ASTM C856-17

(Practice)Standard Practice for Petrographic Examination of Hardened Concrete

Standard Practice for Petrographic Examination of Hardened Concrete

ABSTRACT

This practice outlines the standard procedures for performing petrographic examination of hardened concrete samples. The samples examined may be taken from concrete constructions, that is, all sorts of objects, units, or structures that have been built of hydraulic cement concrete. They may also be concrete products or portions thereof, or concrete or mortar specimens that have been exposed in natural environments or simulated service conditions, or subjected to laboratory tests. This practice applies to samples of all types of hardened hydraulic-cement mixtures, including concrete, mortar, grout, plaster, stucco, terrazzo, and the like. The equipments generally used for specimen preparation are diamond saw, cutting lubricant, horizontal lap wheels, free abrasive machine, polishing wheel, hot plate or oven, prospector's pick and/or bricklayer's hammer, abrasives, plate-glass squares, suitable media, and microscope slides. For specimen examination, the equipments needed are stereomicroscope, dollies, petrographic or polarizing microscope, metallographic microscope, eyepiece micrometer, stage micrometer, microscope lamps, needleholders and points, bottles with droppers, assorted forceps, lens paper, refractometer, and immersion media. Appropriate procedures for the sampling, preparation, and examination of specimens are detailed methodically.

SCOPE

1.1 This practice outlines procedures for the petrographic examination of samples of hardened concrete. The samples examined may be taken from concrete constructions, they may be concrete products or portions thereof, or they may be concrete or mortar specimens that have been exposed in natural environments, or to simulated service conditions, or subjected to laboratory tests. The phrase “concrete constructions” is intended to include all sorts of objects, units, or structures that have been built of hydraulic cement concrete.

