ASTM D1071-83(2003)

(Test Method)Standard Test Methods for Volumetric Measurement of Gaseous Fuel Samples

Standard Test Methods for Volumetric Measurement of Gaseous Fuel Samples

SIGNIFICANCE AND USE

The knowledge of the volume of samples used in a test is necessary for meaningful results. Validity of the volume measurement equipment and procedures must be assured for accurate results.

SCOPE

1.1 These test methods cover the volumetric measuring of gaseous fuel samples, including liquefied petroleum gases, in the gaseous state at normal temperatures and pressures. The apparatus selected covers a sufficient variety of types so that one or more of the methods prescribed may be employed for laboratory, control, reference, or in fact any purpose where it is desired to know the quantity of gaseous fuel or fuel samples under consideration. The various types of apparatus are listed in Table 1.

1.2This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1071–83 (Reapproved 2003)

Standard Test Methods for

Volumetric Measurement of Gaseous Fuel Samples

This standard is issued under the fixed designation D1071; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

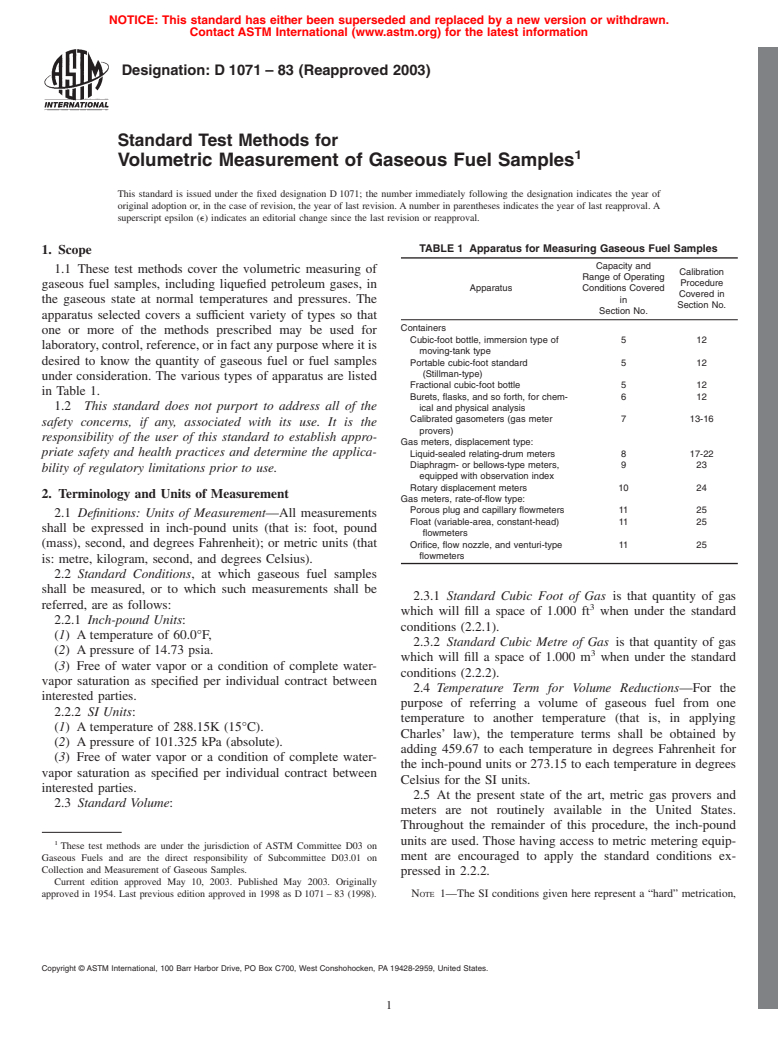

TABLE 1 Apparatus for Measuring Gaseous Fuel Samples

1. Scope

Capacity and

1.1 These test methods cover the volumetric measuring of

Calibration

Range of Operating

Procedure

gaseous fuel samples, including liquefied petroleum gases, in

Apparatus Conditions Covered

Covered in

the gaseous state at normal temperatures and pressures. The in

Section No.

Section No.

apparatus selected covers a sufficient variety of types so that

Containers

one or more of the methods prescribed may be used for

Cubic-foot bottle, immersion type of 512

laboratory,control,reference,orinfactanypurposewhereitis

moving-tank type

desired to know the quantity of gaseous fuel or fuel samples

Portable cubic-foot standard 512

(Stillman-type)

under consideration. The various types of apparatus are listed

Fractional cubic-foot bottle 5 12

in Table 1.

