ASTM F833-21

(Specification)Standard Consumer Safety Performance Specification for Carriages and Strollers

Standard Consumer Safety Performance Specification for Carriages and Strollers

SCOPE

1.1 This consumer safety specification establishes safety performance requirements, test methods, and labeling requirements to minimize the hazards to children presented by carriages and strollers as identified in the introduction. Children’s products such as tricycles, bicycles, or other similar wheeled products that can be self-propelled by a child are not considered carriages or strollers subject to the requirements of this standard, even if the item has a temporary or permanent handle.

1.2 No carriage or stroller produced after the approval date of this consumer safety performance specification shall, either by label or other means, indicate compliance with this specification unless it conforms to all requirements herein.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The following precautionary caveat pertains only to the test method portion, Section 7, of this consumer safety specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

- Status

- Published

- Publication Date

- 14-Jun-2021

- Technical Committee

- F15 - Consumer Products

- Drafting Committee

- F15.17 - Carriages, Strollers, Walkers and Stationary Activity Centers

- Current Stage

Relations

- Effective Date

- 01-Aug-2023

- Effective Date

- 01-Dec-2017

- Effective Date

- 01-Sep-2017

- Effective Date

- 01-Aug-2016

- Effective Date

- 01-Nov-2015

- Effective Date

- 01-Apr-2014

- Effective Date

- 01-May-2013

- Refers

ASTM F406-12a - Standard Consumer Safety Specification for Non-Full-Size Baby Cribs/Play Yards - Effective Date

- 01-May-2012

- Effective Date

- 15-Jan-2012

- Effective Date

- 01-Dec-2011

- Refers

ASTM F406-11b - Standard Consumer Safety Specification for Non-Full-Size Baby Cribs/Play Yards - Effective Date

- 15-Aug-2011

- Refers

ASTM F406-11a - Standard Consumer Safety Specification for Non-Full-Size Baby Cribs/Play Yards - Effective Date

- 01-Jul-2011

- Effective Date

- 15-May-2011

- Refers

ASTM F406-10b - Standard Consumer Safety Specification for Non-Full-Size Baby Cribs/Play Yards - Effective Date

- 01-Dec-2010

- Refers

ASTM F406-10a - Standard Consumer Safety Specification for Non-Full-Size Baby Cribs/Play Yards - Effective Date

- 15-Oct-2010

ASTM F833-21 - Standard Consumer Safety Performance Specification for Carriages and Strollers

REDLINE ASTM F833-21 - Standard Consumer Safety Performance Specification for Carriages and Strollers

Frequently Asked Questions

ASTM F833-21 is a technical specification published by ASTM International. Its full title is "Standard Consumer Safety Performance Specification for Carriages and Strollers". This standard covers: SCOPE 1.1 This consumer safety specification establishes safety performance requirements, test methods, and labeling requirements to minimize the hazards to children presented by carriages and strollers as identified in the introduction. Children’s products such as tricycles, bicycles, or other similar wheeled products that can be self-propelled by a child are not considered carriages or strollers subject to the requirements of this standard, even if the item has a temporary or permanent handle. 1.2 No carriage or stroller produced after the approval date of this consumer safety performance specification shall, either by label or other means, indicate compliance with this specification unless it conforms to all requirements herein. 1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. 1.4 The following precautionary caveat pertains only to the test method portion, Section 7, of this consumer safety specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

SCOPE 1.1 This consumer safety specification establishes safety performance requirements, test methods, and labeling requirements to minimize the hazards to children presented by carriages and strollers as identified in the introduction. Children’s products such as tricycles, bicycles, or other similar wheeled products that can be self-propelled by a child are not considered carriages or strollers subject to the requirements of this standard, even if the item has a temporary or permanent handle. 1.2 No carriage or stroller produced after the approval date of this consumer safety performance specification shall, either by label or other means, indicate compliance with this specification unless it conforms to all requirements herein. 1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. 1.4 The following precautionary caveat pertains only to the test method portion, Section 7, of this consumer safety specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ASTM F833-21 is classified under the following ICS (International Classification for Standards) categories: 97.190 - Equipment for children. The ICS classification helps identify the subject area and facilitates finding related standards.

ASTM F833-21 has the following relationships with other standards: It is inter standard links to ASTM F963-23, ASTM F406-17, ASTM F2680-17, ASTM F963-16, ASTM F406-15, ASTM F2680-09(2014), ASTM F406-13, ASTM F406-12a, ASTM F406-12, ASTM F963-11, ASTM F406-11b, ASTM F406-11a, ASTM F406-11, ASTM F406-10b, ASTM F406-10a. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ASTM F833-21 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ASTM standards.

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F833 −21

Standard Consumer Safety Performance Specification for

Carriages and Strollers

ThisstandardisissuedunderthefixeddesignationF833;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This consumer safety performance specification addresses carriage and stroller incidents that were

identified by the U.S. Consumer Product Safety Commission (CPSC).

The CPSC identified injuries to children associated with the following: stability, brakes, restraint

systems, latches and folding mechanisms, structural integrity, cords, wheel detachment, and deaths

due to entrapment in openings of convertible carriage/strollers. In response to the incident-data

compiled by the CPSC, this consumer safety performance specification attempts to minimize the

previously listed problems. This specification does not cover carriages and strollers that are blatantly

misused, although warnings and safety instructions are required to be prominently displayed on or

with each carriage or stroller.

NOTE 1—This consumer safety performance specification is not intended to address incidents and

injuries resulting from the interaction of other persons with children in carriages or strollers or

incidents resulting from unforeseeable abuse or misuse.

This consumer safety performance specification is written within the current state of the art of

carriage and stroller technology. It is intended that this specification will be updated whenever

substantive information becomes available which necessitates additional requirements or justifies the

revision of existing requirements.

1. Scope 1.4 The following precautionary caveat pertains only to the

test method portion, Section 7, of this consumer safety speci-

1.1 This consumer safety specification establishes safety

fication: This standard does not purport to address all of the

performance requirements, test methods, and labeling require-

safety concerns, if any, associated with its use. It is the

ments to minimize the hazards to children presented by

responsibility of the user of this standard to establish appro-

carriages and strollers as identified in the introduction. Chil-

priate safety, health, and environmental practices and deter-

dren’s products such as tricycles, bicycles, or other similar

mine the applicability of regulatory limitations prior to use.

wheeled products that can be self-propelled by a child are not

1.5 This international standard was developed in accor-

considered carriages or strollers subject to the requirements of

dance with internationally recognized principles on standard-

this standard, even if the item has a temporary or permanent

ization established in the Decision on Principles for the

handle.

Development of International Standards, Guides and Recom-

1.2 No carriage or stroller produced after the approval date

mendations issued by the World Trade Organization Technical

of this consumer safety performance specification shall, either

Barriers to Trade (TBT) Committee.

by label or other means, indicate compliance with this speci-

fication unless it conforms to all requirements herein.

2. Referenced Documents

1.3 The values stated in inch-pound units are to be regarded

2.1 ASTM Standards:

as standard. The values given in parentheses are mathematical

D3359 Test Methods for Rating Adhesion by Tape Test

conversions to SI units that are provided for information only

F406 Consumer Safety Specification for Non-Full-Size

and are not considered standard.

Baby Cribs/Play Yards

F963 Consumer Safety Specification for Toy Safety

This specification is under the jurisdiction of ASTM Committee F15 on

Consumer Products and is the direct responsibility of Subcommittee F15.17 on

Carriages, Strollers, Walkers and Stationary Activity Centers. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved June 15, 2021. Published August 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1983. Last previous edition approved in 2019 as F833 – 19. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F0833-21. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F833−21

F2680 Test Methods and Specifications for Bicycle Manu- cords, plastic textile tapes, ribbon, and those fibrous materials

ally Operated Front Wheel Retention Systems commonly called string.

2.2 Federal Standards: 3.1.8 double-action release mechanism, n—a release

16 CFR 1303 Ban of Lead-Containing Paint and Certain

mechanism that requires either two consecutive actions, the

Consumer Products Bearing Lead-Containing Paint first of which must be maintained while the second is carried

16 CFR 1500 Hazardous Substances Act Regulations in-

out, or two separate and independent single-action locking

cluding sections:

mechanisms that must be activated simultaneously to fully

1500.48 Mechanical Requirements for Determining a Sharp

release.

Point in Toys or Other Articles Intended for Use by

3.1.9 harness system, n—shall include a waist and crotch

Children Under Eight Years of Age

restraint and a means of restraining the upper torso.

1500.49 Technical Requirements for Determining a Sharp

3.1.10 infant, n—young child who is not capable of sitting

MetalorGlassEdgeinToysorOtherArticlesIntendedfor

unassisted.

Use by Children Under Eight Years of Age

1500.50-52 Test Methods for Simulating Use and Abuse of

3.1.11 jogging stroller, n—stroller intended to be used for

Toys and Other Articles Intended for Use by Children

children at a jogging rate (run at a steady slow trot).

