terms of a temperature index.

1.2 This test method is applicable to insulating powders used over a substrate material of copper or aluminum.

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated

in each system are not necessarily exact equivalents; therefore, each system shall be used independently of the other. Combining

values from the two systems is likely to result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 7.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D149 Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at

Commercial Power Frequencies

D1711 Terminology Relating to Electrical Insulation

D5423 Specification for Forced-Convection Laboratory Ovens for Evaluation of Electrical Insulation

3

2.2 IEEE Document:

IEEE 101A Simplified Method for Calculation of the Regression Line

3. Terminology

3.1 Definitions—For definitions of terms used in this test method refer to Terminology D1711.

4. Summary of Test Method

4.1 Specimens are aged in air at a minimum of three temperatures above the expected use temperature of the material. Exposure

to ambient stress conditions, followed by dielectric proof voltage tests in an electrically conductive solution, are periodically

conducted to determine the time of aging at each elevated temperature required to reduce the breakdown voltage to a pre-selected

percentage of the original breakdown value. These thermal life values are used to construct a thermal endurance graph by means

of which it is possible to estimate a temperature index, corresponding to a thermal life as specified in the material specification

or as agreed upon between the user and the supplier. It is possible that a material will have multiple indices, each corresponding

to a different thermal life as required by a given application.

1

This test method is under the jurisdiction of ASTM Committee D09 on Electrical and Electronic Insulating Materials and is the direct responsibility of Subcommittee

D09.01 on Electrical Insulating Varnishes, Powders and Encapsulating CompoundsProducts.

Current edition approved Nov. 1, 2014Nov. 1, 2018. Published November 2014November 2018. Originally approved in 2014. Last previous edition approved in 2014 as

D7894/D7894M – 14. DOI: 10.1520/D7894_D7894M-14.10.1520/D7894_D7894M-14R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE), 445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331, http://www.ieee.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7894/D7894M − 14 (2018)

5. Significance and Use

5.1 A majo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.