ASTM D2578-09

(Test Method)Standard Test Method for Wetting Tension of Polyethylene and Polypropylene Films

Standard Test Method for Wetting Tension of Polyethylene and Polypropylene Films

SIGNIFICANCE AND USE

When a drop of liquid rests on the surface of a solid, and a gas is in contact with both, the forces acting at the interfaces must balance. These forces can be represented by surface energies acting in the direction of the surfaces and it follows that:

where: θ = angle of contact of the edge of the drop with the solid surface, γGL = surface energy of the gas - liquid interface, γGS = surface energy of the gas - solid interface, and γSL = surface energy of the solid - liquid interface.

The right side of the above equation (the difference between the surface energies of the gas - solid and solid - liquid interfaces) is defined as the wetting tension of the solid surface. It is not a fundamental property of the surface but depends on interaction between the solid and a particular environment.

When the gas is air saturated with vapors of the liquid, γGL will be the surface tension of the liquid. If the angle of contact is 0° the liquid is said to just wet the surface of the solid, and in this particular case (since cos θ = 1) the wetting tension of the solid will be equal to the surface tension of the liquid.

The ability of polyethylene and polypropylene films to retain inks, coatings, adhesives, etc., is primarily dependent upon the character of their surfaces, and can be improved by one of several surface-treating techniques. These same treating techniques have been found to increase the wetting tension of a polyethylene or a polypropylene film surface in contact with mixtures of formamide and ethyl Cellosolve in the presence of air. It is therefore possible to relate the wetting tension of a polyethylene or a polypropylene film surface to its ability to accept and retain inks, coatings, adhesives, etc. The measured wetting tension of a specific film surface can only be related to acceptable ink, coating, or adhesive retention through experience. Wetting tension in itself is not a completely acceptable measure of ink, coating, or adhesive adhesi...

SCOPE

1.1 This test method covers the measurement of the wetting tension of a polyethylene or polypropylene film surface in contact with drops of specific test solutions in the presence of air.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

Note 1—This test method and the specified reagents were specifically developed for polyethylene and polypropylene films. It is possible to utilize this test method and the specified reagents for films composed of other polymers, but this can affect the surface energies of the gas-liquid and solid-liquid interfaces, which will affect the contact angle and wetting tension. The applicability and significance for use of non-polyolefin materials must be established by the user.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazards statements are given in Section 8.

Note 2—This test method is equivalent to ISO 8296.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2578 − 09

Standard Test Method for

1

Wetting Tension of Polyethylene and Polypropylene Films

This standard is issued under the fixed designation D2578; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Summary of Test Method

1.1 This test method covers the measurement of the wetting 3.1 In this test method drops of a series of mixtures of

4

tension of a polyethylene or polypropylene film surface in formamide and ethyl Cellosolve of gradually increasing sur-

contact with drops of specific test solutions in the presence of face tension are applied to the surface of the polyethylene or

air. polypropylene film until a mixture is found that just wets the

film surface. The wetting tension of the polyethylene or

1.2 The values stated in SI units are to be regarded as

polypropylenefilmsurfacewillbeapproximatedbythesurface

standard. The values given in parentheses are mathematical

tension of this particular mixture.

conversions to inch-pound units that are provided for informa-

tion only and are not considered standard.

4. Significance and Use

NOTE 1—This test method and the specified reagents were specifically

4.1 Whenadropofliquidrestsonthesurfaceofasolid,and

developed for polyethylene and polypropylene films. It is possible to

a gas is in contact with both, the forces acting at the interfaces

utilize this test method and the specified reagents for films composed of

must balance. These forces can be represented by surface

other polymers, but this can affect the surface energies of the gas-liquid

andsolid-liquidinterfaces,whichwillaffectthecontactangleandwetting

energies acting in the direction of the surfaces and it follows

tension. The applicability and significance for use of non-polyolefin

that:

materials must be established by the user.

γGLcosθ 5 γGS 2 γSL (1)

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the where:

responsibility of the user of this standard to establish appro-

θ = angle of contact of the edge of the drop with the

priate safety and health practices and determine the applica-

solid surface,

bility of regulatory limitations prior to use. Specific hazards

γGL = surface energy of the gas-liquid interface,

statements are given in Section 8.

γGS = surface energy of the gas-solid interface, and

γSL = surface energy of the solid-liquid interface.

NOTE 2—This test method is equivalent to ISO8296.

4.1.1 The right side of the above equation (the difference

2. Referenced Documents

between the surface energies of the gas-solid and solid-liq-

2

uid interfaces) is defined as the wetting tension of the solid

2.1 ASTM Standards:

surface. It is not a fundamental property of the surface but

D618Practice for Conditioning Plastics for Testing

depends on interaction between the solid and a particular

E691Practice for Conducting an Interlaboratory Study to

environment.

Determine the Precision of a Test Method

4.1.2 Whenthegasisairsaturatedwithvaporsoftheliquid,

2.2 ISO Standard:

γGL will be the surface tension of the liquid. If the angle of

ISO 8296Plastics—Film and Sheeting—Determination of

3

contact is 0° the liquid is said to just wet the surface of the

Wetting Tension

solid, and in this particular case (since cos θ=1) the wetting

tension of the solid will be equal to the surface tension of the

1

liquid.