16 CFR 1501 Method for Identifying Toys and Other Ar-

3.1.12 manufacturer’s recommended use position, n—any

ticles Intended for Use by Children Under Three Years of

position that is presented as a normal, allowable, or acceptable

Age Which Present Choking, Aspiration, or Ingestion

configuration for use of the product by the manufacturer in any

Hazards Because of Small Parts

descriptive or instructional literature. This specifically ex-

16 CFR 1508.07 (c)

cludes positions that the manufacturer shows in a like manner

2.3 Other Standards:

in its literature to be unacceptable, unsafe, or not recom-

AS/NZS 2088 Prams and strollers—safety requirements

mended.

EN 1888 Child care articles - Wheeled child conveyances -

3.1.13 non-paper label, n—any label material (such as

Safety requirements and test methods

plasticormetal)thateitherwillnottearwithouttheaidoftools

or tears leaving a sharply defined edge.

3. Terminology

3.1.14 occupant(s), n—that individual or those individuals

3.1 Definitions of Terms Specific to This Standard:

who are in a product that is set up in one of the manufacturer’s

3.1.1 2D fold stroller, n—a stroller that folds the handlebars

recommended use positions.

and leg tubes only in the front-to-back (or back-to-front)

3.1.15 occupant retention space, n—space enclosed by the

direction.

surfaces, for example, side walls or the floor, or both, of a

3.1.2 3D fold stroller, n—a stroller that, when folded,

carriage or convertible carriage/stroller that contains the occu-

collapses all handlebars and leg tubes both in the front-to-back

pant within a carriage or a stroller in the reclined carriage

(or back-to-front) and side-to-side directions.

position.

3.1.3 carriage, n—wheeled vehicle generally used for the

3.1.16 paper label, n—any label material that tears without

transportofaninfantwhoisgenerallyinalyingdownposition.

the aid of tools and leaves a fibrous edge.

The motive power is supplied by a person or persons pushing

or pulling on a handle attached to the vehicle. A carriage may

3.1.17 quick-release mechanism, n—lever-actuated cam

be capable of being folded for storage.

mechanism that connects and retains a wheel in a fork

assembly.

3.1.4 conspicuous, n—label that is visible, when the unit is

in a manufacturer’s recommended use position, to a person

3.1.18 reclined carriage position, n—adjustment position of

standing near the unit at any one position around the unit but

a convertible carriage/stroller that allows for an interior angle

not necessarily visible from all positions.

of greater than 150° between the seat surface and the backrest.

3.1.5 convertible car seat/stroller, n—car seat that has

3.1.19 removable-wheel fork assembly, n—fork assembly

wheels and handle that can be converted to become a stroller

from which the wheel can be removed and reattached as a

without the addition of other components.

manufacturer recommended normal product use.

3.1.6 convertible carriage/stroller, n—wheeled vehicle that

3.1.19.1 Discussion—A removable-wheel fork assembly

is intended to be converted by the owner to be used as either a

can employ a quick release mechanism or other manually

carriage or a stroller.

operated mechanism that does not require the use of tools for

installation or removal.

3.1.7 cord, n—a length of slender, flexible material includ-

ing monofilaments, woven and twisted cord, rope, elastic

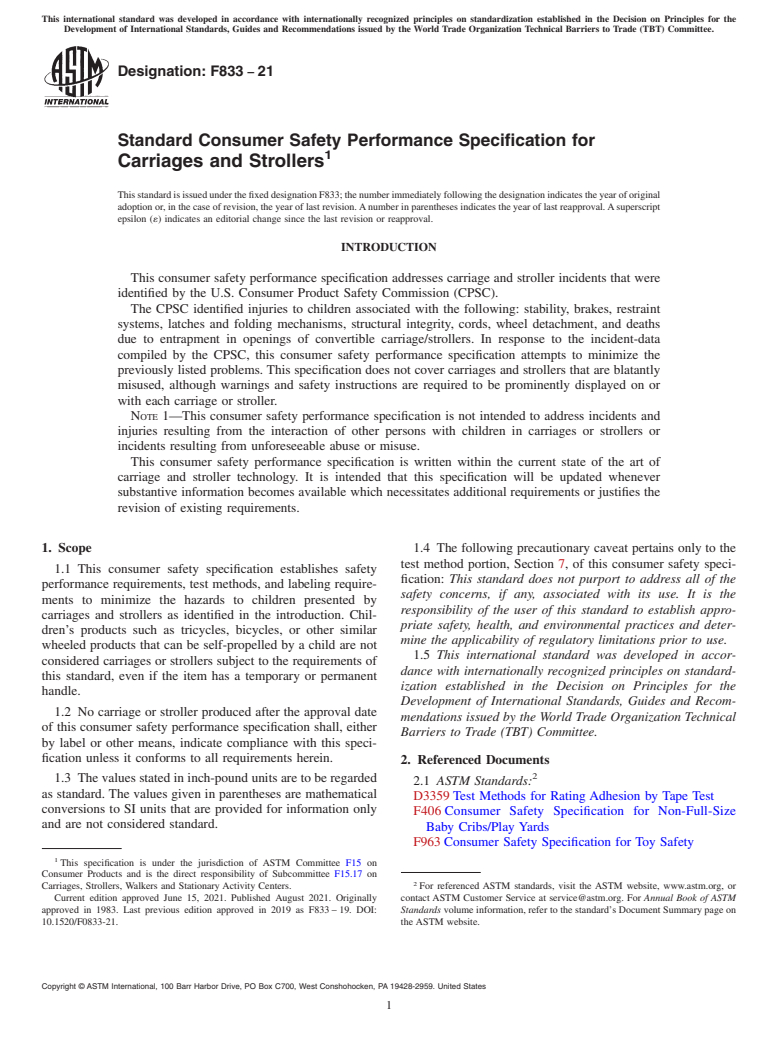

3.1.20 saddle hinge link, n—a folding joint on the side of a

3D fold stroller that connects the front leg tube and handle

tube.

Code of Federal Regulations, available from U.S. Government Printing Office,

3.1.20.1 Discussion—It includes a component (saddle

Washington, DC 20402.

hinge) that contains a pivot location and a recessed groove (see

Available from SAI Global, http://www.saiglobal.com.

Fig. 1). When the stroller is unfolded, one of the tubes rotates

Available from European Committee for Standardization (CEN), Avenue

Marnix 17, B-1000, Brussels, Belgium, http://www.cen.eu. around the saddle hinge pivot and rests in the recessed groove.

F833−21

FIG. 1Saddle Hinge Link

3.1.21 static load, n—vertically downward force applied by 5. General Requirements

a calibrated force gage or by dead weights.

5.1 There shall be no hazardous points or edges as defined

3.1.22 strap, n—piece of flexible material of which the

by 16 CFR 1500.48 and 16 CFR 1500.49 before and after

width is significantly greater than the thickness.

testing to this consumer safety specification.

3.1.23 stroller, n—wheeled vehicle for the transport of

5.2 Thereshallbenosmallpartsasdefinedby16CFR1501

infants or children generally in a sitting-up or semi-reclined

before testing or liberated as a result of testing to this

position. The motive power is supplied by a person moving at

specification.

a walking rate while pushing on a handle attached to the

5.3 The paint and surface-coating on the product shall

stroller. A stroller generally is capable of being folded for

comply to 16 CFR 1303.

storage. Strollers normally are used for children from infancy

5.4 Priortotesting,anyexposedwoodpartsshallbesmooth

to 36 months of age.

and free of splinters.

3.1.24 tray/grab bar locking position, n—any position in

which the tray or grab bar can lock including positions 5.5 Latching Mechanisms:

5.5.1 Any unit that folds shall have a latching device or

intended by the manufacturer for non-occupant use.

other provision in the design that will prevent the unit from

3.1.25 tray/grab bar protective covering, n—component

unintentional folding when properly placed in the manufactur-

designed and intended as a means to prevent exposure of any

er’s recommended use position. Products with latching devices

underlying accessible foammaterial.Examplesinclude,butare

for prevention of unintentional folding shall be tested in

not limited to woven, knit, coated, laminated, extruded, or

accordance with 7.2. During and upon completion of this test,

calendered textile-based materials and leathers.

the unit shall meet the requirements in 5.5.1.1 or 5.5.1.2.

3.1.26 tray/grab bar stop position, n—anypositioninwhich

5.5.1.1 The locking device on the unit shall remain latched.

the tray or grab bar is forward of the occupant, is not in a

5.5.1.2 The stroller frame components yield and perma-

locking position, and remains stationary whena5lb force is

nently deform in a manner such that the full load specified

applied to it for 10 s at any location and in any direction likely

cannot be applied in the direction of folding and the locking

to cause it to change position.

device remains engaged.

