ASTM E747-97

(Practice)Standard Practice for Design, Manufacture and Material Grouping Classification of Wire Image Quality Indicators (IQI) Used for Radiology

Standard Practice for Design, Manufacture and Material Grouping Classification of Wire Image Quality Indicators (IQI) Used for Radiology

SCOPE

1.1 This practice covers the design, material grouping classification, and manufacture of wire image quality indicators (IQI) used to indicate the quality of radiologic images.

1.2 This practice is applicable to X-ray and gamma-ray radiology.

1.3 This practice covers the use of wire penetrameters as the controlling image quality indicator for the material thickness range from 6.4 to 152 mm (0.25 to 6.0 in.).

1.4 The values stated in inch-pound units are to be regarded as standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 747 – 97

Standard Practice for

Design, Manufacture and Material Grouping Classification of

Wire Image Quality Indicators (IQI) Used for Radiology

This standard is issued under the fixed designation E 747; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 1316 Terminology for Nondestructive Examinations

1.1 This practice covers the design, material grouping

3. Terminology

classification, and manufacture of wire image quality indica-

3.1 Definitions—The definitions of terms in Terminology

tors (IQI) used to indicate the quality of radiologic images.

E 1316, Section D, relating to gamma and x-radiology, shall

1.2 This practice is applicable to X-ray and gamma-ray

apply to the terms used in this practice.

radiology.

1.3 This practice covers the use of wire penetrameters as the

4. Wire IQI Requirements

controlling image quality indicator for the material thickness

4.1 The quality of all levels of examination shall be deter-

range from 6.4 to 152 mm (0.25 to 6.0 in.).

mined by a set of wires conforming to the following require-

1.4 The values stated in inch-pound units are to be regarded

ments:

as standard.

4.1.1 Wires shall be fabricated from materials or alloys

1.5 This standard does not purport to address all of the

identified or listed in accordance with 7.2. Other materials may

safety concerns, if any, associated with its use. It is the

be used in accordance with 7.3.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

TABLE 1 Wire IQI Sizes and Wire Identity Numbers

SET A SET B

2. Referenced Documents

Wire Diameter Wire Diameter

2.1 ASTM Standards: Wire Identity Wire Identity

in. (mm) in. (mm)

B 139 Specification for Phosphor Bronze Rod, Bar, and

A

0.0032 (0.08) 1 0.010 (0.25) 6

Shapes

0.004 (0.1) 2 0.013 (0.33) 7

B 150 Specification for Aluminum Bronze Rod, Bar, and

0.005 (0.13) 3 0.016 (0.4) 8

0.0063 (0.16) 4 0.020 (0.51) 9

Shapes

0.008 (0.2) 5 0.025 (0.64) 10

B 161 Specification for Nickel Seamless Pipe and Tube

0.010 (0.25) 6 0.032 (0.81) 11

B 164 Specification for Nickel-Copper Alloy Rod, Bar, and

SET C SET D

Wire

Wire Diameter Wire Diameter

Wire Identity Wire Identity

B 166 Specification for Nickel-Chromium-Iron Alloys

in. (mm) in. (mm)

(UNS N06600, N06601, and N06690) and Nickel-

0.032 (0.81) 11 0.10 (2.5) 16

Chromium-Cobalt-Molybdenum Alloy (UNS N06617)

0.040 h(1.02) 12 0.126 (3.2) 17

0.050 (1.27) 13 0.160 (4.06) 18

Rod, Bar, and Wire

0.063 (1.6) 14 0.20 (5.1) 19

E 1025 Practice for Design, Manufacture, and Material

0.080 (2.03) 15 0.25 (6.4) 20

Grouping Classification of Hole-Type Image Quality Indi-

0.100 (2.5) 16 0.32 (8) 21

cators (IQI) Used for Radiology A

The 0.0032 wire may be used to establish a special quality level as agreed

upon between the purchaser and the supplier.

TABLE 2 Wire Diameter Tolerances, (mm)

This practice is under the jurisdiction of ASTM Committee E-7 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.01 on Wire Diameter (d), mm Tolerance, mm

Radiographic Practice and Penetrameters.