Burets, flasks, and so forth, for chem- 612

1.2 This standard does not purport to address all of the ical and physical analysis

Calibrated gasometers (gas meter 7 13-16

safety concerns, if any, associated with its use. It is the

provers)

responsibility of the user of this standard to establish appro-

Gas meters, displacement type:

priate safety and health practices and determine the applica- Liquid-sealed relating-drum meters 8 17-22

Diaphragm- or bellows-type meters, 923

bility of regulatory limitations prior to use.

equipped with observation index

Rotary displacement meters 10 24

2. Terminology and Units of Measurement

Gas meters, rate-of-flow type:

Porous plug and capillary flowmeters 11 25

2.1 Definitions: Units of Measurement—All measurements

Float (variable-area, constant-head) 11 25

shall be expressed in inch-pound units (that is: foot, pound

flowmeters

(mass), second, and degrees Fahrenheit); or metric units (that Orifice, flow nozzle, and venturi-type 11 25

flowmeters

is: metre, kilogram, second, and degrees Celsius).

2.2 Standard Conditions, at which gaseous fuel samples

shall be measured, or to which such measurements shall be

2.3.1 Standard Cubic Foot of Gas is that quantity of gas

referred, are as follows:

which will fill a space of 1.000 ft when under the standard

2.2.1 Inch-pound Units:

conditions (2.2.1).

(1) A temperature of 60.0°F,

2.3.2 Standard Cubic Metre of Gas is that quantity of gas

(2) A pressure of 14.73 psia.

which will fill a space of 1.000 m when under the standard

(3) Free of water vapor or a condition of complete water-

conditions (2.2.2).

vapor saturation as specified per individual contract between

2.4 Temperature Term for Volume Reductions—For the

interested parties.

purpose of referring a volume of gaseous fuel from one

2.2.2 SI Units:

temperature to another temperature (that is, in applying

(1) A temperature of 288.15K (15°C).

Charles’ law), the temperature terms shall be obtained by

(2) A pressure of 101.325 kPa (absolute).

adding 459.67 to each temperature in degrees Fahrenheit for

(3) Free of water vapor or a condition of complete water-

the inch-pound units or 273.15 to each temperature in degrees

vapor saturation as specified per individual contract between

Celsius for the SI units.

interested parties.

2.5 At the present state of the art, metric gas provers and

2.3 Standard Volume:

meters are not routinely available in the United States.

Throughout the remainder of this procedure, the inch-pound

1 units are used. Those having access to metric metering equip-

These test methods are under the jurisdiction of ASTM Committee D03 on

ment are encouraged to apply the standard conditions ex-

Gaseous Fuels and are the direct responsibility of Subcommittee D03.01 on

Collection and Measurement of Gaseous Samples.

pressed in 2.2.2.

Current edition approved May 10, 2003. Published May 2003. Originally

approved in 1954. Last previous edition approved in 1998 as D1071–83 (1998). NOTE 1—The SI conditions given here represent a “hard” metrication,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1071–83 (2003)

in that the reference temperature and the reference pressure have been

changed. Thus, amounts of gas given in metric units should always be

referredtotheSIstandardconditionsandtheamountsgivenininch-pound

units should always be referred to the inch-pound standard conditions.

3. Significance and Use

3.1 The knowledge of the volume of samples used in a test

is necessary for meaningful results. Validity of the volume

measurement equipment and procedures must be assured for

accurate results.

4. Apparatus

4.1 The various types of apparatus used for the measure-

ment of gaseous fuel samples may be grouped in three classes,

as shown in Table 1. References to the portions of these

methods covering the capacity and range of operating condi-

tions, and the calibration, of each type are given in Table 1.