3.1.26.1 Discussion—The 5 lb force is designed to over-

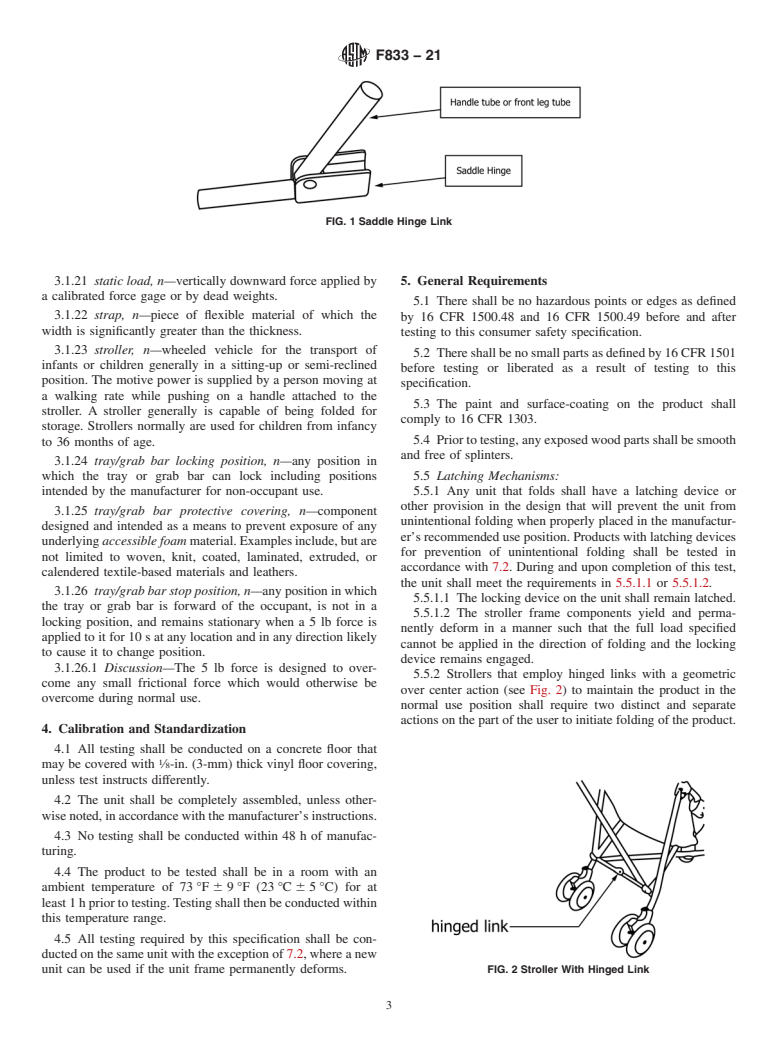

5.5.2 Strollers that employ hinged links with a geometric

come any small frictional force which would otherwise be

over center action (see Fig. 2) to maintain the product in the

overcome during normal use.

normal use position shall require two distinct and separate

actions on the part of the user to initiate folding of the product.

4. Calibration and Standardization

4.1 All testing shall be conducted on a concrete floor that

may be covered with ⁄8-in. (3-mm) thick vinyl floor covering,

unless test instructs differently.

4.2 The unit shall be completely assembled, unless other-

wisenoted,inaccordancewiththemanufacturer’sinstructions.

4.3 No testing shall be conducted within 48 h of manufac-

turing.

4.4 The product to be tested shall be in a room with an

ambient temperature of 73 °F 6 9 °F (23 °C 6 5 °C) for at

least1hpriortotesting.Testingshallthenbeconductedwithin

this temperature range.

4.5 All testing required by this specification shall be con-

ducted on the same unit with the exception of 7.2, where a new

unit can be used if the unit frame permanently deforms. FIG. 2Stroller With Hinged Link

F833−21

Such strollers shall require only a single action on the part of 5.7.2 Saddle hinge links on 3D fold strollers shall be

the user to secure the stroller in the normal use position. designed and constructed so as to prevent injury from

scissoring, shearing, or pinching. Scissoring, shearing, or

5.6 Openings—Holes or slots that extend entirely through a

pinching that may cause injury exists in a saddle hinge link

wall section of any rigid material less than 0.375 in. (9.53 mm)

when the edges of the rigid parts admit a 0.210-in. (5.33-mm)

thick and admit a 0.210-in. (5.33-mm) diameter rod shall also

diameter probe but do not admit a 0.375-in. (9.53-mm)

admit a 0.375-in. (9.53-mm) diameter rod. Holes or slots that

diameter probe when tested in accordance with 7.17.1.

are between 0.210 in. (5.33 mm) and 0.375 in. (9.53 mm) and

have a wall thickness less than 0.375 in. (9.53 mm) but are

NOTE 2—The evaluation at any given location is performed with the

limited in depth to 0.375 in. (9.53 mm) maximum by another

understanding that the probes are allowed to enter the location from any

angle/direction.

rigidsurfaceshallbepermissible(seeFig.3).Theproductshall

be evaluated in all manufacturer’s recommended use positions.

5.7.3 Canopy pivots and canopy frame members shall

comply with 5.7.1 when tested in accordance with 7.17.2.

5.7 Scissoring, Shearing, and Pinching:

Canopy stretcher/locking device(s) are exempt from this re-

5.7.1 The unit, when in the manufacturer’s recommended

use position, shall be designed and constructed so as to prevent quirement (see Fig. 4). The interface between canopy rods and

canopy stops are exempt from this requirement if the canopy

injury to the occupant from any scissoring, shearing, or

pinchingwhenmembersorcomponentsrotateaboutacommon rod does not pass over or through the final canopy stop. Final

canopy stops are those that prevent further movement or

axis or fastening point, slide, pivot, fold, or otherwise move

relative to one another. Scissoring, shearing, or pinching that adjustment of the canopy (see example in Fig. 5). Intermediate

canopy stop positions are not exempt from this requirement.

may cause injury exists when the edges of the rigid parts admit

a 0.210-in. (5.33-mm) diameter probe but do not admit a

5.7.4 The frame folding action of a 2D fold stroller and

0.375-in. (9.53-mm) diameter probe at any accessible point

convertible carriage/stroller (carriages are exempted from this

throughouttherangeofmotionofsuchparts.Thisexcludesthe

requirement)shallbedesignedandconstructedsoastoprevent

adjustment of accessory items such as storage latches, baskets,

injury from scissoring, shearing, or pinching. Scissoring,

etc.

shearing, or pinching that may cause injury exists when the

edges of the rigid parts admit a 0.210-in. (5.33-mm) diameter

NOTE 1—The evaluation at any given location is performed with the

probe but do not admit a 0.375-in. (9.53-mm) diameter probe

understanding that the probes are allowed to enter the location from any

angle/direction. when tested in accordance with 7.15. Units with a removable

seat that prevent the complete folding of the unit when still

attached are exempt from this requirement.

NOTE 3—The evaluation at any given location is performed with the

understanding that the probes are allowed to enter the location from any

angle/direction.

5.8 Exposed Coil Springs—Any exposed coil spring which

is accessible to the occupant, having or capable of generating

a space between coils of 0.210 in. (5.33 mm) or greater during

static load testing (see 6.2 and 7.3) shall be covered or

otherwise designed to prevent injury from entrapment.

5.9 Labeling:

5.9.1 Warning labels (whether paper or non-paper) shall be

permanent when tested in accordance with 7.8.1 – 7.8.3.

FIG. 3Opening Example FIG. 4Stretcher/Locking Device

F833−21

5.11 Seat Recline Measurement—Place the back of the

stroller in the most reclined position. Place the hinged boards

with the hinged edge into the junction of the stroller back and

seat (see Fig. 6). Measure the angle between the two boards.

5.12 Toy—Toy accessories attached to, removable from, or

sold with unit, as well as their means of attachment, shall meet

applicable requirements of Consumer Safety Specification

F963.

5.13 Cord/Strap Length—Cords and straps that originate

within or extend into the occupant space shall not create a loop

that has an internal perimeter exceeding 14.8 in. (376 mm) nor

have a free stretched length that exceeds a length of 7.4 in.

(188 mm) when evaluated with 7.16. Cords or straps that do

FIG. 5Canopy Stop

notoriginatewithintheoccupantspacebutthatcanextendinto

the occupant space shall be evaluated in accordance with 7.16

only on the portion of the cord/strap that can extend into the

occupant space. Restraint systems used to secure an occupant,

5.9.2 Warning statements applied directly onto the surface

all straps used to attach hand held infant carriers, and straps on

of the product by hot stamping, heat transfer, printing, wood

hand held infant carriers, stroller carry straps, and stroller

burning, etc. shall be permanent when tested in accordance

tether straps are exempt from this requirement.

with 7.8.4.

5.9.3 Non-paper labels shall not liberate small parts when

5.14 Tray/Grab Bar Protective Covering Requirement—

tested in accordance with 7.8.5.