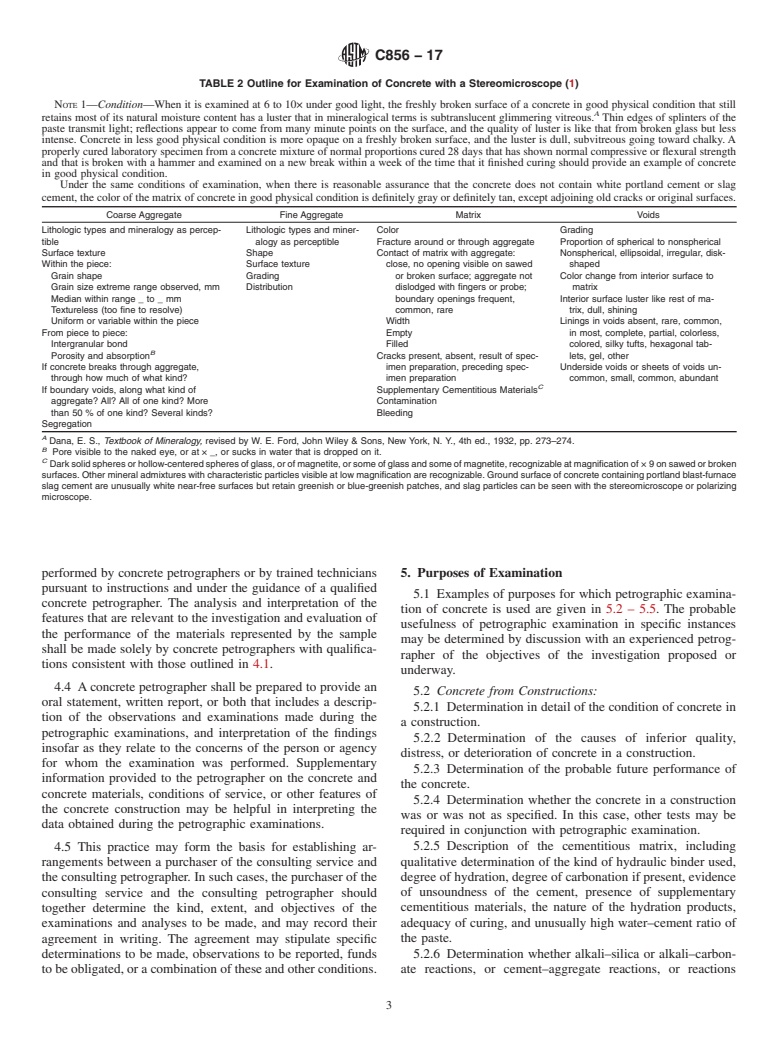

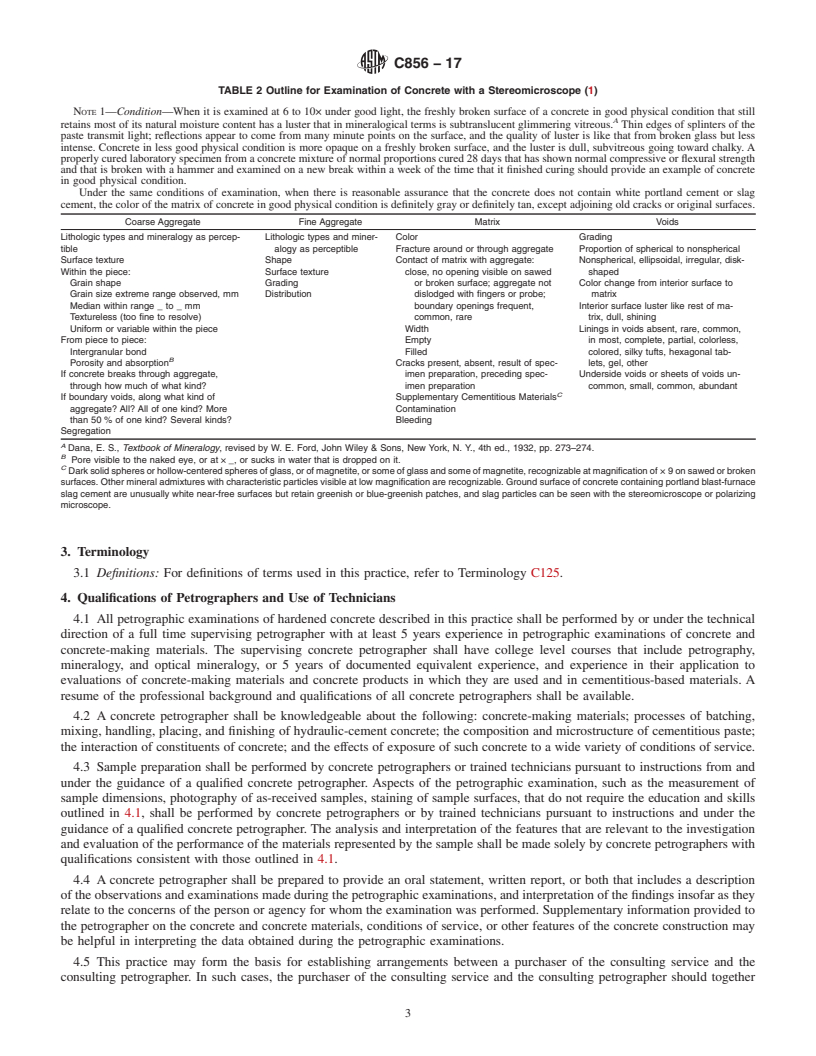

Note 1: A photographic chart of materials, phenomena, and reaction products discussed in Sections 8 – 13 and Tables 1-6 are available as Adjunct C856 (ADJCO856). (A) A substantial portion of the coarse aggregate has maximum dimensions in the range shown as measured on sawed or broken surfaces.(B) Sections sawed or drilled close to and parallel to formed surfaces appear to show local turbulence as a result of spading or rodding close to the form. Sections sawed in the plane of bedding (normal to the direction of placement) are likely to have inconspicuous orientation. Sections broken normal to placement in conventionally placed concrete with normal bond tend to have aggregate knobs abundant on the bottom of the upper piece as cast and sockets abundant on the top of the lower piece as cast. (A) Dana, E. S., Textbook of Mineralogy, revised by W. E. Ford, John Wiley & Sons, New York, N. Y., 4th ed., 1932, pp. 273–274.(B) Pore visible to the naked eye, or at × _, or sucks in water that is dropped on it.(C) Dark solid spheres or hollow-centered spheres of glass, or of magnetite, or some of glass and some of magnetite, recognizable at magnification of × 9 on sawed or broken surfaces. Other mineral admixtures with characteristic particles visible at low magnification are recognizable. Ground surface of concrete containing portland blast-furnace slag cement are unusually white near-free surfaces but retain greenish or blue-greenish patches, and slag particles can be seen with the stereomicroscope or polarizing microscope. (A) Secondary ettringite can sometimes be recognized by crystal habit and silky luster.(B) Fly ash can be detected by color and shape when dark spheres are present. In concrete that has not oxidized the presence of slag may be inferred from the green or blue color of the paste.(C) Ettringite and calcium hydroxide in voids may be recognized by their crystal habits.(D) Magnesium oxide and calcium oxide should be identifiable in polished section. (A) The literature and private reports include data on many unidentified second...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C856 − 17