CAPACITY OFAPPARATUS AND RANGE OF

OPERATING CONDITIONS

5. Cubic-Foot Bottles, Standards, and So Forth

5.1 The capacities of cubic-foot bottles, standards, and so

FIG. 2 One-Tenth Cubic Foot Bottle, Transfer Tank, and Bubble-

forth, are indicated by their names. A portable cubic-foot Type Saturator for Testing Laboratory Wet Gas Meters

standardoftheStillmantypeisshowninFig.1andafractional

cubic-foot bottle is shown in Fig. 2. The temperatures and

always be low, and probably nonuniform, and in any given

pressures at which these types of apparatus are used must be

instance will be affected by the test being made and the

very close to those existing in the room in which they are

connections used.

located. Since these containers are generally used as standards

forthetestingofothergas-measuringdevices,therateatwhich

6. Burets, Flasks, and So Forth

they may be operated is of little or no importance. It will

6.1 Thecapacitiesofburets,flasks,andsoforth,willdepend

upon their function in the equipment and service in which they

are to be used. The range of temperatures and pressures under

which they may be used, which will be affected by their

function, will depend upon the material of construction and

may be relatively high (for example, 1000°F and 10 000 psi)

if suitable materials are used.

7. Calibrated Gasometers

7.1 Thestockcapacitiesofcalibratedgasometers(gasmeter

provers) are 2, 5, and 10 ft . The temperature and pressure at

which they can be operated must be close to the ambient

temperature and within a few inches of water column of

atmospheric pressure.The equivalent rates of flow that may be

attained, conveniently, are as follows:

3 3

Size, ft Equivalent Rate, ft of air/h

2 990

5 2250

10 5000

NOTE 2—Gasometers having volumetric capacities up to several thou-

sand cubic feet have been made for special purposes. Their use is limited

to temperatures close to the ambient temperature, although some may be

operated as pressures slightly higher than mentioned above. These large

gasometers can hardly be classed as equipment for measuring gaseous

samples, and are mentioned only for the sake of completeness.

8. Liquid-Sealed Rotating-Drum Meters

8.1 The drum capacities of commercial stock sizes of

FIG. 1 Stillman-Type Portable Cubic-Foot Standard liquid-sealed rotating-drum meters range from ⁄20 (or litre) to

D1071–83 (2003)

3 3

7.0 ft per revolution. A 0.1-ft per revolution meter is shown 9. Diaphragm-Type Test Meters

inFig.3.Theoperatingcapacities,definedasthevolumeofgas

9.1 The displacement capacities of commercial stock sizes

having a specific gravity of 0.64 that will pass through the

of diaphragm-type test meters range from about 0.05 to 2.5 ft

meter in 1 h with a pressure drop of 0.3-in. water column

per revolution (of the tangent arm or operating cycle). The

across the meter, range from 5 to 1200 ft /h. Liquid-sealed

operating capacities, defined as the volume of gas having a

rotating-drum meters may be calibrated for use at any rate for

specific gravity of 0.64 that a meter will pass with a pressure

which the pressure drop across the meter does not blow the

drop of 0.5 in. of water column across the meter, range from

meter seal. However, if the meter is to be used for metering

about 20 to 1800 ft /h. Usually these meters can be operated at

differing rates of flow, a calibration curve should be obtained,

rates in excess of their rated capacities, at least for short

as described in Section 20, or the meter should be fitted with a

periods. A meter having a capacity of 1 ft per revolution is

rate compensating chamber (see Appendix X1).

shown in Fig. 4.

8.2 The temperature at which these meters may be operated

9.2 Thetemperaturerangeunderwhichthesemetersmaybe

will depend almost entirely upon the character of the sealing

operated will depend largely upon the diaphragm material. For

liquid. If water is the sealing liquid, the temperature must be

leather diaphragms, 0 to 130°F is probably a safe operating

above the freezing point and below that at which evaporation

range. At very low temperatures, the diaphragms are likely to

will affect the accuracy of the meter indications (about 120°F).

become very stiff and cause an excessive pressure drop across

Outside of these limits some other liquid will be required.

the meter.At higher temperatures, the diaphragms may dry out

8.3 While the cases of most meters of this type may

rapidly or even become scorched causing embrittlement and

withstand pressures of about 2-in. Hg column above or below

leaks.

atmospheric pressure, it is recommended that the maximum

operating pressure to which they are subjected should not 9.3 Thepressurerange(linepressure)towhichthesemeters

exceed 1-in. Hg or 13 in. of water column. For higher

maybesubjectedsafelywilldependuponthecasematerialand

pressures, the meter case must be proportionally heavier or the design. For the lighter sheet metal (tin case) meters, the line

meter enclosed in a suitable pressure chamber. For pressures

pressure should not be more than 3- or 4-in. Hg column above

more than 1-in. Hg (13 in. of water) below atmospheric or below atmospheric pressure. For use under higher or lower

pressure,notonlymustaheaviercaseorapressurechamberbe

line pressures, other types of meter cases are available, such as

used,butasealingfluidhavingaverylowvaporpressuremust

cast aluminum alloy, cast iron, or pressed steel.

be used in place of water.