Trays/grab bars that are accessible and forward of the occupant

shall meet any one of the following:

5.10 Protective Components—If a child can grasp compo-

5.14.1 The tray/grab bar does not contain foam material.

nents between the thumb and forefinger, or teeth, such as caps,

5.14.2 The tray/grab bar covering prevents the underlying

sleeves, or plugs used for protection from sharp edges, points,

foam material from being exposed when tested per 7.19.

orentrapmentoffingersortoes,orifthereisatleasta0.040-in.

(1.00-mm) gap between the component and its adjacent parent

6. Performance Requirements

component, such component shall not be removed when tested

NOTE 4—The forces that are to be applied to the sample in the test

in accordance with 7.9.

methods described in Section 7 of this specification are applied readily by

3 3

NOTE 1— ⁄4 in. (19 mm) by 6 in. (150 mm) by 6 in. (150 mm) board hinged to a ⁄4 in. (19 mm) by 6 in. (150 mm) by 9 in. (225 mm) board placed

in the junction of the stroller seat.

FIG. 6Seat Back Recline Board

F833−21

means of a calibrated force gage, or in the case of static load and dynamic

is excluded from the parking brake access zone. Where a

load test methods, by dead weights.

stroller is suitable for two or more children, the space located

6.1 Parking Brake Requirements:

behind the backrest shall be considered if it enters another

6.1.1 A parking brake shall be provided on the unit. Each

parking brake access zone. The access zone located under the

parking brake shall remain engaged during the test as specified

seat is defined as a 2-in. (51-mm) band extending inward from

in 7.6. Each parking brake shall prevent the braked wheel(s)

each side of the seat/leg rest edge and downward for 5.9 in.

th

from rotating more than 90° during the 5 test cycle specified

(150 mm) from the uncompressed upper surface of the seat.

in 7.6.

(See Fig. 8.)

6.1.2 After completing the test described in 7.6, each

6.1.3.2 The parking brake release mechanism consists of

parking brake shall be able to be engaged and shall meet the

one single-action release mechanism that shall not be released

requirements of this standard in all parking brake engagement

whenaforceof10 lbf(45 N)oratorqueof3 lbf-in.(0.34 Nm)

positions.

is applied directly to the release mechanism in the direction

6.1.3 The parking brake release mechanism(s) shall comply

tending to release it.

with either 6.1.3.1, 6.1.3.2,or 6.1.3.3 when evaluated for each

6.1.3.3 The parking brake release mechanism is a double-

seating position of the product.

6.1.3.1 Each parking brake release mechanism shall be action release mechanism.

located outside the parking brake access zone for each seating

6.2 Static Load:

position. Refer to Fig. 7.The space located behind the backrest

FIG. 7Parking Brake Access Zone

F833−21

FIG. 8Parking Brake Access Zone Located Under the Seat

6.2.1 Acarriage shall support a static load of 50 lb (22.7 kg) 6.3 Stability—The product shall remain on the appropriate

when placed in the approximate center of the area intended to

test plane and not tip over when tested in accordance with 7.4.

support the infant occupant. At the end of this test method, the unit shall remain in the

6.2.2 Astrollershallsupportastaticloadof100lb(45.4kg)

manufacturer’s recommended-use position on the inclined test

or 2.5 times the manufacturer’s recommended maximum

plane when tested in accordance to 7.4.1 and on a horizontal

weight, whichever is greater, per individual seating area, when

test plane when tested in accordance with 7.4.2. In cases of

placedintheapproximatecenteroftheareaintendedtosupport

multiple-occupancy units, the specified test weight shall be

the child occupant.

placed in any occupant seat deemed to be the worst or the most

6.2.3 A convertible carriage/stroller shall support a static

likely to fail. Products that include as original equipment

load appropriate to the configuration in which the unit is

manufacturer-supplied accessories for carrying any type of

erected. All configurations shall be tested.

packages must be tested with these accessories both empty and

6.2.4 A combination unit of a car seat on a stroller shall

loaded with the most adverse configured combination of

support a static load of 50 lb (22.7 kg) when placed in the

weights, including the maximum weight(s) specified by the

approximate center of the area intended to support the occu-

manufacturer,whileeachavailableseatingpositionisoccupied

pant.

by the specified test weight.

6.2.5 Test methods shall be performed in accordance with

6.4 Restraining System—All products covered by this

7.3. At the conclusion of the test method, there shall be no

specification, except carriages designed only for an infant,

unacceptable conditions as identified within this specification

must have a child restraint system. The manufacturer shall

(see Note 5). In cases of multiple occupancy units, a specified

attach the restraint system in such a manner that it will not

test weight shall be applied simultaneously to each occupant

become detached through normal usage. The restraint system

position.

shall include both waist and crotch restraint. The crotch

NOTE 5—For the purpose of this specification, the unacceptable

resistant shall be designed such that its use is mandatory when

conditions that might be identified by the static load test methods shall be

the restraint system is in use.

failure to support the test weight, tip over, collapse of the product or a

component of the product, sharp edges or points, and small parts.

6.4.1 Carriage—No restraining system is required if the

carriage is intended to be used for an infant only. Carriages

6.2.6 Any step or footrest on the product shall support a

static load of 50 lb (22.7 kg) or 1.25 times the manufacturer’s with accessory sit-up backs or other items indicating intent to

be used for children developed beyond infancy must have a

recommended maximum weight, per individual seating area,

whichever is greater. restraining system (see 6.4.4).

F833−21

6.4.2 Stroller—A restraining system shall be provided pre-

assembled by the manufacturer to a component of the stroller.

6.4.3 Convertible Carriage/Stroller—A restraining system

shall be provided on each convertible carriage/stroller that will

function as though the unit is specifically a carriage (see 6.4.1)

or stroller (see 6.4.2).

6.4.4 Restraining System—Test methods for all restraining

systems shall be in accordance with 7.5. The restraint system

and its closing means (for example, buckle) shall not part or

slipmorethan1in.(25mm).Theanchoragesshallnotseparate

from their attachment points.At the end of the tests, the CAMI

dummy shall not be released fully. When tested in accordance

with 7.5.2.8, the restraint system (see Fig. 9 for Point C) shall

not move more than 2 in. (51 mm).

6.4.5 HarnessSystem—Ifaharnesssystemutilizesseatback

anchor points for shoulder straps, then the system shall meet

the requirements of 7.5.3.

6.4.6 Location of Restraining System—When tested in ac-

cordance with 7.5.4, the restraining system shall meet the

following requirements.

6.4.6.1 The anchor points of the waist restraint shall be

between the 2-in. (50-mm) line and the 5-in. (127-mm) line on

the test cylinder when tested in accordance with 7.5.4.3. (See

Fig. 10.)

6.4.6.2 A1-in.(25-mm)diameterprobeshallnotfreelypass

through any gap between the waist restraint and the test

cylinder when tested in accordance with 7.5.4.4.

6.4.6.3 The forward most position of the junction of the

crotch strap and seat surface shall not be in front of the test

cylinder when tested in accordance with 7.5.4.5. A removable

seat pad shall not be considered part of the seat surface.

6.4.6.4 The point on the lower edge of the waist strap shall

be between the 4.5-in. (114-mm) line and the 7.5-in. (190-mm)

lineonthetestcylinderwhentestedinaccordancewith7.5.4.6.

6.4.7 Buckle Release—The waist buckle release mechanism

shall meet either 6.4.7.1 or 6.4.7.2 when tested in accordance

with 7.5.5.

FIG. 10Thigh Depth, Seated

6.4.7.1 Thebuckleshallhaveasingle-actionreleasemecha-

nismthatdoesnotreleaseataforcelessthan9lbf(40N)when

tested in accordance with 7.5.5.2.

6.4.7.2 The buckle shall consist of a double-action release

mechanism that does not release with any one of the release

mechanisms activated alone when tested in accordance with

7.5.5.3.

6.5 Occupant Retention—Carriages or seating locations of

convertible carriage/strollers with a reclined carriage posi-

tion(s)shallhaveawall(s)surroundingallsidesabovethefloor

of the occupant retention space. The enclosure shall not allow

thecompletepassageofthetestprobeshowninFig.11through

any completely bounded external openings (any holes) below

the top edge of the occupant retention space when tested in

accordance with 7.7.

6.5.1 Products with a reclined carriage position(s) must

have a nondetachable feature to enable them to conform to the

requirement in 6.5 unless the product only can be adjusted to

any reclined carriage position when a detachable device is

FIG. 9Restraint System Setup attached.

F833−21

FIG. 11Occupant Retention Probe

6.5.1.1 Nondetachable denotes that the occupant retention

assembly cannot be separated or removed from the product

without damaging it or be removed without the aid of tools.

6.6 Car Seat/Stroller Products:

6.6.1 Combination Unit of a Car Seat on a Stroller—The

combined unit shall conform to the requirements of 2.2, 6.1 in

accordance with 7.6, 6.2.4 in accordance with 7.3.2, 6.3 in

accordance with 7.4.1, 6.7.1 in accordance with 7.11, 6.10 in

accordance with 7.18, 7.10, and 9.1 when the car seat is

installed in all manufacturer’s recommended use positions.