0.000 < d# 0.125 60.0025

Current edition approved July 10, 1997. Published November 1997. Originally

0.125 < d # 0.25 60.005

published as E 747 – 80. Last previous edition E 747 – 94.

0.25 < d # 0.5 60.01

For ASME Boiler and Pressure Vessel Code applications see related Practice

0.50 < d # 1.6 60.02

SE-747 in Section II of that Code.

1.6 < d # 4 60.03

Annual Book of ASTM Standards, Vol 02.01.

4.0 < d # 8 60.05

Annual Book of ASTM Standards, Vol 02.04.

Annual Book of ASTM Standards, Vol 03.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E747–97

TABLE 3 Wire Diameter Tolerances, (in.)

5.1.2 Determine the thickness or thickness range of the

Wire Diameter (d), in. Tolerance, in. material(s) to be examined.

5.1.3 Select the applicable IQI’s that represent the required

0.000 < d # 0.005 60.0001

0.005 < d # 0.010 60.0002

IQI thickness(s) and alloy(s).

0.010 < d # 0.020 60.0004

0.020 < d # 0.063 60.0008

0.063 < d # 0.160 60.0012 6. Image Quality Levels

0.160 < d # 0.320 60.0020

6.1 The quality level required using wire penetrameters

shall be equivalent to the 2-2T level of Practice E 1025 for

hole-type IQI’s unless a higher or lower quality level is agreed

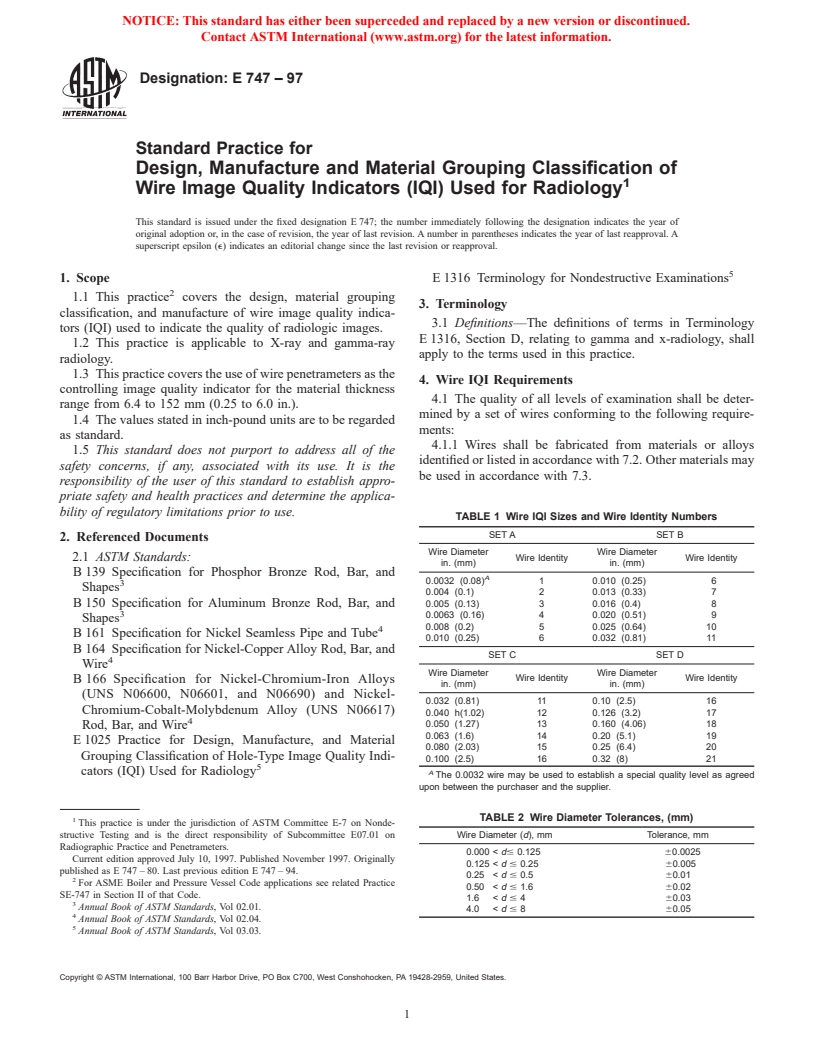

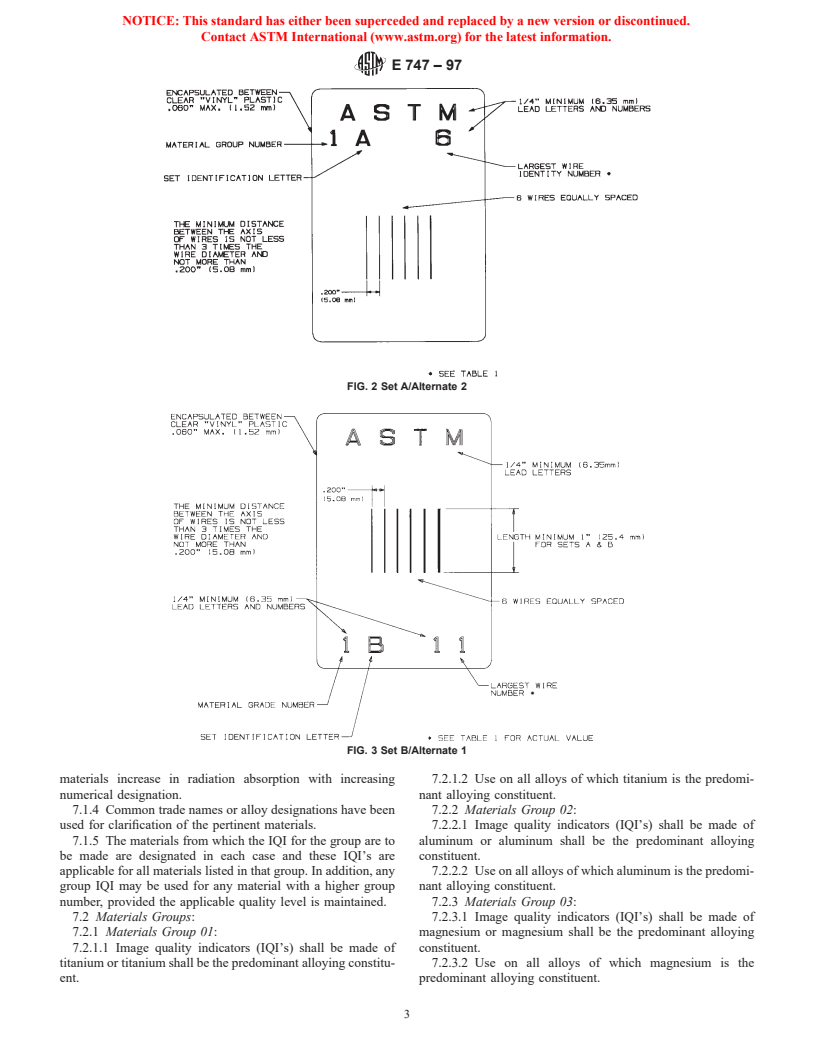

4.1.2 The IQI consists of sets of wires arranged in order of

upon between purchaser and supplier. Table 4 provides a list of

increasing diameter. The diameter sizes specified in Table 1 are

various hole-type IQI’s and the diameter of wires of corre-

established from a consecutive series of numbers taken in

sponding equivalent penetrameter sensitivity (EPS) with the

general from the ISO/R 10 series. The IQI shall be fabricated

applicable 1T, 2T, and 4T holes in the IQI. This table can be

in accordance with the requirements specified in Figs. 1-8 and

used for determining 1T, 2T, and 4T quality levels. Appendix

Tables 1-3. IQIs previously manufactured to the requirements

X1 gives the equation for calculating other equivalencies if

of Annex A1 may be used as an alternate provided all other

needed.

requirements of this practice are met.

6.2 In specifying quality levels, the contract, purchase order,

4.1.3 Image quality indicator (IQI) designs other than those

product specification, or drawing should clearly indicate the

shown in Figs. 1-8 and Annex A1 are permitted by contractual

thickness of material to which the quality level applies. Careful

agreement. If an IQI set as listed in Table 1 or Annex A1 is

consideration of required quality levels is particularly impor-

modified in size, it must contain the grade number, set identity,

tant.

and essential wire. It must also contain two additional wires

that are the next size larger and the next size smaller as

7. Material Groups

specified in the applicable set listed in Table 1.

