ASTM C75-56

(Specification)Specification for Reinforced Concrete Sewer Pipe (Withdrawn 1956)

Specification for Reinforced Concrete Sewer Pipe (Withdrawn 1956)

General Information

Standards Content (Sample)

Standard Specifications for

REINFORCED CONCRETE SEWER PIPE'

ASTM Designation: C 75 - 56

1

AnoPTBD, 1935; Rmvrsxo, 1941, 1952, 1954, 1955, 1956.

This Sta.ndartl of the Americ11;n Society for Tr.sting Material! ls lasued .under

the fixed designation C 75; tb e 6m1l number indicate. the year of original

Adoption as 1tandard or, in the cue of revision, the year of last revision.

Scope

MATERIALS

1. T liese specifications .cover . rein Reinforced Concrete

forced concrete pipe intended to be used

4. The reinforced concrete shall con

for the conveyance of sewage, industrial

sist of portland cement, mineral aggre

wastes, and storm water.

gates, and water, in which .steel bas been

embedded in such a manner that the steel

Clase

and the concrete act together.

2. Pipe manufactured according to

Cement

these specifications shall be known as

"Standard Reinforced Concrete Sewer

5. Portland cement shall conform to

Pipe."

the requirements of the Specifications

for Portland Cement (ASTM Designa

Basis of Acceptance

tion: C 150),' or shall be air-entraining

3. The acceptability of the pipe. shall portla.nd cement conforming to the re

be determined by the results of the quirements of the Specifi.cations for Air

strength end absorption tests prescribed Ent~ining Portland Cement (AsTM

1

in these specin.cations, if .and when re- ' Designation: C 175), .Qr shall be port

quired, and by inspection to deterinh1e land bl8.st-fumace slag cement conform

whether the pipe conforms to these ing to the requirements of the Specifica

specificatio1?5 as to design and freedom tions for Portland Blast-Furnace Slag

1

from defects. Ce~nt (ASrM Designation: C 205).

1

Under the etandardiaation procedure of the

Steel Reinforcement

Society, these 11pemfieation1 are under t he jurlt

diotion of tho ASTM Committee C-13 on Con

6. ReinfQrcemen~ may consist of wire

crete Pipo,

• Appeai. in this publication, - Contents

•Prior to adoption u 11tand&rd, these apooili

in Numorio St!quence of ASTM D calanatlons at

cations wero published aa ten~tive from 1930 to

front of book.

1935, beint revi11ed in 1{)34 and ·19311.

67

A "tentatlTO revlalon•• of thla standard appears on p. 322.

---------------------- Page: 1 ----------------------

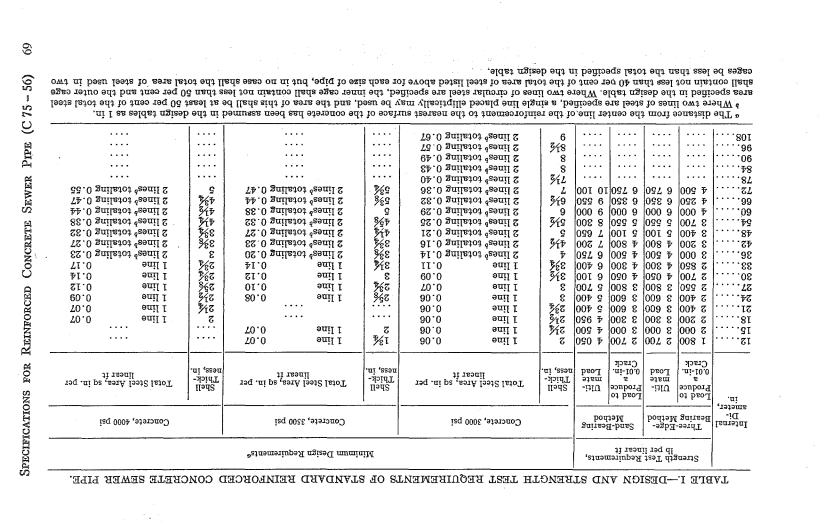

68 SPECIFICATIONS FOR REINFORCED CONCRETE SEWER PIPE (C 75 - 56)

such pipe shall conform to the same

conforming to the Specifications for

physical tests and inspection require

Cold-Drawn Steel Wire for Concrete

ments prescribed in these specifications

Reinforcement (ASTM Designation: A

4

for the pipe for which it is substituted.

82), or of wire fabric conforming to the

In no alternate design, however,. shall

Specifications for Welded Steel Wire

the shell thickness be less than that

Fabric for Concrete Reinforcement

5

prescribed in Table I.

(ASTM Designation: A 185), or of bars

of structural or intermediate grade con

Placing Reinforcement

forming to the Specifications for Billet

11. When two lines of reinforcement

Steel Bars for Concrete Reinforcement

4

are used in circular pipe, one shall be

(ASTM Designation: A 15).

placed near the inner and one near the

Aggregates

outer surfaces of the pipe. When a

7. Aggregates shall conform to the single line of circular reinforcement is

Specifications for Concrete Aggregates used in circular pipe, it shall be placed

3

(ASTM Designation: C 33), except that near the inner surface of the pipe shell.

the requirement for gradation shall not The single line of elliptical reinforcement

apply. used in circular pipe, or the single line of

circular reinforcement in elliptical pipe

Mixture

shall be placed near the inner surface at

the "top" and "bottom" of the pipe and

8. The aggregates shall be so sized and

near the outer surface at the sides (see

so graded and proportioned and thor

Section 33 ( d)). ·

oughly mixed in a batch mixer with such

proportions of cement and water as will

Longitudinals

produce a homogeneous concrete mixture

of such quality that the pipe will con 12. Each line of circumferential rein

form to the test and design requirements forcement shall be assembled into a cage

of these specifications. Admixtures or which shall contain sufficient longitu

blends may be used with the approval of dinal bars or members, extending

the consumer. In no case, however, shall through the barrel of the pipe, to main

the proportion of portland cement in the tain the reinforcement rigidly in exact

mixture be less than six U. S. standard shape and correct position within the

bags (94 lb) per cubic yard of concrete. form.

Laps, Welds, and Spacing

DESIGN

13. If the splices are not welded, the

Minimum Designs

reinforcement shall be lapped not less

9. The shell thickness and the amount

than 30 diameters for bars, and 40 di

of circumferential reinforcement shall

ameters for cold~drawn wire. If welded,

be not less than the minimum design

the member at either a welded splice or

requirements prescrib

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.