When testing the combination unit according to 7.10 (16 CFR

1500.52 (b) (4) (iii)), the unit shall neither have any broken

parts nor allow the car seat to completely separate from the

stroller.

8.0-in. (203-mm) hollow sphere

6.6.2 Convertible Car Seat/Stroller—A restraint system

Material: ABS

which is certified to restrain a child in a motor vehicle, shall be Weight: 5 lb (2.3 kg)

exempt from the requirements of 6.4.5 and 6.4.6.

FIG. 12Head Probe

6.7 Impact Test:

6.7.1 For combination unit of a car seat on a carriage,

complete passage of the torso probe (Fig. 13) when tested in

stroller, or convertible carriage/stroller:

accordance with 7.12.

6.7.1.1 The unit shall not allow any attachment point(s)

provided by the manufacturer for securing the car seat to the 6.9 Wheel and Swivel Assemblies Detachment:

unit to release when tested in accordance with 7.11.1 – 7.11.5. 6.9.1 Wheel(s) and swivel(s) assemblies shall not detach

After the test, the car seat shall remain in the manufacturer’s from the unit upon completion of the test in accordance with

recommended use position. 7.13.1 and 7.13.2.

6.7.2 For carriage, stroller, or convertible carriage/stroller: 6.9.2 Aremovable-wheel fork assembly(s) shall incorporate

6.7.2.1 The fold locking/latching mechanism shall not dis- a secondary retention device and shall be so designed as to

engage or break, or both, and breakage shall not occur to the prevent unintended detachment of the wheel from the unit

frame of the unit when tested in accordance with 7.11.6. when tested in accordance with 7.14.

6.8 Passive Containment/Foot Opening—The test shall be 6.10 Head Entrapment with Car Seat on a Stroller or

performed on all strollers and convertible carriage/strollers, Convertible Carriage/Stroller—This requirement applies to a

while in stroller mode, that have a tray(s) or grab bar(s) that combination unit of a rear-facing car seat on a stroller or

create a completely or partial bounded opening(s) in front of convertible carriage/stroller when tested in accordance with

the occupant. An opening(s) shall either permit complete 7.18. Any completely bounded external opening within 5 in.

passage of the head probe (Fig. 12) or shall not permit (127 mm) above the foot end of the car seat shall either not

F833−21

7.3.1 Place the product in the manufacturer’s recommended

use position.

7.3.2 Place the specified weight from 6.2 upon a 6-in. by

6-in.(150-mmby150-mm)woodblock ⁄4 in.(19mm)thickin

the unit at the location called for in 6.2. If the unit has a

hammock-type seat, use a standard 6-in. weld cap as identified

in Fig. 14 instead of the specified wood block upon which to

place the test weight. Make allowances for the mass of the

weld cap. Gradually apply the weight within 5 s and maintain

for an additional 60 s.

7.3.3 Place a 50-lb (22.7-kg) weight or 1.25 times the

manufacturer’s recommended maximum weight of an indi-

vidual seating area, whichever is greater, upon the center of

any step or footrest and distribute it upon a 3-in. by 6-in.

(75-mm by 150-mm) wood block ⁄4 in. (19 mm) thick. If the

step or foot rest is adjustable, the test method shall be done in

the lowest use position. Gradually apply the weight within 5 s

and maintain for an additional 60 s.

7.4 Stability Test Method:

NOTE 1—Not to scale.

7.4.1 Stability with Occupant(s) in the Product:

FIG. 13Torso Probe

7.4.1.1 Place the product in the manufacturer’s use position

withallwheelsona12°inclinedplane.Ifthetestmodelhasan

adjustable back rest, test in the most upright, recline, and

allow the complete passage of the torso probe (Fig. 13) when

carriage use positions. If the unit has a rotating seat, test the

tested in accordance with 7.18.3 or shall permit complete

unit with the seat in all recommended use positions.

passage of the head probe (Fig. 12) when tested in accordance

7.4.1.2 In the upright and recline (an interior angle of 150°

with 7.18.5.Any horizontal openings between the car seat foot

or less as measured in accordance with 5.11 between the seat

end and the front surface of the unit seat back are excluded

surfaceandthebackrest)usepositions,placeaCAMIDummy,

from this requirement.

Mark II (see Fig. 15) in the carriage or stroller, and secure the

restraint system in accordance with the manufacturer’s instruc-

7. Test Methods

tion.

7.4.1.3 For the carriage use position, an interior angle of

7.1 Testing Guidelines:

greaterthan150°asmeasuredinaccordancewith5.11between

7.1.1 The last three tests under this section shall be as listed

the seat surface and the backrest, place the CAMI Dummy,

below and conducted in the order shown.

Mark II (see Fig. 15) with the dummy’s head against the rear

(1) 7.11.1 – 7.11.5

surface of the occupant retention space and the handle in the

(2) 7.11.6

stroller mode.

(3) 7.2 (the last test)

7.4.1.4 Place a stop on the plane against the wheels in a

7.2 Latching Mechanisms for Prevention of Unintentional

manner that will prevent the carriage or stroller from moving

Folding:

on the plane but will not prevent it from tipping.

7.2.1 Place the product in the manufacturer’s recommended

7.4.1.5 Position the stroller or carriage on the plane in all

use position. Gradually place a 5-lb (2.3-kg) weight in the

orientations that present maximum tendency for the unstable

center of each seating surface.

condition to exist.

7.2.2 Secure the product so that the normal folding motion

is not impeded.

7.2.3 Apply a force of 67 lbf (298 N) at the location

normallyassociatedwiththefoldingactionandinthedirection

normally associated with folding the product in accordance

with the manufacturer’s instructions. Gradually apply the force

within 5 s while maintaining the direction of force relative to

thefloorandmaintainforanadditional10s.Toapplytheforce

tothehandleofaproductwithseparategrippinghandles,place

a rigid bar horizontally across the handles and apply the force

centered between the handles. Discontinue the application of

the force if the condition outlined in 5.5.1.2 occurs.

NOTE 6—Do not apply this force on latching or unlatching means itself.

7.2.4 Repeat 7.2.3 for a total of 5 times within 4 min.

7.3 Static Load Test Method: FIG. 14Weld Cap

F833−21

7.5 Restraining System Integrity and Occupant Retention

Test Methods:

7.5.1 Restraining System Integrity Test Method:

7.5.1.1 Secure the test model so that it cannot move verti-

cally or horizontally.

7.5.1.2 Apply a force of 45 lbf (200 N) to a single

attachment point of the restraint system in the normal use

direction(s) that stress would be applied to that attachment.

Gradually apply the force within 5 s and maintain for an

additional 10 s.

7.5.1.3 Repeat 7.5.1.2 for a total of five times with a

maximum interval of 5 s between tests.

7.5.1.4 Repeat 7.5.1.2 and 7.5.1.3 for each attachment point

of the restraint system and fastening device.

7.5.2 Restraining System Occupant Retention Test Method:

7.5.2.1 If the test model has an adjustable back rest, place it

in the most upright use position. Place a CAMI Infant Dummy,

MarkII(seeFig.15)inthetestunitwiththerestrainingsystem

fastened in accordance with the manufacturer’s instructions.

NOTE 1—Department of Transportation, Federal Aviation

Tighten the restraining system in such a manner that a force of

Administration, Drawing No. SA-1001.

2 lbf (9 N) or less will provide at least a ⁄4-in. (6-mm) space

FIG. 15CAMI Dummy, Mark II

between the restraint system and the dummy. The webbing

tension pull device shown (Fig. 17) is required to determine

NOTE 1—Disk shall be made of aluminum with a smooth finish.

FIG. 161.5 in. Disk

7.4.2 Front Stability (Child Climbing in) for Stroller or

Convertible Carriage/Stroller in Stroller Use Only:

7.4.2.1 Place the unit in the manufacturer’s recommended

use position with all wheels on a flat horizontal plane. With no

weightintheseatingcompartment,placethefootrestorstep,or

both, in the lowest use position. If the wheels swivel, test with

the wheels positioned to most likely cause failure.

7.4.2.2 Apply a force of 40 lbf (178 N) with a disk (see Fig.

16) vertically downward to any member forward of the front

edge of the seat on any location likely to cause the unit to tip

over. The position must support the vertical force applied

through the disk and without the disk sliding off the surface.

Gradually apply the force within 5 s, and maintain it for 10 s.

7.4.2.3 If the disk slides off at a particular spot on the 1

NOTE 1—Dimension A: Width of webbing plus ⁄8 in. (3 mm).

footrest or step, it is considered a pass at that particular spot on

NOTE 2—Dimension B: One half of Dimension A.

the unit. FIG. 17Webbing Tension Pull Device

F833−21

proper restraint system fit. Perform the following tests without

readjusting the restraint system.

