ASTM D5125-10(2020)e1

(Test Method)Standard Test Method for Viscosity of Paints and Related Materials by ISO Flow Cups

Standard Test Method for Viscosity of Paints and Related Materials by ISO Flow Cups

SIGNIFICANCE AND USE

5.1 This test method is useful for the determination of package and application viscosities of paints and other coatings. It is limited to Newtonian or near-Newtonian liquids.

5.2 This test method may be used similarly to ISO 2431 in conjunction with flashpoint to determine the hazard grouping of viscous liquids in international regulations.

SCOPE

1.1 This test method covers the determination of the flow time (viscosity) of Newtonian and near-Newtonian paints, and related coatings and products using ISO capillary flow cups.

Note 1: If the liquid is non-Newtonian, that is shear-thinning or thixotropic, Test Methods D2196 should be used.

1.2 The cup-orifice combination (ISO cup with orifice diameter of 3 mm, 4 mm, 5 mm, or 6 mm)2 is selected to provide an efflux time with the range of 20 to 100 s and viscosities up to 700 cSt (700 mm2/s). The most commonly used cup is the one with the 4-mm orifice.

1.3 This test method is limited to testing materials for which the breakpoint of the flow from the orifice of the flow cup can be determined with certainty. This point is difficult to determine and reproduce for materials with flow times in excess of 100 s due to slowing-down effects.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

Note 2: The International Civil Aviation Organization (ICAO) and the International Maritime Organization (IMO) include in their regulations a similar test (ISO 2431) to determine the viscosity of hazardous viscous liquids. The viscosity is then used to place these liquids in a hazard packaging group depending on their viscosity/flashpoint relationship. The U. S. Department of Transportation permits the use of these regulations for transhipment of hazardous material within the U.S. when bound for foreign destinations.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: D5125 − 10 (Reapproved 2020)

Standard Test Method for

Viscosity of Paints and Related Materials by ISO Flow Cups

This standard is issued under the fixed designation D5125; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—An editorial change was made in 10.2.2 in December 2020.

1. Scope ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.1 This test method covers the determination of the flow

mendations issued by the World Trade Organization Technical

time (viscosity) of Newtonian and near-Newtonian paints, and

Barriers to Trade (TBT) Committee.

related coatings and products using ISO capillary flow cups.

NOTE 1—If the liquid is non-Newtonian, that is shear-thinning or 2. Referenced Documents

thixotropic, Test Methods D2196 should be used.

2.1 ASTM Standards:

1.2 The cup-orifice combination (ISO cup with orifice

D2196 Test Methods for Rheological Properties of Non-

diameter of 3 mm, 4 mm, 5 mm, or 6 mm) is selected to

Newtonian Materials by Rotational Viscometer

provide an efflux time with the range of 20 to 100 s and

D3924 Specification for Standard Environment for Condi-

viscosities up to 700 cSt (700 mm /s). The most commonly

tioning and Testing Paint, Varnish, Lacquer, and Related

used cup is the one with the 4-mm orifice.

Materials

D3925 Practice for Sampling Liquid Paints and Related

1.3 Thistestmethodislimitedtotestingmaterialsforwhich

Pigmented Coatings

the breakpoint of the flow from the orifice of the flow cup can

E1 Specification for ASTM Liquid-in-Glass Thermometers

be determined with certainty. This point is difficult to deter-

mine and reproduce for materials with flow times in excess of 2.2 ISO Documents:

100 s due to slowing-down effects.

ISO2431 PaintsandVarnishes:DeterminationofFlowTime

by Use of a Flow Cup

1.4 The values stated in SI units are to be regarded as

standard. The values given in parentheses are for information

3. Terminology

only.

3.1 Definitions:

NOTE 2—The International CivilAviation Organization (ICAO) and the

International Maritime Organization (IMO) include in their regulations a

3.1.1 dynamic viscosity, n—the ratio of the applied shear

similar test (ISO 2431) to determine the viscosity of hazardous viscous

stress to shear rate.

liquids. The viscosity is then used to place these liquids in a hazard

3.1.1.1 Discussion—TheSIunitfordynamicviscosityisthe

packaging group depending on their viscosity/flashpoint relationship. The

pascal second (Pas). The traditional unit is the centipoise (cP);

U.S.DepartmentofTransportationpermitstheuseoftheseregulationsfor

transhipment of hazardous material within the U.S. when bound for 1 cP = 1 mPas.

foreign destinations.

