ASTM D1185-98a(2017)

(Test Method)Standard Test Methods for Pallets and Related Structures Employed in Materials Handling and Shipping

Standard Test Methods for Pallets and Related Structures Employed in Materials Handling and Shipping

SIGNIFICANCE AND USE

4.1 Static compression and bending tests provide data that are used to estimate stiffness, strength, and safe working loads for pallets under specified load and support conditions. These estimates provide a basis for designing pallets and comparing the performance between pallets of different designs and constructions.

4.2 Dynamic tests provide data which are used to estimate the physical durability and functionality of a pallet in specified material handling and shipping environments. These estimates provide a basis for designing single or multiple-use pallets.

4.3 Other tests may be performed to assess the properties of specific materials (Test Methods D2395, D4442, D4444, and T 208 OM) and connecting devices (Test Methods D1761, F680, Test Method F1575, and Specification F1667), design features, use applications, and other variables encountered.

SCOPE

1.1 These test methods cover the performance of pallets and related structures, functioning as skids, bases, platforms, and bins in materials handling and shipping. Their use facilitates the protection of both packaged and unpackaged products during storage and transportation. The test methods include measurements of the relative resistance of pallets and related structures to deformations, damages, and structural failures which detrimentally affect the functionality of the unit load.

1.2 These test methods include conditioning requirements, static stiffness and strength tests, and dynamic tests of structural reliability. These test methods are used to evaluate the relative performance of new, used, or reconditioned general and special-purpose pallets fabricated from various materials including solid wood, wood composites, fiberboard, honeycomb, plastics, or metal, or to compare the performance of such pallets and related structures to specified performance criteria. Recommended criteria for all tests specified in this standard are listed in Appendix X2.

1.2.1 These test methods are also used to classify pallets as single- or multiple-use pallets and to determine the safe working loads for pallets under specified load and support conditions.

1.3 Nonmandatory Preliminary Tests—Because each pallet may be used under several different conditions of load and support, pallet-design considerations and safe working-load estimates shall be based on that condition under which the pallet offers least resistance or is most severely stressed.

1.3.1 Preliminary, short-duration static tests up to the ultimate (see 8.2, 8.3, and 8.4) shall be performed on previously non-tested pallets to determine which load and support conditions influence most severely the pallet load-carrying capacity and safe working loads.

1.3.2 During the development of prototypes leading to designs that will be subject to acceptance testing, as described in 1.4, these preliminary tests shall include the free-fall drop tests in accordance with 9.1.

1.4 Mandatory Acceptance Tests:

1.4.1 General-Purpose Pallets—When the objective of the test is to determine the safe working load or to classify a general-purpose pallet as a single- or multiple-use pallet, all tests described in these test methods shall be performed in the order specified. The same pallet shall be used for all static and dynamic tests, where feasible.

1.4.2 Special-Purpose Pallets—When the objective of the test is to determine the safe working load or to classify a special-purpose pallet, as a single- or multiple-use pallet, only those tests representing the intended condition of use shall be performed. Certain special–purpose pallet designs, because of the pallet size, its shape, or the material of fabrication, or combinations thereof, cannot be reliably tested using this methodology. When available, alternative test methods should be used.

1.4.3 Field Testing—It is recommended that pallet designs passing these acceptance tests be further subjected to field testing in the distribution en...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D1185 − 98a (Reapproved 2017)

Standard Test Methods for

Pallets and Related Structures Employed in Materials

1

Handling and Shipping

This standard is issued under the fixed designation D1185; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.3.2 During the development of prototypes leading to

designs that will be subject to acceptance testing, as described

1.1 Thesetestmethodscovertheperformanceofpalletsand

in 1.4, these preliminary tests shall include the free-fall drop

related structures, functioning as skids, bases, platforms, and

tests in accordance with 9.1.

bins in materials handling and shipping. Their use facilitates

the protection of both packaged and unpackaged products

1.4 Mandatory Acceptance Tests :

during storage and transportation. The test methods include

1.4.1 General-Purpose Pallets—When the objective of the

measurements of the relative resistance of pallets and related

test is to determine the safe working load or to classify a

structures to deformations, damages, and structural failures

general-purpose pallet as a single- or multiple-use pallet, all

which detrimentally affect the functionality of the unit load.

tests described in these test methods shall be performed in the

1.2 These test methods include conditioning requirements,

order specified. The same pallet shall be used for all static and

static stiffness and strength tests, and dynamic tests of struc-

dynamic tests, where feasible.

