ASTM E127-04

(Practice)Standard Practice for Fabricating and Checking Aluminum Alloy Ultrasonic Standard Reference Blocks

Standard Practice for Fabricating and Checking Aluminum Alloy Ultrasonic Standard Reference Blocks

SCOPE

1.1 This practice covers a procedure for fabricating aluminum alloy ultrasonic standard reference blocks that can be used for checking performance of ultrasonic testing equipment and for standardization and control of ultrasonic tests of aluminum alloy products using pulsed longitudinal waves introduced into test material either by the direct-contact method or by the immersion method. A recommended procedure for checking blocks is described and calibration data for a number of reference blocks are tabulated. Statements concerning procedures are provided without a discussion of the technical background for the preference. The necessary technical background can be found in Refs. (1-15).Note 1Practice E 428 and Guide E 1158 also describe procedures for selecting material, fabricating blocks, and checking response. Unlike this practice, there is no requirement for evaluation relative to a specified standard target.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 127 – 04

Standard Practice for

Fabricating and Checking Aluminum Alloy Ultrasonic

1

Standard Reference Blocks

This standard is issued under the fixed designation E127; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This specification has been approved for use by agencies of the Department of Defense.

1. Scope E428 Practice for Fabrication and Control of Steel Refer-

ence Blocks Used in Ultrasonic Inspection

1.1 This practice covers a procedure for fabricating alumi-

E1158 Guide for Material Selection and Fabrication of

numalloyultrasonicstandardreferenceblocksthatcanbeused

Reference Blocks for the Pulsed LongitudinalWave Ultra-

for checking performance of ultrasonic testing equipment and

sonic Examination of Metal and Metal Alloy Production

for standardization and control of ultrasonic tests of aluminum

Material

alloy products using pulsed longitudinal waves introduced into

E1316 Terminology for Nondestructive Examinations

test material either by the direct-contact method or by the

E1324 Guide for Measuring Some Electronic Characteris-

immersion method. A recommended procedure for checking

3

tics of Ultrasonic Examination Instruments

blocks is described and calibration data for a number of

reference blocks are tabulated. Statements concerning proce-

3. Terminology

dures are provided without a discussion of the technical

3.1 Definitions—For definitions of terms not specific to this

background for the preference. The necessary technical back-

2 practice, refer to Terminology E1316.

ground can be found in Refs. (1-15).

3.2 Definitions of Terms Specific to This Standard:

NOTE 1—PracticeE428andGuideE1158alsodescribeproceduresfor

3.2.1 angular error—the condition observed in ultrasonic

selecting material, fabricating blocks, and checking response. Unlike this

tests of reference blocks when the response from the hole

practice, there is no requirement for evaluation relative to a specified

bottom is not maximum while the search unit is positioned to

standard target.

obtain either a maximum number of back reflections from a

1.2 This standard does not purport to address all of the

reference block or a maximum indication from its entry

safety concerns, if any, associated with its use. It is the

surface. Angular error results when the entry surface, hole

responsibility of the user of this standard to establish appro-

bottom, and back surface are not parallel to each other.

priate safety and health practices and determine the applica-

3.2.2 area-amplitude response curve—a curve showing the

bility of regulatory limitations prior to use.

relationshipbetweendifferentareasofreflectingtargetslocated

ataconstantdistanceinanultrasonictransmittingmediumand

2. Referenced Documents

their respective amplitudes of ultrasonic response.

3

2.1 ASTM Standards:

3.2.3 back reflection—the indication, observed on the dis-

E317 Practice for Evaluating Performance Characteristics

play screen of a test instrument, that represents the ultrasonic

ofUltrasonicPulse-EchoTestingSystemsWithouttheUse

energy reflected from the back surface of a reference block.

of Electronic Measurement Instruments

3.2.4 back surface—the end of a reference block that is

opposite the entry surface.

1 3.2.5 entry surface—the end of a reference block through

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

which ultrasonic energy must pass when reflections from the

structive Testing and is the direct responsibility of Subcommittee E07.06 on

Ultrasonic Method.

hole bottom are obtained.

CurrenteditionapprovedJuly1,2004.PublishedJuly2004.Originallyapproved

3.2.6 hole bottom—the flat reflecting surface in a reference

in 1958. Last previous edition approved in 1998 as E127-98.

2

blockthatisobtainedbymakingtheentireendofadrilledhole

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

this practice. smooth and flat using best machining practices. The hole

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

bottom is parallel to the entry surface of the block.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.2.7 hole size—the diameter of the hole in a reference

Standards volume information, refer to the standard’s Document Summary page on

block that determines the area of the hole bottom.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E127–04

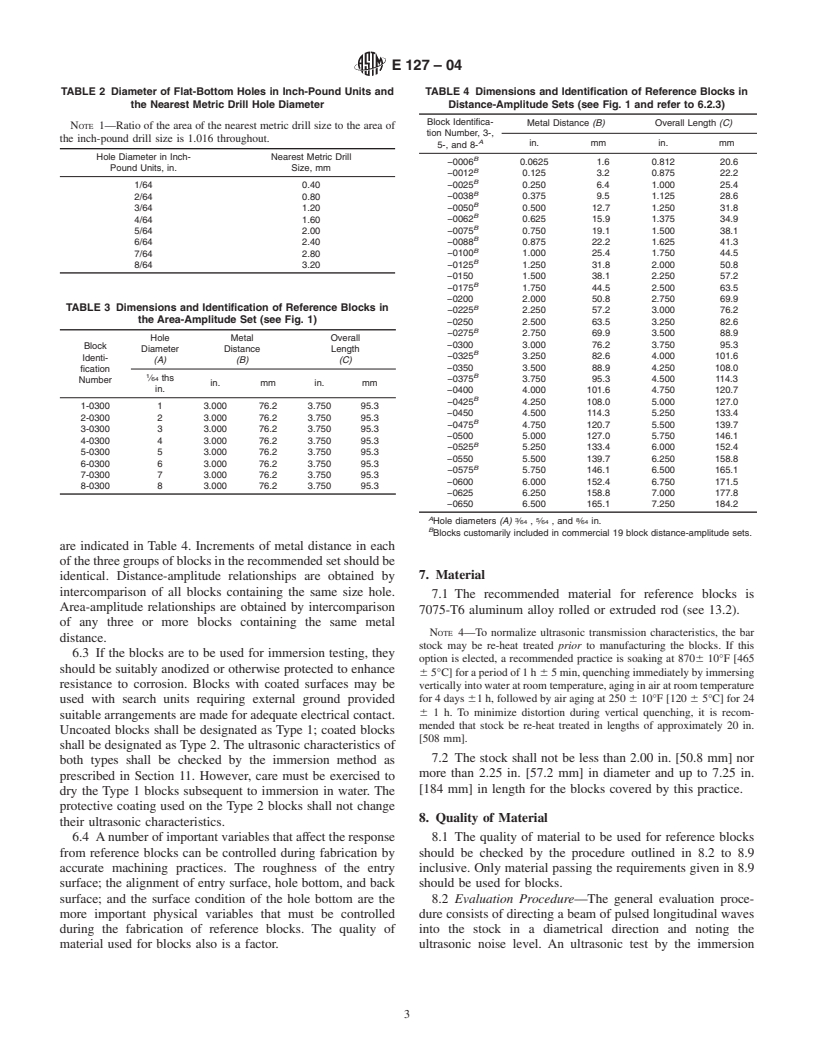

3.2.8 metal distance—thedistanceinareferenceblockfrom standardize ultrasonic tests at any frequen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.