7.5.2.2 Apply a pull force of 45 lbf (200 N) horizontally on

the approximate centerline of either leg of the dummy (at the

ankle).Graduallyapplytheforcewithin5sandmaintainforan

additional 10 s.

7.5.2.3 Repeat 7.5.2.2 for a total of five times with a

maximum interval of 5 s between tests.

7.5.2.4 Release the test unit from its attachment to the test

plane (7.5.1).

7.5.2.5 Reposition the CAMI Infant Dummy, Mark II (Fig.

15) into the seated position without adjusting the restraint

system.

7.5.2.6 By any convenient means, lift the unit and rotate it

NOTE 1—5.37-in. (136-mm) diameter by 12-in. (304-mm) high, weigh-

backwards 360° around an axis approximating the intersection

ing 10 lb. (4.6 kg), rigid material with bottom.

of the seat back and bottom. The rotation must hesitate for a

NOTE 2—The rationale for the 5.37 diameter was determined by taking

minimum of 1 s every 90°.

the average of the waist diameter converted from the waist circumference,

waist breadth, and hip circumference of a 5 % 6-month-old to a 95 %

7.5.2.7 Rotate the stroller 360° around an axis approximat-

15-month-old child. Most incidents of children falling from strollers are

ing the side edge of the seat bottom. Rotation must hesitate a

with children between 6 months and 15 months.

minimum of 1 s every 90°.

Waist Circumference

7.5.2.8 Remove any removable soft goods.Adjust the waist

6 to 8 months 5 % 14.137 4.5 diameter

strap(s) to the position in 7.5.2.1 (see Fig. 9), without the 12 to 15 months 95 % 17.874 5.7 diameter

Waist Breadth

CAMI Infant Dummy, Mark II. Place a 5-lb (2.2-kg) weight on

6 to 8 months 5 % 11.8 4.65 diameter

a 6-in. by 6-in. (150-mm by 150-mm) wood block ⁄4 in.

12 to 15 months 95 % 15.3 6.02 diameter

(19 mm) thick in the center of the seat. Establish a horizontal Hip Circumference

6 to 8 months 5 % 16.22 5.1 diameter

reference line (LineA) forward of the seat back and on a plane

12 to 15 months 95 % 19.57 6.2 diameter

(Plane B) perpendicular to the seat back and through the point

where the waist strap(s) attaches to or emerges from the seat

FIG. 18Test Cylinder

back rest (Point C). Apply a force of ⁄2 lbf (2.2 N), using the

web tension device (Fig. 17), to the loop to remove any slack

and measure (D1) from the forward most point of the loop

(Point E) to the horizontal reference line (Line A). Apply a

force of 7 lbf (31 N) to Point E perpendicular to the seat back

(Plane B), and measure the distance (D2). The difference

between the initial measurement (D1) and the second measure-

ment (D2) shall conform to 6.4.4.

7.5.3 The height of the shoulder strap’s potential anchors

shall be at 10.5 in. 6 1.0 in. (267 mm 6 26 mm) and 12.5 in.

6 1.0 in. (318 mm 6 26 mm) from the junction of the stroller

back and seat (see Fig. 6) with the stroller back in most upright

position. For strollers with a maximum child weight of greater

than 40 lb (18.1 kg) per seat, a third potential anchor shall be

at 15 in. 6 1.0 in. (380 6 26 mm). The measurement shall be

from the junction of the seat/back to the lowest point of the

strap/seat back junction. With the stroller back in the most

upright position, these measurements shall be taken from the

top of the uncompressed seat or the bottom of the seat board

FIG. 19Test Cylinder in Stroller

(see Fig. 6) parallel to the back.

7.5.4 Restraining System Waist Restraint/Crotch Strap Test

it is parallel with the lines on the test cylinder. Determine the

Method:

location of the waist restraint anchor center point(s) by visual

7.5.4.1 If the test model has an adjustable backrest, place it

inspection.

in the fully upright position.

7.5.4.4 With the same configuration in accordance with

7.5.4.2 Snugly secure the test cylinder (see Fig. 18)inthe

7.5.4.3, attempt to freely pass a 1-in. (25-mm) diameter probe

unit (see Fig. 19) with the restraint system.

through any space between the waist restraint system and the

7.5.4.3 The lower corner of the test cylinder shall be at the test cylinder.

seatbottom/backjunctionwiththetestcylindercenteredandin 7.5.4.5 Position the test cylinder so that the lower corner is

full contact with the seat back.Align the waist restraint so that at the seat surface/back junction and the bottom of the test

F833−21

cylinder is in full contact with the seat surface. Determine the located 0.125 in. (3.17 mm) away from the movable edge

forward most position of the junction of the crotch strap and directly opposite the fixed edge, and in the direction that

seat surface by visual inspection. produces maximum releasing effect.

7.5.4.6 Position the test cylinder in accordance with 7.5.4.5. (2) Floating Button Buckles (Fig.21d)—Preloadthebuckle

If the crotch strap is adjustable, adjust it to the maximum

using the appropriate method in 7.5.5.1. Apply a release force

length. Locate the points 2-in. (50-mm) to the right and left of using a conical surface (Fig. 22) located at the center of the

the center of the crotch/waist junction in accordance with Fig.

releasemechanisminthedirectionthatproducesthemaximum

20. With the waist restraint adjusted to allow full extension of releasing effect.

the crotch restraint, pull the crotch restraint to its highest point

(3) For all other single-action buckle release mechanisms,

on the test cylinder.

the force shall be applied on the centerline of the buckle lever

7.5.5 Buckle Release Test Method:

or finger tab in the direction that produces the maximum

7.5.5.1 Buckle Pre-load:

releasing effect. Measure the force required to release the

(1) SingleLatchPlateBuckles(Fig.21a)—Placethebuckle

buckle. (Fig. 21 illustrates the loading for the different buckles

on a hard, flat horizontal surface shaped so that it does not

and the point where the release force should be applied, and

impedethereleasewhenbeingtested.Preloadthestrapendsof

Fig. 22 illustrates the conical surface used to apply the release

thebucklewith2lb(9N)inopposingdirectionsawayfromthe

force to pushbutton release buckles.)

buckle.

7.5.5.3 Double-action Release Mechanisms:

(2) Double Latch Plate Buckles (Fig. 21b)—Place the

(1) Secure the buckle in a manner that does not contact any

buckle on a hard, flat horizontal surface shaped so that it does

activation buttons. Fully activate and maintain one of the two

not impede the release when being tested. Preload the strap

mechanisms so that it is no longer fully engaged. While

ends of the buckle with 2 lb (9 N) in opposing directions away

maintaining activation, applya2lb(9N) force to each strap

from the buckle. Latch plates that are removed from the buckle

endinoppositedirectionsawayfromthebucklereleasebutton.

in the same direction shall be loaded equally so that the total

SeeFig.23as

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F833 − 19 F833 − 21

Standard Consumer Safety Performance Specification for

Carriages and Strollers

This standard is issued under the fixed designation F833; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This consumer safety performance specification addresses carriage and stroller incidents that were

identified by the U.S. Consumer Product Safety Commission (CPSC).

The CPSC identified injuries to children associated with the following: stability, brakes, restraint

systems, latches and folding mechanisms, structural integrity, cords, wheel detachment, and deaths

due to entrapment in openings of convertible carriage/strollers. In response to the incident-data

compiled by the CPSC, this consumer safety performance specification attempts to minimize the

previously listed problems. This specification does not cover carriages and strollers that are blatantly

misused, although warnings and safety instructions are required to be prominently displayed on or

with each carriage or stroller.

NOTE 1—This consumer safety performance specification is not intended to address incidents and

injuries resulting from the interaction of other persons with children in carriages or strollers or

incidents resulting from unforeseeable abuse or misuse.

This consumer safety performance specification is written within the current state of the art of

carriage and stroller technology. It is intended that this specification will be updated whenever

substantive information becomes available which necessitates additional requirements or justifies the

revision of existing requirements.

1. Scope

1.1 This consumer safety specification establishes safety performance requirements, test methods, and labeling requirements to

minimize the hazards to children presented by carriages and strollers as identified in the introduction. Children’s products such as

tricycles, bicycles, or other similar wheeled products that can be self-propelled by a child are not considered carriages or strollers

subject to the requirements of this standard, even if the item has a temporary or permanent handle.

1.2 No carriage or stroller produced after the approval date of this consumer safety performance specification shall, either by label

or other means, indicate compliance with this specification unless it conforms to all requirements herein.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 The following precautionary caveat pertains only to the test method portion, Section 7, of this consumer safety specification:

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the

user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

This specification is under the jurisdiction of ASTM Committee F15 on Consumer Products and is the direct responsibility of Subcommittee F15.17 on Carriages,

Strollers, Walkers and Stationary Activity Centers.