Standard Practice for

1

Petrographic Examination of Hardened Concrete

This standard is issued under the fixed designation C856; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This practice outlines procedures for the petrographic

responsibility of the user of this standard to establish appro-

examination of samples of hardened concrete. The samples

priate safety and health practices and determine the applica-

examined may be taken from concrete constructions, they may

bility of regulatory limitations prior to use. A specific hazard

be concrete products or portions thereof, or they may be

statement is given in 6.2.10.1.

concreteormortarspecimensthathavebeenexposedinnatural

environments, or to simulated service conditions, or subjected

2. Referenced Documents

to laboratory tests. The phrase “concrete constructions” is

2

2.1 ASTM Standards:

intended to include all sorts of objects, units, or structures that

C125Terminology Relating to Concrete and Concrete Ag-

have been built of hydraulic cement concrete.

gregates

NOTE 1—A photographic chart of materials, phenomena, and reaction

C215 Test Method for Fundamental Transverse,

products discussed in Sections8–13 and Tables 1-6 are available as

Longitudinal, and Torsional Resonant Frequencies of

Adjunct C856 (ADJCO856).

Concrete Specimens

1.2 The petrographic procedures outlined herein are appli-

C227 Test Method for Potential Alkali Reactivity of

cable to the examination of samples of all types of hardened

Cement-Aggregate Combinations (Mortar-Bar Method)

hydraulic-cement mixtures, including concrete, mortar, grout,

C342Test Method for PotentialVolume Change of Cement-

3

plaster, stucco, terrazzo, and the like. In this practice, the

Aggregate Combinations (Withdrawn 2001)

material for examination is designated as “concrete,” even

C441TestMethodforEffectivenessofPozzolansorGround

though the commentary may be applicable to the other

Blast-Furnace Slag in Preventing Excessive Expansion of

mixtures, unless the reference is specifically to media other

Concrete Due to the Alkali-Silica Reaction

than concrete.

C452Test Method for Potential Expansion of Portland-

1.3 Thepurposesofandproceduresforpetrographicexami- Cement Mortars Exposed to Sulfate

nationofhardenedconcretearegiveninthefollowingsections: C457Test Method for Microscopical Determination of Pa-

rameters of the Air-Void System in Hardened Concrete

Section

C496/C496MTest Method for Splitting Tensile Strength of

Qualifications of Petrographers and Use of Technicians 4

Cylindrical Concrete Specimens

Purposes of Examination 5

C597Test Method for Pulse Velocity Through Concrete

Apparatus 6

Selection and Use of Apparatus 7

C803/C803MTest Method for Penetration Resistance of

Samples 8

Hardened Concrete

Examination of Samples 9

C805Test Method for Rebound Number of Hardened Con-

Specimen Preparation 10

Visual and Stereomicroscope Examination 11

crete

Polarizing Microscope Examination 12

C823Practice for Examination and Sampling of Hardened

Paste Features 13

Concrete in Constructions

Report 14

C1012Test Method for Length Change of Hydraulic-

1.4 Thevaluesstatedininch-poundunitsaretoberegarded

Cement Mortars Exposed to a Sulfate Solution

as the standard. The SI units in parentheses are provided for

C1260Test Method for Potential Alkali Reactivity of Ag-

information purposes only.

gregates (Mortar-Bar Method)

1 2

This practice is under the jurisdiction of ASTM Committee C09 on Concrete For referenced ASTM standards, visit the ASTM website, www.astm.org, or

andConcreteAggregatesandisthedirectresponsibilityofSubcommitteeC09.65on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Petrography. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Jan. 1, 2017. Published March 2017. Originally the ASTM website.

