ASTM F592-84(2012)

(Terminology)Standard Terminology of Collated and Cohered Fasteners and Their Application Tools (Withdrawn 2017)

Standard Terminology of Collated and Cohered Fasteners and Their Application Tools (Withdrawn 2017)

SCOPE

0

WITHDRAWN RATIONALE

The terms included in these definitions are listed in alphabetical order to facilitate quick reference. They are intended to apply to collated and cohered nails, staples, and pins driven by strike, pneumatic, electric, manual, and spring tools. Omitted from consideration are terms relating to the testing and the performance of fasteners, that is, their drivability, withdrawal resistance, pull-through resistance, lateral load transmission, creep, protrusion resistance, splitting, and methods of use, such as face, toe, side, and end-nailing, spacing, loading conditions, etc.

Formerly under the jurisdiction of Committee F16 on Fasteners, this terminology standard was withdrawn in March 2017. This standard is being withdrawn with no replacement because most of the terminology in the standard is no longer relevant.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F592 − 84 (Reapproved 2012)

Standard Terminology of

Collated and Cohered Fasteners and Their Application

1

Tools

ThisstandardisissuedunderthefixeddesignationF592;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The terms included in these definitions are listed in alphabetical order to facilitate quick reference.

They are intended to apply to collated and cohered nails, staples, and pins driven by strike, pneumatic,

electric, manual, and spring tools. Omitted from consideration are terms relating to the testing and the

performance of fasteners, that is, their drivability, withdrawal resistance, pull-through resistance,

lateral load transmission, creep, protrusion resistance, splitting, and methods of use, such as face, toe,

side, and end-nailing, spacing, loading conditions, etc. Reference is made to ASTM Terminology

2

F547, Terminology of Nails for Use with Wood and Wood-Base Materials, for terms that are

applicable to related fasteners that may or may not be collated or cohered.

Common acceptance and usage are the basis for most of the definitions listed. In some instances,

this common usage results in more than one definition for a given term. In other cases, registered

trademarks have become generic in nature; hence, are included among the terms listed.

Anysuchlistingcannotbecomplete.AsadditionaltermsarereferredtotheSociety’sattention,they

will be considered for inclusion in this standard.

This listing of definitions of terms is in agreement so far as feasible with and supplementary to

Terminology F547.

The definitions are listed under the following headings:

Collated and Cohered Fasteners

Tools for Driving Collated and Cohered Fasteners

1

These definitions are under the jurisdiction of ASTM Committee F16 on

Fasteners and are the direct responsibility of Subcommittee F16.05 on Driven and

2

Other Fasteners. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2012. Published May 2012. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1978. Last previous edition approved in 2006 as F592 – 84 (2006). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/F0592-84R12. the ASTM website.

COLLATED AND COHERED FASTENERS

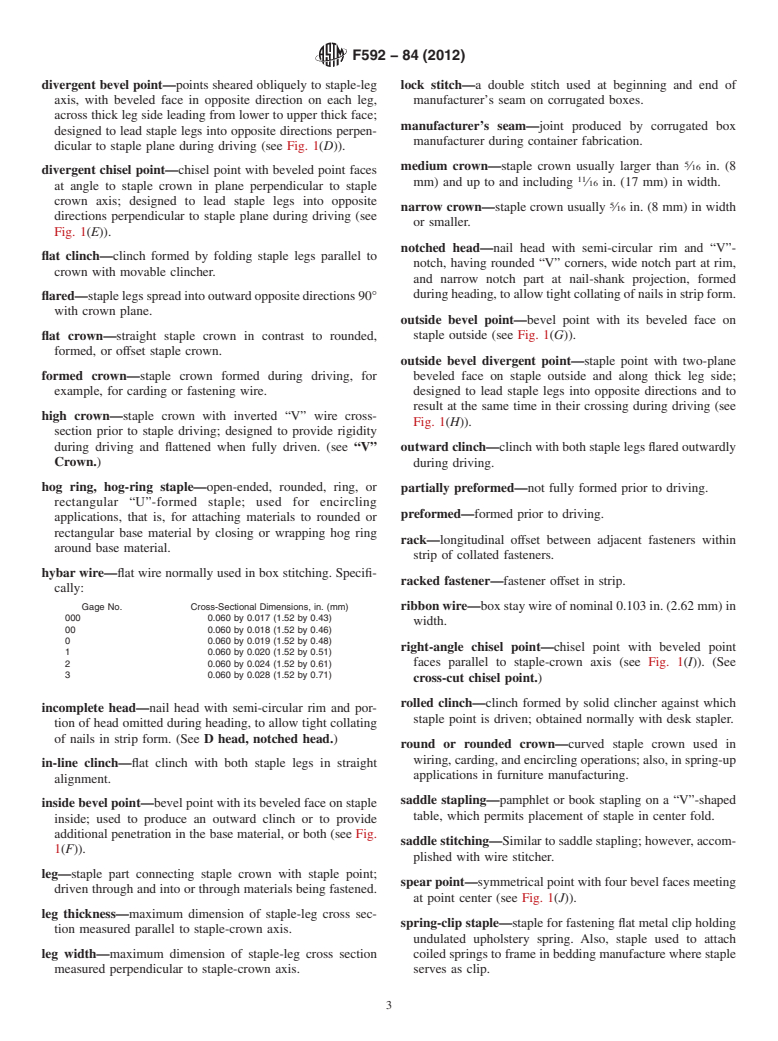

bevel point—point sheared obliquely to staple-leg axis, with breakaway staple—staplewithitscrowndesignedtobreakoff

beveled face across staple-leg end; used to produce an if removal is attempted; used to discourage pilfering and

outward clinch or to provide additional penetration, or both, shop-lifting.

in thin stapling member (see Fig. 1(A)).

by-pass clinch—clinch with legs paralleling and adjacent to

blind clinch—clinch between the layers of corrugated boards, each other.

usually buried with wide-crown retractable anvil tools.

calendar staple—staple formed to provide a hanger for use

bookbinder’s wire—wire used in stitchers to fasten paper; with calendars or booklets.

measured according to AWG sizes.

chisel point—point with two symmetrically beveled planes

box stay wire—wire used in stitchers for assembly of contain- forming “V” at end of staple leg, resulting in straight

ers; with dimensions measured in thousandths of inches. penetration (see Fig. 1(B)). (See cross-cut chisel point.)

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F592 − 84 (2012)

NOTE 1—Staple chisel point has two faces, forming rectangular cross section; whereas nail chisel point (except collatedT-nail chisel point and collated

round-head nail chisel point) has six faces, forming hexagonal cross section, that is, two major planes forming a “V” and pair of minor planes on each

flank (see ASTM Definitions F547).

FIG. 1 Various Types of Staple Points

clinch—protruding point end turned over or flattened when cross-cut chisel point—chisel point with beveled point faces

driven or driven against clinching plate. parallel to staple-crown axis (see Fig. 1(C)). (See right-

angle chisel point.)

clinch point—point designed to facilitate clinching when

driven against clinching plate. (See step point.)

crown—staple end opposite staple point, connecting both

staple legs and providing bearing area.

clip—See strip.

clipped head—misnomer for D head. (See notched head.)

crown width—overall width of staple including both staple

coated fastener—a fastener with appropriate material applied

legs.

to its surface to increase the fastener-withdrawal resistance.

D head—nail head

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.