ASTM D5483-05

(Test Method)Standard Test Method for Oxidation Induction Time of Lubricating Greases by Pressure Differential Scanning Calorimetry

Standard Test Method for Oxidation Induction Time of Lubricating Greases by Pressure Differential Scanning Calorimetry

SIGNIFICANCE AND USE

Oxidation induction time, as determined under the conditions of this test method, can be used as an indication of oxidation stability.3 This test method can be used for research and development, quality control and specification purposes. However, no correlation has been determined between the results of this test method and service performance.

SCOPE

1.1 This test method covers the determination of oxidation induction time of lubricating greases subjected to oxygen at 3.5 MPa (500 psig) and temperatures between 155 and 210C.

1.2 The values in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5483–05

Standard Test Method for

Oxidation Induction Time of Lubricating Greases by

1

Pressure Differential Scanning Calorimetry

This standard is issued under the fixed designation D5483; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

4.1 Asmall quantity of grease is weighed into a sample pan

1.1 This test method covers the determination of oxidation

induction time of lubricating greases subjected to oxygen at and placed in a test cell. The cell is heated to a specified

3.5 MPa (500 psig) and temperatures between 155 and 210°C. temperature and then pressurized with oxygen. The cell is held

1.2 The values stated in SI units are to be regarded as at a regulated temperature and pressure until an exothermic

standard. The values given in parentheses are for information reaction occurs. The extrapolated onset time is measured and

only. reported as the oxidation induction time for the grease under

1.3 This standard does not purport to address all of the the specified test temperature.

safety concerns, if any, associated with its use. It is the 4.2 A kinetic equation incorporated with this test method

responsibility of the user of this standard to establish appro- can estimate oxidation induction times at other temperatures.

priate safety and health practices and determine the applica-

5. Significance and Use

bility of regulatory limitations prior to use.

5.1 Oxidation induction time, as determined under the

2. Referenced Documents

conditions of this test method, can be used as an indication of

2 3

2.1 ASTM Standards: oxidation stability. This test method can be used for research

E473 Terminology Relating to Thermal Analysis and Rhe- and development, quality control and specification purposes.

ology However, no correlation has been determined between the

results of this test method and service performance.

3. Terminology

6. Apparatus

3.1 Definitions of Terms Specific to This Standard:

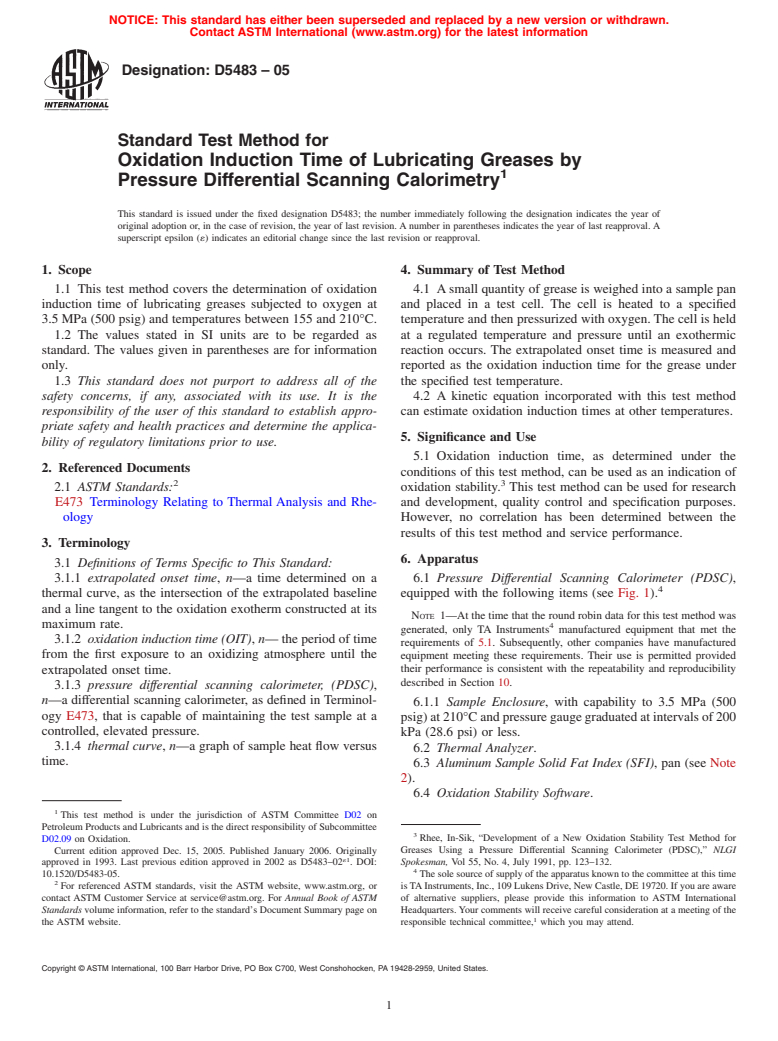

3.1.1 extrapolated onset time, n—a time determined on a 6.1 Pressure Differential Scanning Calorimeter (PDSC),