3.1.2 flow time, n—the elapsed time from the moment when

1.5 This standard does not purport to address all of the

the material under test starts to flow from the orifice of the

safety concerns, if any, associated with its use. It is the

filled cup to the moment when the flow stream of material first

responsibility of the user of this standard to establish appro-

breaks close to the orifice.

priate safety, health, and environmental practices and deter-

3.1.3 kinematic viscosity, n—the ratio of the dynamic vis-

mine the applicability of regulatory limitations prior to use.

cosity to the density of the liquid.

1.6 This international standard was developed in accor-

3.1.3.1 Discussion—The SI unit for kinematic viscosity is

dance with internationally recognized principles on standard-

the square metre per second (m /s). The traditional unit is the

centistokes (cSt); 1 cSt = 1 mm /s.

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.24 on Physical Properties of Liquid Paints & Paint Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 1, 2020. Published December 2020. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1991. Last previous edition approved in 2014 as D5125 – 10 (2014). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D5125-10R20E01. the ASTM website.

2 4

An ISO-type cup with an orifice diameter of 8 mm is available, but it is not Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

listed in ISO 2431 and precision and accuracy are not known. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D5125 − 10 (2020)

3.1.4 near-Newtonian liquid, n—a liquid in which the varia- 27°C) (60 to 80°F) as prescribed in Specification E1 is

tion of viscosity with shear rate is small and the effect on required. In addition, temperature measuring devices such as

viscosity of mechanical disturbances such as stirring is negli- non-mercury liquid-in-glass thermometers, thermocouples, or

gible. platinum resistance thermometers that provide equivalent or

better accuracy and precision, that cover the temperature range

3.1.5 Newtonian liquid, n—a liquid in which the viscosity is

for thermometer 17C and 17F, may be used.

independent of the shear stress or shear rate. Compare non-

Newtonian liquid.

6.3 Stand, suitable for holding the flow cup and provided

with leveling screws.

3.1.6 non-Newtonian liquid, n—a liquid in which the ratio

of shear stress to shear rate is not constant.

6.4 Spirit Level, preferably of the circular type.

6.5 Flat Glass Plate or Straight-Edge Scraper.

4. Summary of Test Method

6.6 Stopwatch, or other suitable timing-device with scale

4.1 The ISO flow cup is filled level full with the material

divisions of 0.5 s or finer and accurate to within 0.2 % when

under test that has been conditioned at the specified measuring

tested over a 60-min period.

temperature (see 10.2.2) and the time for the material to flow

through one of the standard orifices is determined. 6.7 Temperature-Controlled Room or Enclosure, capable of

maintaining the cup and sample at a recommended, constant

5. Significance and Use

temperature.

5.1 This test method is useful for the determination of

7. Reagents and Materials

package and application viscosities of paints and other coat-

ings. It is limited to Newtonian or near-Newtonian liquids.

7.1 Certified kinematic viscosity standards.

5.2 This test method may be used similarly to ISO 2431 in

8. Sampling

conjunction with flashpoint to determine the hazard grouping

of viscous liquids in international regulations. 8.1 Sample material in accordance with Practice D3925.

8.2 Before testing, it is advisable to strain the sample

6. Apparatus

through an appropriate sieve into a clean dry container. This is

6.1 ISO Capillary Flow Cups—ISO cups look like Ford

mandatory for referee purposes. Mix the material thoroughly

cups, but instead of the non-capillary hole in the bottom of the

while at the same time avoiding, as far as possible, loss of

Ford cup, the ISO cup has a 20-mm capillary and is more like

solvent by evaporation.

a true capillary viscometer.

NOTE 4—150 mL of strained material is sufficient for one test.