Current edition approved March 15, 2019June 15, 2021. Published April 2019August 2021. Originally approved in 1983. Last previous edition approved in 20152019 as

F833 – 15.F833 – 19. DOI: 10.1520/F0833-19.10.1520/F0833-21.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F833 − 21

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D3359 Test Methods for Rating Adhesion by Tape Test

F406 Consumer Safety Specification for Non-Full-Size Baby Cribs/Play Yards

F963 Consumer Safety Specification for Toy Safety

F2680 Test Methods and Specifications for Bicycle Manually Operated Front Wheel Retention Systems

2.2 Federal Standards:

16 CFR 1303 Ban of Lead-Containing Paint and Certain Consumer Products Bearing Lead-Containing Paint

16 CFR 1500 Hazardous Substances Act Regulations including sections:

1500.48 Mechanical Requirements for Determining a Sharp Point in Toys or Other Articles Intended for Use by Children Under

Eight Years of Age

1500.49 Technical Requirements for Determining a Sharp Metal or Glass Edge in Toys or Other Articles Intended for Use by

Children Under Eight Years of Age

1500.50-52 Test Methods for Simulating Use and Abuse of Toys and Other Articles Intended for Use by Children

16 CFR 1501 Method for Identifying Toys and Other Articles Intended for Use by Children Under Three Years of Age Which

Present Choking, Aspiration, or Ingestion Hazards Because of Small Parts

16 CFR 1508.07 (c)

2.3 Other Standards:

AS/NZS 2088 Prams and strollers—safety requirements

EN 1888 Child care articles - Wheeled child conveyances - Safety requirements and test methods

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 2D fold stroller, n—a stroller that folds the handlebars and leg tubes only in the front-to-back (or back-to-front) direction.

3.1.2 3D fold stroller, n—a stroller that, when folded, collapses all handlebars and leg tubes both in the front-to-back (or

back-to-front) and side-to-side directions.

3.1.3 carriage, n—wheeled vehicle generally used for the transport of an infant who is generally in a lying down position. The

motive power is supplied by a person or persons pushing or pulling on a handle attached to the vehicle. A carriage may be capable

of being folded for storage.

3.1.4 conspicuous, n—label that is visible, when the unit is in a manufacturer’s recommended use position, to a person standing

near the unit at any one position around the unit but not necessarily visible from all positions.

3.1.5 convertible car seat/stroller, n—car seat that has wheels and handle that can be converted to become a stroller without the

addition of other components.

3.1.6 convertible carriage/stroller, n—wheeled vehicle that is intended to be converted by the owner to be used as either a carriage

or a stroller.

3.1.7 cord, n—a length of slender, flexible material including monofilaments, woven and twisted cord, rope, elastic cords, plastic

textile tapes, ribbon, and those fibrous materials commonly called string.

3.1.8 double action double-action release mechanism, n—a release mechanism that requires either two consecutive actions, the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Code of Federal Regulations, available from U.S. Government Printing Office, Washington, DC 20402.

Available from SAI Global, http://www.saiglobal.com.

Available from European Committee for Standardization (CEN), Avenue Marnix 17, B-1000, Brussels, Belgium, http://www.cen.eu.

F833 − 21

first of which must be maintained while the second is carried out, or two separate and independent single action single-action

locking mechanisms that must be activated simultaneously to fully release.

3.1.9 harness system, n—shall include a waist and crotch restraint and a means of restraining the upper torso.

3.1.10 infant, n—young child who is not capable of sitting unassisted.

3.1.11 jogging stroller, n—stroller intended to be used for children at a jogging rate (run at a steady slow trot).

3.1.12 manufacturer’s recommended use position, n—any position that is presented as a normal, allowable, or acceptable

configuration for use of the product by the manufacturer in any descriptive or instructional literature. This specifically excludes

positions that the manufacturer shows in a like manner in its literature to be unacceptable, unsafe, or not recommended.

3.1.13 non-paper label, n—any label material (such as plastic or metal) that either will not tear without the aid of tools or tears

leaving a sharply defined edge.

3.1.14 occupant(s), n—that individual or those individuals who are in a product that is set up in one of the manufacturer’s

recommended use positions.

3.1.15 occupant retention space, n—space enclosed by the surfaces, for example, side walls or the floor, or both, of a carriage or

convertible carriage/stroller that contains the occupant within a carriage or a stroller in the reclined carriage position.

3.1.16 paper label, n—any label material that tears without the aid of tools and leaves a fibrous edge.

3.1.17 quick release quick-release mechanism, n—lever-actuated cam mechanism that connects and retains a wheel in a fork

assembly.

3.1.18 reclined carriage position, n—adjustment position of a convertible carriage/stroller that allows for an interior angle of

greater than 150° between the seat surface and the backrest.

3.1.19 removable-wheel fork assembly, n—fork assembly from which the wheel can be removed and reattached as a manufacturer

recommended normal product use.

3.1.19.1 Discussion—

A removable-wheel fork assembly can employ a quick release mechanism or other manually operated mechanism that does not

require the use of tools for installation or removal.

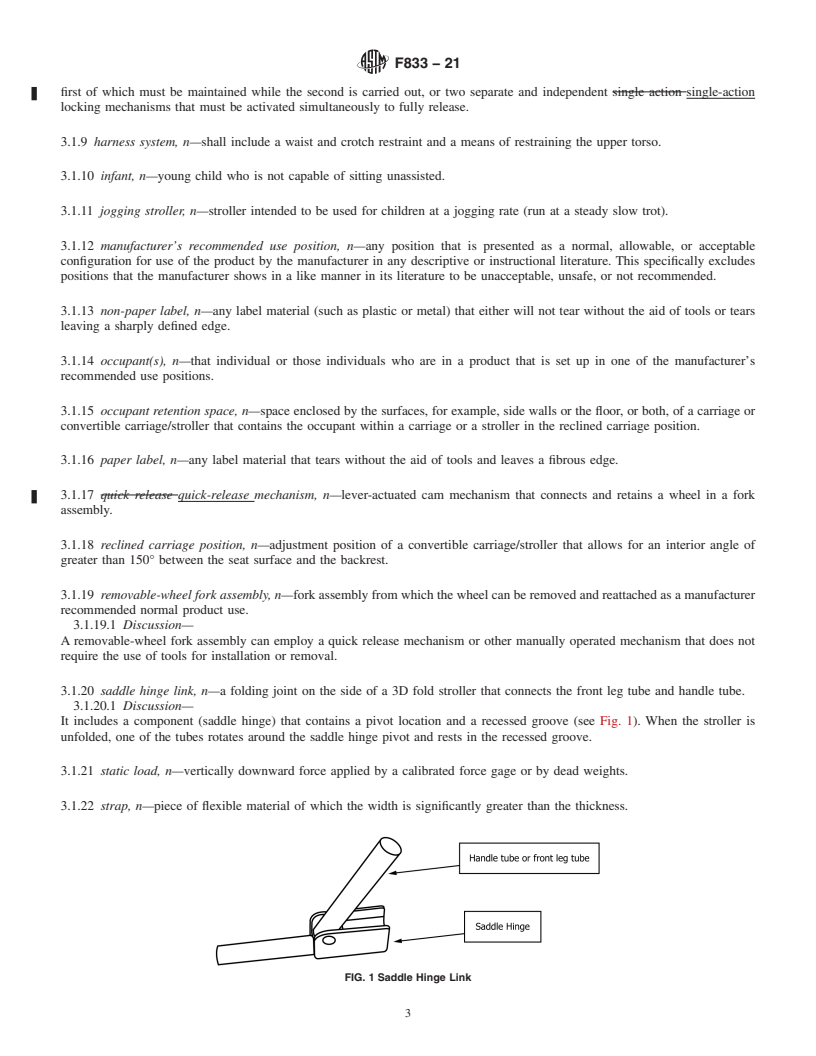

3.1.20 saddle hinge link, n—a folding joint on the side of a 3D fold stroller that connects the front leg tube and handle tube.

3.1.20.1 Discussion—

It includes a component (saddle hinge) that contains a pivot location and a recessed groove (see Fig. 1). When the stroller is

unfolded, one of the tubes rotates around the saddle hinge pivot and rests in the recessed groove.

3.1.21 static load, n—vertically downward force applied by a calibrated force gage or by dead weights.

3.1.22 strap, n—piece of flexible material of which the width is significantly greater than the thickness.

FIG. 1 Saddle Hinge Link

F833 − 21

3.1.23 stroller, n—wheeled vehicle for the transport of infants or children generally in a sitting-up or semi-reclined position. The

motive power is supplied by a person moving at a walking rate while pushing on a handle attached to the stroller. A stroller

generally is capable of being folded for storage. Strollers normally are used for children from infancy to 36 months of age.

3.1.24 tray/grab bar locking position, n—any position in which the tray or grab bar can lock including positions intended by the

manufacturer for non-occupant use.

3.1.25 tray/grab bar protective covering, n—component designed and intended as a means to prevent exposure of any underlying

accessible foam material. Examples include, but are not limited to woven, knit, coated, laminated, extruded, or calendered

textile-based materials and leathers.