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and

4.2 The ability of polyethylene and polypropylene films to

Molded Products.

retain inks, coatings, adhesives, etc., is primarily dependent

Current edition approved Sept. 1, 2009. Published September 2009. Originally

approved in 1967. Last previous edition approved in 2008 as D2578-08. DOI:

upon the character of their surfaces, and can be improved by

10.1520/D2578-09.

oneofseveralsurface-treatingtechniques.Thesesametreating

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

techniques have been found to increase the wetting tension of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., Registered trademark of Union Carbide Corp. for ethylene glycol monoethyl

4th Floor, New York, NY 10036, http://www.ansi.org. ether.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 194

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D2578–08 Designation:D2578–09

Standard Test Method for

1

Wetting Tension of Polyethylene and Polypropylene Films

This standard is issued under the fixed designation D 2578; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the measurement of the wetting tension of a polyethylene or polypropylene film surface in contact

with drops of specific test solutions in the presence of air.

1.2The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions

to inch-pound units that are provided for information only and are not considered standard.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions

to inch-pound units that are provided for information only and are not considered standard.

NOTE 1—This test method and the specified reagents were specifically developed for polyethylene and polypropylene films. It is possible to utilize this

test method and the specified reagents for films composed of other polymers, but this can affect the surface energies of the gas-liquid and solid-liquid

interfaces, which will affect the contact angle and wetting tension. The applicability and significance for use of non-polyolefin materials must be

established by the user.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific hazards statements are given in Section 8.

NOTE1—This 2—This test method is equivalent to ISO 8296.

2. Referenced Documents

2

2.1 ASTM Standards:

D 618 Practice for Conditioning Plastics for Testing

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

2.2 ISO Standard:

3

ISO 8296 Plastics—Film and Sheeting—Determination of Wetting Tension

3. Summary of Test Method

4

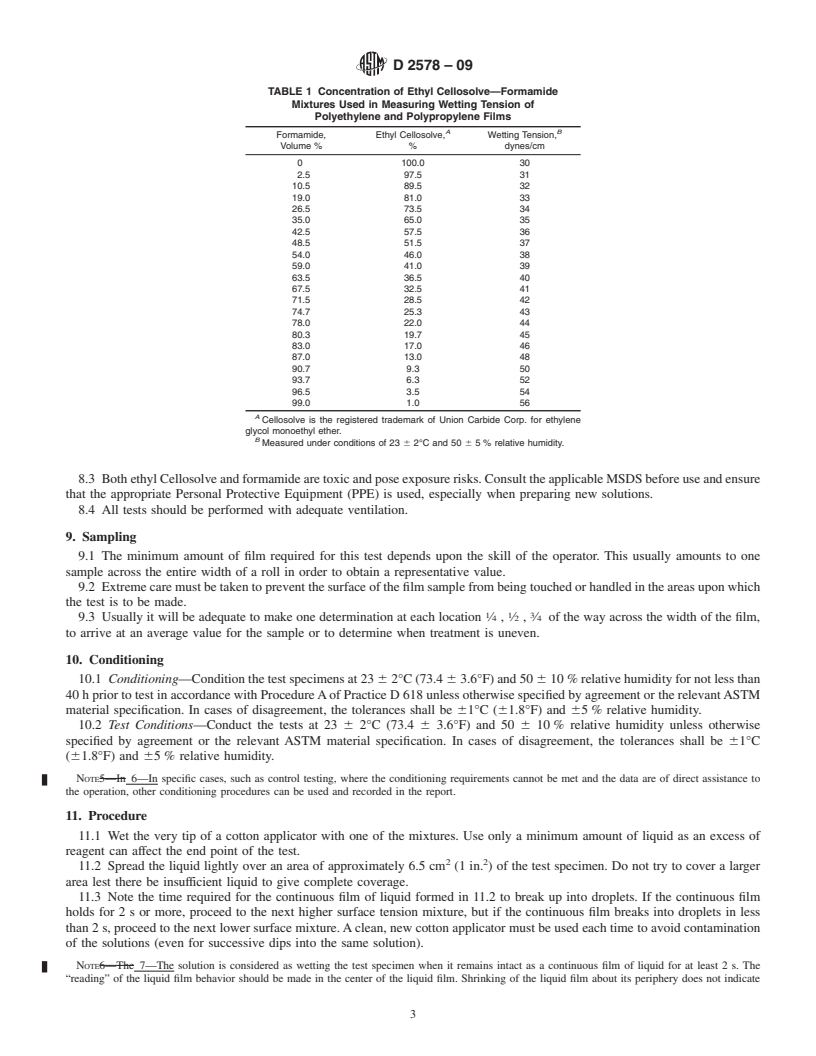

3.1 In this test method drops of a series of mixtures of formamide and ethyl Cellosolve of gradually increasing surface tension

are applied to the surface of the polyethylene or polypropylene film until a mixture is found that just wets the film surface. The

wetting tension of the polyethylene or polypropylene film surface will be approximated by the surface tension of this particular

mixture.

4. Significance and Use

4.1 When a drop of liquid rests on the surface of a solid, and a gas is in contact with both, the forces acting at the interfaces

must balance. These forces can be represented by surface energies acting in the direction of the surfaces and it follows that:

gGL cosu5gGS2gSL (1)

where:

u = angle of contact of the edge of the drop with the solid surface,

gGL = surface energy of the gas - liquid interface,

gGS = surface energy of the gas - solid interface, and

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.19 on Film and Sheeting.

Current edition approved Nov.Sept. 1, 2008.2009. Published November 2008.September 2009. Originally approved in 1967. Last previous edition approved in 20042008

as D2578-04a.D 2578 - 08.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Registered trademark of Union Carbide Corp. for ethylene glycol monoethyl ether.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2578–09

gSL = surface energy of the solid - liquid interface.

4.1.1 The right side of the above equation (the difference between the surface energies of the gas - solid and solid - liquid

interfaces) is defined as the wetting tension of the solid surface. It is not a fundamental property of the surface but depends on

interaction betw

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.