NOTE 3—The diaphragm-type test meter and the diaphragm-type con-

sumers meter are similar in most respects. The principal difference is the

type of index or counter. The test meter index has a main hand indicating

1ft perrevolutionovera3-in.orlargerdial,withadditionalsmallerdials

giving readings to 999 before repeating. On the index of consumers

meters, aside from the test hand, the first dial indicates 1000 ft per

revolution of its hand so that the smallest volume read is 100 ft . The

maximumreadingforaconsumersmeterindexmaybe99900or999900.

Anotherminordifferenceisthatthemaximumratedcapacityforthelarger

consumers meters may be 17000 ft /h.

FIG. 3 Liquid-Sealed Rotating-Drum Gas Meter of 0.1 ft per FIG. 4 Iron-Case Diaphragm-Type Gas Meter with Large

Revolution Size Observation Index

D1071–83 (2003)

10. Rotary Displacement Meters provided the temperature of the entire system is maintained

constant. This requires that the test should be made in a room

10.1 Rotary displacement gas meters are mentioned here

in which the temperature can be maintained constant and

only to have a complete coverage of meters for gas, since

uniform within less than 0.5°F. Moreover, to diminish the

meters of this type are of relatively large capacity, beyond that

cooling effects of evaporation from the surfaces of the bottle

of sample measurement (Note 4).The rated capacities of stock

andbell,thesealingfluidshouldbealight,low-vaporpressure

sizes range from about 4000 to about 1000000 ft /h. They

oil. Other observations forming a part of this calibration are

may be used at somewhat higher temperatures than other

those of the time intervals required for raising the bottle and

displacement meters, probably 400 to 500°F and are available

bell from their respective tanks and the intervals they are held

for use under line pressures up to about 125 psi.

up for drainage to take place before pressure readings are

NOTE 4—It is of course possible to use a very small meter of this type

made. From these times, corrections are determined for the

as a test or “sample” meter. See Bean, H. S., Benesh, M. E., andWhiting,

volumes of undrained liquid.

F. C., “Testing Large-Capacity Rotary Gas Meters,” Journal of Research,

12.3 Burets,flasks,andsoforth,areconsideredapartofthe

Nat. Bureau Standards, JRNBA, Vol 37, No. 3, Sept. 1946, p. 183.

analytical apparatus in which they are used, and methods of

(Research Paper RP1741).

calibrating them therefore are not covered here.

11. Rate-of-Flow Meters

NOTE 6—An outline of such methods is given in National Bureau of

11.1 Rate-of-flowmeters,asthenameimplies,indicaterates

Standards Circular C434 NBSCA, “Testing of Glass VolumetricAppara-

of flow, and volumes are obtained only for a definite time

tus,” by E. L. Peffer and Grace C. Mulligan.

interval. They are especially useful in those situations where

13. Calibration of Secondary or Working Standards

theflowissteady,butarenotsuitedforuseinthemeasurement

(Provers), General Considerations

of specified quantities nor on flows that are subject to wide or

more or less rapid variations of either rate or pressure. In the

13.1 Gas meter provers of 2-, 5-, and 10-ft capacity

smaller sizes, they may be particularly useful for both regulat-

customarily are calibrated by comparison with a cubic-foot

ing and measuring continuous samples of a gaseous fuel.

bottle or standard as described in Sections 14 and 15. The

11.2 Nodefinitelimitscanbesettotherangeofrateofflow

procedureconsistsofmeasuringairoutoforintotheproverby

to which these meters may be applied, nor to the range of

means of the standard, 1 ft at a time, noting the reading of the

temperatures and pressures under which they may be operated.

prover scale at the start and finish of each transfer. Some

Where meters of this type are desired, it will usually be

general considerations to be observed are given in 13.2 and

possible to design one to meet the particular service require-

13.3.

ments. Of particular interest for continuous sampl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.