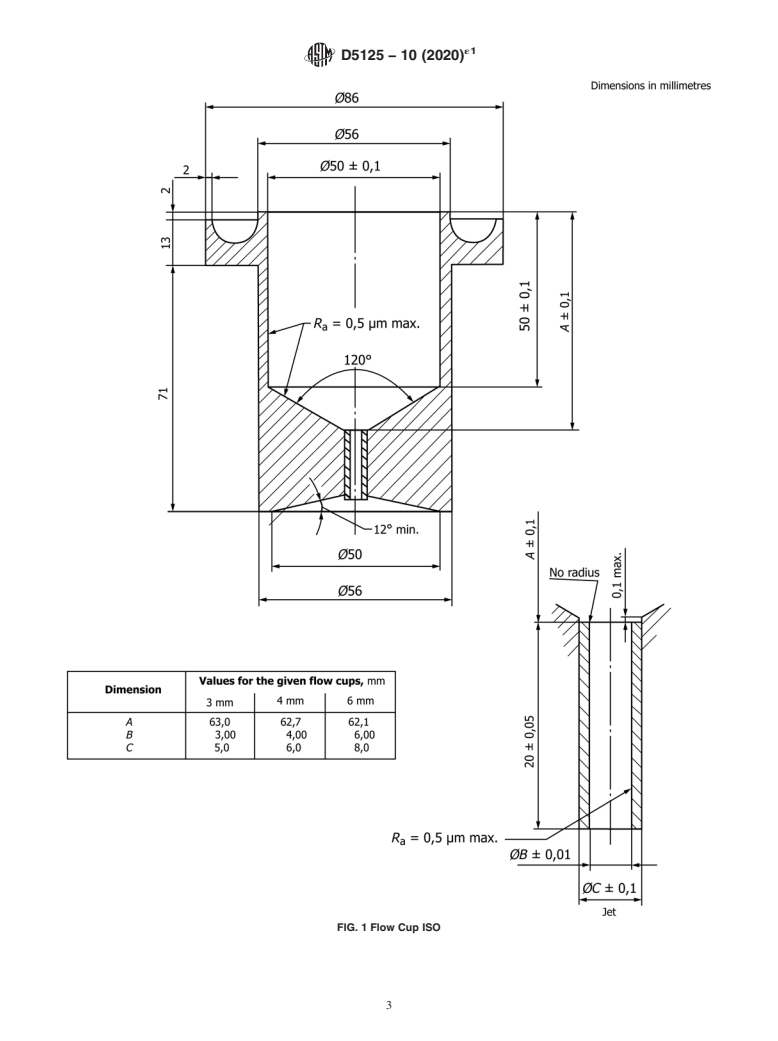

6.1.1 Dimensions—The dimensions of the ISO flow cup and

the tolerances allowed in manufacture shall be as given in Fig.

9. Calibration

1. The most critical tolerance is the internal diameter of the jet

9.1 Dimensionally similar cups will give, with Newtonian

of the cup, because the flow time is inversely proportional to

liquids,suchasastandardoil,similarflowtimes,providedthat

the fourth power of this dimension. The jet of the cup shall be

the temperature of testing is precisely the same. The use of

made of stainless steel or sintered carbide unless otherwise

such liquids to calibrate cups provides a useful means of

specified, and the body of the cup shall be made of a material

initially checking that dimensionally similar cups are within

that is corrosion resistant and is not affected by the products to

the accepted tolerances of performance and also for checking

be tested.

from time to time whether any wear or damage has taken place

6.1.2 Construction—The dimensions not specified, such as

sufficient to bring a cup outside the accepted tolerances.

wall thickness, shall be such that no distortion of the cup can

occur in use. The external shape shown in Fig. 1 is

9.2 For calibration of any particular cup, use a standard oil

recommended, but may be modified for convenience of use, or

of known kinematic viscosity and draw a graph of kinematic

manufacture, provided that the protruding jet of the cup is

viscosity versus temperature from the data given by the

protected from accidental damage as far as possible by an

supplier for the oil.

external protective sleeve. Such a protective sleeve shall not be

9.3 Using the relevant procedure described in Section 10,

immediately adjacent to the jet, so as to prevent a capillary

determine the flow of time of the oil at a known temperature

action when the material under test flows out.

within the range 20 to 30°C (68 to 80°F), measured to the

6.1.3 Finish—The interior surfaces of the cups, including

nearest 0.1°C.

the orifice, shall be smooth and free of turning marks, crevices,

9.3.1 Recordthisflowtime,whichshouldbeinthe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.