tural reliability. These test methods are used to evaluate the

1.4.2 Special-Purpose Pallets—When the objective of the

relative performance of new, used, or reconditioned general

test is to determine the safe working load or to classify a

and special-purpose pallets fabricated from various materials

special-purpose pallet, as a single- or multiple-use pallet, only

including solid wood, wood composites, fiberboard,

those tests representing the intended condition of use shall be

honeycomb, plastics, or metal, or to compare the performance

performed. Certain special–purpose pallet designs, because of

of such pallets and related structures to specified performance

the pallet size, its shape, or the material of fabrication, or

criteria. Recommended criteria for all tests specified in this

combinations thereof, cannot be reliably tested using this

standard are listed in Appendix X2.

methodology. When available, alternative test methods should

1.2.1 These test methods are also used to classify pallets as

be used.

single- or multiple-use pallets and to determine the safe

working loads for pallets under specified load and support

1.4.3 Field Testing— It is recommended that pallet designs

conditions.

passing these acceptance tests be further subjected to field

testing in the distribution environment.

1.3 Nonmandatory Preliminary Tests —Because each pallet

may be used under several different conditions of load and

1.5 Simulation of the Distribution Environment—These test

support, pallet-design considerations and safe working-load

methods are not intended to lead to exact simulations of pallet

estimates shall be based on that condition under which the

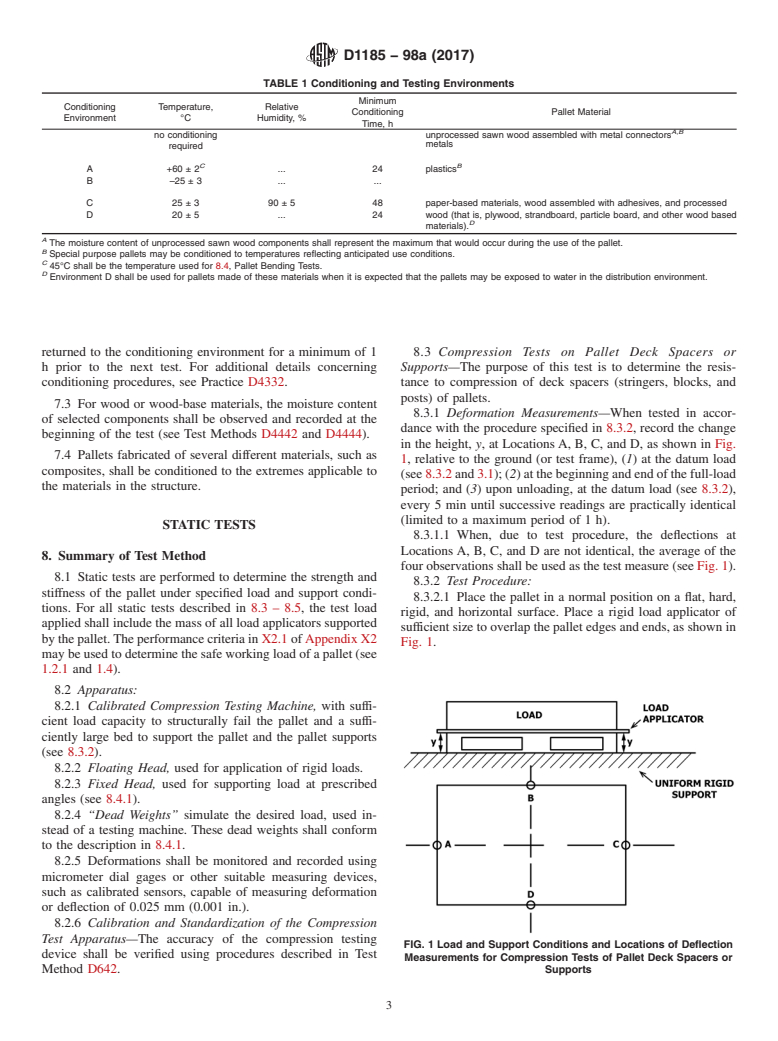

performance in the distribution environment. These test meth-

pallet offers least resistance or is most severely stressed.

ods are designed to relate to practice with the added provision

1.3.1 Preliminary, short-duration static tests up to the ulti-

that they are repeatable, do not depend on exceptional skills,

mate (see 8.2, 8.3, and 8.4) shall be performed on previously

and are safe to conduct without elaborate precautions.The test

non-tested pallets to determine which load and support condi-

findings are not expected to lead to unalterable conclusions.

tions influence most severely the pallet load-carrying capacity

Testing in the distribution environment may be necessary to

and safe working loads.

verify the results obtained from laboratory tests.

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1

These test methods are under the jurisdiction of ASTM Committee D10 on

Packaging and are the direct responsibility of Subcommittee D10.21 on Shipping responsibility of the user of this standard to establish appro-

Containers and Systems - Application of Performance Test Methods.

priate safety and health practices and determine the applica-

Curre

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.