7.1 General:

4.1.4 Each set must be identified using letters and numbers

7.1.1 Materials have been designated in eight groups based

made of industrial grade lead or of a material of similar

on their radiographic absorption characteristics: groups 03, 02,

radiographic density. Identification shall be as shown on Figs.

and 01 for light metals and groups 1 through 5 for heavy

1-8 or Annex A1, unless otherwise specified by contractual

metals.

agreement.

7.1.2 The light metal groups, magnesium (Mg), aluminum

5. Image Quality Indicator (IQI) Procurement

(Al), and titanium (Ti) are identified 03, 02, and 01 respec-

tively, for their predominant alloying constituent. The materials

5.1 When selecting IQI’s for procurement, the following

are listed in order of increasing radiation absorption.

factors should be considered:

5.1.1 Determine the alloy group(s) of the material to be 7.1.3 The heavy metal groups, steel, copper-base, nickel-

examined. base, and kindred alloys are identified 1 through 5. The

FIG. 1 Set A/Alternate 1

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E747–97

FIG. 2 Set A/Alternate 2

FIG. 3 Set B/Alternate 1

materials increase in radiation absorption with increasing 7.2.1.2 Use on all alloys of which titanium is the predomi-

numerical designation. nant alloying constituent.

7.1.4 Common trade names or alloy designations have been 7.2.2 Materials Group 02:

used for clarification of the pertinent materials. 7.2.2.1 Image quality indicators (IQI’s) shall be made of

7.1.5 The materials from which the IQI for the group are to aluminum or aluminum shall be the predominant alloying

be made are designated in each case and these IQI’s are constituent.

applicable for all materials listed in that group. In addition, any 7.2.2.2 Use on all alloys of which aluminum is the predomi-

group IQI may be used for any material with a higher group nant alloying constituent.

number, provided the applicable quality level is maintained. 7.2.3 Materials Group 03:

7.2 Materials Groups: 7.2.3.1 Image quality indicators (IQI’s) shall be made of

7.2.1 Materials Group 01: magnesium or magnesium shall be the predominant alloying

7.2.1.1 Image quality indicators (IQI’s) shall be made of constituent.

titanium or titanium shall be the predominant alloying constitu- 7.2.3.2 Use on all alloys of which magnesium is the

ent. predominant alloying constituent.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E747–97

FIG. 4 Set B/Alternate 2

FIG. 5 Set C/Alternate 1

7.2.4 Materials Group 1: 7.2.5 Materials Group 2:

7.2.4.1 Image quality indicators (IQI’s) shall be made of

7.2.5.1 Image quality indicators (IQI’s) shall be made of

carbon steel or Type 300 series stainless steel.

aluminum bronze (Alloy No. 623 of Specification B 150) or

7.2.4.2 Use on all carbon steel, low-alloy steels, stainless

equivalent, or nickel-aluminum bronze (Alloy No. 630 of

steels, and manganese-nickel-aluminum bronze (Superston).

Specification B 150) or equivalent.

7.2.5.2 Use on all aluminum bronzes and all nickel-

aluminum bronzes.

Superston is a registered trademark of Superston Corp., Jersey City, NJ.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E747–97

FIG. 6 Set C/Alternate 2

FIG. 7 Set D/Alternate 1

7.2.6 Materials Group 3:

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E747–97

FIG. 8 Set D/Alternate 2

TABLE 4 Wire Sizes Equivalent to Corresponding 1T, 2T, and 4T Holes in Various Hole Type Plaques

Diameter of wire with EPS of hole in plaque, in. (mm)

Plaque Thickness, Plaque IQI Identication

in. (mm) Number

1T 2T 4T

0.005 (0.13) 5 0.0038 (0.09) 0.006 (0.15)

0.006 (0.16) 6 0.004 (0.10) 0.0067 (0.18)

0.008 (0.20) 8 0.0032 (0.08) 0.005 (0.13) 0.008 (

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.