3

approved in 1977. Last previous edition approved in 2014 as C856 – 14. DOI: The last approved version of this historical standard is referenced on

10.1520/C0856-17. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C856 − 17

5

TABLE 1 Visual Examination of Concrete (1)

Coarse Aggregate + Fine Aggregate + Matrix + Air + Embedded Items

Composition:

A

Maximum dimension, in. or

mm, in the rang

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C856 − 14 C856 − 17

Standard Practice for

1

Petrographic Examination of Hardened Concrete

This standard is issued under the fixed designation C856; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice outlines procedures for the petrographic examination of samples of hardened concrete. The samples examined

may be taken from concrete constructions, they may be concrete products or portions thereof, or they may be concrete or mortar

specimens that have been exposed in natural environments, or to simulated service conditions, or subjected to laboratory tests. The

phrase “concrete constructions” is intended to include all sorts of objects, units, or structures that have been built of hydraulic

cement concrete.

NOTE 1—A photographic chart of materials, phenomena, and reaction products discussed in Sections 8 – 13 and Tables 1-6 are available as Adjunct

C856 (ADJCO856).

1.2 The petrographic procedures outlined herein are applicable to the examination of samples of all types of hardened

hydraulic-cement mixtures, including concrete, mortar, grout, plaster, stucco, terrazzo, and the like. In this practice, the material

for examination is designated as “concrete,” even though the commentary may be applicable to the other mixtures, unless the

reference is specifically to media other than concrete.

NOTE 2—Appendix X1 outlines an uranyl acetate method for identifying locations where alkali-silica gel may be present. It is a requirement that the

substances in those locations must be identified using any other more definitive techniques, such as petrographic microscopy.

1.3 The purposes of and procedures for petrographic examination of hardened concrete are given in the following sections:

Section

Qualifications of Petrographers and Use of Technicians 4

Purposes of Examination 5

Apparatus 6

Selection and Use of Apparatus 7

Samples 8

Examination of Samples 9

Specimen Preparation 10

Visual and Stereomicroscope Examination 11

Polarizing Microscope Examination 12

Paste Features 13

Report 14

1.4 The values stated in inch-pound units are to be regarded as the standard. The SI units in parentheses are provided for

information purposes only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. A specific hazard statement is given in 6.2.10.1.

2. Referenced Documents

2

2.1 ASTM Standards:

C125 Terminology Relating to Concrete and Concrete Aggregates

C215 Test Method for Fundamental Transverse, Longitudinal, and Torsional Resonant Frequencies of Concrete Specimens

C227 Test Method for Potential Alkali Reactivity of Cement-Aggregate Combinations (Mortar-Bar Method)

1

This practice is under the jurisdiction of ASTM Committee C09 on Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee C09.65 on

Petrography.

Current edition approved June 1, 2014Jan. 1, 2017. Published June 2014March 2017. Originally approved in 1977. Last previous edition approved in 20132014 as C856

– 13.14. DOI: 10.1520/C0856-14.10.1520/C0856-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C856 − 17

5

TABLE 1 Visual Examination of Concrete (1)

Coarse Aggregate + Fine Aggregate + Matrix + Air + Embedded Items

Composition:

A

Maximum dimension, in. or

mm, in the range> d>

Type: Type: color, by comparison with more than 3 % of total, Type, size, location;

National Research kinds of metal; other

Council Rock Color items

Chart (1963)

1 Gravel 1 Natural sand predominantly in spherical

2 Crushed stone 2 Manufactured sand color distribution: voids?

3 Mixed 1 and 2 3 Mixed 1 mottled less than 3 % of total,

4 Other (name) 4 Other (name) 2 even abundant nonspherical

5 Mixe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.