ASTM B214-99

(Test Method)Standard Test Method for Sieve Analysis of Metal Powders

Standard Test Method for Sieve Analysis of Metal Powders

SCOPE

1.1 This test method covers the determination of the dry sieve analysis of granular metal powders.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B214–99

Standard Test Method for

Sieve Analysis of Metal Powders

This standard is issued under the fixed designation B 214; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope agreementbetweenpowdermanufactureranduser,oritmaybe

an internal quality control test for either. This test method is

1.1 This test method covers the determination of the dry

appropriate for materials with size distributions typified by

sieve analysis of metal powders.

metal powders used in powder metallurgy.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Apparatus

responsibility of the user of this standard to establish appro-

5.1 Sieves—A set of standard sieves selected from Table 1

priate safety and health practices and determine the applica-

of Specification E 11, or the equivalent Tyler standard sieves.

bility of regulatory limitations prior to use.

The sieves shall be 8 in. (203.2 mm) in diameter and either 1

2. Referenced Documents or 2 in. (25 or 50 mm) in depth and fitted with bronze, brass,

stainless steel, or other suitable wire cloth. The U.S. sieves

2.1 ASTM Standards:

given in Table 1 of this method shall conform to Specification

B 212 Test Method for Apparent Density of Free-Flowing

E 11. If Tyler standard sieves are substituted, they shall

Metal Powders Using the Hall Flowmeter Funnel

conform to the permissible variations given in Table 1 of

B 215 Practices for Sampling Finished Lots of Metal Pow-

Specification E 11.

ders

B 243 Terminology of Powder Metallurgy

NOTE 1—The new U.S. Series standard sieves, adopted in 1970, are the

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

preferred sieves to use.The old U.S. Series standard sieves and equivalent

sieves manufactured by other companies, such as Tyler, may also be used

poses

if the new U.S. Series is not available. Care should be taken to make sure

E 691 Practice for Conducting an Interlaboratory Study to

4 that sieve opening sizes are correct when performing standardization

Determine the Precision of a Test Method

work.

2.2 MPIF Standard:

5.2 Sieve Shaker— A mechanically operated, single eccen-

MPIF 05 Determination of Sieve Analysis of Metal Pow-

tric sieve shaker which imparts to the set of sieves a rotary

ders

motion and tapping action of uniform speed, shall be used.The

3. Terminology

number of rotations per minute shall be between 270 and 300.

The number of taps per minute shall be between 140 and 160.

3.1 Definitions—Useful definitions of terms for metal pow-

The sieve shaker shall be fitted with a plug to receive the

ders and powder metallurgy are found in Terminology B 243.

impact of the tapping device. The entire apparatus shall be

4. Significance and Use

rigidly mounted by bolting to a solid foundation, preferably of

concrete.Atime switch should be provided to ensure accuracy

4.1 The particle size distribution of a metal powder affects

of duration of the test.

its behavior in P/M processing and other applications of these

materials. The test method may be part of the purchase

NOTE 2—Use of a sound proof enclosure is recommended.

5.3 Balance—A balance having a capacity of at least 110 g

This test method is under the jurisdiction of ASTM Committee B-9 on Metal and a sensitivity of 0.01 g.

Powders and Metal Powder Products, and is the direct responsibility of Subcom-

mittee B09.02 on Base Metal Powders.

6. Test Specimen

Current edition approved April 10, 1999. Published August 1999. Originally

6.1 Thesizeofthetestspecimenshallbe90to100gforany

published as B 214 – 46 T. Last previous edition B 214 – 92.

Annual Book of ASTM Standards , Vol 02.05 metal powder having an apparent density greater than 1.50

Annual Book of ASTM Standards , Vol 14.02.

g/cm when determined in accordance with Test Method

Annual Book of ASTM Standards, Vol 14.02.