4

thermal curve, as the intersection of the extrapolated baseline equipped with the following items (see Fig. 1).

and a line tangent to the oxidation exotherm constructed at its

NOTE 1—At the time that the round robin data for this test method was

maximum rate. 4

generated, only TA Instruments manufactured equipment that met the

3.1.2 oxidation induction time (OIT), n— the period of time

requirements of 5.1. Subsequently, other companies have manufactured

from the first exposure to an oxidizing atmosphere until the equipment meeting these requirements. Their use is permitted provided

their performance is consistent with the repeatability and reproducibility

extrapolated onset time.

described in Section 10.

3.1.3 pressure differential scanning calorimeter, (PDSC),

n—a differential scanning calorimeter, as defined in Terminol-

6.1.1 Sample Enclosure, with capability to 3.5 MPa (500

ogy E473, that is capable of maintaining the test sample at a

psig)at210°Candpressuregaugegraduatedatintervalsof200

controlled, elevated pressure.

kPa (28.6 psi) or less.

3.1.4 thermal curve, n—a graph of sample heat flow versus

6.2 Thermal Analyzer.

time.

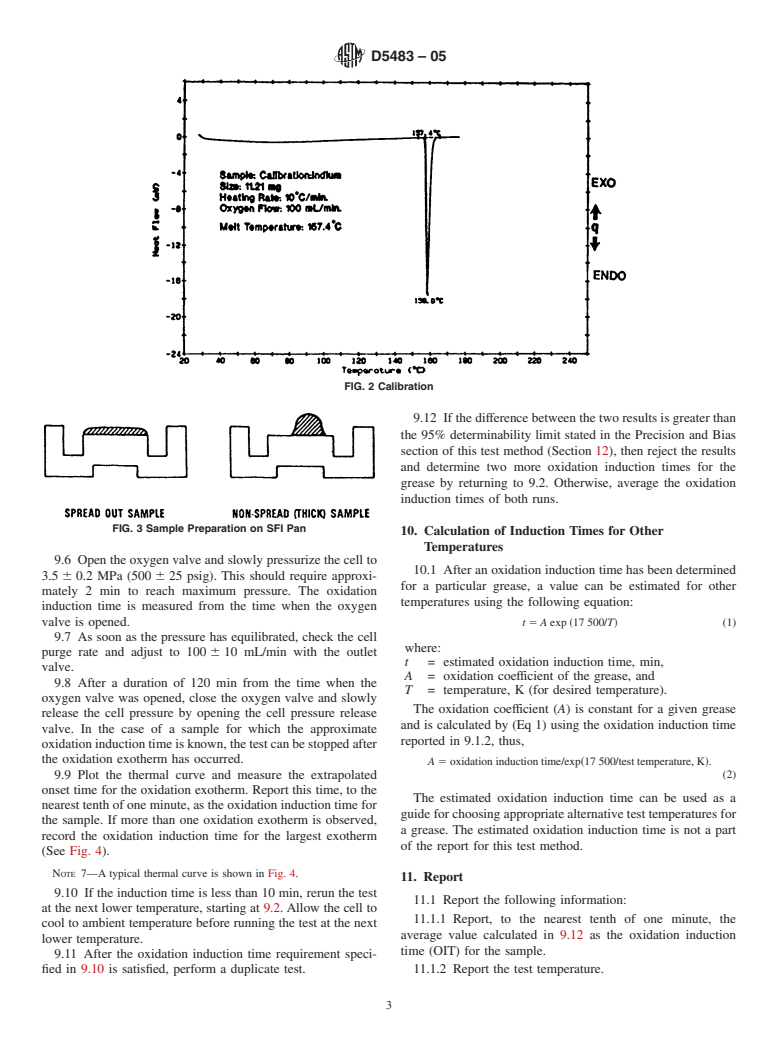

6.3 Aluminum Sample Solid Fat Index (SFI), pan (see Note

2).

6.4 Oxidation Stability Software.

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

3

D02.09 on Oxidation. Rhee, In-Sik, “Development of a New Oxidation Stability Test Method for

Current edition approved Dec. 15, 2005. Published January 2006. Originally Greases Using a Pressure Differential Scanning Calorimeter (PDSC),” NLGI

´1

approved in 1993. Last previous edition approved in 2002 as D5483–02 . DOI: Spokesman, Vol 55, No. 4, July 1991, pp. 123–132.

4

10.1520/D5483-05. The sole source of supply of the apparatus known to the committee at this time

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or isTAInstruments, Inc., 109 Lukens Drive, New Castle, DE 19720. If you are aware

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM of alternative suppliers, please provide this information to ASTM International

Standards volume information, refer to the standard’s Document Summary page on Headquarters.Your comments will receive careful consideration at a meeting of the

1

the ASTM website. responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.