3.1.26 tray/grab bar stop position, n—any position in which the tray or grab bar is forward of the occupant, is not in a locking

position, and remains stationary when a 5 lb force is applied to it for 10 s at any location and in any direction likely to cause it

to change position.

3.1.26.1 Discussion—

The 5 lb force is designed to overcome any small frictional force which would otherwise be overcome during normal use.

4. Calibration and Standardization

4.1 All testing shall be conducted on a concrete floor that shallmay be covered with ⁄8-in. (3-mm) thick vinyl floor covering,

unless test instructs differently.

4.2 The unit shall be completely assembled, unless otherwise noted, in accordance with the manufacturer’s instructions.

4.3 No testing shall be conducted within 48 h of manufacturing.

4.4 The product to be tested shall be in a room with an ambient temperature of 73 6 9°F (23 6 5°C)73 °F 6 9 °F (23 °C 6 5 °C)

for at least 1 h prior to testing. Testing shall then be conducted within this temperature range.

4.5 All testing required by this specification shall be conducted on the same unit with the exception of 7.2, where a new unit can

be used if the unit frame permanently deforms.

5. General Requirements

5.1 There shall be no hazardous points or edges as defined by 16 CFR 1500.48 and 16 CFR 1500.49 before and after testing to

this consumer safety specification.

5.2 There shall be no small parts as defined by 16 CFR 1501 before testing or liberated as a result of testing to this specification.

5.3 The paint and surface-coating on the product shall comply to 16 CFR 1303.

5.4 Prior to testing, any exposed wood parts shall be smooth and free of splinters.

5.5 Latching Mechanisms:

5.5.1 Any unit that folds shall have a latching device or other provision in the design that will prevent the unit from unintentional

folding when properly placed in the manufacturer’s recommended use position. Products with latching devices for prevention of

unintentional folding shall be tested in accordance with 7.2. During and upon completion of this test, the unit shall meet the

requirements in 5.5.1.1 or 5.5.1.2.

5.5.1.1 The locking device on the unit shall remain latched.

5.5.1.2 The stroller frame components yield and permanently deform in a manner such that the full load specified cannot be

applied in the direction of folding and the locking device remains engaged.

F833 − 21

5.5.2 Strollers that employ hinged links with a geometric over center action (see Fig. 2) to maintain the product in the normal use

position shall require two distinct and separate actions on the part of the user to initiate folding of the product. Such strollers shall

require only a single action on the part of the user to secure the stroller in the normal use position.

5.6 Openings—Holes or slots that extend entirely through a wall section of any rigid material less than 0.375 in. (9.53 mm) thick

and admit a 0.210-in. (5.33-mm) diameter rod shall also admit a 0.375-in. (9.53-mm) diameter rod. Holes or slots that are between

0.210 in. (5.33 mm) and 0.375 in. (9.53 mm) and have a wall thickness less than 0.375 in. (9.53 mm) but are limited in depth to

0.375 in. (9.53 mm) maximum by another rigid surface shall be permissible (see Fig. 3). The product shall be evaluated in all

manufacturer’s recommended use positions.

5.7 Scissoring, Shearing, and Pinching:

5.7.1 The unit, when in the manufacturer’s recommended use position, shall be designed and constructed so as to prevent injury

to the occupant from any scissoring, shearing, or pinching when members or components rotate about a common axis or fastening

point, slide, pivot, fold, or otherwise move relative to one another. Scissoring, shearing, or pinching that may cause injury exists

when the edges of the rigid parts admit a 0.210-in. (5.33-mm) diameter probe but do not admit a 0.375-in. (9.53-mm) diameter

probe at any accessible point throughout the range of motion of such parts. This excludes the adjustment of accessory items such

as storage latches, baskets, etc.

NOTE 1—The evaluation at any given location is performed with the understanding that the probes are allowed to enter the location from any

angle/direction.

5.7.2 Saddle hinge links on 3D fold strollers shall be designed and constructed so as to prevent injury from scissoring, shearing,

or pinching. Scissoring, shearing, or pinching that may cause injury exists in a saddle hinge link when the edges of the rigid parts

admit a 0.210-in. (5.33-mm) diameter probe but do not admit a 0.375-in. (9.53-mm) diameter probe when tested in accordance with

7.17.1.

NOTE 2—The evaluation at any given location is performed with the understanding that the probes are allowed to enter the location from any

angle/direction.

5.7.3 Canopy pivots and canopy frame members shall comply with 5.7.1 when tested in accordance with 7.17.2. Canopy

stretcher/locking device(s) are exempt from this requirement (see Fig. 4). The interface between canopy rods and canopy stops are

exempt from this requirement if the canopy rod does not pass over or through the final canopy stop. Final canopy stops are those

that prevent further movement or adjustment of the canopy (see example in Fig. 5). Intermediate canopy stop positions are not

exempt from this requirement.

5.7.4 The frame folding action of a 2D fold stroller and convertible carriage/stroller (carriages are exempted from this

requirement) shall be designed and constructed so as to prevent injury from scissoring, shearing, or pinching. Scissoring, shearing,

or pinching that may cause injury exists when the edges of the rigid parts admit a 0.210-in. (5.33-mm) diameter probe but do not

admit a 0.375-in. (9.53-mm) diameter probe when tested in accordance with 7.15. Units with a removable seat that prevent the

complete folding of the unit when still attached are exempt from this requirement.

FIG. 2 Stroller With Hinged Link

F833 − 21

FIG. 3 Opening Example

FIG. 4 Stretcher/Locking Device

NOTE 3—The evaluation at any given location is performed with the understanding that the probes are allowed to enter the location from any

angle/direction.

5.8 Exposed Coil Springs—Any exposed coil spring which is accessible to the occupant, having or capable of generating a space

between coils of 0.210 in. (5.33 mm) or greater during static load testing (see 6.2 and 7.3) shall be covered or otherwise designed

to prevent injury from entrapment.

5.9 Labeling:

5.9.1 Warning labels (whether paper or non-paper) shall be permanent when tested in accordance with 7.8.1 – 7.8.3.

5.9.2 Warning statements applied directly onto the surface of the product by hot stamping, heat transfer, printing, wood burning,

etc. shall be permanent when tested in accordance with 7.8.4.

F833 − 21

FIG. 5 Canopy Stop

5.9.3 Non-paper labels shall not liberate small parts when tested in accordance with 7.8.5.

5.10 Protective Components—If a child can grasp components between the thumb and forefinger, or teeth, such as caps, sleeves,

or plugs used for protection from sharp edges, points, or entrapment of fingers or toes, or if there is at least a 0.040-in. (1.00-mm)

gap between the component and its adjacent parent component, such component shall not be removed when tested in accordance

with 7.9.

5.11 Seat Recline Measurement—Place the back of the stroller in the most reclined position. Place the hinged boards with the

hinged edge into the junction of the stroller back and seat (see Fig. 6). Measure the angle between the two boards.

5.12 Toy—Toy accessories attached to, removable from, or sold with unit, as well as their means of attachment, shall meet

applicable requirements of Consumer Safety Specification F963.

3 3

NOTE 1— ⁄4 in. (19 mm) by 6 in. (150 mm) by 6 in. (150 mm) board hinged to a ⁄4 in. (19 mm) by 6 in. (150 mm) by 9 in. (225 mm) board placed

in the junction of the stroller seat.

FIG. 6 Seat Back Recline Board

F833 − 21

5.13 Cord/Strap Length—Cords and straps that originate within or extend into the occupant space shall not create a loop that has

an internal perimeter exceeding 14.8 in. (376 mm) nor have a free stretched length that exceeds a length of 7.4 in. (188 mm)

(188 mm) when evaluated with 7.16. Cords or straps that do not originate within the occupant space but that can extend into the

occupant space shall be evaluated in accordance with 7.16 only on the portion of the cord/strap that can extend into the occupant

space. Restraint systems used to secure an occupant, all straps used to attach hand held infant carriers, and straps on hand held

infant carriers, stroller carry straps, and stroller tether straps are exempt from this requirement.

5.14 Tray/Grab Bar Protective Covering Requirement—Trays/grab bars that are accessible and forward of the occupant shall meet

any one of the following:

5.14.1 The tray/grab bar does not contain foam material.

5.14.2 The tray/grab bar covering prevents the underlying foam material from being exposed when tested per 7.19.

6. Performance Requirements

NOTE 4—The forces that are to be applied to the sample in the test methods described in Section 7 of this specification are applied readily by means of

a calibrated force gage, or in the case of static load and dynamic load test methods, by dead weights.

6.1 Parking Brake Requirements:

6.1.1 A parking brake shall be provided on the unit. Each parking brake shall remain engaged during the test as specified in 7.6.

th

Each parking brake shall prevent the braked wheel(s) from rotating more than 90° during the 5 test cycle specified in 7.6.