B 212.A40 to 60-g specimen shall be used when the apparent

Available from Metal Powder Industries Federation (MPIF), 105 College Road

East, Princeton, NJ 08540.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

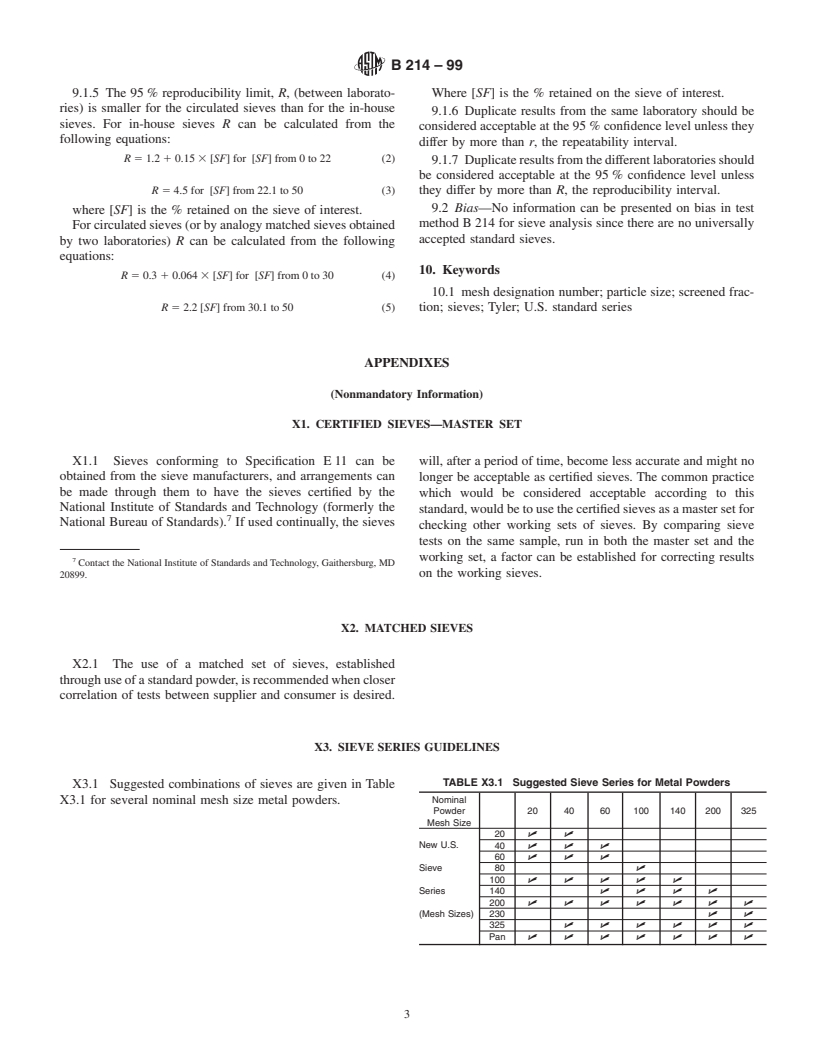

B214–99

TABLE 1 U.S. Standard Series Test Sieves and Equivalent Tyler TABLE 2 Format for Reporting Test Data of a Typical 100-Mesh

Standard Sieves Powder

Sieve Opening (µm) New U.S. Standard Series

Mesh Designation

New U.S. Old U.S. Mesh Designation %By

Number

Tyler Series Particle Size (µm)

Series Series No. Mass

20 850 841 833 >180 + 80 .

35 — — 417 # 180 > 150 − 80 + 100 .

40 425 420 — # 150 > 106 − 100 + 140 .

60 250 250 250 # 106 > 75 − 140 + 200 .

80 180 177 175 # 75 > 45 − 200 + 325 .

100 150 149 147 # 45 − 325 .

140 106 105 —

Old U.S. Standard Series

150 — — 104

200 75 74 74

Particle Size (µm) Mesh Designation Percentage

230 63 63 — No. by Mass

250 — — 63

> 177 + 80 .

325 45 44 45

# 177 > 149 − 80 + 100 .

# 149 > 105 − 100 + 140 .

# 105 > 74 − 140 + 200 .

# 74 > 44 − 200 + 325 .

# 44 − 325 .

density of the powder is less than 1.50 g/cm . The test

Tyler Standard Sieve Series

specimen should be obtained in accordance with Practices

Particle Size (µm) Mesh Designation Percentage

B 215.

No By Mass

> 175 + 80 .

7. Procedure

# 175 > 147 − 80 + 100 .

# 147 > 104 − 100 + 150 .

7.1 Assemble the group of sieves selected in consecutive

# 104 > 74 − 150 + 200 .

order as to size of openings, with the coarsest sieve at the top, # 74 > 45 − 200 + 325 .

# 45 − 325 .

the assembly being completed by a solid collecting pan below

the bottom sieve. Place the test specimen on the top sieve and

close this sieve with a solid cover. Then fasten the sieve

9. Precision and Bias

assembly securely in a suitable mechanical sieve shaking

device and operate the machine for a period of 15 min.

9.1 Precision:

9.1.1 An interlaboratory study of the sieve analysis of metal

7.2 Remove the screened fractions from the nest of sieves

powders was run in 1993 and 1994 using the procedures

by removing the coarsest sieve from the nest, gently tapping its

contained in MPIF Standard 05 (1992). Each of twelve

contents to one side and pouring them upon a glazed paper.

laboratories made three tests on four powder samples us

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.